non rotating wire rope specifications brands

This wire rope construction is available in both galvanised and ungalvanised finish with either ordinary or langs lay. The construction family includes 17X7, 18X7 and 19X7. For further flexibility and other performance characteristics we also supply 32X7, 35X7 and 37X7.

Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications as well as being available with plastic impregnated.

Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications as well as being available with plastic impregnated or in compacted constructions.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

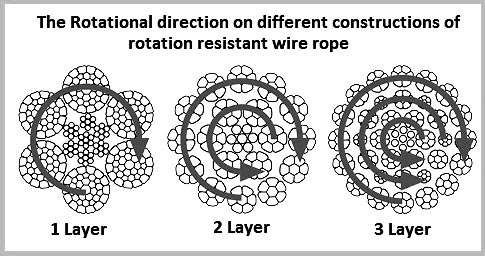

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

Manufacturer of standard and custom wire ropes made from phosphorous bronze, Monel®, Inconel® and stainless steel materials. Available in various cable dia. with color and coating options. Features include bright wire, galvanized, rotation and corrosion resistance. Suitable for straight line, medical devices, winches, exercise equipment, aircraft control, rigging and railing applications. Secondary services such as design, CNC machining, electric cutting, extrusion, hydroforming, swaging, coating, tensile testing and zinc die casting are also provided. Serves the aircraft, agricultural, automotive, construction, entertainment, lighting, marine, material handling, medical, military and security industries. Most items available in stock.

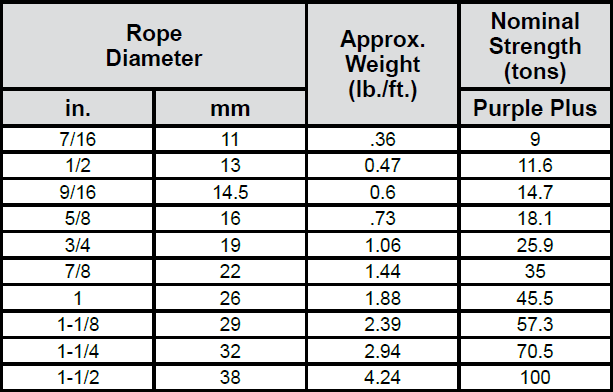

For industries that use wire rope, it’s frustrating and potentially dangerous if the rope spins or rotates. Unless using non-rotating steel wire rope, it can take longer than necessary to complete a job. At Murphy Industrial Products, Inc., we have a perfect solution. Our line of non-spin wire rope is reliable, safe, and cost-effective.

We manufacture our non-rotating wire rope in compliance with the Federal Specification RR-W-410E. That means our 35x7 wire rope meets or even exceeds industry standards. In addition, the non-spin wire rope we manufacture meets the performance requirements of both API-9A and A.S.T.M. A1023/1023M Wire Rope. So, it is rated as a top-of-the-line rope for general purposes.

One advantage of buying non-rotating steel wire rope manufactured by Murphy Industrial Products is that we keep a broad range of products in stock. If you need to have a product delivered quickly, we can accommodate. In fact, if you place an order for non-spin wire rope before 3:30 p.m. C.S.T., Monday through Friday, we can ship it out to you that same day at no extra charge.

The non-rotating wire ropes we produce are of the highest quality possible. They are ideal for building cranes, mobile cranes, offshore cranes, and main hoists. Our non-spin wire ropes can handle a range of minimum breaking loads, from 5.1 tons to 138 tons.

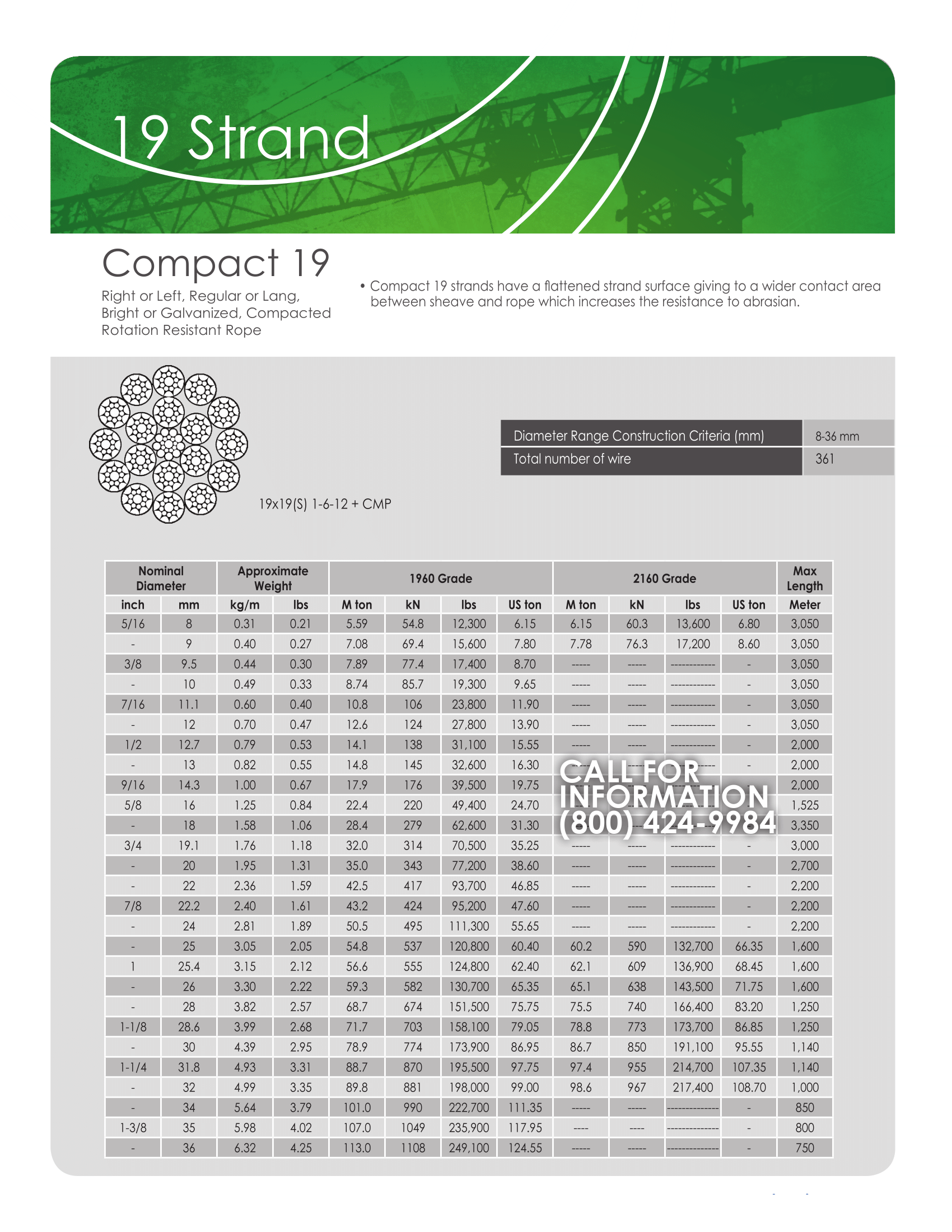

Main and auxiliary hoist line for mobile and for all types of construction tower cranes which require a high strength rotation resistant rope construction.

The large number of outer strands distribute the pressures introduced by sheaves and drum more evenly onto the core minimizing the danger of unexpected rope failures because of undetected core deterioration.

Aside from this safety issue PYTHON® COMPAC 35 satisfies the high-strength requirements of late model tower and mobile cranes which can NOT be met with neither 19 x 7 nor 19 x 19 style ropes.

Some sizes of Python® Compac 35 are available in right AND left hand lay to comply with OEM specifications (LinkBelt, Grove, Favelle Favco, Terex, Krupp, Demag, Liebherr, etc.).

19x7 Rotation- Resistant Wire Rope is a special class of wire rope designed to resist the tendency to spin or rotate under load. This is achieved by laying 6 strands around the core in one direction, then laying 12 strands around the first in another direction. It is often used for hoisting unguided loads with a single part rope. Commonly used as a crane wire rope and hoist cable.

Frequent and regular inspection for broken wires is critical when using this rope. Due to its design, the 19 x 7 construction has relatively low reserve strength and this can result in short service life.

Inspect regularly for visible damage, distortion, elongation, corrosion, cracks, nicks or abrasion, which may cause failure or reduce the strength of the Wire Rope.

Rotation resistant wire rope is a special category (class) of wire rope designed to resist the tendency to spin or rotate under load. In general these ropes are used as single part lines, or in situations where operating conditions require a rope that will resist cabling in a multipart system. The essential nature of rotation resistant rope designs impose certain limitations on their application and necessitate special handling requirements not encountered with other rope constructions.

2) Multilayer strand (Multistrand)-consisting of two or more strand layers closed in opposing directions. Torsional forces generated by each layer of the rope counteract one another to minimize rotation.

The multistrand classification includes ropes with between eight and twenty outer strands. Table 1 of this manual describes some of the more commonly available rotation resistant multistrand rope classification. In addition to these, a wide variety of special multistrand ropes is available. See (Figure 9). It would be impractical to cover the specific features of each in this manual.

In multistrand rotation resistant ropes the crossover points between strand layers are points of high stress concentration. Relative motion of the strands at these points results in accelerated deterioration of the internal components of the rope. Because of this design characteristic of the multistrand construction, care must be taken to avoid high loads with small diameter sheaves. Design factors less than five are not recommended.

Non-rotating wire ropes are made so that the outer rotational force of the wire rope naturally balances the rotational force of the inner strands. Standard rope wire has a tendency to create torque and is thus prone to rotation.

In the past, wrought iron chains, which had a history of mechanical failure, gave rise to wire rope. Defects in solid steel bars or chain links can result in catastrophic failure, whereas flaws in the wires that make up a steel cable are less important because the other wires can readily carry the strain. Although friction between the various wires and strands wears the rope over time, it also aids in temporary repair of minor flaws.

This pertains to the scenario in which a load is applied to a rope. In order to create a composite rope known as wire rope, numerous strands of metal wire are twisted into a helix in a pattern called lay rope. A larger diameter wire rope is made up of several strands of this lay rope arranged in a style called cable laid.

The global non rotating wire rope marketaccounted for $XX Billion in 2021 and is anticipated to reach $XX Billion by 2030, registering a CAGR of XX% from 2022 to 2030.

In terms of value, Regular Type of Lay is the fastest-growing Type of Lay for Steel Wires.Lang lay ropes spool poorly in a drum and are less naturally rotation-resistant and resistant to crushing forces than regular lay ropes.

They are employed in a variety of fields, including mining, oil and gas, construction, fishing, and marine. To address the unique wire rope needs of the new cranes, South Korean speciality high carbon steel wire products producer “Kiswire” is growing its operations in India. They not only serve as OEM suppliers to numerous global crane manufacturers, like Tadano and Kobelco, but they also actively pursue the Indian Replacement Market.

For customers who require peak rope performance levels in mission critical applications, Casar manufactures and supplies highly-engineered ropes that exceed industry standards while providing record-setting service life.

Our proprietary and innovative German-engineered rope designs deliver the highest levels of performance and safety, superior breaking strength values, the highest bending fatigue resistance, superior crushing resistance, and the best rotational resistance characteristics for high lifts.We have decades of global experience and on-site engineering support in the crane, OEM and underground mining sectors.

CASAR has an extensive range of products available and we can customize to your application.Our wire rope specialists will assist customers in design, selection, installation and operation to improve rope performance and maximize service life.

AFGHANISTANAland IslandsALBANIAALGERIAAMERICAN SAMOAANDORRAANGOLAANGUILLAANTARCTICAANTIGUA AND BARBUDAARGENTINAARMENIAARUBAAUSTRALIAAUSTRIAAZERBAIJANBAHAMASBAHRAINBANGLADESHBARBADOSBELARUSBELGIUMBELIZEBENINBERMUDABHUTANBOLIVIABOSNIA AND HERZEGOWINABOTSWANABOUVET ISLANDBRAZILBRITISH INDIAN OCEAN TER.BRUNEI DARUSSALAMBULGARIABURKINA FASOBURUNDICAMBODIACAMEROONCANADACAPE VERDECAYMAN ISLANDSCENTRAL AFRICAN REPUBLICCHADCHILECHINACHRISTMAS ISLANDCOCOS (KEELING) ISLANDSCOLOMBIACOMOROSCONGOCOOK ISLANDSCOSTA RICACOTE D"IVOIRECROATIACUBACYPRUSCZECH REPUBLICDEMO. PEOPLE"S REP. KOREADemocratic Republic of CongoDENMARKDJIBOUTIDOMINICADOMINICAN REPUBLICECUADOREGYPTEL SALVADOREQUATORIAL GUINEAERITREAESTONIAETHIOPIAFAEROE ISLANDSFALKLAND ISLANDSFED. STATES MICRONESIAFIJIFINLANDFRANCEFRENCH GUIANAFRENCH POLYNESIAFRENCH SOUTHERN TER.GABONGAMBIAGEORGIAGERMANYGHANAGIBRALTARGREECEGREENLANDGRENADAGUADELOUPEGUAMGUATEMALAGuernseyGUINEAGUINEA-BISSAUGUYANAHAITIHEARD AND MC DONALD ISL.HONDURASHONG KONGHUNGARYICELANDINDIAINDONESIAIRANIRAQIRELANDIsle of ManISRAELITALYJAMAICAJAPANJerseyJORDANKAZAKHSTANKENYAKIRIBATIKUWAITKYRGYZSTANLAOSLATVIALEBANONLESOTHOLIBERIALIBYAN ARAB JAMAHIRIYALIECHTENSTEINLITHUANIALUXEMBOURGMACAOMACEDONIAMADAGASCARMALAWIMALAYSIAMALDIVESMALIMALTAMARSHALL ISLANDSMARTINIQUEMAURITANIAMAURITIUSMAYOTTEMEXICOMONACOMONGOLIAMontenegroMONTSERRATMOROCCOMOZAMBIQUEMYANMARNAMIBIANAURUNEPALNETHERLANDSNETHERLANDS ANTILLESNEW CALEDONIANEW ZEALANDNICARAGUANIGERNIGERIANIUENORFOLK ISLANDNORTHERN MARIANA ISL.NORWAYNOT ON THE LISTOMANPAKISTANPALAUPalestinian TerritoryPANAMAPAPUA NEW GUINEAPARAGUAYPERUPHILIPPINESPITCAIRNPOLANDPORTUGALPUERTO RICOQATARREPUBLIC OF KOREAREPUBLIC OF MOLDOVAREUNIONROMANIARUSSIAN FEDERATIONRWANDASaint BarthelemySAINT KITTS AND NEVISSAINT LUCIASaint MartinSAINT VINCENT & GRNDNSSAMOASAN MARINOSAO TOME AND PRINCIPESAUDI ARABIASENEGALSerbiaSEYCHELLESSIERRA LEONESINGAPORESLOVAKIASLOVENIASO. GA & SO. SNDWCH ISL.SOLOMON ISLANDSSOMALIASOUTH AFRICASPAINSRI LANKAST. HELENAST. PIERRE AND MIQUELONSUDANSURINAMESVALBARD & JAN MAYEN ISL.SWAZILANDSWEDENSWITZERLANDSYRIAN ARAB REPUBLICTAIWANTAJIKISTANTHAILANDTimor-LesteTOGOTOKELAUTONGATRINIDAD AND TOBAGOTUNISIATURKEYTURKMENISTANTURKS & CAICOS ISLANDSTUVALUUGANDAUKRAINEUNITED ARAB EMIRATESUNITED KINGDOMUNITED REP. OF TANZANIAUnited States Minor Outlying IslandsUNITED STATES OF AMERICAURUGUAYUZBEKISTANVANUATUVATICAN CITYVENEZUELAVIETNAMVIRGIN ISLANDS (BRITISH)VIRGIN ISLANDS (U.S.A.)WALLIS & FUTUNA ISLANDSWESTERN SOMOAYEMENZAMBIAZIMBABWE

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

Fatigue Resistance. Improved fatigue properties are derived through the combination of the flexible 19 x 19 construction and die drawn strands. The drawn strand surfaces minimize the interstrand and interlayer nicking that take place in round rotation-resistant ropes.

Abrasion Resistance. Die drawn ropes provide improved abrasion resistance as compared with round wire ropes because of the greater wire and strand bearing surfaces contacting sheaves and drums.

Resistance to Drum Crushing. SFP 19 wire ropes are resistant to the effects of drum crushing due to the compacted strands and smoothness of the rope surface.

8613371530291

8613371530291