osha wire rope guardrail pricelist

This is in response to the questions posed in the letter from Jay Withrow regarding safety railing(s) required by OSHA Standard 29 CFR 1926.750(b)(1)(iii). The standard reads as follows:

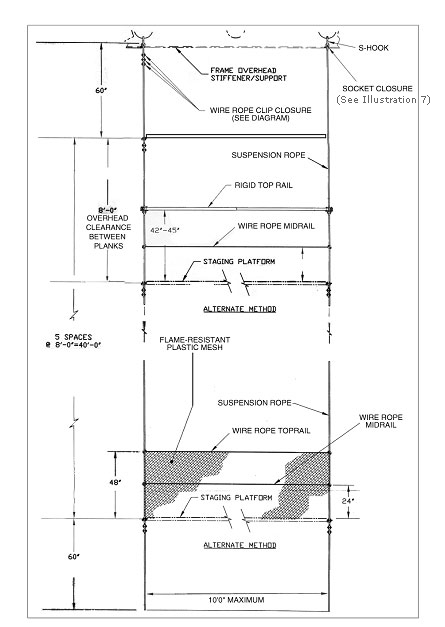

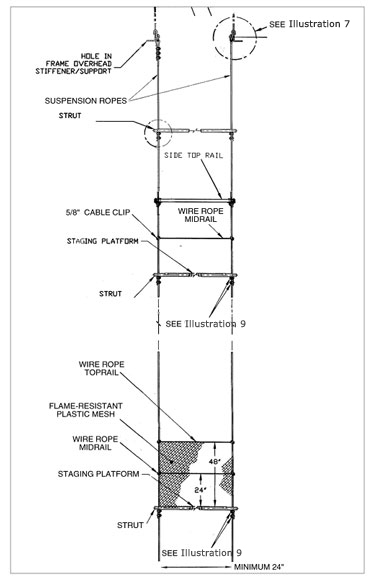

"Floor periphery - safety railing. A safety railing of ½-inch wire rope or equal shall be installed, approximately 42 inches high, around the periphery of all temporary - planked or temporary metal-decked floors of tier buildings and other multifloored structures during structural steel assembly." (emphasis added).

Question 1: Is orange plastic-coated 3/16-inch aircraft wire "equal" to ½-inch wire rope? (Note: This product is seeing extensive use in Northern Virginia).

Answer: The response is a qualified yes. The key to whether the 3/16 aircraft wire is equal to ½-inch wire rope is whether a the 3/16 aircraft wire is equal in strength to ½-inch wire rope.

The standard does not set forth any specifications for the design and construction of the ½-inch wire rope. Thus any wire rope ½-inch in diameter of any design or construction could be used to comply with this standard.

There is at least one 3/16-inch aircraft cable (Galvanized and tinned aircraft cord and strand Construction 1x19 - Nominal Breaking Strength 4700 pounds) that has a greater nominal breaking strength than does at least one type of ½-inch wire rope (Iron Galvanized Running Rope - Construction 6x12 - Nominal Breaking Strength 4560 pounds). Therefore, the previously referenced aircraft cable would have to be considered equal to ½-inch wire rope.

Question 3: Although it is not stated anywhere, must the wire rope used to comply with 1926.750(b)(1)(iii) (½-inch wire rope; or 3/16-inch aircraft wire if you find that to be equivalent) have a maximum permissible deflection of 3-inches in one direction when a load of 200 pounds is applied in any direction at any point?

Answer: The response to this question is a qualified yes. OSHA Standard 29 CFR 1926.750(b)(1)(iii) does not address the issue of deflection. The standard, as written, could be enforced so that no deflection is permitted. However that would be contrary to guidance relating to wire rope used for guardrails contained in directives (STD 3-10.3), memoranda and proposed standards (Fall Protection In Construction.)

Therefore in Region III, for the purpose of complying with OSHA Standard 29 CFR 1926.750(b)(1)(iii), a safety railing that meets the following criteria would be considered to be equal to a ½-inch wire rope:

[Correction 6/20/2005. See OSHA Directive CPL 02-01-034 "Inspection policy and procedures for OSHA"s steel erection standards for construction" published on 3/22/2002 for the current policy on OSHA"s steel erection standards (1926 Subpart R) for construction.]

This responds to your June 1, 1999, letter to the Occupational Safety and Health Administration (OSHA), requesting information on wire rope and Crosby clips used around the perimeter of buildings as a guardrail. You also requested clarification on when employees must tie-off when a guardrail system is removed to facilitate hoisting operations. We apologize for the long delay in providing this response.

Question 1: How many Crosby clips are required to be used when setting up a wire rope guardrail? Is it permissible to splice two wire ropes by overlapping or must the connections be turned back into eyelets and properly secured?

Answer: For construction work covered by 29 CFR 1926 Subpart M, §1926.502(b) sets forth the criteria that must be met when using wire rope as a guardrail. The standard requires guardrails to meet several specific criteria. For example, 1926.502(b)(3) states that the guardrail shall be capable of withstanding, without failure, a force of at least 200 pounds applied within 2 inches of the top edge, in any outward or downward direction, at any point along the top edge. Section 1926.502(b)(4) states that when the 200 pound test load noted in §1926.502(b)(3) is applied in a downward direction, the top edge of the guardrail shall not deflect to a height less than 39 inches above the walking/working level. Section 1926.502(b)(9) states that the top rail and mid-rails shall be at least ¼-inch nominal diameter or thickness to prevent cuts and lacerations. These and other criteria must be met when using wire rope as a guardrail around the perimeter of a building.

The OSHA standard does not specify a minimum number of clips when using wire rope as a guardrail. However, as a practical matter, it is unlikely you could meet the specific requirements under §1926.502(b) unless you follow the manufacturer"s recommendations for the number of clips to be used on wire ropes of different diameters (for example, the Crosby Group Inc. general catalog, 2000 edition has tables showing their recommendations for their clips). Also, note that OSHA"s standard for rigging equipment used for material handling, 29 CFR §1926.251, has a table for the number of clips required for wire rope ½-inch and greater. Although that standard does not apply to wire rope used for guardrails, when you design a rope system to meet the §1926.502 requirements, following those tables will normally ensure that you have enough clips.

Question 2: What are the requirements for tying-off employees when a guardrail system is removed to facilitate hoisting operations? 29 CFR §1926.501(b)(3) states that, when guardrails are removed to facilitate hoisting operations, employees who have to lean out over the edge must be tied off. What about other employees, who do not have to lean out—do they have to be tied-off also?

Answer: Section 1926.501(b)(3) states that each employee in a hoist area shall be protected from falls of 6 feet or more by guardrail systems or personal fall arrest systems. It also states that, "If guardrail systems ... are removed to facilitate the hoisting operation (e.g., during landing of materials), and an employee must lean through the access opening or out over the edge of the access opening (to receive or guide equipment and materials, for example), that employee shall be protected from fall hazards by a personal fall arrest system." (59 FR 40710).

You ask if this means that the only employees who must use fall protection when the guardrails are removed are those who must lean out. The answer is no; the first sentence of §1926.501(d)(3) requires that all employees in the hoist area be protected by either a guardrail or personal fall arrest system. So, when all or part of a guardrail has been removed, all employees must be protected by a personal fall arrest system.

If you need additional information, please contact us by fax at: U.S. Department of Labor, OSHA, Directorate of Construction, Office of Construction Standards and Guidance, fax # 202-693-1689. You can also contact us by mail at the above office, Room N3468, 200 Constitution Avenue, N.W., Washington, D.C. 20210, although there will be a delay in our receiving correspondence by mail.

Top edge height of top rails, or equivalent guardrail system members, shall be 42 inches (1.1 m) plus or minus 3 inches (8 cm) above the walking/working level. When conditions warrant, the height of the top edge may exceed the 45-inch height, provided the guardrail system meets all other criteria of this paragraph.

Midrails, screens, mesh, intermediate vertical members, or equivalent intermediate structural members shall be installed between the top edge of the guardrail system and the walking/working surface when there is no wall or parapet wall at least 21 inches (53 cm) high.

Other structural members (such as additional midrails and architectural panels) shall be installed such that there are no openings in the guardrail system that are more than 19 inches (.5 m) wide.

Guardrail systems shall be capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied within 2 inches (5.1 cm) of the top edge, in any outward or downward direction, at any point along the top edge.

When the 200 pound (890 N) test load specified in paragraph (b)(3) of this section is applied in a downward direction, the top edge of the guardrail shall not deflect to a height less than 39 inches (1.0 m) above the walking/working level. Guardrail system components selected and constructed in accordance with the Appendix B to subpart M of this part will be deemed to meet this requirement.

Top rails and midrails shall be at least one-quarter inch (0.6 cm) nominal diameter or thickness to prevent cuts and lacerations. If wire rope is used for top rails, it shall be flagged at not more than 6-foot intervals with high-visibility material.

When guardrail systems are used at hoisting areas, a chain, gate or removable guardrail section shall be placed across the access opening between guardrail sections when hoisting operations are not taking place.

When guardrail systems are used around holes used for the passage of materials, the hole shall have not more than two sides provided with removable guardrail sections to allow the passage of materials. When the hole is not in use, it shall be closed over with a cover, or a guardrail system shall be provided along all unprotected sides or edges.

When guardrail systems are used around holes which are used as points of access (such as ladderways), they shall be provided with a gate, or be so offset that a person cannot walk directly into the hole.

Manila, plastic or synthetic rope being used for top rails or midrails shall be inspected as frequently as necessary to ensure that it continues to meet the strength requirements of paragraph (b)(3) of this section.

The maximum size of each safety net mesh opening shall not exceed 36 square inches (230 cm) nor be longer than 6 inches (15 cm) on any side, and the opening, measured center-to-center of mesh ropes or webbing, shall not be longer than 6 inches (15 cm). All mesh crossings shall be secured to prevent enlargement of the mesh opening.

During the construction of elevator shafts, two employees may be attached to the same lifeline in the hoistway, provided both employees are working atop a false car that is equipped with guardrails; the strength of the lifeline is 10,000 pounds [5,000 pounds per employee attached] (44.4 kN); and all other criteria specified in this paragraph for lifelines have been met.

Note: If the personal fall arrest system meets the criteria and protocols contained in Appendix C to subpart M, and if the system is being used by an employee having a combined person and tool weight of less than 310 pounds (140 kg), the system will be considered to be in compliance with the provisions of paragraph (d)(16) of this section. If the system is used by an employee having a combined tool and body weight of 310 pounds (140 kg) or more, then the employer must appropriately modify the criteria and protocols of the Appendix to provide proper protection for such heavier weights, or the system will not be deemed to be in compliance with the requirements of paragraph (d)(16) of this section.

Personal fall arrest systems shall not be attached to guardrail systems, nor shall they be attached to hoists except as specified in other subparts of this Part.

When the path to a point of access is not in use, a rope, wire, chain, or other barricade, equivalent in strength and height to the warning line, shall be placed across the path at the point where the path intersects the warning line erected around the work area, or the path shall be offset such that a person cannot walk directly into the work area.

The rope, wire, or chain shall be rigged and supported in such a way that its lowest point (including sag) is no less than 34 inches (.9 m) from the walking/working surface and its highest point is no more than 39 inches (1.0 m) from the walking/working surface;

After being erected, with the rope, wire, or chain attached, stanchions shall be capable of resisting, without tipping over, a force of at least 16 pounds (71 N) applied horizontally against the stanchion, 30 inches (.8 m) above the walking/working surface, perpendicular to the warning line, and in the direction of the floor, roof, or platform edge;

The rope, wire, or chain shall have a minimum tensile strength of 500 pounds (2.22 kN), and after being attached to the stanchions, shall be capable of supporting, without breaking, the loads applied to the stanchions as prescribed in paragraph (f)(2)(iii) of this section; and

Mechanical equipment on roofs shall be used or stored only in areas where employees are protected by a warning line system, guardrail system, or personal fall arrest system.

On floors and roofs where guardrail systems are not in place prior to the beginning of overhand bricklaying operations, controlled access zones shall be enlarged, as necessary, to enclose all points of access, material handling areas, and storage areas.

On floors and roofs where guardrail systems are in place, but need to be removed to allow overhand bricklaying work or leading edge work to take place, only that portion of the guardrail necessary to accomplish that day"s work shall be removed.

Where tools, equipment, or materials are piled higher than the top edge of a toeboard, paneling or screening shall be erected from the walking/working surface or toeboard to the top of a guardrail system"s top rail or midrail, for a distance sufficient to protect employees below.

The fall protection plan shall document the reasons why the use of conventional fall protection systems (guardrail systems, personal fall arrest systems, or safety nets systems) are infeasible or why their use would create a greater hazard.

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Top edge height of top rails, or equivalent guardrail system members, shall be 42 inches (1.1 m) plus or minus 3 inches (8 cm) above the walking/working level. When conditions warrant, the height of the top edge may exceed the 45-inch height, provided the guardrail system meets all other criteria of this paragraph (§ 1926.502(b)).

Midrails, screens, mesh, intermediate vertical members, or equivalent intermediate structural members shall be installed between the top edge of the guardrail system and the walking/working surface when there is no wall or parapet wall at least 21 inches (53 cm) high.

Other structural members (such as additional midrails and architectural panels) shall be installed such that there are no openings in the guardrail system that are more than 19 inches (.5 m) wide.

Guardrail systems shall be capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied within 2 inches (5.1 cm) of the top edge, in any outward or downward direction, at any point along the top edge.

When the 200 pound (890 N) test load specified in paragraph (b)(3) of this section (§ 1926.502) is applied in a downward direction, the top edge of the guardrail shall not deflect to a height less than 39 inches (1.0 m) above the walking/working level. Guardrail system components selected and constructed in accordance with the appendix B to subpart M of this part will be deemed to meet this requirement.

Top rails and midrails shall be at least one-quarter inch (0.6 cm) nominal diameter or thickness to prevent cuts and lacerations. If wire rope is used for top rails, it shall be flagged at not more than 6-foot intervals with high-visibility material.

When guardrail systems are used at hoisting areas, a chain, gate or removable guardrail section shall be placed across the access opening between guardrail sections when hoisting operations are not taking place.

When guardrail systems are used around holes used for the passage of materials, the hole shall have not more than two sides provided with removable guardrail sections to allow the passage of materials. When the hole is not in use, it shall be closed over with a cover, or a guardrail system shall be provided along all unprotected sides or edges.

When guardrail systems are used around holes which are used as points of access (such as ladderways), they shall be provided with a gate, or be so offset that a person cannot walk directly into the hole.

Manila, plastic or synthetic rope being used for top rails or midrails shall be inspected as frequently as necessary to ensure that it continues to meet the strength requirements of paragraph (b)(3) of this section (§ 1926.502).

The maximum size of each safety net mesh opening shall not exceed 36 square inches (230 cm) nor be longer than 6 inches (15 cm) on any side, and the opening, measured center-to-center of mesh ropes or webbing, shall not be longer than 6 inches (15 cm). All mesh crossings shall be secured to prevent enlargement of the mesh opening.

During the construction of elevator shafts, two employees may be attached to the same lifeline in the hoistway, provided both employees are working atop a false car that is equipped with guardrails; the strength of the lifeline is 10,000 pounds [5,000 pounds per employee attached] (44.4 kN); and all other criteria specified in this paragraph for lifelines have been met.

Note: If the personal fall arrest system meets the criteria and protocols contained in Appendix C to subpart M, and if the system is being used by an employee having a combined person and tool weight of less than 310 pounds (140 kg), the system will be considered to be in compliance with the provisions of paragraph (d)(16) of this section [§ 1926.502]. If the system is used by an employee having a combined tool and body weight of 310 pounds (140 kg) or more, then the employer must appropriately modify the criteria and protocols of the Appendix to provide proper protection for such heavier weights, or the system will not be deemed to be in compliance with the requirements of paragraph (d)(16) of this section (§ 1926.502).

Personal fall arrest systems shall not be attached to guardrail systems, nor shall they be attached to hoists except as specified in other subparts of this Part.

This is in response to your letter of June 29, concerning the acceptability of wire rope and/or cable as a method of perimeter protection for a building under construction.

The use of wire ropes as top rails and intermediate rails of guardrail systems used for perimeter protection or for guardrails used on scaffolding meeting the equivalent requirements of 29 CFR 1926.500(d)(1) and 29 CFR 1926.451(a)(5) is acceptable provided it meets the following guidelines:

(3) The maximum deflection of the top rail when a load of 200 pounds is applied in any direction at any point on the top rail shall not exceed 3 inches in one direction which includes the free hanging sag in the wire rope.

OSHA’s steel erection standard 29 CFR Subpart R 1926.760, encompasses new construction, alteration or repair of “structures” when the erection of steel takes place. Specifically excluded from coverage are Tanks, Electrical Transmission Towers and Communication or Broadcast Towers.

We’ll start with ANSI, which establishes a set of “best practices.” These are voluntary standards. OSHA may adopt ANSI standards by amendment, as a whole or in part.

At minimum, your internal regs must meet OSHA requirements. They may reflect ANSI standards, even if not adopted by OSHA, or be your own. Once adopted, you must comply.

Look at criteria C and E above. Both reference a six-foot drop. Some time ago a GC sent this question to OSHA and received the accompanying interpretation:

Answer: §1926.502(d)(16) also requires that the maximum arresting force be limited to 900 pounds when the personal fall arrest system incorporates a body belt and 1800 pounds when the system incorporates a body harness. If the employer has documentation to demonstrate that these maximum arresting forces are not exceeded and that the personal fall arrest system will operate properly, OSHA will not issue a citation for violation of the free fall distance.

• 3/8″ galvanized cable has an M.B.L. (minimum break load) of approximately 14,000 lbs. So it’s good for two people right? Wrong. Example: In the mid-90s My Wire Rope Company sold a trailer manufacturer 100 ft. of 3/8” cable with a large turn buckle at one end. Unfortunately my order desk didn’t ask enough questions on what the application was. They strung it above the trailers and tightened it tight enough to play a song on it. They dropped a pulley on the cable and hooked a retractable to it; the employee could go along the top of the trailer stapling the roof. When the supervisor wasn’t looking, one of the employees decided to use it as a zip line and run off the back of the trailer to see how far he could go down the line. Another employee would pick him up with a boom truck when he stopped. The cable snapped on the first try, resulting in a few broken bones. Engineers use some of these factors when calculating deflection under load (Diagram 3)

• Load: Only a few retractables are on the market designed for foot level drops and even fewer designed for below the feet drops. The unit engineered into the system above has a mechanical shock absorber with a disk brake mechanism designed for free falls up to 78″ when tied to a rigid tie-off point, keeping the impact to the body under 900 lbs. Another benefit of the acceptable retractable: the line is under tension during the drop. The web or wire coils back into the unit and then the disk brake kicks in for a soft drop with less chance of lower level contact. Plus, when dropping on a catenary line (not a rigid tie-off point) there is shock absorber capability in the line itself. This lessens the impact to the line and increases the safety factor.

Not if the engineer’s design will allow it. According to the wire rope Technical Board D/d ratio on 3/8″ cable with a 3/8″ pin there is a 50% reduction. But since the eye is twice as strong as the body in a pull test, the cable always breaks at the weakest link behind the last D.F. clip. Note: Rule of thumb for added safety factor always go one size up on the shackle.

Hands-free, 5/8" diameter rope grab designed as a mobile-type, energy-absorbing grab with less sensitivity to rope variations. Systems feature flexible counterweight to enhance performance. Complete system includes rope grab (5000335), flexible counterweight (5901583), 3" shock-absorbing lanyard (1240007), 3" tie-off adapter (1003000), carrying bag and choice of 50" lifeline (1202794) or 100" lifeline (1202844). Meets or exceeds all applicable OSHA regulations and ANSI Z359.15 standard.

Industrial guardrails and forklift safety barriers provide protection for employees, machinery, and other equipment and pedestrians from falls or accidents. Guardrails are powder coat painted OSHA safety yellow and available in single and double-rails. Components bolt together and are easy to install, move, or add to in the future.

8613371530291

8613371530291