non rotating wire rope specifications price

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

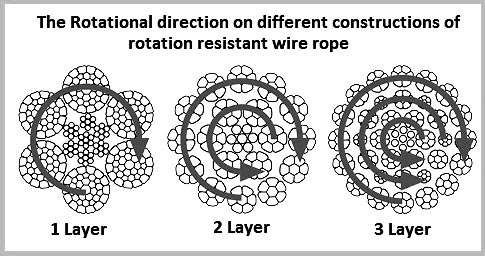

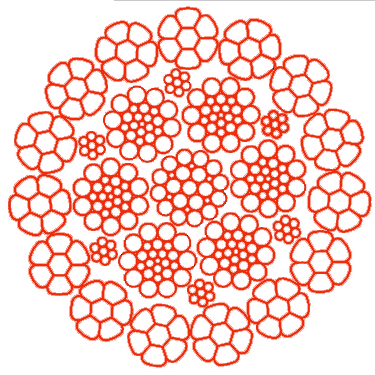

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

For industries that use wire rope, it’s frustrating and potentially dangerous if the rope spins or rotates. Unless using non-rotating steel wire rope, it can take longer than necessary to complete a job. At Murphy Industrial Products, Inc., we have a perfect solution. Our line of non-spin wire rope is reliable, safe, and cost-effective.

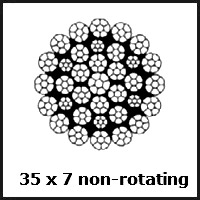

We manufacture our non-rotating wire rope in compliance with the Federal Specification RR-W-410E. That means our 35x7 wire rope meets or even exceeds industry standards. In addition, the non-spin wire rope we manufacture meets the performance requirements of both API-9A and A.S.T.M. A1023/1023M Wire Rope. So, it is rated as a top-of-the-line rope for general purposes.

One advantage of buying non-rotating steel wire rope manufactured by Murphy Industrial Products is that we keep a broad range of products in stock. If you need to have a product delivered quickly, we can accommodate. In fact, if you place an order for non-spin wire rope before 3:30 p.m. C.S.T., Monday through Friday, we can ship it out to you that same day at no extra charge.

The non-rotating wire ropes we produce are of the highest quality possible. They are ideal for building cranes, mobile cranes, offshore cranes, and main hoists. Our non-spin wire ropes can handle a range of minimum breaking loads, from 5.1 tons to 138 tons.

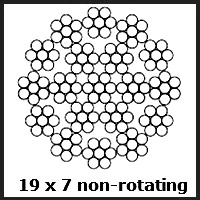

This wire rope construction is available in both galvanised and ungalvanised finish with either ordinary or langs lay. The construction family includes 17X7, 18X7 and 19X7. For further flexibility and other performance characteristics we also supply 32X7, 35X7 and 37X7.

Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications as well as being available with plastic impregnated.

19x7 Rotation- Resistant Wire Rope is a special class of wire rope designed to resist the tendency to spin or rotate under load. This is achieved by laying 6 strands around the core in one direction, then laying 12 strands around the first in another direction. It is often used for hoisting unguided loads with a single part rope. Commonly used as a crane wire rope and hoist cable.

Frequent and regular inspection for broken wires is critical when using this rope. Due to its design, the 19 x 7 construction has relatively low reserve strength and this can result in short service life.

Inspect regularly for visible damage, distortion, elongation, corrosion, cracks, nicks or abrasion, which may cause failure or reduce the strength of the Wire Rope.

Inspect regularly for visible damage, distortion, elongation, corrosion, cracks, nicks or abrasion, which may cause failure or reduce the strength of the Wire Rope.

Whether you are looking for waterproof salon capes, salon chemical capes, ordinary hair cutting capes, or even special salon gowns such as customised barber capes, you can likely find them on Alibaba.com! Look out for amazing deals for these haircut hair catches and barber gowns and sell them to the many salons in the market! The beauty industry is constantly growing, and even in the worst of economic times, simple beauty tools, cosmetics, and treatments have continued to retain their market size and even growth. The lucrative market draws many barber and hairdresser salons to open at any one time, and you can in turn cater to this market with wholesale equipment and simple wares such as non rotating wire rope!

If you want to gain a competitive edge, you can even sell cute salon capes or cool barber capes with different colours or logo and design customisations. Some wholesalers that are also OEM manufacturers will allow you to do simple printing and customisations. This is especially if you order in large bulk quantities. You can also cater to the upmarket salons with high end salon capes that may be more sleek, made of more durable or slightly better materials. Look out for these non rotating wire rope wholesale or discuss with suppliers when making your purchases to check!

We provide Best of Best quality Wire rope as per customer requirement and price wise starting with USHA MARTIN, BWR,BEDMUTHA,OREINT,VIKRANT,NAVIN as per client requirement all with Test certificate

Multi Layer non rotating wire rope is also called resistance rotary wire rope. Multi storey non rotating wire rope specifications: 35W*7,18*7,19*7,18*19S. Among them, 18*7,19*7 is also called micro rotary wire rope and half rotary wire rope. Non rotating wire rope is mainly used for wharf crane, electric hoist crane, automobile crane, tower crane. The structure wire rope specifications: 18*7-3mm-60mm, 35W*7-12mm-60mm

The steel wire rope of the rotary excavator must first withstand the extrusion resistance, so the wire rope and rope must be rolled. Secondly, it must have good wear resistance, so the special steel wire rope steel wire for the rotary excavator is required as a flat steel wire, so the contact surface of the wire rope and the wheel groove is larger, third, the wire rope has to be revolving, so the special steel of the rotary excavator is made. The wire rope 35W*K7 and 35T*7 are born in this case; the Sany, the South car, the Xugong, the north and so on are used for the use of this type of wire rope, the Chengdu rotary excavator wire rope, the Chongqing rotary excavator wire rope, the Bijie rotary excavator wire rope, the Zhengzhou rotary excavator wire rope, the Guiyang Roger wire ropes, Hangzhou rotary excavator wire rope . The wire ropes of the rotary excavator are all clear 35W*K7

Excellent rotation resistant properties make this rope the preferred choice for all single- and multiple line overhead crane applications which require a stable yet truly non-rotating type.

This rope is constructed from 16 outer compacted- over 12 inner compacted strands. The compacted Lang Lay strands reduce interlocking while spooling onto multiple layer drums as well as inter strand- and inter layer nicking. Improved wear resistance because of increased wire surface contacting the sheave.

This rope is suited to be used on tower cranes as well as on all overhead- and mobile crane models which require non-rotating rope properties. The large number of outer strands distribute the pressures introduced by sheaves and drum more evenly onto the core minimizing the danger of unexpected rope failures because of undetected core deterioration.

We "Pentest" from 1995are one of the leadingManufacturer, WholesalersandTrader ofUsha Martin Elevator Ropes, Wire Rope Slings and much more. Making use of quality tested material, our presented array of products are designed with high excellence. Extensively valued for their long service life, high strength and perfect finish, our provided products are highly commended.

SSTE offers high quality wire ropes for a wide range of applications. The company effectively combines variety of experience and tradition with an up to the minute range of products, and a customer service package ideal for the modern market place.

19X7 is a non-flexible wire rope. It is used for a wide range of applications, example of applications for non-rotating wire ropes include the following

.jpg)

Non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force in the event of a load applied.

Rather than all wires and strands being laid in the same direction, a rotation resistant wire rope consists of inner strands being laid in the opposite direction to the outer layers, for example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. This construction means that torsional forces on the inner and outer wires / strands will counteract each other and so minimise the risk of unraveling.

Using an ordinary lifting wire rope for a job or equipment which demand a non-rotating wire rope si very dangerous and it presents the following risks:

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

Application: For general purpose overhead lifting, suspension, skidding, and drag lines. Used as boom hoist ropes for cranes. Ideal for rigging, mining, construction, logging, oilfield, machine moving, and aerospace

Description: Manufactured by Wire Rope Industries, the Dy-Pac strand compaction process of this Surelift line improves the rotation resistance. Tested and designed for superior quality and value. This resilient multi-strand construction crane cable provides strength and performance while improving rope fatigue life. The smooth outside strand profile creates and improves rope wear resistance, reduces sheave and drum wear, and allows the rope to run efficiently on high speed hoisting lines.

Application: For general purpose overhead lifting, suspension, skidding, and drag lines. Used as boom hoist ropes for cranes. Ideal for rigging, mining, construction, logging, oilfield, machine moving, and aerospace

Description: Manufactured by Wire Rope Industries, the Dy-Pac strand compaction process of this Surelift line improves the rotation resistance. Tested and designed for superior quality and value. This resilient multi-strand construction crane cable provides strength and performance while improving rope fatigue life. The smooth outside strand profile creates and improves rope wear resistance, reduces sheave and drum wear, and allows the rope to run efficiently on high speed hoisting lines.

The non-rotating steel wire rope is also called multi-strand wire rope. Gaosheng Company specially produces and sales many a wire rope. We have 35W*7 series, 18*7 series, 19*7 series, 18*19S series, and 24W*7 series.

All those series, twisted in the same or different direction, have been galvanizing and polishing treated. If you need the wire rope of higher breaking strength or better abrasion resistance, the product can be processed with different surface treatments, for instance, lubrication, plastic dipping, etc.

This non-rotating steel wire rope is suited for kinds of hoisting and dragging equipment. It can be applied in the condition of impact load, as well as in the heated or squeezed condition. The steel cored wire rope of different diameter is suitable for different cranes. A wire rope with the diameter of 12mm-28mm is suitable for truck crane, portal crane, electric hoist crane, etc.

8613371530291

8613371530291