overhead crane wire rope inspection pricelist

As a Safety, Maintenance, or Operations Manager, overhead crane inspectionshould be top of mind for you to stay in compliance with inspection standards laid out by sanctioning bodies like OSHA, ASME/ANSI, and CMAA.

This can seem daunting—especially with all of the other work that you have on your plate—and it can be confusing to understand how often your overhead cranes need to be inspected, and how much that will add to your budget each year.

As a company that employs over 100 certified and experienced crane and hoist inspectors, one of the most frequently asked questions that we get from our customers (often, on a daily basis), is “how much will my crane inspection cost?”

The answer itself can be complex as there are many factors that can affect the cost of an overhead crane and hoist inspection. We’ll dive deeper into these factors below to help you better understand how much an overhead crane inspection will cost you.

The most important factor in determining the cost of an overhead crane inspection is the type of crane or cranes that need to be inspected. There are many different kinds of cranes, and each one has its own unique inspection criteria and requirements, and can take varying lengths of time to complete the inspection process.

As the duty cycle increases, the cost of the inspection will increase due to the components and the time required to complete a thorough inspection. Think about all of the moving parts required to operate an overhead double girder top running electrified crane. Now, compare that to a basic jib crane or mechanical workstation crane with no electronics, and a basic support structure.Number of cranes – The total number of cranes on-site will play a major factor in the cost of the crane inspection. The more cranes there are on site, the longer the inspector(s) will have to remain at your facility to complete the job.

Components – A double girder or single girder overhead crane is going to have significantly more parts than a basic jib or workstation crane. Things like electrification systems, braking systems, radio remote controls/pendants, variable speed controls, etc. have their own inspection requirements and are more complex pieces than what you would find on a jib or workstation crane.

Environment and accessibility of cranes – What type of environment is the crane in? Hazardous or chemical environments, and accessibility considerations like maneuvering lifts to access the crane equipment, have a direct relationship on the cost of the inspection.

A major factor in determining the cost of an overhead crane inspection is the frequency, or type of crane inspection, that is being performed. Knowing how often your overhead cranes need to be inspected is one of the first steps in determining the criteria for inspection and how often it will be performed. Developing an inspection program that will meet compliance requirements for OSHA, ASME, and CMAA standards will help to keep you compliant for overhead crane inspection—scheduling only one annual inspection will not.

Inspection frequency is based on crane service, environmental factors, and application factors according to OSHA 1910.179:“Inspection procedure for cranes in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals, in turn, are dependent upon the nature of the critical components of the crane and the degree of their exposure to wear, deterioration, or malfunction. The two general classifications are herein designated as ‘frequent’ and ‘periodic’ with respective intervals between inspections…”

The section highlighted in bold above is the most critical piece of this statement. Specifically, “the degree of their exposure to wear, deterioration, or malfunction.” The degree of exposure of the crane’s critical components is determined by the duty cycle of the crane, or crane service classification, as determined by CMAA:Class A (Standby or Infrequent Service) – This equipment, including installation and maintenance cranes, usually operates at slow speeds for precise handling with long idle periods between lifts. Maximum capacity lifts are sometimes required.

Class B (Light Service) – This class of equipment includes cranes in repair shops, light assembly operations, service buildings, light warehousing, etc. and service requirements are light and the speed is slow. Loads vary from no load to occasional full-rated loads with 2-5 lifts per hour, averaging 10 feet per lift.

Class C (Moderate Service) – In terms of numbers, most cranes are built to meet Class C service requirements, including cranes used in machine shops or paper mill machine rooms. These types of cranes will handle loads that average 50% of the rated capacity with 5-10 lifts per hour, averaging 15 feet per lift.

Class D (Heavy Service)– Typical examples of these types of crane include ones used in heavy machine shops, foundries, fabricating plants, steel warehouses, container yards, lumber mills, etc. These types of cranes constantly handle loads approaching 50% of the rated capacity. High speeds are desirable for this type of service with 10-20 lifts per hour, averaging 15 feet, with not 65% of the lifts at rated capacity.

Class E (Severe Service) – This equipment is a top riding bridge or gantry type multiple girder electric overhead crane. Applications include magnet, bucket, or magnet/bucket combination and are most commonly found at scrap yards, cement mills, lumber mills, fertilizer plants, container yards, etc. This service class requires a crane capable of handling loads approaching the rated capacity throughout its life with 20 or more lifts per hour at or near rated capacity.

Class F (Continuous Severe Service) – This equipment is a top riding bridge or gantry type multiple girder electric overhead crane. Applications include custom-designed specialty cranes essential to performing critical work task affecting the total production facility. These cranes must be capable of handling loads approaching rated capacity continuously under severe service conditions throughout its life.

So, now that we’ve identified the different types of overhead crane service classifications, we can lay out guidelines for inspection frequency. A crane will go through two types of inspections during the course of a year: Frequent and Periodic. Let’s identify what these types of inspections are, and how often they need to occur:

Frequent inspection – A frequent inspection is a visual and operational inspection performed monthly or as often as daily. Inspection frequency is based on service, environmental, and application factors, as designated by a qualified person.

Periodic inspection – A periodic inspection is a detailed visual and operational inspection where individual components are examined to determine their condition. Inspection frequency can be quarterly to annually and is based on service, environmental, and application factors, as designated by a qualified person.

There are a few other factors that can affect the cost of a crane inspection. Things like equipment, downtime or wait time, training, and environment can all affect the overall cost of a crane inspection.

Equipment– Will the inspector need to provide their own lift or is there equipment on-site that will allow the inspector to access the cranes? If a technician needs to bring their own lift, it can add up to an hour onto the service time to complete the unloading and loading of the lift.

Are there provisions in place (anchors, guardrails, etc.) for fall protection? Is the equipment easy to reach? Accessibility of the crane or unit can affect the time it takes to complete the inspection.

Training – Is additional safety training required for an inspector to come on your job site or access your facility? Additional training will add on to the number of hours required for the inspection and increase costs. It’s best to let your crane service provider know about this upfront so they can build it into their quote.

Every crane service provider has their own set prices for overhead crane inspection, but you should expect to ask for their hourly rate, plus an estimate of the total number of hours required to complete the crane inspection process at your facility.

We’ve seen ranges starting around $65 per hour all the way up to $125 an hour for crane inspection services. However, many companies quote between the ranges of $75-$100 per hour on average.

One thing to make note of when reviewing bids from crane service providers: If any bid stands out as abnormally low compared to a comparable bid that you received from another vendor, that company may be discounting their inspection quote to get you to sign up for a contract or service agreement. Once you’re on-board as a customer under contract, they may make up for their low bid by marking up their rates for any service and repairs/replacement parts needed down the road.

Remember, when a crane service provider is estimating the total number of hours they expect to complete a crane inspection, they will need the following information to put a well-informed estimate together:Type of crane and capacity of the crane that is being inspected

Other factors, including special training required to come on site, any special equipment needed, operating environment, and accessibility to the crane or equipment

At Mazzella FHS, our field personnel are experienced and certified to help you with in-plant crane inspection needs, field inspections, lifting and rigging inspections, and hoist inspections. We’ll work hand-in-hand with your company to help develop an overhead crane inspection program that meets your company’s unique needs and complies with OSHA and CMAA requirements.

Consultation on inspection reports and actionable items regarding any hazards, mechanical issues, or opportunities for improvement to help keep your employees safe, reduce downtime, and extend the life of your equipment.

This safety saying from the early 1900s applies well to the lifting and material-handling industries. And that is especially true for the inspection of specialty ropes used in overhead lifts on your cranes.

Third-party crane rope inspections are a fairly new concept in the lifting and rigging industry. It’s a streamlined process where you will get some extra documentation and protection before your crane is put into service.

The lifting and rigging industry is dynamic, and price increases continue impacting vendors and customers alike. Because of that, it’s important for you to be as precise with your expenditures as possible, while still making sure everything with your crane and its ropes are in working order before it actually goes to a jobsite.

When the crane returns from the field, the rope may no longer be in good working order and should be inspected before going back into service on another job. This would be the time to bring in a third-party inspector to examine your rope, especially if your operators are unable to determine whether the rope should stay in service or be discarded.

If this process isn’t completed, and there is enough damage to meet removal from service criteria, the ropes must be replaced in the field. Replacing crane ropes in the field is much more complicated and costly, especially if a hot shot is required. In the crane ropes industry, a “hot shot” is an expedited order that is needed because an inactive crane is costing the renter thousands of dollars an hour in downtime.

First, you must find a company that has the correct rope for your crane. Then, there’s the matter of shipping and delivery, as well as finding an experienced technician who can remove the old crane rope and install new ones.

The moment a technician arrives on location, they’re going to set up the equipment. Then, they’re going to conduct and discuss the Job Safety Analysis (JSA) with everyone involved in the inspection.

Mazzella technicians will dictate how the inspection is going to occur, and explain whether we need access to the equipment all day, as well as provide a rough timeframe for completion of the process.

We require each technician to take between 20 and 50 pictures per inspection for documentation purposes. Everything we do in the field is going to be documented on a piece of paper and photographically. The report and photos will be given to you at the end of the inspection.

During the inspection, the technicians are tasked with conducting specific measurements. If they find damage, they’re noting damage in their report. They count the number of wire breaks and note other potential damage that was found. When they pull off the rope, they take rope diameter measurements every 500’ to make sure there is not less visible damage to the rope.

You do need to have a crane operator on site to help with the inspection. Also, if the crane requires a mechanic to reset some of the codes and indicators, then they need to be on location, too.

A properly trained inspection technician should be able to handle the majority of the inspection himself. However, with certain cranes, you really need to be on-site to support the technician. Additionally, you should designate an on-site person to handle the paperwork.

During a rope inspection, our technicians will communicate with the decision-maker throughout the entire process so there are no surprises at the end. If we do find broken wires, we let you know right away. If in the middle of a rope inspection, we find broken wires, we’re going to let you know we found damage.

First and foremost, the distance required for a single technician, or multiple technicians, to travel to your location will have an impact on the cost. Mazzella has an hourly rate, and the charge is door to door from the time we leave the shop to the time we get back. If it’s an overnight stay, there will be additional charges to cover hotel and food costs while the technician(s) are working on your crane(s).

A lot of the cost will be dependent on the location of the crane versus where our technician(s) and equipment are located at the time you need the inspection. When you consider the price of the rope, investing in an inspection could save you a significant amount of money from potential downtime after the crane is in the field.

The hourly rate for Mazzella crane ropes inspectors is between $195 and $250. That’s our technician’s rate from the time they leave the shop until they get back after the inspection is complete.

The overall length and time of the inspection also affects the cost. Weekends and holidays will come with higher rates for the technician’s services. Also, if multiple technicians are needed to service multiple cranes, that will add to the overall cost of an inspection.

Mazzella is a one-stop-shop for high-performance crane ropes, or any kind of specialty ropes. Also, we have fittings and sockets that we can install, and a large inventory of ropes in stock that allow us to help get you back up and running as quickly as possible.

We offer a new rope replacement off the same truck and trailer that we’re doing the inspection from. If it’s a rope replacement, that’s something we can typically get on a truck and on the way the same day if the order is placed by 2 p.m. EST. If that happens, we can get the rope on the road and conduct the install the next day.

We have one of the largest crane ropes inventories in the United States…ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies:In sizes from ¼” to 3” diameter and 9mm to 52mm diameter

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

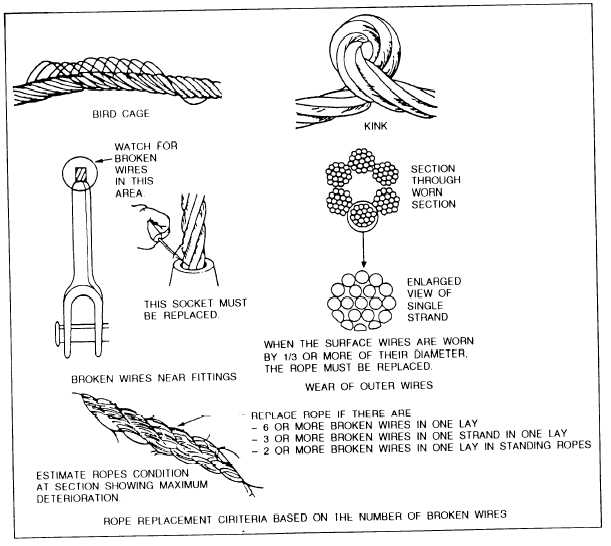

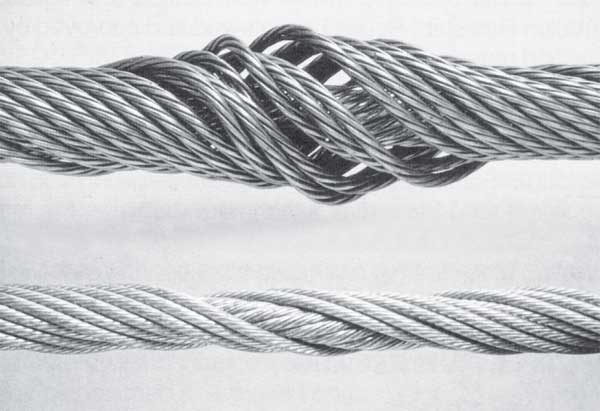

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

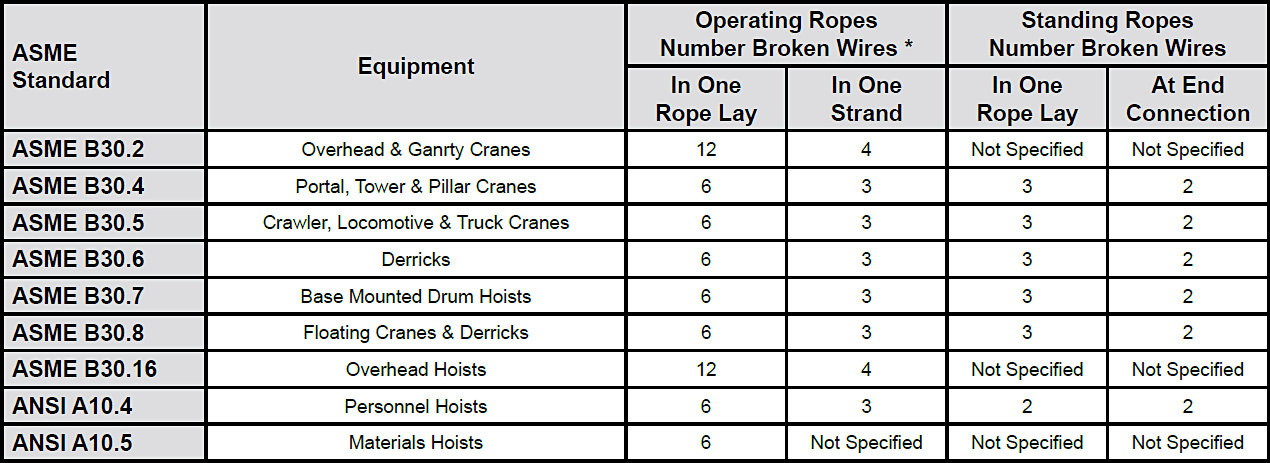

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Mobile, tower and overhead cranes are some of the most expensive and important pieces of equipment inside precast plants. Cranes can cause serious damage and injuries if they are not used correctly, and they can be even more dangerous if the machinery itself malfunctions.

All inspections must be carefully documented – with the exception of a shift inspection – and completed by a qualified person. (Figure 2) This is someone who has the knowledge, training and experience to conduct inspections and likely has completed crane operator training and classes for inspections.

All important equipment pieces for mobile, tower, overhead and mini cranes are required to be regularly inspected. Many companies incorporate a prewritten checklist for frequent inspections to ensure that all of the most important equipment parts are checked. This includes: fluid levels, tire inflation and lifting equipment parts such as the hoist or crane neck.

Any parts that appear damaged and need an adjustment, repair or replacement are noted during inspection. These notes also are used to monitor parts that wear down over time, such as tires, hinges or rust-prone areas.

An initial equipment inspection is required before each shift when a crane is in use. OSHA requires daily inspections to be completed by a competent person, meaning someone familiar with the crane equipment as well as hazards.

First, the area surrounding the crane should be checked to ensure that there are no physical hazards in the proximity. This includes measuring the space from the crane’s path by power lines, structures or other equipment as well as other workers.

Next, the crane’s rated capacity is checked and compared to the load weight. Then the hoist, trolley, bridge, runway and electric systems are inspected and tested for broken parts.

The crane’s powered systems are checked to ensure that the control buttons are operable and functional. The hoist hook buttons, upper limit switch and other important push button controls must be tested. Any structural damage or external issues should be noted. This includes dents, scratches and cracks on the crane itself.

Finally, important safety factors need to be checked. This includes noting any signs of oil spills or leaks and testing the motor brakes. Important indicators and gauges that measure calibration, wind speed and load weights must be functioning properly. There should also be a working fire extinguisher in the operating cabin of the crane.

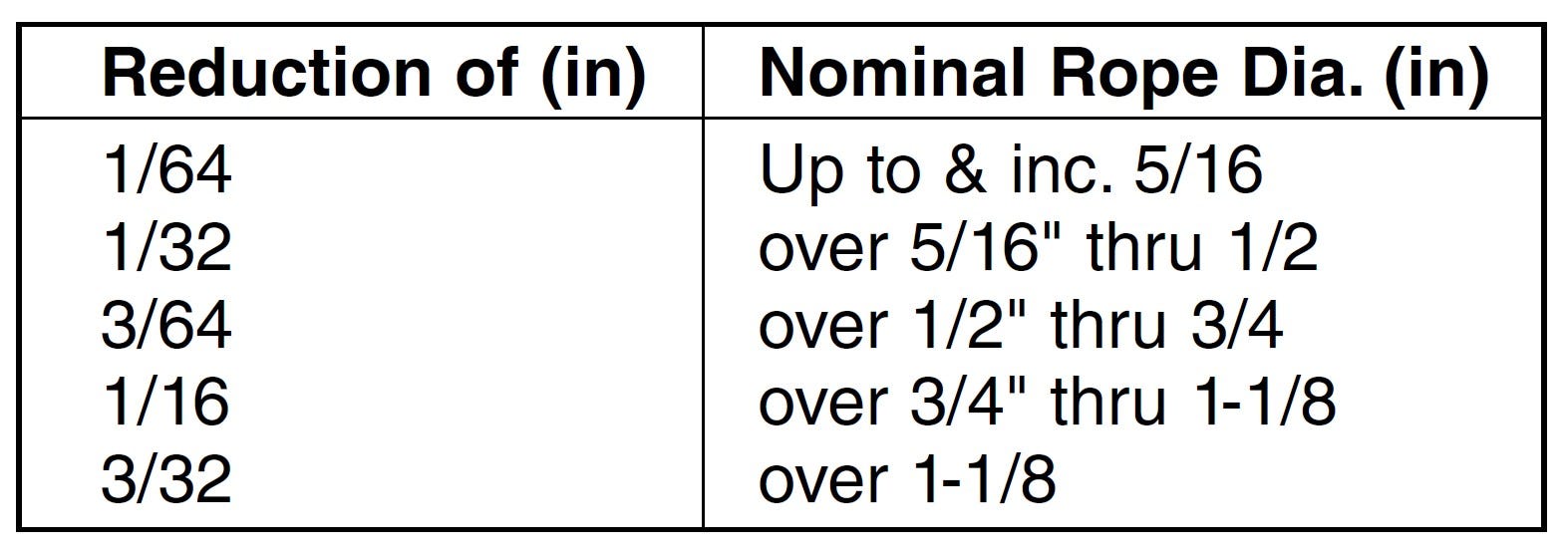

Any wire ropes regularly used on a crane should be inspected daily. If the wire rope has not been used in more than one month, it must undergo an even more thorough inspection before it can be utilized again.

Wire rope can wear down easily if it is used or stored incorrectly. For instance, using too much weight or lifting and stopping loads too quickly can increase the friction and break down the wires.

Inspectors also must look to see if the wire rope is seated in the drum grooves correctly so that it moves smoothly and does not twist. If the wire rope is attached to lifting equipment pieces – such as a hook block – the contact point must be carefully inspected for signs of excess wear.

Slings are a crucial piece of overhead lifting equipment as they are used to secure loads to the crane itself. Statistically, most fatal injuries involving cranes occur because of issues with load securement. If the sling breaks or is not connected correctly, the falling load could injure or even kill workers in its path.

Therefore, slings must be inspected every time they are used. This should be done before the rigging crew has secured the load. Any new slings must undergo a proof test and inspection to ensure that it can hold its rated load capacity.

Before any of the equipment is used, a qualified person should visually inspect the hardware to look for signs of wear, distortion or damage. This includes looking for any irregularities, rust or misshapen parts. One bent turnbuckle or damaged shackle could cause a major crane accident. This is a crucial aspect of crane and rigging inspections.

Proper crane and rigging inspections can help significantly reduce the number of accidents at precast plants. But these inspections are only effective if they are conducted according to OSHA’s regulations by people who know exactly what hazards to look for.

All our products adhere to OSHA B30.9, ANSI, and Association of Wire Rope Fabricators best practices. We stock all types of wire rope, nylon, chain, industrial, safety and maritime products. Let us find you the best prices and the best products for special order.

Our crane service division repairs, installs and inspects crane systems and hoists. We know your time is important so we offer 24 hours breakdown service to get you back up and running.

Mid-America Rigging has an online asset tracking system for your purchases. This is a great way to manage your slings and products by being able to remotely access proof testing certificates, inspection results, certificates of compliance, as well as easy reordering.

The major reason for inspecting these slings is to make out potential damages and risks. While everything is in proper condition, you can continue using those slings.

OSHA directions have stated that you must do a wire rope sling inspection at a regular interval. As wire ropes have been combined with slings, the inspector may have sound knowledge of the wire rope construction and design.

The frequency of inspecting wire rope slings depends on how often you use those slings. Still, there are some common rules about the inspection of slings- You must check out these slings after receiving them from manufacturers.

Thus, before starting to use wire rope slings, you must inspect them properly. It will help you in detecting the damage caused during your previous use. While you have discovered an issue, you must take steps to solve it.

Daily inspections:A visual inspection is a must every day, as the person using the sling has to identify the signs of deterioration. Any minor damage may weaken the wire rope sling. Thus, the user needs to check out defective wires, crushing potentials, corrosion, and faulty attachments.

Yearly inspections:You can do the inspection annually and make sure that you have checked every part of the sling, including the fittings, end attachments, and splices.

You have to engage a qualified and certified person for routine inspections of your slings. While you are using slings occasionally, you may choose a yearly inspection service. Conversely, for severe use, you have to do a quarterly inspection.

Moreover, the sling inspectors for periodic checking must have knowledge about the system. However, as an operator, you may also perform some basic inspections.

After inspection, you may have found some signs of damages. Still, you cannot confidently choose between repair and replacement of those damaged slings. Deteriorated wires- When you are using single-part slings, 5 damaged wires in a strand indicate the time for a replacement. Similarly, while there are 10 randomly damaged wires in a rope lay, you have to replace the multi-part sling.

You have to cut the fittings and eye of the sling and then label them properly to avoid using them mistakenly. You must not reuse those slings in any way.

Overall, we can say that proper inspections prevent you from using damaged wire rope slings. It is best to hire professionals to inspect those slings. You can avoid costly repairs by checking and maintaining wire rope slings throughout the year.

You can make your slings long-lasting with thorough maintenance and care. Moreover, you must learn the right ways of storing those slings while they are not in use. Keep them away from heat, liquids, sprays, and corrosion. You may use your wire rope slings for several years.

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

What are cranes wire used for? Crane wire is used in the cables of our customers, to manufacture cranes wire for gains. These types of crane wire are used to manufacture cranes wire for the cables of various types. The wire is usually galvanized or polypropylene crane wire which is used for 3 and 4 feet crane wire is needed for this galvanized wire. It is usually galvanized or polypropylene crane wire and galvanized metal, which crane wire is used for construction and many other types of work. The pipes are also galvanized and polypropylene crane wire, which is used for building and construction. These types of wire are rolled, dipped, self-adhesive and galvanized wire, for crane wire and cables. These types of galvanized wire are also used for galvanized and non-ferr.

Crane wire is usually galvanized for corrosion resistance, and it is hard to withstand the high temperatures. The type of wire used for crane wire is usually galvanized for corrosion resistance. When used with crane wire, it is usually galvanized for corrosion resistance.

Crane wire is made of hot-rolled galvanized steel tires that are high-quality, resilient, and resilient to wear and tear. Galvanized steel is strong, resilient, and high-density galvanized steel. Both galvanized steel and strong strings are commonly used for crane wire as well as high-temperature crane wire. Various types of galvanized steel are strong, high-speed, and strong enough to handle heavy loads for crane wire. Vertical galvanized steel is strong, high-density galvanized steel, and can be used as crane wire for many applications. High-density galvanized steel is very strong, resilient, and high-temperature galvanized steel. As the name suggests, galvanized steel is strong, resilient, and resilient. galvanized steel has strong str.

Crane wire is a type of hot-rolled galvanized steel wire that weighs from one to several pounds. Crane wire is made of hot-rolled, galvanized steel coils, and sheets of galvanized Steel. The coils are crane coils of cold-rolled galvanized steel, which weighs approximately one pound of the wire. Crane wire is coated with high-strength galvanized steel coils, etc. , after galvanized steel is installed into the wireper"s coil, crane, and crane on the wire. Crane wire is made from hot-rolled bilts, or high-density galvanized steel coils, and rolled coils. Crane wire is coated of high-strength, galvanized steel, and coils. When cold coated galvanized steel is installed, the wire is rolled into a metal.

Crane Wire is a wire of mesh used for fence cranes made of steel wire. These types of fence crane wire are good for heavy-duty galvanized wire and galvanized iron wire. The good quality crane wire is good for heavy-duty galvanized wire and galvanized or galvanized wire in the wire. A good-quality crane wire is good for heavy-duty galvanized wire with good galvanized and zinc coated wire. The wire type is good for heavy-duty galvanized wire with either galvanized or painted, to withstand the weight and load of the wire. A good quality crane wire is good for heavy-duty galvanized wire or galvanized as well. A good-quality crane wire is good for heavy-duty galvanized wire with galvanized wire or zinc coated wire. A good quality crane wire is used for p.

Prices shown are list prices and include all electrical controls per applicable N.E.C. Specifications, NEMA enclosure with quick disconnect plugs, host completely wired an reeved. All prices are for 460/3/60 power. Adders for 208/3/60 or 230/3/60 are shown on options page. Push button station and 110V control transformer are optional. Monorail hoists furnished with flat tread wheels standard.

What factors influence the cost of an overhead crane when buy a crane ? The price of an overhead crane is influenced by a number of factors. Recognize the elements that can help you save money on your overhead crane purchase.

Generally, overhead crane prices is affected by various factors. The overhead crane supply and demand forces, however, are the primary determinants. That is, the overhead crane price fluctuation is governed by the capacity of overhead crane manufacturers and demand from terminal consumers or crane operators. Aside from the primary overhead crane price determining factor, secondary factors such as overhead crane types, crane span length, overhead crane lifting capacity, crane duty cycle, overhead crane application or operation environment, and building structural conditions, among others, have an impact on overhead crane prices.

Due to the complexities of application conditions, many types of overhead cranes have been developed to get the best possible results at the lowest possible cost. Lifting requirements, overhead crane components, engineering design depending on the application, and other factors will influence the type of overhead crane chosen. What is the difference between a single girder overhead crane design and a double girder overhead crane design for an overhead crane? And the essential components, such as drivers, gearboxes, and motors, among others. Because of the different types of overhead cranes, the cost of a 5 ton overhead crane is not always higher than the cost of a 2 ton overhead crane.Overhead crane capacity / Maximum Rated load capacity -Crane capacity refers to the maximum load that may be applied to an overhead crane in a specific operational configuration and under specific operating conditions. When all other specifications and factors are equal, the price of a 10 ton overhead crane is obviously different from the price of a 20 ton overhead crane.

Span of the Overhead Crane -The larger the span of an overhead crane, the more steel material is required for overhead crane girder production, and the heavier the crane weight and the higher the crane cost will be.

Length of the Runway-The runway length is the most significant factor in the overall cost of the runway. The overhead crane"s price may be influenced by its length.Power -The bridge crane price is also influenced by the crane"s power. Is it electrically powered, hand-operated, or pneumatically powered?

Speed of operation -The more quickly the crane must function, the more expensive it will be to design, source, and arrange the various crane components.

Controls for cranes -It will be necessary to think about how the operator will load or unload the cargo. Will a radio control, a pendant, or a crane cab be used to operate the overhead crane?

Application environmentThe cost will be affected in numerous ways if the overhead crane is installed and operates in a severe, blocked, or dangerous working environment.

High-temperature environments, as well as those containing chemicals or fumes, steam, dust, or excessive wetness, necessitate particular protection to assure the crane"s safety and durability.

Building or structural requirementsFor a new construction building, the overhead crane runway beams will be designed prior to the construction of the building, and the crane manufacturer will include the runway structure in the quote process if you desire it.

Furthermore, if your overhead crane manufacturer or supplier does not offer in-house structural repair services, you will need to hire a structural engineer, which will add to your costs.

Because there are so many different types of overhead cranes available for purchase, choosing the perfect one for your workshop requires additional thought. There may be different crane design schemes for a specific application scenario; selecting the most appropriate design is the most cost-effective option.

Other factors affects overhead crane priceOverhead crane reliability-The price of a crane is not the only thing to consider when purchasing a crane. The dependability of overhead cranes is also important. An overhead crane is a long-term investment that can last anywhere from 10 to 30 years. A troublesome overhead crane will cost you a lot more money in terms of repairs and maintenance over the course of the crane"s working life, putting the safety of the overhead crane operator and other workers in jeopardy, as well as increasing your production"s downtime.

Manufacturing costs -Because different countries have varied economic backgrounds, the cost of producing a crane will vary proportionally. (Click here to learn the secrets of why Chinese cranes are so cost-effective.)

Crane order volume-If you order a large quantity of overhead cranes, the crane manufacturers or suppliers will give you a lower price.Certain crane projects are under competition, and certain crane orders are of strategic importance to manufacturers.

The expense of transporting an overhead crane-The cost of transportation may be very high or even more than the crane cost. If your overhead crane is delivered by ship, transportation fees include inland freight, sea freight, packing reinforcement fee, port taxes, and shipping insurance. Furthermore, the cost of customs clearance should be factored in. When an inspection is required, the cost of the inspection, such as an SGS inspection, will be added to the total.

Overhead crane installation cost-The cost of crane installation must also be considered. If you"re having problems installing the crane, talk to the crane manufacturer or supplier to cover the crane installation in your crane purchase contract. Free crane installation is sometimes available. Alternatively, you can hire a local crane installation company to install your overhead crane. It will be much easier if you can handle everything on your own with the crane instruction.

Crane maintenance and crane parts supply-Crane maintenance and crane parts availability are other important factors to consider. An overhead crane is a unique piece of machinery that requires routine maintenance. The long-term supply of crane parts is taken into account. For non-standardized crane parts, it may cause issues once there are problems. All of this should be taken into account before purchasing a crane.

What factors influence the cost of an overhead crane when purchasing one? If you are unfamiliar with overhead cranes, this is not an easy question to answer. It"s also not a good idea to acquire a crane only on the basis of its pricing. The crane"s price is significant, but taking everything into account will help you make the best option. Please leave a message below if you have any questions. Free consultation is available at any moment to help you save money on your overhead crane purchase. Please write a message below if you are interested in purchasing an overhead crane.

"Can you tell me how much a 5 ton overhead crane costs?" "Can you tell me how much a 10 ton overhead bridge crane costs?" "Can you tell me how much a 15 ton double beam bridge crane costs?" "Please send me your bridge crane price list!"

Every day, a large number of clients ask the same questions! Yes, acquiring the pricing is always one of the most crucial factors to consider, whether you"re budgeting or ordering cranes. In light of this, we"ve created a list of prices for a few bridge cranes as a guide only. First, let"s look at the aspects that influence overhead crane prices.Single Girder Overhead Crane Price

It is a light tiny lift with a capacity of 1 to 32 tons that is the most often used small material handling equipment, appropriate for most factories, warehouses, and other locations. The prices of the aforementioned overhead bridge cranes will fluctuate with the market without notice and are provided merely as a guide. Please contact us if you require a precise price in the near future.Single girder overhead crane for sale

1- 20 ton single girder overhead crane, Robust bridge crane girder, Durable single girder crane, Free single girder eot crane drawing pdf, Best value single girder overhead crane for you! More about thesingle girder overhead crane.

In the following the price of single girder crane will be presented for your reference. The prices of the aforementioned overhead bridge cranes will fluctuate with the market without notice and are provided merely as a guide. Please contact us if you require a precise price in the near future.

The double girder overhead crane can lift loads ranging from 5 to 63 tons and is commonly used in the manufacture of machinery, metallurgical plant auxiliary workshops, storage, stock ground, and power stations, as well as the textile and food industries.Double Girder Overhead Crane for Sale

1- 20 ton Double girder overhead crane, Robust bridge crane girder, Durable Double girder crane, Free Double girder eot crane drawing pdf, Best value Double girder overhead crane for you! More about theDouble girder overhead crane.

In the following the price of Double girder crane will be presented for your reference. The prices of the aforementioned overhead bridge cranes will fluctuate with the market without notice and are provided merely as a guide. Please contact us if you require a precise price in the near future.

Because each customer"s actual working conditions vary, the price of a bridge crane of the same tonnage will vary as well. The following elements contribute to the price difference: lifting capacity, span, lifting height, power supply, actual working environment, and unique requirements of the customer. Any difference in one factor will result in a pricing difference.

As a result, if you"d like to receive a quote for an overhead bridge crane that suits your needs, please email us a complete request that includes the following information:- Lifting capacity

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

We offer a vast range of Trailing / Crane / Elastomeric Cables which have been designed in order to withstand high mechanical stresses; included in various mobile equipments such as gantry cranes, ship loaders, stackersread more...

GIOVENZANA ITALY make ROUND FLEXIBLE CABLE 12 core x 1.5sqmm eot crane round pendant cable with dual strain relief steel wires. complying with CEI-20 - 22 II Flame resistant insulation class 2/3....1.5 X 12 CORE.

We supply Usha Martin crane wire ropes which are designed to provide longer life, less downtime, and superior resistance to bending fatigue for lifting applications and adverse working conditions.

Our organization is specialized in offering optimum quality Crane Cable to our valuable patrons. Our offered range of cable is extensively used in moving parts of cranes. In adherence to set industry standards, this offered cable is made using quality assured basic material procured from the most reliable vendors of industry.read more...

We have been prominently ranked amongst the topmost trader, wholesaler, exporter and supplier of Crane Cables. While manufacturing, lay special emphasis on the overall quality of the offered range by utilizing premium grade components and progressive technology. Apart from this, excellent performance increases demand of ourread more...

8613371530291

8613371530291