nylon coated steel wire rope manufacturer

ISO 9001:2000 certified manufacturer & distributor of standard & custom rigging equipment & supplies including coated wire rope. Types include vinyl coated stainless steel wire ropes, vinyl coated galvanized steel wire ropes, nylon coated galvanized steel wire ropes & nylon coated galvanized steel Military Spec. wire ropes. Wire ropes are available in strand configurations including 1 x 19, 7 x 7 & 7 x 19 in different dia. & working load limits. Nylon coated galvanized steel Military Spec. wire ropes are available in 7 x 19 strand configurations in wire dia. ranging from 1/16 in. to 3/16 in. with working load limits ranging from 96 lbs. to 840 lbs. Wire ropes are available in spool lengths ranging from 500 ft. to 5,000 ft.

Manufacturer of nylon coated cables including military specification and commercial cables. Military specification cables such as instrumentation control, single or multi conductor, insulated, shielded and jacketed, stranded, braided, special purpose, low-tension, miniature flexible and RG/U cables are available. Types of commercial cables include alarm and security, audio, data, fire alarm, multi-pair, coaxial, air plenum, traffic signal and appliance lead cables. Available in different materials and sizes. Capabilities include designing, prototyping, cutting, striping and tapping. Cables are RoHS compliant, UL listed and meet different military specifications. JIT delivery available.

FEP cable, which is commonly known as Teflon® coated cable, is best-known for its frictionless and chemical inertness, meaning that this extrusion material requires less force to achieve movement and can withstand a variety of chemical environments. While other coated cables may offer minor levels of chemical resistance, Teflon® coated cable offers chemical compatibility, including hydrochloric and hydrofluoric acid, along many extremely corrosive chemicals.

Medical devices using mechanical cable commonly use FEP coated cable. The benefits to Teflon® in these complex endoscopic and surgical instruments are the low coefficient of friction and chemical compatibilities required in such devices.

Polyurethane cable is ideal in mechanical cable applications where resistance to a wide host of particulates and invasive material are present. Polyurethane, or PU coated cabled, is highly resistant to oils, water, exposure to the harsh conditions created by the ozone, artificial or natural and is largely unaffected by the presence of radiation.

Lastly, but critically, polyethylene coated cable is eco-friendly. Unless discarded improperly, as compare with many other extruded materials, polyethylene has no verifiable environmental or health concerns, nor negative impacts on ecosystems.

SwageRight™ creates quality nylon-coated galvanized stainless steel wire rope in a 7x19 diameter that is best suited for rigging, lifting, towing, and heavy construction applications. Galvanization is ideal for heavy-duty applications and offers greater protection against deformation and wear. 7x19 nylon-coated aircraft cable provides additional abrasion resistance as well as added protection in extreme conditions. Available with a clear or black coat.

We can coat both galvanised or stainless steel wire ropes with a PVC, Nylon or Polypropylene coating to best suit your needs, the coatings are available in a wide range of colours to best suit your application.

Though not often used in the heavy lifting and hoisting operations for which wire ropes are most commonly known, plastic coated cables are optimal for consumer goods and applications in which increased abrasion and corrosion resistance and cost-effectiveness are desired.

Though the work is often less strenuous the goal of easier lifting and hoisting is still applicable to plastic coated cables which also afford increased durability. Fitness industries use plastic coated cable in most weight machines; theater industries use black powder coated cables for stage rigging; outdoor playground equipment often use plastic coated cables, and many types of electronic equipment, communications devices, and medical devices use miniature wire rope and wire rope fittings.

Plastic jackets are also used when complete adherence to the wire or cable is not necessary. Casings made of non-plastics may be coated in plastics for added water resistance, visual appeal, etc.

In all applications, the construction of both the wire cable and the coating itself should be carefully considered to avoid mechanical failure or ill-performance.

There are three basic components: metal wire filaments, strands, and cores. Filaments, cold drawn metal rods of relatively small diameter, are twisted or braided to form strands. These strands may consist of two or several dozen filaments and are wrapped in a helical pattern around a core which may be metal, fiber, or polymer based.

In addition to identifications based on all materials used, plastic coated stranded wires are identified by both the number of strands per cable and the number of filaments per strand respectively. Further considerations include overall diameter, difficulty of flattening, temperature resistance, average lifespan, and material construction.

The wires themselves are often fabricated from steel, stainless steel or galvanized steel, and then coated in either nylon or vinyl (PVC), although polyethylene coatings are applied for electrical insulation and polypropylene coating is used when chemical resistance is required.

Vinyl coating is the most common since it is by far the most cost-effective; although vinyl coated cables do not have optimal abrasion and fatigue resistance, they have better flexibility and UV light resistance than nylon coated cables.

Material choice is largely determined by the intended use for a cable. The rope can be coated at any stage of construction, whether individually coated filaments or an assembled cable.

We’re experts at plastic coating extrusions for wire rope and aircraft cable with decades of experience and our in-house coating process consisting of a jacketing application via pressurized extrusion. We supply nylon as well as polyvinyl chloride, also known as PVC or vinyl, coated wire rope and aircraft cable on reels, in pre-cut lengths, or fabricated into assemblies.

Please let us know if you require RoHS or REACH compliant coated wire rope. Upon special request, we can also supply coatings such as HDPE, Hytrel, and FEP.

Nylon coatings deliver improved endurance in high friction applications with its higher temperature rating and hardness protecting the inner-cable from fraying. Typical nylon applications include:

There are two nylon product families that we coat: nylon-6 and nylon-11. Nylon-6 is standard grade and the more economical nylon option which is typically recommended for residential applications of fitness cables. Nylon-11 is the highest quality option which is slightly more flexible and recommended for maximizing life cycles in the most demanding applications such as push-pull control applications. Nylon coatings are available in a wide range of colors with quotes for custom colors available if our standard colors do not match your preferred color scheme.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Stainless Round Bar , Brushed Stainless Steel Flat Bar , Stainless Steel Capillary Tube , We think this sets us apart from the competition and makes prospects choose and trust us. We all wish to build win-win deals with our customers, so give us a call today and make a new friend!

Includes standard products such as wire ropes composed of strand (s) of 0.03mm wires as well as special wire ropes composed of strand (s) of 0.013mm ultra-fine wires.

Saky Steel Co.,Ltd is located in Jiangsu Province. The company was founded in 1995. Now the company covers totally 220,000 square meters . The company has a total employee of 150 out of whom 120 are professionals .The company has been continually expanding itself ever since it‘s founded .Now the company is a ISO9001:2000 certified company and has been continually awarded by the local government .

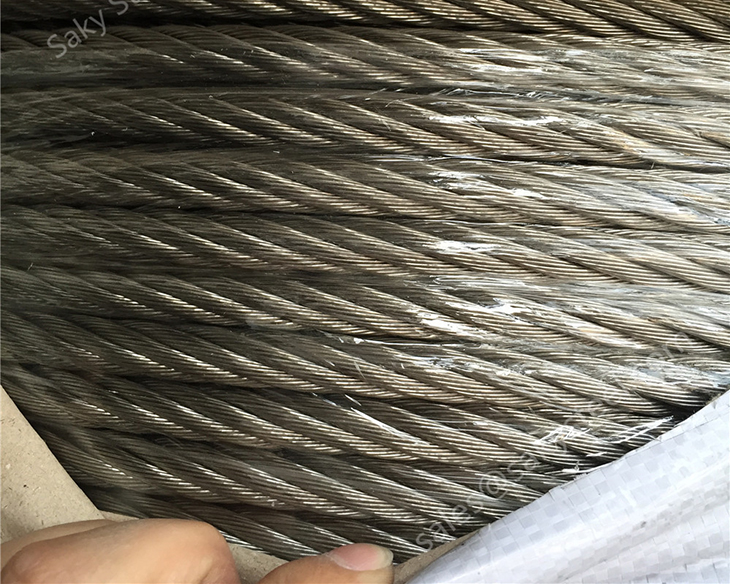

Sakysteel is specicalizing in manufacturing of Stainless steel Wire,Wire Rope, Welding,Flat Wire,Profile Wire.It is capable of supplying various types of stainless steel products in different grades,hardness and surface.our factory supply raw material from TISCO,LISCO,BAOSTEEL,JISCO,ZPSS,SAKYSTEEL,etc.

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for OEM Factory for Nylon Coated Stainless Steel Wire - 304 316 316L stainless steel wire rope 6×19 7×19 1×19 – Saky Steel, The product will supply to all over the world, such as: Guatemala, Morocco, Oman, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers" faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do professional products.

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys and the stainless steel wire rope withstands outdoor and washdown applications.

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the nylon coated wire rope you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal nylon coated wire rope for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, nylon coated wire rope will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

At our well-equipped production unit, this rope is coated using polyvinyl chloride and avant-garde techniques with the help of our adept professionals.

Pvc or nylon coated steel wire rope are extensively used for easy smooth working of movement of wire rope. coating gives long life and frictionless movement of steel rope,.

8613371530291

8613371530291