safe working load wire rope chart pricelist

1/2" 25M Messenger guy strand wire made in USA. Messenger Wire, Guy Wire, Overhead ground or static wire, Tower Guying, Class A Galvanized.Guy Strand/Wire 1/2" X 2500 FT EHS 1/2" USA

Real Jacks make wire pulls run smooth and easy. These innovative reel jack stands have four 20,000 lb. sealed bearings that capture the axle to prevent reels from traveling during the pull.

Slingco�s guy wire dispenser is constructed of high strength steel coated in a durable black finish to enable the unit to endure the harsh outdoor environment.

Line Pulling Swivels - Stainless Steel SLINGCO ZSW2093Slingco Reel Lifter is a high capacity, compact unit that allows users in the utility construction industry to safely load, transport, and dispense wire and/or cable on-site.SAFE WORKING LOAD (lb):5,000UNDERGROUND &3,000OVERHEAD4-15/16" LENGTH

Line Pulling Swivels - Stainless Steel SLINGCO ZSW2093Slingco Reel Lifter is a high capacity, compact unit that allows users in the utility construction industry to safely load, transport, and dispense wire and/or cable on-site.SAFE WORKING LOAD (lb):5,000UNDERGROUND &3,000OVERHEAD4-15/16" LENGTH

Preform Line Products Safety guy-wire dispenser is designed to provide safe, easy, completely controlled handling and paying-out of strand coils up to 500 ft in length, including EHS strand. It also can be used with wire, wire rope, cable, conductor, etc. Eliminate weight lifting, handling struggle, and the hazards of "runaway" coil ends. Small and light in weight (a carton of 50 weighs only 22 pounds), the safety guy-wire dispenser occupies minimal truck space. No banding or taping of coils is necessary. Saves personnel cost (only one person to pay out a loaded coil) and reduces inventory (just one universal size). Coil not included*

Preform Line Products Safety guy-wire dispenser is designed to provide safe, easy, completely controlled handling and paying-out of strand coils up to 500 ft in length, including EHS strand. It also can be used with wire, wire rope, cable, conductor, etc. Eliminate weight lifting, handling struggle, and the hazards of "runaway" coil ends. Small and light in weight (a carton of 50 weighs only 22 pounds), the safety guy-wire dispenser occupies minimal truck space. No banding or taping of coils is necessary. Saves personnel cost (only one person to pay out a loaded coil) and reduces inventory (just one universal size). Coil Not Included*

Used to terminate strand at a right angle to the building wall. A wire rope thimble is recommended to protect the strand when using the wall strap. 1 7/32 X 15/64 x 8" Long W 9/16 HOLES J7692

Thimble Open, ADSS Drope Cable Dead-Ends 1/2 in; Opening Width - 3/4 in; Eye Width - 1 1/8 in; Eye Length - 2 in; Material - Steel, PlatedTHIMBLE OPEN 1/2 Guy Strand J1058

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.91, up from 374.68 last month and up from 317.27 one year ago. This is a change of 0.06% from last month and 18.17% from one year ago.

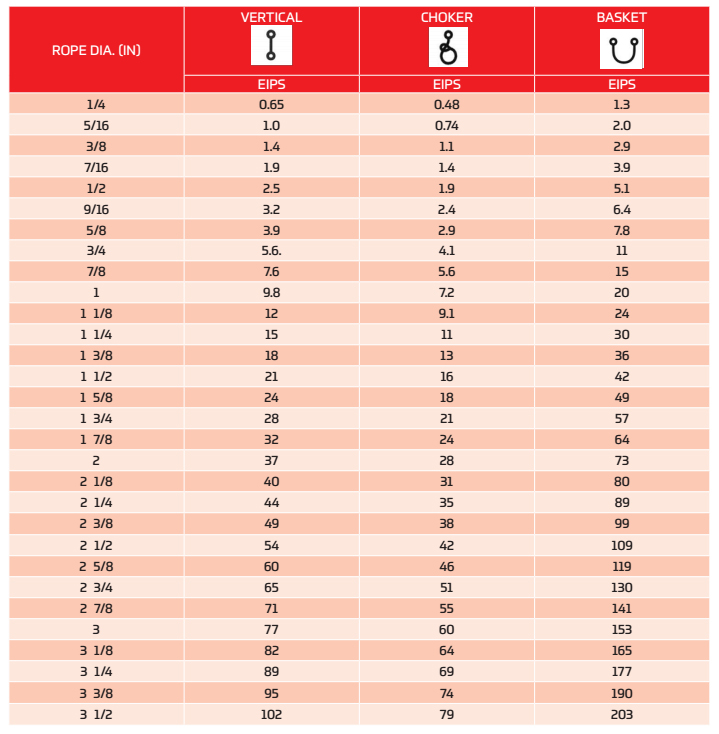

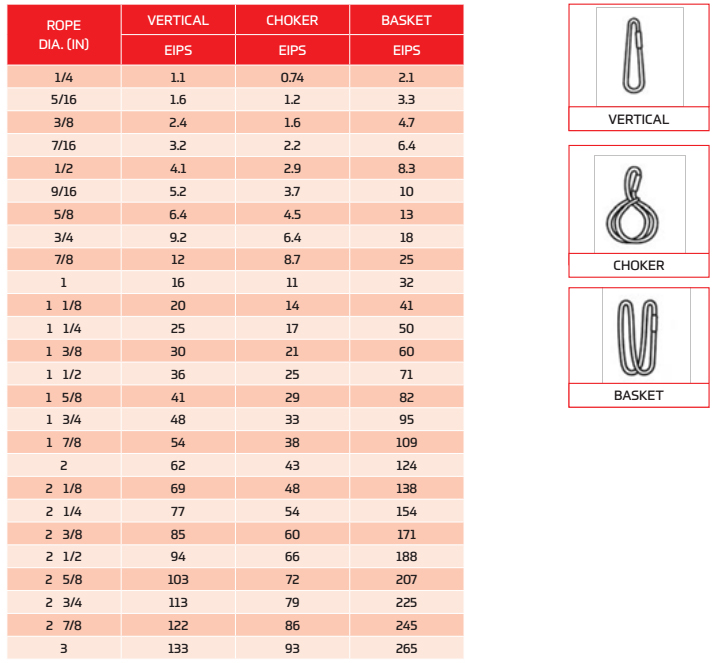

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

8613371530291

8613371530291