north american safety valve industries pricelist

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

A customer urgently needed information on the availability of five 4-inch liquid flanged valves. Unfortunately, the end user had ordered the wrong valves and desperately needed the correct ones right away. NASVI not only had them in stock, but also shipped the valves same day. It was a happy ending to the customer’s frustrating day of tracking down the valves only to hear there was a six-week lead time. It’s why our customers’ call NASVI, their trusted safety valve distributor, first.

When the pressure is on, you can count on us to come through with 35,000 safety valves in stock shipped same or next-day. When there are unknowns involved, our experienced applications engineers guide you to the right valve make and model so you can be your customers’ hero.

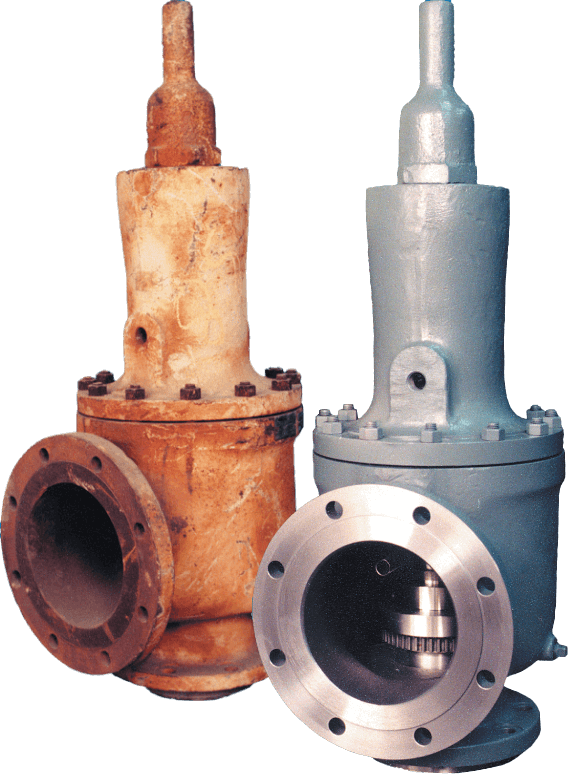

More companies today have found that it makes sense to rely on remanufactured safety valves. For most industrial uses, remanufactured valves offer excellent availability and are extremely cost effective without compromising quality or safety. Now you can be part of this growing trend by offering remanufactured steel flanged safety valves with full confidence. We have the facilities and extensive experience in all areas of safety valve repair and remanufacturing.

For over 30 years, North American Safety Valve has maintained the nation’s largest inventory of Kunkle Safety Valves. We stock big numbers of every valve Kunkle makes. At NASVI, we don’t talk long factory lead times, we simply pull the valve from our stock, set it, test it, then send it on its way—usually the same day! Besides our large inventory of new Kunkle valves, we also stock new safety and relief valves from Farris, Crosby, Conbraco, Consolidated, Aquatrol and many others. And be assured it’s backed by the quality service that has earned us one of the finest reputations in the business. Next time you need Kunkle or any new safety or relief valve, call our sales team toll-free at 1-800-800-8882. We promise immediate information on prices, availability and delivery.

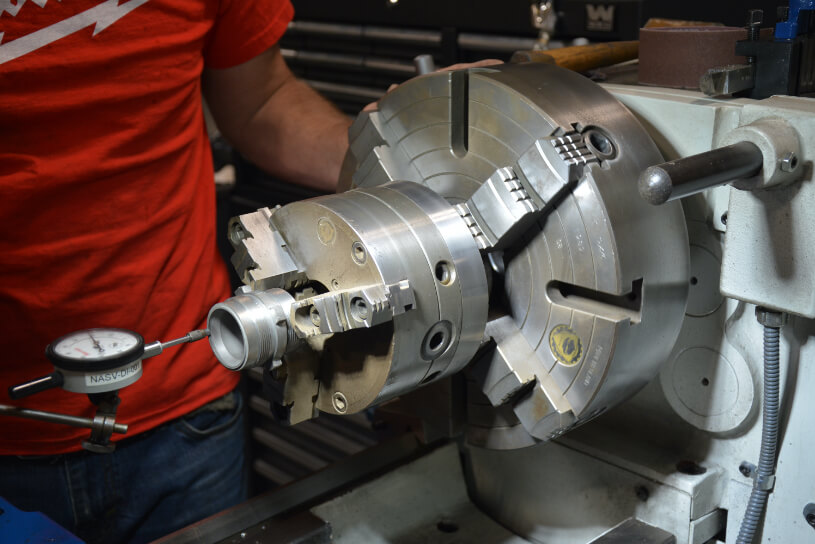

Safety valves, when properly maintained, can last a long time—upwards of 30 years or more. Much more. Recently, a century-old valve arrived at NASVI for repair. After machining and lapping […]

William Rock III, NASVI Valve Disassembler Since 2001 When a valve arrives at our facility for remanufacturing, William Rock III (Bill) is ready and waiting on the front line. He […]

Bronze, steel and stainless steel safety relief valves for air, gas, steam, liquid and vacuum service that meet ASME Section VIII, ‘UV’; Section I, ‘V’, are National Board certified and […]

When it comes to safety valve experience NASVI employees have a mountain of knowledge. Guess how many years of collective experience these three long-time employees have in this short video. […]

This direct spring-operated pressure relief valve, part of the Series 60 and 80, uses special internals and soft seats for optimum, accurate performance. Of course, we have them in stock. […]

The NASVI team goes the extra step in safety valve quality control. Before we ship any valve, we set and test them to the end user’s specifications. This is an […]

Q: My customer has a 2-inch line. Do I need to sell them a 2-inch safety valve? A: Safety valves should be sized and selected based on the set pressure […]

Not only is Kunkle’s 6252/6254 among their largest valves, also it’s a very sought-after one. You guessed it; we keep several in stock. For general application, it is suitable for […]

Valve manufacturers are not immune from the supply chain issues plaguing most industries right now. It’s predicted that it will take some time for shipping channels to be adjusted. NASVI […]

With supply chain disruptions hitting manufacturers, it’s important to be proactive as we approach heating season. With 35,000 relief and safety valves in stock & same day shipping, our extensive […]

Supply the following information: Example: 1. Quantity of Valves 4 2. Size of Valve Inlet and Outlet 1 ½” x 2” 3. Type, Model or Figure Number 1905FC 4. Manufacturer Consolidated 5. Inlet and […]

If you’re searching for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and 1900-P1 Series economizer valves, look no further than NASVI. We’re the only company in […]

Did you know that NASVI has 35,000 safety & relief valves ready to ship at a moment’s notice? Or that warehouse is so huge (63,000 square feet!) we have a […]

NASVI pressure tests over 150 valves every day. Watch the process from adjusting the blow down ring to field service guidelines and performing the test pop, to sealing and shipping […]

If your customers are requesting a Kunkle liquid relief valve, model 218, then it’ll come as no surprise to you that not all distributors stock them and the manufacturer’s lead […]

A cracked valve, a broken part. There are always unwelcome surprises during a scheduled or unplanned shut down. Operations need to be back up and running ASAP. Don’t wait 7-10 […]

A No Brainer. Wearing face masks and social distancing is a no brainer. It isn’t pleasant, but you do what you have to do. Selling safety valves is also a […]

If you’re on the hunt for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and P1 Series economizer valves, look no further than NASVI. We’re the only […]

What’s the purpose of a drip pan elbow? It provides a means to handle condensate from safety valves used in steam applications. Where are drip pan elbows used? The drip […]

When you sell safety valves, your customers are under pressure to get what they need fast. That’s why NASVI stocks the largest selection of Kunkle Valves for a variety of […]

Suggest a NASVI Valve Exchange Program. If your customer has several safety valves in need of repair but can’t afford to shut down for lengthy repairs, there’s an easy solution: […]

Offer remanufactured safety valves and watch sales grow. More companies today have found that it makes sense to rely on remanufactured safety valves. For most industrial uses, remanufactured valves offer […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

You don’t have to be an expert in the field of safety and relief valves to sell them because that’s our job. And we’re only a phone call away. We’ll […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Increase profits, make our new Repair Facility your first stop. North American’s new Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every […]

A.J. Podschwit has an extensive background in industrial sales. In his role as application engineer at North American, he puts it to use every day. “Customers call with specs, but […]

Our goal is to make it easy for you to profit from the sales of safety and relief valves. Call us for assistance. We can help you with sales planning, […]

I am writing this on March 26 and the virus is well into its third week in the United States. We received a letter from Homeland Security that North American […]

Earlier this year, I shared a little product education on safety valves that can make you look really smart to customers, which usually means more orders for everything you sell. […]

• More than 35,000 valves in 3,100 varieties • Currently set and ship over 200 valves per day • We repair over 40 valves a week with plenty of capabilities […]

Kolby Gabbert has been with North American for nearly a year, and compared to many NASVI employees, he’s still a newcomer. Kolby is an application engineer and enjoys the customer […]

Offer North American’s remanufactured safety valves as an alternative and watch your sales grow. Many companies have found that it makes sense to rely on remanufactured safety valves. For most […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. In addition to an experienced, skilled staff, NASVI’s Service Center is equipped […]

Our giant inventory and remarkable selection awaits your call. One of the customers recently inquired about the availability of five 4-inch liquid flanged valves. The end user had made a […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket. North American’s Service Center is […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

For some reason I get asked pretty frequently if I’m a surgeon. Believe me, you don’t want me operating on you. I tell people I’m the Safety Value Doctor because […]

Offer NASVI’s quick turn-around on repair and testing services. Over the years, our Service Center has proven popular with maintenance managers. It allows your customer’s plant to have their valves […]

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

Choosing remanufactured safety and relief valves is a smart alternative for saving money and minimizing down time. It makes good sense for the majority of industrial uses because they are:

How much time and money have you lost because of price, availability and delivery times associated with new safety valves? Get production back up to speed affordably and confidently with remanufactured valves.

If a remanufactured valve doesn’t meet your expectations for any reason, within 5 days of receipt and prior to installation, return it for full credit plus shipping and return freight costs.

2 North American Safety Valve Industries, Inc Iron Street North Kansas City Missouri U.S.A. Telephone: (816) (800) Fax: (816) Dear Customer, As a wholesaler, you know the importance of being responsive to your customers in terms of products and service. In a competitive market, it can make or break a business. We at North American Safety Valve share the belief that servicing the customer completely and competently every time is the key to success. Since 1975, that formula has worked for us. We have supplied wholesalers like you with the widest spectrum of safety and relief valves possible. Although it may only be a fraction of your sales, safety valves are our entire business. You don t have to be an expert to sell safety valves to your customers, because that s our job. We ll help you spec the proper valve to fill an order and give an immediate price quote on the phone. Because we stock all makes of safety and relief valves in our 50,000-sq. ft. warehouse, next-day delivery is the rule, not the exception. Our valves are built and set according to Code requirements and come ready to install. In addition to handling both common and hard-to-find valves, we also offer an extensive inventory of remanufactured safety valves. Repairs? Our company offers both standard and emergency repairs for your customer s safety valves. We even offer a 24-hour emergency turnaround when needed. And North American guarantees all parts and workmanship on every safety valve we repair for one year. Finally, we try to make inquiring to North American as easy as possible. At the other end of our toll-free number, you ll find a friendly, helpful sales representative who will take you through the process. If you need confirmations of your quotes, just ask and we will you one immediately. Thank you for considering North American for all your safety and relief valve needs. We re always here for you. Sincerely, Allen Tanis President

3 OUR SERVICE PEOPLE Over 140 years of safety valve experience. We try to make the process of ordering as easy as possible. Our specialized computer gives us quick access to availability on any valve. We can provide an accurate price quote, offer alternatives and give a delivery date immediately. No waiting or call backs. Many times this makes all the difference in getting an order. Al Tanis One of our customers recently inquired about the availability of five 4-inch liquid flanged valves. The end user had made a mistake in ordering and was in desperate need of these valves immediately. They were pleasantly surprised to find that we had them and could ship all five that same day. Paul Stratman "We provide the best service in the business. And that takes the commitment of everyone who works here. We re all in this together working and doing whatever needs to be done to ensure the customer s needs are taken care of. We treat every customer the same and make them our number one priority. Andrea Tanis At North American, we do one thing other companies don t: When wholesalers call us for price and availability, we give the information over the phone. Then, if requested, we can a quotation with a job or reference number to the wholesaler for his records. When the order goes through, he has the information. A quick call to us and the valves are on the way. Norman Pursley Wholesalers tell me we have a reputation of being good people to work with. An example is how we ll talk directly with the enduser at the wholesaler s request. When asked, we even use the wholesaler s name. It gets customer problems solved faster and gives the credit to the wholesaler. Jim Cook Today, keeping abreast of Code requirements in the many jurisdictions can be impossible for a wholesaler. That s why we maintain all the latest Code information in our library. Isaac Kostrow To say the least, safety valves are a specialized field. It takes knowledge of the products, manufacturers and end users. When a customer needs a valve which requires modification, specialized connections, coatings or special materials, we offer quick solutions. On items that take months from the factory, we deliver in days. Bruce McDermid Our whole company is truly committed to the customer. It is great to be part of a team that puts the customer first and can come through for them when they really need us. Kevin Walbridge

4 A RELIABLE ALTERNATIVE is the quality in a remanufactured valve. The difference between remanufactured valves and new OEM valves is: Half the price! Twice the warranty! Lower prices, reliable products and quick availability make remanufactured valves a profitable option. In the past few years, many companies have found that it makes sense to rely on remanufactured safety valves. For most industrial uses, remanufactured valves offer excellent availability and are extremely cost effective without compromising quality or safety. Now you can be part of this growing trend. We not only have the facilities but also extensive experience in all areas of valve remanufacturing. Two-year Warranty Guarantees Workmanship During the remanufacturing process, all valves receive the utmost attention to ensure they meet original specifications. Our quality control program allows our personnel to carefully monitor all steps of the remanufacturing process to assure the highest quality. And we provide guarantees on all remanufactured valves for two years on parts and workmanship. Valve Exchange Programs If you"re customer has several safety valves in need of repair but can t afford to shut down for lengthy repairs. Solution: A valve exchange program. Before a maintenance shutdown, we ship the safety valves to the customer in advance. The old valves are then shipped to us for repair or remanufacture. After servicing, the valves are set and shipped back to the customer for use during their next scheduled maintenance shutdown. As with our new valves, computer-aided ordering and parts inventory ensure a fast, reliable turnaround for remanufactured safety valves. Check with your Application Engineer for details on how remanufactured valves can work for you and your customers. 4

5 FIELD SERVICE UNIT delivers on-site valve testing and repair. Fully-equipped repair shop on wheels. Sometimes even the fastest off-site service isn t good enough the work must be performed at the site and within a very tight window of opportunity. And that s where our Field Service Unit delivers. The self-contained repair shop and mobile testing stand unit offers on-site repair and resetting of safety valves during scheduled maintenance shutdowns. Step into the mobile repair unit and you ll find all the equipment necessary to perform the highest-caliber repairs. Included is a sand blaster, compressor, lathe, mill/drill press, lapping stones it s all inside. There s also a seat-resurfacing machine with all the adapters for every orifice in the Maxi-Flow boiler line. Completed safety valve work will carry the VR stamp. State-of-the-art computerized testing. The Field Service Unit also includes a state-of-the-art computerized lift-assist testing unit that allows for testing set pressures and resetting high-pressure safety valves in the field. The testing unit makes testing valves that are welded in-line or stationary possible without removing the valves. You won t be required to pressure down or increase pressure to test for set pressure. The lift-assist testing unit also allows for resetting valves after repairs have been made while the valves are on-line. If removing from service and shipping valves isn t practical or possible at your customer"s plant, then the on-site Field Service Unit is the perfect answer. From the equipment on the truck to the people on the repair team, NASVI backs everything. Whether the customer needs the Field Service Unit for three days or three weeks, you re going to save them a lot of downtime and increase your opportunities for more valve sales. For more information on scheduling and costs, give your Application Engineer a call at On-site testing, repair and resetting of: Safety valves

6 VALVE SERVICE CENTER repairs carry a one-year warranty. Our service center repair capabilities are designed to keep the customer"s safety and relief valves in top operating efficiency. The factory-trained service personnel spot potential problems and recommend the most economical ways to solve them. Over the years, our service center has proven popular with maintenance managers. It allows their plants to have valves repaired, serviced and set quickly, which minimizes downtime. They also like the service because it saves them money. BEFORE AFTER REPAIR CASE STUDY: Quick Turnaround This severe duty safety valve was sent to the service center for repair. Castings were sandblasted, flanges were refaced, worn critical metal surfaces were resurfaced and machined to original tolerances, and all gaskets, bolts and nuts were replaced. The valve was then tested under the same rigorous quality guidelines as a new valve and returned to the customer. The turnaround... only one week. The savings... significant! 6 The service center updates the valve to the latest design standards when necessary. These upgrades use only genuine factory standard parts to assure maximum reliability and long life. All valves serviced in our repair facility carry a one-year standard warranty. The service center holds ASME s V & UV stamps and National Board s NB & VR stamps. Exchange and Rental Programs It is no longer necessary to purchase large stocks of back-up valves or risk excessive downtime costs due to non-availability of needed valves. Our service center s Valve Exchange Program lets your customer eliminate both the capital commitment and the risk. Instead, you provide significant savings in logistics costs during their turnaround maintenance outages. This exchange program is individually structured to meet the needs of each customer. If your customer has safety valves in need of repair but doesn t have the numbers that justify an on-site service unit or can t afford a shut down, a valve rental program can offer a solution. Before a maintenance shutdown, the service center ships the safety valves your customer needs in advance. The old valves are then shipped to the service center for repair, testing and reset. After service, your valves are shipped back to you for replacement of the rented valves. A service center Application Engineer will work directly with you to customize a program to meet your customer s plant s needs.

7 Process/Safety-Relief Valve Flanged Sizes Series Series Plain cap, open test lever and packed test lever D Series DB Series Stainless steel or special DO DH DS alloy trim WH R W For process and general JOS/JO Series JBS/JB Series service industries JL JW JJC Crosby JO112C C.S. or special alloy bodies Sage 600 Series All stainless O Ring Seat Farris 26EA10 26RB11 26PA12 Balance Seal 5000 Series 5100 Series Process/Safety-Relief Valve Screwed 264/266 Sizes 1/4-2 Plain cap, open test lever and packed test lever Stainless steel or special alloy trim For process and general service industries All stainless O Ring Seat Special Connections Flanged Butt Weld Socket Weld Crosby Farris TXT/Texsteam Anderson- Greenwood Republic Hydro- Seal Series JR JRU JMB Series Series LS FT HC LCT-11 LCT-13 LCT-14 LCT-20 LCT-30 LCT-40 L40 7

8 Cast Steel Boiler Safety Valve 300/600 Sizes 1-8 Steel or alloy body Steel or alloy spring Test lever Exposed spring Flanged or Butt Weld Crosby Farris A 600A Series HS HSA HC HSJ HCA HN HNA HE V S W R Cast Iron & Cast Steel Liquid Relief Valve 91 Sizes 1/2-8 FM approval for fire system service Bronze or stainless steel trim Screwed and flanged connections Stainless steel throughout Lunkenheimer S S S S S H HU 41HH200 HU-D HDF 11H200 HTC 23H 34H HRN FSS HCA HSS HIB HU3 HU4 8

9 Portable Bronze Safety Valve Sizes 1/4-3 Steam or air service Plain cap or test lever Side outlet Bronze or stainless steel trim Soft seal Cryogenic Rockwood/ M XM RSO RSO-L Swendeman RXSO SO XSO Republic Texsteam 2 2-A M 23-S 23-MS ROW 550-SO Conbraco Taylor Farris Crosby-ORR Aquatrol Crane Jayco/Scott Lunkenheimer Spence 19 Series 29 Series 80 Series MC W200 12W200 13W200 KVT OVS FBF ODP EIF BBJ BIA A T Bronze Liquid Relief Valve 20 Size 1/4-3 Plain cap or test lever Bronze or stainless steel trim Screwed or flanged connections Hand wheel adjustment UL or FM approval Soft seat M M P 200-H 200-A 1478/ / Crosby GC 25 Aquatrol Texsteam 35-R 550-ROV Kingston D Lunkenheimer Rockwood/ SL Swendeman RSL HL Jayco Crane Farris Republic T TBB 11H200 12H200 9

10 Cast Iron Safety Valve 252/6252 Sizes 1-1/2-6 Steam or air service Test lever Bronze or stainless steel trim Screwed or flanged connections Crosby Farris Lunkenheimer Conbraco S HO HOB HR Series Crane Spence Low Pressure Steam Boiler Safety Valve A GIF YIA YIJ 930 Screwed or flanged connections Medium or high capacity Sizes 3/ T 216R T Conbraco Crane Crosby-ORR A Spence/Watts W Drip Pan Elbows DPE/299 Cast iron and cast steel Flanged and screwed connections Sizes 3/ Crane 1100 Crosby EFS DPE DPE 10

11 Air Compressor Safety Valve 30 Sizes 1/8-3 Soft seat Atmospheric Relief 1 1A 28A 29A 30 39A 48A Conbraco Kingston Jayco/Scott Aquatrol Lunkenheimer C 112C 112CT C Hot Water Boiler Relief Valve 537 Sizes 3/ McDonnel-Miller Watts 174A 740 Conbraco Bell & Gossett Vacuum Relief Valve 215V Iron, steel, stainless steel, bronze or aluminum Sizes 1/2-14 Flanged or screwed connections 215V 11V 80-V Crane 1155V Conbraco Union Flonetics/ Foster V-1 Protectoseal Aquatrol 27 VAK-14C 11

12 WE"RE YOUR TOTAL SOURCE when it comes to safety valves. Calibration North American has facilities for setting safety valves with steam, air or liquid. Our testing facilities can handle sizes 1/8 inch to 12 inches, with pressures to 10,000 PSI. We also have a vacuum test stand as well as oxygen cleaning equipment to handle special services. On-Line Inventory Our computer monitors all inventory in our 50,000-sq. ft. warehouse. This technology allows our salespeople to give you immediate information on availability, price and delivery. When you call, the information is ready and up to date. No waiting. No factory delays. No Guesswork To assist you in keeping track of quotes, just ask and we can you a confirmation stating: the description of the valve the price you were quoted any additional information you require We can even add your reference number to our system. This allows our system to work with yours for fast, convenient ordering. Remember, when you use North American you don t have to be an expert in safety valves. That s our job. In fact, that s our only job! For your ordering convenience Call toll-free in the U.S.A., Canada & Puerto Rico In Kansas City call (816) (816) (Fax) sales@nasvi.com North American Safety Valve Industries, Inc Iron Street North Kansas City, MO North American Safety Valve Industries, Inc.

Our plumbing valves are designed and monitored to minimize the impact that harmful chemicals can have on the health and safety of people and the environment.

4000 Series™ flanged and grooved-end ball valves featuring a patented corrosion resistant PFA-fused solid ball, making them more durable, less susceptible to buildup, and longer-lasting than an ordinary unprotected ball.

Our design provides maximum flow rate free from obstruction. Seats are protected from wear, and automation is a breeze with low operating torque and an ISO standard mounting pad. 4000 Series™ ball valves are used in critical applications around the world where gate, butterfly, or eccentric plug valves cannot be trusted.

Mechanical contractors, plumbers, and facilities maintenance engineers have trusted American Valve’s MILANO valves for decades. Every MILANO valve is manufactured in an ISO-certified facility to American Valve specifications. MILANO plumbing valves are backed by a world-class quality management system and American Valve’s 100+ years of manufacturing experience.

Our thermoplastic valves and fittings combine the best in corrosion resistance, dependability, and value. Our designs ensure superior flow characteristics and consistency in body design, while our unique molding process uses all virgin material with no reground plastic that could introduce contaminants.

American Valve has been producing high-quality plumbing products for more than 100 years. Our goal is to provide affordable ball valves, plumbing valves, thermoplastic valves and fittings, and specialty plumbing products that are durable and dependable, helping you preserve the life of piping systems and other equipment.

Our products are engineered from the finest quality material and are designed to minimize the impact of harmful chemicals on people and the environment. Customers of American Valve also enjoy features like build-up resistance and zero leakage. All of our products are backed by our incredible customer service, which we’re confident is the best in the industry.

Quality is one of our most highly regarded values at American Valve. We believe that, by engineering products with high-quality materials and to the highest standards, we can minimize plumbing maintenance and equipment replacement. We pride ourselves on our unique, innovative approach to plumbing valves and specialty plumbing products.

In 2023, the sales of Pressure Relief Valve in Global Market is expected to reach US$ 4,509.8 Mn. and is projected to expand steadily at a CAGR of 4.6% to reach a market valuation of close to US$ 7,070.9 Mn by 2033.

In recent past valve costs have increased globally, which can be attributed to growing tariffs from the North American region, particularly the US. Leading players from the European and American regions have facilities in both high- and low-income nations. In contrast, labor-intensive production processes like the creation of rough castings for valves and valve components take occur in low-cost manufacturing nations like China. These processes include design, research and development, and testing. Due to low prices and quality maintenance, OEMs are able to do so. However, growing US government tariffs on steel and aluminum imports from China have had a substantial negative influence on pressure relief valve profit margins and costs.

However, the rapid growing industrialization and increasing safety precaution are the factors that are expected to fuel the market growth of Pressure relief valves across the globe during the assessment period, the Pressure relief valve market is expected to experience demand growth with CAGR of 4.6% during the forecasted period.

From 2017 to 2022, the Global Pressure Relief Valve Market expanded at a CAGR of around 2.4%. The advancement in product technology to connect the valves digitally enables end users to monitor pressure in various applications digitally which has generated significant demand from the various industry sector during the forecasted period.

Numerous applications where pressure levels are crucial for continuous and efficient machinery performance demand for the utilization of pressure relief valves. These include the various sectors operating with steam, air, gas, or liquid such as oil and gas, power generation and the petrochemicals industry. Multiphase applications and chemical processing systems both have high installation rate of pressure relief valves. With rapid development industrial sector & expansion of oil & Gas pipelines across the developing as well as developed economies the demand for PRV is also expected to expand, Persistence Market Research expects the market to expand at a 4.6% CAGR through 2033.

Both emerging and advanced regions have seen a surge in oil and gas consumption. In order to meet the rising demand and supply for oil and gas, industries are concentrating on expanding their production facilities through onshore and offshore exploration. Since the oil and gas sector is one of the key end uses for the global pressure relief valves market thus expanding oil & gas Sector is generating lucrative opportunity for the demand growth of PRVs in upcoming period.

Furthermore, growing regulation for use of pressure relief valves in power generation sector is further set to create opportunities for the market. For instance, there are currently about 50 nuclear reactors under development. By safeguarding turbines, super heaters, and boilers to enable the stations to operate at prescribed pressures, pressure relief valves play a crucial part in the successful and safe operations of nuclear facilities.

Manufacturing businesses will be significantly and directly impacted by the Asia Pacific region"s volatile and uncertain markets. The operational costs of the manufacturing processes, which are the main concern of manufacturers, will be directly impacted by rising tariffs and raw material costs used to manufacture valves. Rising raw material costs immediately impact the integrity of the supply chain and the selling price of a product. Manufacturers in the Asia Pacific region are becoming increasingly concerned about the steady growth in cost of the raw materials used to make pressure relief valves. This is expected to, restrain the market"s expansion for pressure relief valves.

With an absolute dollar opportunity of around US$ 600.0 Mn, North America is expected to be the most lucrative market for pressure relief valves suppliers. U.S is leading the North American market, and is expected to witness a 1.5X growth during 2023-2033. The market for pressure relief valves has recently experienced considerable growth in sales as a result of growing industrialisation and advancements in urban waste water management systems. Apart from that U.S. is also second largest importer & Exporter of Pressure relief valves, which makes it a targeting region for the manufacturers & Suppliers.

In 2023, the German Pressure Relief Valve market is likely to hold around 25% of the market by value share in Europe. Germany"s extensive remanufacturing capabilities are likely to play a crucial part in development of industrial growth. Sales growth for pressure relief valves is anticipated to be boosted in the upcoming years as manufacturers are planning to invest more in safety & developments of industrial Sites.

With a CAGR of 5.9%, India is expected to lead the South Asian market throughout the assessment period and experience significant expansion. Pressure relief valve demand is anticipated to increase as a result of India"s low production and labour costs, as well as less regulations & certifications required for PRVs, which are encouraging various industry players, including oil & gas, pharmaceutical, chemical, and textile manufacturers, to expand their manufacturing facilities in India.

By the end of the assessment period, spring-loaded pressure relief valves will hold a value share of over 40% of the market for pressure relief valves worldwide. Due to its broad range of applications and other technological advantages over other valves, this valve is widely utilized. The design and use of pressure relief valves is covered by a number of international codes and standards, the most popular of which being the ASME (American organization for mechanical engineers) Boiler and Pressure Vessel Code, also known as ASME code. Despite the fact that this code varies by region.

In 2023, the demand for pressure relief valves is primarily driven by the Medium Pressure segment in Set Pressure segment of the market. By the end of the forecast period, it is projected that pressure relief valves with a medium pressure range will still be widely utilized in a variety of end use sectors. The market for medium pressure relief valves is expected to continue expanding due to rising end-use sectors including oil and gas, chemical, and others.

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

Cla-Val is a world-leading designer and manufacturer of automatic control valves. From reducing and relief valves to deluge, air valves and more, Cla-Val manufactures and provides a wide variety of solutions for use in some of the world’s most demanding applications.

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

8613371530291

8613371530291