non rotating wire rope specifications in stock

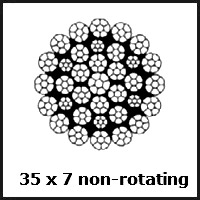

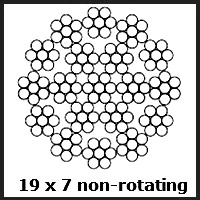

This wire rope construction is available in both galvanised and ungalvanised finish with either ordinary or langs lay. The construction family includes 17X7, 18X7 and 19X7. For further flexibility and other performance characteristics we also supply 32X7, 35X7 and 37X7.

Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications as well as being available with plastic impregnated.

For industries that use wire rope, it’s frustrating and potentially dangerous if the rope spins or rotates. Unless using non-rotating steel wire rope, it can take longer than necessary to complete a job. At Murphy Industrial Products, Inc., we have a perfect solution. Our line of non-spin wire rope is reliable, safe, and cost-effective.

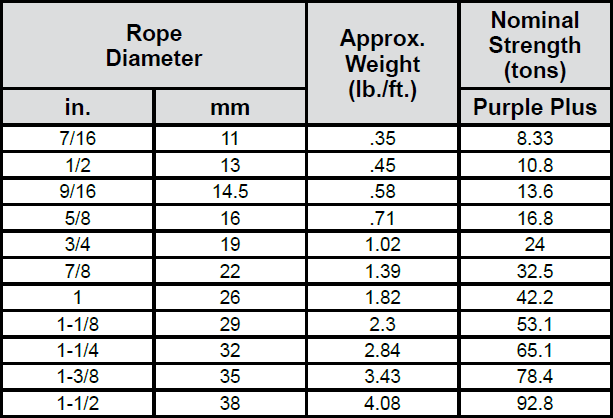

We manufacture our non-rotating wire rope in compliance with the Federal Specification RR-W-410E. That means our 35x7 wire rope meets or even exceeds industry standards. In addition, the non-spin wire rope we manufacture meets the performance requirements of both API-9A and A.S.T.M. A1023/1023M Wire Rope. So, it is rated as a top-of-the-line rope for general purposes.

One advantage of buying non-rotating steel wire rope manufactured by Murphy Industrial Products is that we keep a broad range of products in stock. If you need to have a product delivered quickly, we can accommodate. In fact, if you place an order for non-spin wire rope before 3:30 p.m. C.S.T., Monday through Friday, we can ship it out to you that same day at no extra charge.

The non-rotating wire ropes we produce are of the highest quality possible. They are ideal for building cranes, mobile cranes, offshore cranes, and main hoists. Our non-spin wire ropes can handle a range of minimum breaking loads, from 5.1 tons to 138 tons.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.

Non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force in the event of a load applied.

Rather than all wires and strands being laid in the same direction, a rotation resistant wire rope consists of inner strands being laid in the opposite direction to the outer layers, for example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. This construction means that torsional forces on the inner and outer wires / strands will counteract each other and so minimise the risk of unraveling.

Using an ordinary lifting wire rope for a job or equipment which demand a non-rotating wire rope si very dangerous and it presents the following risks:

Inspect regularly for visible damage, distortion, elongation, corrosion, cracks, nicks or abrasion, which may cause failure or reduce the strength of the Wire Rope.

Main and auxiliary hoist line for mobile and for all types of construction tower cranes which require a high strength rotation resistant rope construction.

The large number of outer strands distribute the pressures introduced by sheaves and drum more evenly onto the core minimizing the danger of unexpected rope failures because of undetected core deterioration.

Aside from this safety issue PYTHON® COMPAC 35 satisfies the high-strength requirements of late model tower and mobile cranes which can NOT be met with neither 19 x 7 nor 19 x 19 style ropes.

Some sizes of Python® Compac 35 are available in right AND left hand lay to comply with OEM specifications (LinkBelt, Grove, Favelle Favco, Terex, Krupp, Demag, Liebherr, etc.).

Manufacturer of standard and custom wire ropes made from phosphorous bronze, Monel®, Inconel® and stainless steel materials. Available in various cable dia. with color and coating options. Features include bright wire, galvanized, rotation and corrosion resistance. Suitable for straight line, medical devices, winches, exercise equipment, aircraft control, rigging and railing applications. Secondary services such as design, CNC machining, electric cutting, extrusion, hydroforming, swaging, coating, tensile testing and zinc die casting are also provided. Serves the aircraft, agricultural, automotive, construction, entertainment, lighting, marine, material handling, medical, military and security industries. Most items available in stock.

SSTE offers high quality wire ropes for a wide range of applications. The company effectively combines variety of experience and tradition with an up to the minute range of products, and a customer service package ideal for the modern market place.

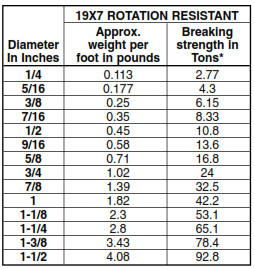

19X7 is a non-flexible wire rope. It is used for a wide range of applications, example of applications for non-rotating wire ropes include the following

Non-rotating wire ropes are made so that the outer rotational force of the wire rope naturally balances the rotational force of the inner strands. Standard rope wire has a tendency to create torque and is thus prone to rotation.

In the past, wrought iron chains, which had a history of mechanical failure, gave rise to wire rope. Defects in solid steel bars or chain links can result in catastrophic failure, whereas flaws in the wires that make up a steel cable are less important because the other wires can readily carry the strain. Although friction between the various wires and strands wears the rope over time, it also aids in temporary repair of minor flaws.

This pertains to the scenario in which a load is applied to a rope. In order to create a composite rope known as wire rope, numerous strands of metal wire are twisted into a helix in a pattern called lay rope. A larger diameter wire rope is made up of several strands of this lay rope arranged in a style called cable laid.

The global non rotating wire rope marketaccounted for $XX Billion in 2021 and is anticipated to reach $XX Billion by 2030, registering a CAGR of XX% from 2022 to 2030.

In terms of value, Regular Type of Lay is the fastest-growing Type of Lay for Steel Wires.Lang lay ropes spool poorly in a drum and are less naturally rotation-resistant and resistant to crushing forces than regular lay ropes.

They are employed in a variety of fields, including mining, oil and gas, construction, fishing, and marine. To address the unique wire rope needs of the new cranes, South Korean speciality high carbon steel wire products producer “Kiswire” is growing its operations in India. They not only serve as OEM suppliers to numerous global crane manufacturers, like Tadano and Kobelco, but they also actively pursue the Indian Replacement Market.

Small diameter 7×7 and 7×19 construction wire rope is commonly referred to as “aircraft cable”. IT IS NOT INTENDED FOR AIRCRAFT USE but designed for industrial and marine applications. According to Federal Specifications RR-W-410D, preformed, right regular lay, strand core, drawn galvanized. Aircraft cable is very versatile and is used for everything from hoisting ropes and tie-backs to safety barricades. It is available galvanized, stainless, or vinyl coated.

We provide Best of Best quality Wire rope as per customer requirement and price wise starting with USHA MARTIN, BWR,BEDMUTHA,OREINT,VIKRANT,NAVIN as per client requirement all with Test certificate

Type 302/304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine- and salt water.

Type 316 stainless steel is the standard high corrosion resistant steel for rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing and textile industries. It has the best pitting resistance in marine and salt water and can be used in temperatures up to 480°C (900°F).

D07B2201/1056—Rope or cable structures twisted using alternate lay, i.e. the wires or filaments in the strands being oppositely inclined relative to the rope axis

The invention discloses an anti-rotation alternate lay wire rope comprising right-laid strands and left-laid strands. The wire rope is composed of the right-laid strands and the left-laid strands identical in number, the lay directions of the adjacent strand layers are opposite, in other words, the right-laid strands and the left-laid strands are arrayed alternatively, the up-down strand layer of any one of the right-laid strands is left-laid, and the up-down strand layer of any one of the left-laid strands is right-laid. The anti-rotation alternate lay wire rope has the advantages of regular lay wire ropes and Lang lay wire ropes, the strands in different directions are arrayed in the rope alternatively, the contact area of the wire rope is increased, mechanical property is better than that of the regular lay wire ropes and the Lang lay wire ropes, and mechanical property test and bonding strength test show that under the condition that same raw materials are selected, breaking force is increased by 12% as compared with that of the regular lay wire ropes of same specifications, and bonding strength with rubber is increased by 20% as compared with the regular lay wire ropes of the same specifications.

The breed structure of steel wire rope is a lot, traditional steel wire rope by the sth. made by twisting of left-hand lay and right-laid to being generally divided into ordinary lay and twist-on-twist two kinds.

Its rope of non-spinning wire rope, is twisted with the fingers to dividing sinistral coiling and a dextrad spiral to contrary (as shown in Figure 1) with the sth. made by twisting of stock.If rightlay rope is namely for be twisted into stock by steel wire rope by sinistral coiling, then make rope by stock to dextrad spiral turn.Because rope is contrary with reversing the trend of stock, cancel each other and there is no twist ties, loose trend, use more convenient, be mainly all kinds of lifting at present, elevation and subsidence mechanical adopts, but also have flexibility less, air spots is sliding, little with the contact area of pulley, to wear and tear shortcoming faster, cause using consume larger.

Its rope of Lang lay rope is twisted with the fingers to identical (as shown in Figure 2) with stock, and it is twisted with the fingers to being also divided into left and right sth. made by twisting, is twisted stock as right-laid is silk along wiring, and stock is twisted rope again and is dextrad spiral twisting and forms.The silk of this steel wire rope and the Contact of silk better, have good around property, that the life-span is long feature, but have twist ties, easily loose trend, can only be used for tensioned lines or pull rope, should not be used for lifting and winding rope.

Goal of the invention: for the deficiencies in the prior art, my company technique personnel, through repeatedly putting into practice improvement, devise a kind of anti-rotation alternatelaywirerope, the object that the twist stress reaching steel wire rope balances mutually, realize good anti-rotation effect.

Technical scheme: in order to realize foregoing invention object, the technical solution adopted in the present invention is: a kind of anti-rotation alternatelaywirerope, comprise right-laid and left-hand lay, described steel wire rope is made up of the identical right-laid of quantity and left-hand lay, the sth. made by twisting of each adjacent layer stock is on the contrary, namely described right-laid and left-hand lay are alternately arranged, and the levels stock of any right-laid is left-hand lay, and the levels stock of any left-hand lay is right-laid.

1, a kind of anti-rotation alternatelaywirerope of the present invention has the advantage of non-spinning wire rope and Lang lay rope, variantly to be alternately arranged in rope to stock, add the contact surface of steel wire, mechanical property also than non-spinning wire rope and Lang lay rope good, by to Mechanics Performance Testing of the present invention and adhesion test, select same materials, its performance change is as follows:

2, the present invention can substitute original left-hand lay wire rope and right-hand lay wire rope half and half completely, the situation that combination collocation uses.

As shown in Figure 1, the rope of non-spinning wire rope to the sth. made by twisting of stock to contrary, twist with the fingers to point sinistral coiling and a dextrad spiral.If rightlay rope is namely for be twisted into stock by steel wire rope by sinistral coiling, then make rope by stock to dextrad spiral turn.

As shown in Figure 2, the rope of Lang lay rope to the sth. made by twisting of stock to identical, it is twisted with the fingers to being also divided into left and right sth. made by twisting, is twisted stock as right-laid is silk along wiring, and stock is twisted rope again and is dextrad spiral twisting and forms.

As shown in Figure 3, a kind of anti-rotation alternatelaywirerope, comprise right-laid 1 and left-hand lay 2, described steel wire rope is made up of 3 bursts of right-laid 1 and 3 bursts of left-hand lays 2, and described right-laid 1 is alternately arranged with left-hand lay 2, i.e. the levels stock of any right-laid 1 is left-hand lay 2, the levels stock of any left-hand lay 2 is right-laid 1, the sth. made by twisting of each adjacent layer stock, on the contrary, makes the twist stress of stock mutually balance, reaches good anti-rotation effect.

1. an anti-rotation alternatelaywirerope, comprise right-laid (1) and left-hand lay (2), it is characterized in that: described steel wire rope is made up of the right-laid (1) of equal number and left-hand lay (2), described right-laid (1) and left-hand lay (2) are alternately arranged, namely the levels stock of any right-laid (1) is left-hand lay (2), and the levels stock of any left-hand lay (2) is right-laid (1).

8613371530291

8613371530291