rotation resistant wire rope inspection for sale

Using the rope to its maximum fatigue life will cause the rope to deteriorate from the inside out. Sudden rope failures may be the result. For this reason we do not recommend this construction for tower cranes. There have been fatal and catastrophic accidents involving this rope construction because of undetected inner rope fatigue.

However, mobile and truck mounted cranes are operated on a much less severe duty cycle and it is not expected that 19x7 has to be replaced because of inner rope fatigue but because of other mechanical damages. Keep in mind that this statement covers normal mobile crane use. If you use a mobile crane like a production crane you WILL experience the above mentioned danger situations.

The load which a new wire rope may handle under given operating conditions and at an assumed design factor. A design factor of five is chosen most frequently for wire rope. (Operating loads not to exceed 20% of catalog breaking strength). Operating loads may have to be reduced when life, limb, or valuable property are at risk, or other than new wire rope is used. A design factor of 10 is usually chosen when wire rope is used to carry personnel. (Operating loads not to exceed 10% of catalog breaking strength). Responsibility for choosing a design factor with the user.

Rope sockets, thimbles, sleeves, hooks, links, shackles, sheaves, blocks, etc., must match in size, materials and strength, to provide adequate safety protection. Proper installation is crucial for maximum efficiency and safety.

.jpg)

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

Wire ropes are complex machines with a great many moving parts. They require attention, skilled operators, careful maintenance, inspection and lubrication.

In spite of their vital importance, wire ropes are frequently treated as and considered low-tech commodities. Failures are frequently accepted as “inevitable.”

With the appropriate inspections, wire rope failures can be predicted, and expenses and losses reduced. Consider that the price tag of rope failures can easily be in the seven or even eight digit range, and the cost of an inspection is marginal.

Much more dependable than visual inspections, magnetic rope testing (MRT) is a reliable non-destructive evaluation/examination (NDE) procedure used for the in-service inspection of wire ropes. NDE methods allow the detection and evaluation of external as well as internal rope deterioration. This allows the inspection of a rope’s entire cross-section to the core. MRT drastically increases wire rope safety. At the same time, it promises significant annual savings.

Ropes usually degrade internally with no visible indications. Internal deterioration modes include inter-strand nicking that will eventually develop into clusters of internal broken wires and corrosion including corrosion pitting.

External deterioration includes winding-on-drum damage. Urgently needed, suitable inspection equipment and procedures are now available – especially for the quantitative characterization of internal rope deterioration.

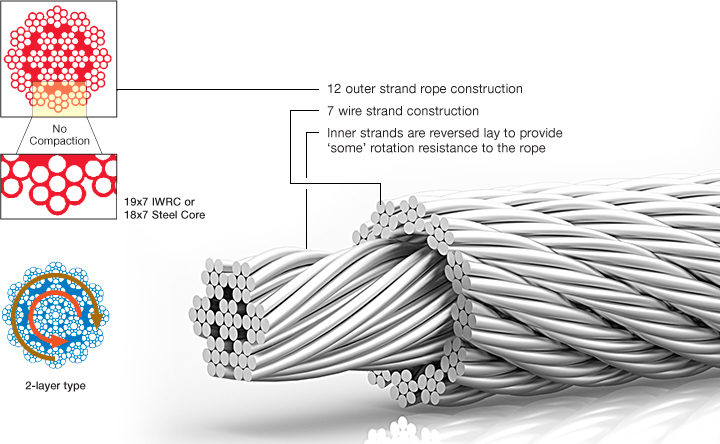

In an application where a single-part hoist rope is used to lift a free load – or where rotation-resistant properties are essential for rope performance – the 19x7 can be used. Its rotation-resistant characteristic is achieved by laying six strands around a core strand in one direction, then laying 12 strands around the first operation in the opposite direction. When the rope is in tension, opposing rotational forces are created between the inner and outer layers.

The strength, quality, and integrity ofwire ropedefine the level of safety for any lift at all construction sites. Each lift is only as safe as the wire rope being used on the crane. Wire rope should be inspected prior to each shift for damage. There are many different types of wire rope used on cranes. The wire ropes used in on cranes will either be a standing wire rope (such as a pendant line) used mainly on lattice boom cranes, or running wire rope (runs over a sheave) used as hoist line or boom hoist reeving. For running wire ropes, there are dozens of types to choose from for the hoist line on a crane. However, out of the dozens of wire ropes available, similar characteristics for inspection and removal criteria are shared by all.

The most common wire rope used on cranes isright regular lay,which usually has a safety factor of 3.5 and must be removed from service when there are 6 broken wires in one rope lay or 3 broken wires in one strand of one lay. Left lay and lang lay share similar criteria for removal from service. Rotation resistantwire rope has different criteria for removal from service. Rotation resistant wire rope is removed when there are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters. Rotation resistant has a safety factor of 5. Special attention should also be given to any reduction in rope diameter, such as kinking, bird caging, or crushing with rotation resistant. Find stainless steel cable, galvanized cable, andwire ropeproviders at Cranehunter.com

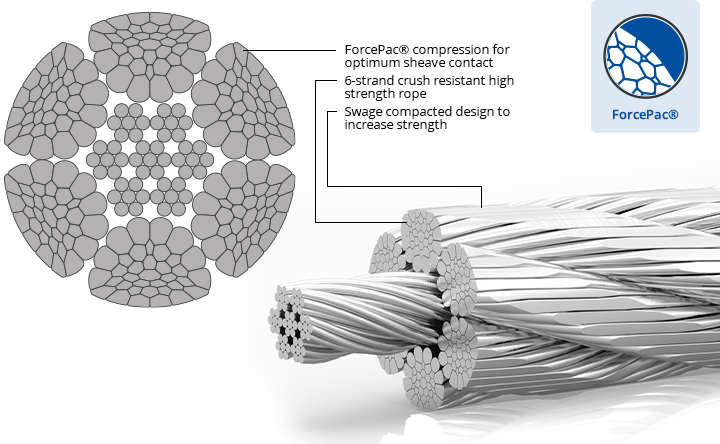

SWR supply a large range of non-rotating wire ropes in both galvanised and ungalvanised finish with either ordinary or langs lay. Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications as well as being available with plastic impregnated.

Nobles Rotation-Resistant wire ropes are available in 6 - 22mm. The ropes from 6 -12mm are the 19x7 construction and our standard ropes are galvanised 1960 grade and come in Right Hand Ordinary Lay.

Rotation-Resistant wire ropes from 13 - 22mm are in the 35x7 construction and are compacted for maximum breaking loads. This range is unglavanised and comes in Right Hand Langs Lay as standard which is ideal for multi layer applications such as winches on mobile cranes.

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

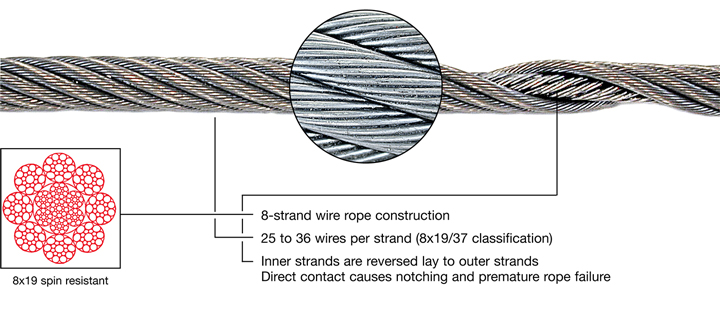

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

8613371530291

8613371530291