north american safety valve company quotation

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

A customer urgently needed information on the availability of five 4-inch liquid flanged valves. Unfortunately, the end user had ordered the wrong valves and desperately needed the correct ones right away. NASVI not only had them in stock, but also shipped the valves same day. It was a happy ending to the customer’s frustrating day of tracking down the valves only to hear there was a six-week lead time. It’s why our customers’ call NASVI, their trusted safety valve distributor, first.

When the pressure is on, you can count on us to come through with 35,000 safety valves in stock shipped same or next-day. When there are unknowns involved, our experienced applications engineers guide you to the right valve make and model so you can be your customers’ hero.

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

The fear of the TARIFFS has driven prices up twice this year, with a third increase coming in September. Good excuses to raise prices. When we quote you a Kunkle Valve, for example, our system might spit out $147.90 as your cost. I realize many of you think the cents is silly but what are you going to do? I always tell the customer that the cents are my tip but now it is my TARIFF.

Speaking of TARIFFS, this shipping business is outlandish. No LAW says if you don’t follow directions that you have to eat the freight. Everyone makes mistakes and you and/or your customer are entitled to pay a discounted price, but not a total freebie. There is one company in Chicago that expects you to pay them an additional $250.00. Good luck with that one. We send back an acknowledgement with every order. Shouldn’t you be able to catch our mistakes? How about the guy who thought we screwed up and sent a big order prepaid instead of using his carrier? It turns out our carrier was cheaper than his and he didn’t offer to TIP us. Instead he put it in his pocket. TARIFF.

Now I have a BIG TIP for you. We will soon have the largest inventory in the country of high-pressure boiler safety valves. It takes eight to nine months for the factory to deliver these valves, which can go up to 2,000 PSIG. If you take this hot TIP to your big end users, it might open all kinds of doors for you. Don’t wait for the guys in the repair business to get there first. There is a TARIFF on these valves but you will be a hero.

Pressure relief valves are designed to protect equipment from overpressure. The valve should be handled with care, not subject to heavy shock loads, and protected to prevent dirt from getting inside. Failure to do so could result in property damage or serious injury to personnel.

Mount the valve in a vertical position so that the valve body is self-draining. If a body drain port is provided, make sure it is open when required by the ASME code. Do not plug any bonnet vent openings. The inlet piping should be as short as possible, with no elbows, and equal to or greater than the size of the pressure relief valve inlet connection. This will help limit the inlet pressure drop to 3% or less when the valve is relieving.

When discharge piping is connected to valve outlet, make sure it is self-draining when a body drain port is not used. The valve should not be connected to any discharge pipe that contains pressure before the valve opens or to any pipe where the pressure build-up is greater than 10% of the set pressure when the valve is open and relieving. Discharge piping other than a short tailpipe must be supported by something other than the valve. For steam service, a drip pan elbow or flexible connection between the valve and the pipe should be used to prevent excessive pipe stress, due to thermal expansion, from being imposed on the valve body.

For threaded valves, apply a small amount of pipe thread sealing compound to external threads only. Do not put any sealing compound on the first thread or any internal threads. To do so may cause the sealing compound to enter the valve and cause seat leakage. Use wrench flats provided to tighten the valve to the connecting pipe. Do not use the valve body or bonnet and do not over-tighten. To do so may cause valve leakage.

Maintain a system operating pressure at least 5 psig or 10% below the set pressure of the valve – whichever is greater. Operating too close to the valve set pressure will cause seat leakage and will shorten the time between valve maintenance.

Do not use the safety valve as a control valve to regulate system operating pressure. Excessive operation will cause the seat to leak and will require more frequent valve maintenance.

ASME Code-stamped valves equipped with lift levers are designed to be operated only when the system pressure is 75% of the set pressure or greater. When hand operating the valve, hold it open long enough to purge any foreign matter from the seat area. If a cable or wire is attached to the lift lever for remote actuation, make sure the direction of pull is the same as it would be if the lever were pulled directly by hand.

Maintenance should be performed on a regular basis. We recommend an initial inspection interval of 12 months. Depending on the service conditions and the condition of the valve, the suggested inspection interval may decrease or increase.

You don’t have to be an expert in the field of safety and relief valves to sell them because that’s our job. And we’re only a phone call away. We’ll help you select the proper valve and give an immediate price quote on the phone. The sole responsibility of our dedicated application engineers is to take care of your requirements.

We will help you with sales planning, product selection and after-sale service when needed. We will even provide you with catalogs that have no reference to NASVI. Place your company’s sticker on it and you’ll have your own safety valve catalog to pass out to your customers … and it costs you nothing.

Our commitment is to you. Our goal is to help you exceed your customer’s requirements – from quality products to on-time delivery backed by quick and accurate customer service. We carry all makes of safety and relief valves in our extensive inventory – from the common to hard to find. And same-day shipping is the rule, not the exception.

We’ve got your back. Let us find the exact part you’re looking for in our 100,000 sq. ft. warehouse stocked with 35,000 ready-to-ship valves from the world’s most renowned brands. We’ll put our decades of experiencing cross-referencing valves to work fast. Just give us a call.

American-based manufacturer of safety and relief valve products, Aquatrol, is and have been experts in the field since 1947. All of their products are manufactured in the U.S., so you rest assured the company takes control of the quality of their safety relief and pressure relief valves.

Over 98% of Aquatrol’s safety and relief valves’ components are manufactured by them, ensuring you receive only the best. Their facilities include modern CNC manufacturing, robotic assistance and many other manufacturing applications. All of Aquatrol’s operations are backed by an experienced team of safety and relief valve specialists.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

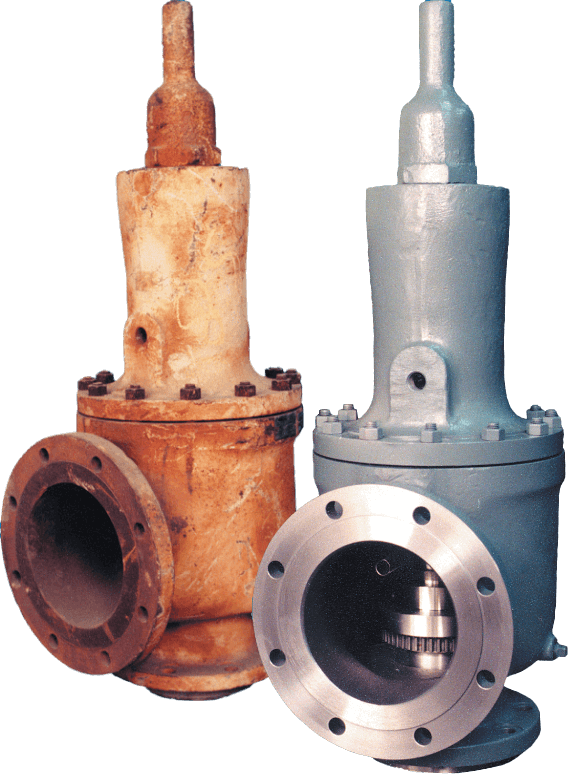

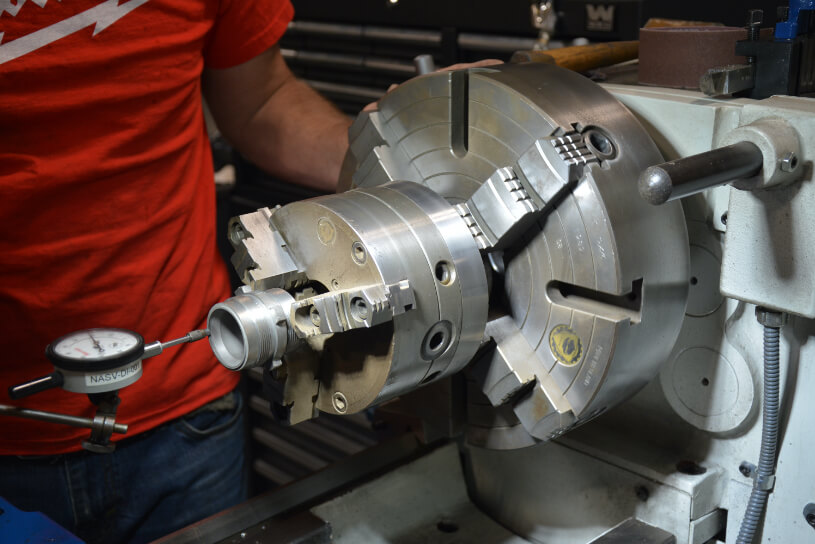

Distributor of safety and relief valves including remanufactured and replacement valves. Types of valves include flanged, screwed, cast steel boiler safety, cast iron and cast steel liquid relief, portable bronze safety, bronze liquid relief, cast iron safety, low pressure steam boiler safety, air compressor safety and hot water boiler relief valves. Made of materials including iron, cast iron, steel, cast steel, aluminum and stainless steel. Replacement parts such as springs, discs, gaskets, bellows, nozzles, guides are available. Capabilities also include lathework, sand blasting and mill/drill pressing. On-site valve testing and repair, upgrade and maintenance and emergency services are available. Meets ASME standards.

Shipment: All products and/or services covered by the quotation are sold F.O.B. either our plant in Linden, NJ or the manufacturer"s plant for the parts and/or valves required, unless otherwise indicated. The risk of loss or damage in transit will be upon the purchaser. The products will be prepared for shipment in a manner prescribed by us or the manufacturer and shipped by any public carrier which we deem satisfactory, unless the purchaser provides other specific shipping instructions when placing orders. Any date provided by us for completion of work or for shipment is intended as an estimate only and is not to be deemed a term of the quotation. Shipping charges shall be pre-paid and billed at the time of shipment.

Warranties and Limitations: We warrant only that our products will conform to their description herein and that at the time of sale our products will be free from defects on workmanship and material. The name and reputation of Certified Valve Repair stands prudently behind every valve or piece of equipment we recondition. We are valve repair specialists, if at any time, in any way, a valve or piece of equipment that we have repaired fails to provide complete satisfaction, please bring the matter to our attention. Every repaired valve, pump, instrument, or equipment when used in accordance with the manufacturer and our recommendations is guaranteed to be free from defective workmanship and material. We will repair or replace without charge, F.O.B. our plant any repaired unit which our own examination proves to be defective within a period stated by our firm at the time of delivery. We assume no responsibility for incidental damage or expense. Authorization is required before returned articles will be accepted.

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

We’re proud to manufacture a wide variety of pressure relief valves, accommodating various military applications. We offer cutting-edge air compressor valves, semi-nozzle, and full-nozzle relief valves composed of bronze, steel, and stainless steel to maintain optimal performance conditions and durability.

VSI is your premier source for control valves, pressure relief valves, and safety relief valves. Our factory-certified experts are on-call 24/7 for repairs, testing, sizing & selection, replacement, and installation.

As your trusted source for factory-certified service solutions and consistent value and quality, VSI offers excellent customer service and world-class products and services. VSI has been focused on a legacy of quality and service since its inception in 1975 in Oklahoma City by founder Bill Campbell. Over the years, VSI has expanded its footprint to include four locations, offering service, repair, installation, and custom solutions across the United States. We offer excellent customer service, best-in-class products, and a wide variety of solutions for the process industry. VSI is the premier source for safety valves, pressure relief valves, control valves, and actuation products and services. Contact us to find out how we can help you.

Adapt almost any rotary actuator to a linear valve. Converting pneumatic actuation to electric helps increase operational efficiency and lower emissions.

VSI is a Consolidated™ Green Tag Center™ offering factory-certified repairs, installation, maintenance, and the full range of Consolidated pressure and safety relief valves. We have in-house certified technicians and product experts, and a large inventory to ensure fast delivery.

Our factory-certified and safety-trained, field service technicians are ready to be dispatched to your site. Capabilities include optimization, repair, and maintenance on pressure relief valves, safety valves, control valves, line valves, and actuation.

Valve Sales Inc. provides outstanding service and support for all of our valve needs. Their dedication to quality and consistency allows our equipment to run more reliably and improves overall performance of our facility. Our goal is to provide consistent high performing products to our customers and VSI allows us to achieve this goal.

VSI has been helpful in many ways, from greasing valves, valve repair, valve replacement, and training our guys as well. We can’t say enough about quotes, labor support, material delivery time, and billing. Aaron has helped us out of several jams over the years and we appreciate it.

The entire team at VSI has always been able to meet my needs and always exceeds my expectations. I have a great relationship with both the sales and service teams they are always ready to answer technical questions and provide excellent advice on ways to solve problems in the field and are always ready with solutions no matter how obscure or unusual the problem. VSI is more than ready and able to meet all my valve needs at any given moment.

VSI has rebuilt our pressure relief valves here at [our processing plant] for several years now and I have always been very pleased with their service and quality of work. The work is always completed on time and we have had no reliability issues with the valves they’ve worked on. It’s always a pleasure working with VSI and I look forward to continuing the relationship.

TULSA, OK – August 31, 2022 - Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated™ pressure relief valves. VSI’s service and… Read More

IVI is a VR certified safety valve repair facility, approved by the National Board of Boiler and Pressure Vessel Inspectors as a VR certificate holder (stamp 179). We certify pressure relief valves in the shop and in the field for sections V and UV. We also perform on-site testing (while the plant operates) providing documented reports for all valves tested. We are also certified to administer special process conversions regarding machining, welding, heat treating, and N.D.T. (non-destructive testing) with our VR certificate.

With our VR stamp, we repair all types of pressure relief valves such as Consolidated, Crosby, Kunkle, Farris, Spence, Anderson Greenwood, and numerous other O.E.M. safety and pressure relief valves.

With History that dates back to the early 1980"s, Mecklenburg Valve Source, LLC was established to service the Eastern territory of the US and beyond. We began full operation in April of 2011 with our focus on continuing the tradition of Service and Excellent Support for the sales of Industrial products. Taking over for a very reputable business in Lee Valve Company, we have all of the facilities and inventory to supply all Relief Valve, Pressure Gauge and Thermometer needs. We are a full-service Assembler of Kunkle Valve Company of Black Mountain with applicable ASME stamps in V and UV.

We also Repair all types of manufacturer"s relief valves in our Charlotte facility. Our expertise in this area is also expressed in years. Our lead technician has been involved in the valve repair field for more than 35 years, while our new valve assembly technician"s combine 30+ years of experience. In other words, there isn"t much that we haven"t seen.

8613371530291

8613371530291