online safety valve testing in stock

Different to a safety valve test bench test an online safety valve test (or ISVT – In Situ Valve Test) is carried out on site with the safety valve remaining in its operational position and the plant remaining in operation. Whenever a safety valve “only” requires testing and no further maintenance or overhaul, a TESON online safety valve test is the most economic approach. Those who are new to the subject kindly refer to our Online Safety valve testing white paper.

Safety valves are used in a variety of applications, including air/gas, vapor, steam and liquid service. Flotech has been approved by the National Board of Boiler and Pressure Vessel Inspectors to perform safety and relief valve testing, repair and certification.

Our valve experts will focus on getting your valves tested, repaired and quickly set to the exact specifications. We evaluate the repair condition of every valve and will recommend the right solution to manage your maintenance program.

In today’s world, with the automation technology available, human error can be significantly reduced. Valve service and repair within the valve industry is no exception.

Designed with the valve technician in mind, The AccuTEST offers many competitive advantages including: ease of use, modern software, portability of equipment, and repeatability of results regardless of which technician conducts the test.

In today’s world, with the automation technology available, human error can be significantly reduced. Valve service and repair within the valve industry is no exception.

Designed with the valve technician in mind, The AccuTEST offers many competitive advantages including: ease of use, modern software, portability of equipment, and repeatability of results regardless of which technician conducts the test.

The old way of pressure relief valve testing could be summarized in one word: downtime. First, the plant went down, then valves were disassembled, and finally, the valves were transported offsite for testing. Time-consuming. Costly. High risk. But using the AccuTEST System, pressure relief valve testing comes to you, right where the valves actually operate. Time saver. Cheaper. Lower risk.

The AccuTEST System is a recognized leader in the valve service and repair industry. Why? Think fully automated one-touch testing for ease of use and repeatable results. It’s compact and portable to reduce the load of pressure relief valve technicians. Ongoing product enhancement based on technicians’ input. And we offer responsive technical support, anytime, directly from our engineers – not from a third-party representative.

The AccuTEST System is an recognized leader in the valve service and repair industry. Why? Think fully automated one-touch testing for ease of use and repeatable results. It’s compact and portable to reduce the load of safety valve technicians. Ongoing product enhancement based on technicians’ input. And we offer responsive technical support, anytime, directly from our engineers – not from a third-party representative.

Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test safety valves while in position, under a full load, for consistently superior, reproducible results.

Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test safety valves while in position, under a full load, for consistently superior, reproducible results.

Tired of keeping track of your valve inventory’s annual certification records? We offer complete management of your safety relief valves. With an inventory of repair parts and in stock relief valves of all sizes, we can respond to any customer emergency. We offer annual certification services as well as repair of all major brands, including Kunkle, Conbraco, Consolidated, Dresser, Apollo and more.

The CALDER PROSET Pilot Valve Tester is a cost-effective way to perform the functionality of the pilot in Pressure Operated Relief Valves (PORV) with unsurpassed quality and ease of use. ROBUST, EASY TO USE, AND STATE OF THE ART Tests both modulating and snap-acting pilot...

The CALDER QUICKSET™ Safety Relief Valve Testers set a new standard for Pressure Relief Valve Testing and provide valve technicians with unrivaled performance, volume, flow, and ease of use. ROBUST, EASY TO USE, MODULAR, AND HIGHLY CONFIGURABLE The unique high flow design allows for free...

The new lineup of CALDER QUICKSET™ Safety Relief Valve Testers raises the bar with unrivaled performance and ease of use. QUICKSET™ SRV Testers are designed to match all your valve testing needs with base machines of different tonnage while offering more than 50 different configurations...

40 years ago, CALDER began manufacturing Valve Testers because founder, John Emmitte, realized that companies were not testing valves properly. Even today, many pressure relief valve testers are homemade or fabricated in a manner that does not provide the valve with enough volume, and are...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up...

Customized to Mobilize Your Specific Valve Testing Needs! CALDER Valve Testers has been customizing valve testing systems for almost 40 years designing and creating unique solutions to meet all your valve testing challenges head-on. The CALDER Mobile Valve Workshop is no exception, offering unrivaled flexibility...

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on October 13 – 14, 2021, at the George R Brown Convention Center in Houston, Texas, booth 1521. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and other valve needs. CLIMAX, the leading...

When safety and time are critical, look no further than CALDER for your valve testing solutions. We offer a variety of valve testing and repair machines, including the new TURN-AROUND-TESTER™ (TAT). The TURN-AROUND-TESTER™ offers the ability to put it in the back of a truck, get it on site,...

Visit us at our CALDER Valve Tester locations in Saudi Arabia and UAE. Meet the experts and get a first-hand look at the latest technology available from CALDER. See live demonstrations of the machines our customers are raving about, like the new CALDER Portable Valve...

See the CALDER TURN-AROUND-TESTER LIVE on April 28, 2021 Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers and brought portable to the valve testing industry. The...

CLIMAX, the world’s #1 choice for portable machining, welding, and valve testing invites you to visit us in Houston on February 15 – 26, 2021. This is a great opportunity to get a first-hand look at the latest technology available from CLIMAX, BORTECH, CALDER & H&S TOOL. Meet the experts...

The CALDER HYDROPRO™ Universal Straight Valve (USV) tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console, the HYDROPRO™ USV is ideal for hydrostatic tests up to 9700 psi...

Congratulations to Dave Briggs and the CLIMAX | CALDER engineering team for officially receiving the Patent for the CALDER Safety Interlock System. The Safety Interlock System is designed with interlocking knobs and valve handles that will not release the clamp pressure until the internal test pressure...

CALDER Advanced Valve Testing & Repair Systems by CLIMAX is excited to announce TOMCO Industrial as an exclusive sales and service representative for all CALDER products in Canada. This new partnership with TOMCO will allow CALDER, the leading global manufacturer of valve pressure test benches...

The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry! The USV system uses our patented Easy-Out Seal Plate™ holders which allows quick change-out of seal plates from flanged to other valve end type connections with minimal effort....

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on June 19-20, 2019 at the George R Brown Convention Center located in Houston Texas. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and...

The CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites. Valve repair shops and technicians are now taking their shop on the road. With superior quality, safety, durability, and performance, owning a CALDER TURN-AROUND-TESTER™ ...

CALDER Advanced Valve Testing Systems proudly announces the appointment of Mr. Kevin Vincent to the position of General Manager. CALDER is a subsidiary of CLIMAX Portable Machining & Welding Systems, headquartered in Newberg, Oregon. Mr. Vincent has been in commercial positions of increasing responsibility at CLIMAX for five years, serving most recently as a...

Fisher Price, CALDER Product Line Manager, focused on CALDER Advanced Valve Testers, has been working in the valve industry since 2004. Spending much of his career with Nuclear power companies, Fisher has held several roles machining, welding, testing, and repairing valves, as well as, providing expertise...

Oil & Gas News, November 2018: CLIMAX Portable Machining and Welding Systems is the world’s premier supplier of portable machining and welding equipment. Under its CALDER product line, the corporation provides the world’s most advanced line of valve testing and repair systems. CLIMAX | CALDER...

CALDER Advanced Valve Repair & Testing Systems cordially invites you to the GRAND OPENING of our new CALDER Saudi Arabia sales office, customer service center and product showroom in Dammam, Saudi Arabia. Please stop by on Monday, November 19 any time between 10:30 AM and 2:00...

Clark Turner has been in the valve industry for more than 35 years, where he’s done everything including repairing, hydrotesting, and installing line valves, as well as installing safety and relief valves in various processes. He also spent significant time as an ASME Section VIII design...

CALDER Valve Testing Systems recently introduced a new, enhanced lineup of valve testing systems that have proven to be a reliable solution for valve repair shops. The new valve testers have quickly earned a reputation as the safest, highest quality, and most durable, versatile, and productive systems...

The new CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites, giving valve repair shops and technicians the opportunity to take their shop on the road. Contact us today at +1.985.974.6070 or [email protected] to...

The TURN-AROUND-TESTER™ (TAT) is the perfect solution for service teams to complete in-field testing of freshly refurbished Control and Safety Relief valves. The self-contained TURN-AROUND-TESTER™ will fit in any full-sized pickup bed with the controls positioned to ergonomically allow the operator to complete the testing even when...

Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers, and now CLIMAX | CALDER has brought portable to the valve testing industry. The new CALDER TURN-AROUND-TESTER™ can efficiently...

We live in a world with valves, and those valves need to be repaired and tested. Today we’re asking all valve repair shops, power plants, refineries, and owners of valves: How much downtime and money could you save if you could repair and TEST your...

GOING PORTABLE WITH A WHOLE NEW TECHNOLOGY We live in a world with valves and those valves need to be repaired and tested! 51 years ago, CLIMAX disrupted traditional repair processes, introducing undeniable value by inventing the portable key mill, bringing portable machining technology directly...

CLIMAX | CALDER invite you to visit our booth (1628) at the VALVE WORLD AMERICAS EXPO, June 20 – 21, 2017 in Houston Texas. VALVE WORLD AMERICAS EXPO is the largest exhibition for services, equipment, and other valve needs. CLIMAX will showcase their valve grinding and...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up to 9700...

The CALDER Safety Relief Valve Tester (SRV) sets a new industry standard for testing safety relief valves with unsurpassed performance and ease of use. EASY TO USE, WITH UNRIVALED QUALITY, SAFETY & CUSTOMER SUPPORT Every component in the SRV pressure circuit is designed to work...

A Dozen Questions That Can Save You Millions in Your Valve Testing Program! When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, usability, productivity and – ultimately – total cost of ownership and return on the investment....

The Most Versatile & Cost-Effective Way to Test Straight Bodied Valves! The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console,...

With vastly superior quality, safety, durability, flexibility, performance and support owning a CALDER Advanced Valve Testing System is by far the most flexible and cost-effective way to manage your valve testing program, reduce your total cost of ownership and maximize your return on investment over the...

BIC Magazine, April 2017 When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, productivity and return on investment. Ask these 12 pivotal questions when purchasing a valve tester: Is every component in the tester certified by the...

Our engineers and valve test experts asked customers what they want in the next generation of valve testers. One message was loud a clear: customers want fast, responsive, expert service and support. So we’ve built that right into the foundation of our new CALDER offering!...

CALDER engineers, in collaboration with key industry experts, spent countless hours designing this next generation of CALDER advanced valve testing systems. Not only are CALDER systems more versatile, accurate, durable and cost-effective, they’re designed with “Safety First!” in mind. Our systems maximize user protection and ensure test...

The new lineup of CALDER advanced valve testing systems, manufactured by CLIMAX, are the most flexible and versatile systems on the market. The CALDER test system can seamlessly expand and evolve with your business, giving you the lowest total cost of ownership (TCO) and the...

The HYDROPRO™ Console – The Most Versatile & Cost-Effective Way to Test Valves! The HYDROPRO™ Console is the most versatile and user-friendly tester in the industry, capable of performing a wide variety of valve tests when paired with a CALDER hydraulic clamping system or even blind...

Introducing the new CALDER Product Family The new platform of CALDER advanced valve testing systems manufactured by CLIMAX are the safest, most accurate and most versatile systems on the market, and we are pleased to announce our new line-up of valve testing equipment. HYDROPRO™ CONSOLE The...

Are you ready? On January 16th, CALDER will transform the valve testing industry, unveiling EIGHT new products! We’re going to show customers, world-wide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. We’ve made a major investment...

Get ready – CALDER valve test systems will transform the valve testing industry starting January 16th! We’re going to show customers, worldwide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. HOW? We have been working...

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket.

North American’s Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every safety valve ever made—allowing technicians to make repairs to exact specifications. The center has six lathes on site, so technicians can restore tolerances on existing parts in quick order. If a part cannot be restored, it can generally be replaced from our extensive parts inventory.

Once repairs are complete, valves are tested and then set at one of six, fully equipped test stations. The boiler is on every day for testing steam valves. It’s always ready, allowing us to set and ship your valves fast.

Over the years, our Service Center has proven popular with maintenance managers. It allows the plant to have their valves repaired, serviced and set quickly, which minimizes downtime. They also like the service because it saves them money.

Our repair service also includes updating the valve to the latest design standard when necessary. All valves serviced in our repair facility carry a one-year standard warranty. North American holds ASME’s V and UV stamps and National Board’s NB and VR stamps. The next time your customer has questions about repairing or upgrading their safety or relief valves, give one of our application engineers a call.

You don’t have to be an expert in the field of safety and relief valves to sell them. We are here to help. Our goal is to make it easy for you to profit from the sales of safety and relief valves. Our expertise comes from taking care of our customers for over 42 years. And our large inventory allows us to offer same day shipment from stock on every valve Kunkle makes.

The sole responsibility of our dedicated applications engineers is to take care of your requirements. We will help you with sales planning, product selection and after sale service when needed. We will even provide you with catalogs that have no reference to NASVI. Our valuable advice is free and as close as your phone. So the next time your customer calls and needs a safety or relief valve, call a NASVI Applications Engineer.

They’ll have a quick answer on price, availability and shipment. When it comes to selling safety valves, you don’t have to stock anything. Simply call 1-800-800-8882 or visit us on the web at www.nasvi.com. We’ll make it easy for you!

Our two-truck unit responds to customer requests anywhere, offering on-site repair and resetting of safety valves during scheduled maintenance shutdowns.

Step into the mobile repair unit and you’ll find all the equipment necessary to perform highest-caliber repairs: sand blaster, compressor, lathe, mill/drill press, lapping machine–-it’s all inside. There’s also a Consolidated® seat-resurfacing machine with all adapters for every orifice in the Maxi-Flow® boiler line. Completed valve work will carry the VR stamp.

The Field Service Unit also includes a state of-the-art computerized lift-assist testing unit that allows for testing set pressures and resetting high-pressure safety valves in the field. The testing unit makes testing valves that are welded in-line or stationary possible without removing the valves. Your customers won’t be required to pressure down or increase pressure to test for set pressure. The lift assist testing unit also allows for resetting valves after repairs have been made while the valves are on-line.

If you have prospects or customers that bought their replacement valves elsewhere because you haven’t been able to provide on-site service, you will want to get back with them and talk about this service. If you have questions about pricing and scheduling of our Field Service Unit, give us a call at (800) 800-8882.

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

Dismounting safety valves from their operational location can be time-consuming and expensive. The Seetru Tru-test® provides the capability to test safety and relief valves in-situ, eliminating the need to remove the valve from the system or shut the system down. In-situ testing of this form is part of a carefully planned and monitored test and maintenance regime, which also includes periodic strip down, inspection & overhaul, and a highly cost effective means of managing safety valve and relief valve inventories.

The Seetru Tru-test® system offers the capacity to test in real operating conditions. This provides added con dence in the protection afforded by the safety valve. It also supports the optimisation/ minimisation of maintenance downtime through Seetru operated condition monitoring of safety valves in service.

Tests can be “hot”, i.e. in-situ with medium pressure acting on the safety valve, or “cold”, i.e. on or off site and in-situ with no medium pressure acting on the safety valve.

Pre-programmed safety limits are sensed and managed automatically during the test cycle in order to prevent damage and to provide fail-safe operation.

Lift limitation is pre-established and provided to minimise the risk of valve damage or a full lift safety valve popping open during test. The computer controlled pre-programmed test eliminates the chance that the inherent vagaries of a human operator manually controlling the lift might result in the safety valve lifting.

The Seetru safety valve test method using the Tru-Test® system is widely approved, for instance, by Lloyds Register of Shipping and the Insurance Industry.

Vinson understands that complete reliability of all Pressure Relief Devices is essential to protect, not only a plant’s assets, but most importantly all personnel and the environment. Vinson offers both field and in-shop repair services, and is proud to be one of the nation’s leading National Board certified VR & TO Repair Facilities. With certifications on air/gas/liquid and steam service (Section I & VIII), Vinson provides setting, repair and testing services on all manufacturers valves up to 10,000 psi.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

With an ever-increasing focus on reducing maintenance expenditure, there is a need for safety critical equipment to function reliably. With preventative maintenance on pressure safety valves (PSVs) being one of the more significant integrity costs, increasing efficiencies in this area is important, with potential for time savings and performance improvement.

The Pressure Safety Valve Manager digital tool is client-accessible and contains all the information used in the RBI, including the (pre-pop) results. Detailed tabs contain the PSV performance history for the asset(s). The tool may also communicate with the operator’s computerized maintenance management system (CMMS) to accurately relay, not only the performance history of each PSV, but also information useful for maintenance planning, such as shutdown requirements, online testing capabilities etc.

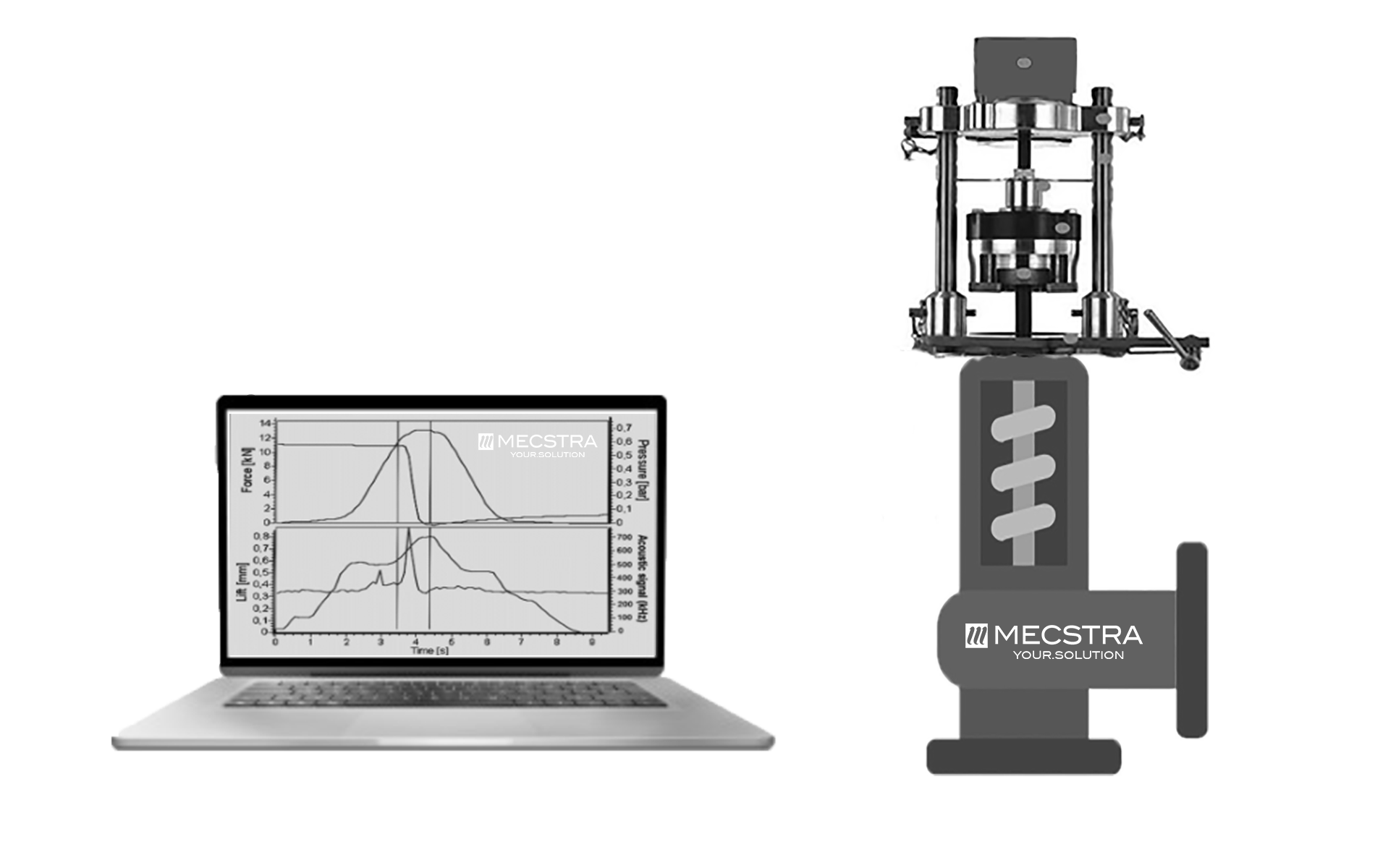

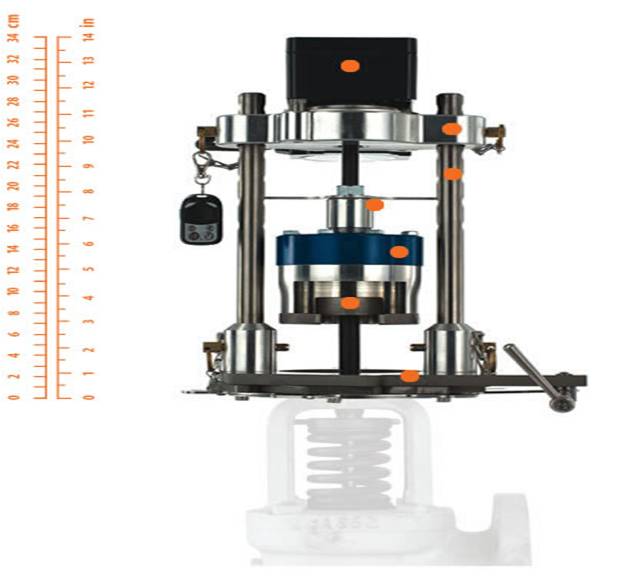

The EVT-Pro device simultaneously examines two critical variables of the relief device — the upward force applied to the spindle and the actual system pressure. Using sophisticated sensors, including an acoustic device, EVT-Pro testing accurately determines the pressure relief valve’s set pressure. It can also immediately sense and automatically close a relief device should it remain open during a test – a unique safety feature built into the software and hardware.

Testing the safety relief valve is extremely important to the overall safety of your boiler system. In this post, we’ll be talking about what goes into testing a steam relief valve, but safety valve repairs should only be performed by a company holding a current Certificate of Authorization (VR) from the National Board of Pressure Vessel Inspectors.

Using certified and calibrated gauges is essential to accurate testing. WARE’s own Rick Walker recommends using two gauges, for maximum accuracy and in case one isn’t properly functioning.

Relief valves need to open and close at very specific pressures, and also need to open smoothly. A smooth opening contains a clean “pop” sound, and not a simmering or chattering sound. Responding to the appropriate pressures and opening and closing cleanly are both important signs a professional maintenance provider will look for in a safety valve.

Safety valves contain a compression screw, which puts pressure on a spring and causes the valve to function. The compression screw is where a maintenance provider will try to dial in your valve’s functionality and make set-pressure adjustments. It’s important to note if a valve is cold it might test higher, but as the valve gets hotter its metal will expand and its innerspring will slightly decompress.

Once the valve is warm and has stabilized, it’s best to give it more than one test (Rick does three) to make sure the valve is consistent and within ASME code.

ASME defines a safety valve as properly functioning at 150 psi if it tests within 3% of the set pressure. If your valve tests within 3% of the set pressure three times in a row on properly calibrated gauges, you’re likely good to go.

Because of their importance, checking or calibrating valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Companies use pressure relief or safety valves to protect equipment from pressure spikes. Because of their importance, checking or calibrating these valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Crystal has a solution with its XP2i Digital Pressure Gauge. The XP2i features a special PSV mode designed to test pressure safety and relief valves. Once the valve opens, the XP2i detects the pressure drop and displays the maximum pressure that the gauge ever reached before the drop. This value remains on the display until the technician clears it. Rather than two technicians possibly reporting different values when the analog gauge spikes, with the XP2i both technicians would write the same value, even to a thousandth of a psi.

The XP2i Digital Pressure Gauge features three accuracy levels to choose from, 0.1% of reading, 0.05% of full scale, or 0.02% of full scale. They are available in ranges from vacuum to 15,000 psi and are fully temperature compensated from –10 to 50 C. All versions are ATEX, IECEx, and CSA intrinsically safe, making them ideal for the oil & gas industry and others requiring intrinsic safety. An optional datalogging upgrade allows the XP2i to collect and store up to 32,000 data points and easily download the results to a spreadsheet or protected pdf file.

Allied Valve is the industry leader in valve sales, service, and distribution. Driven by three key principles – safety, reliability, and quality – Allied Valve is a leading supplier of pressure relief valves, control valves, rupture discs, conservation vents, flame arresters, blanket gas regulators, back pressure valves, actuation, and valve services in the upper Midwest. Helping your business meet tight production schedules and reduce downtime with 24/7/365 services delivered on-time, on-site, and in-person, Allied Valve is your trusted partner to keep your business running seamlessly.

Our factory-trained, OEM-certified technicians deliver time-tested solutions that reduce downtime and costs while maintaining the integrity of your safety program. With locations in IA, IL, IN, MN, ND, OH, and WI, our 100+ certified service technicians are at your service. We operate five Consolidated Green Tag Centers, two authorized Kunkle Assemblers plants, and five Masoneilan™ Authorized Repair Center (MARC™), dedicated to providing quality products.

8613371530291

8613371530291