seismic wire rope manufacturer

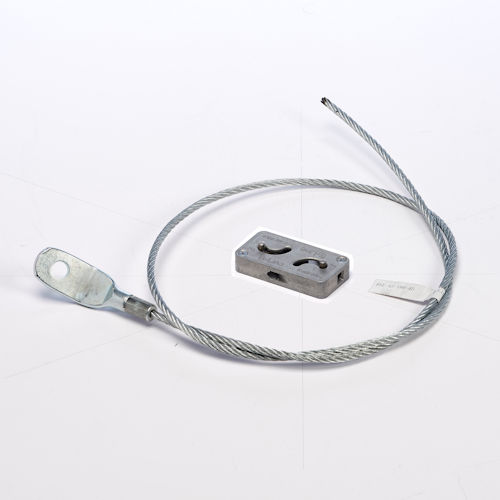

Loos & Co., Inc. manufactures and sells pre-stretched, color-coded, break strength certified Seismic Bracing Cable for use in satisfying the requirements of the laws, codes, standards, and specifications for earthquake resistance of architectural, mechanical, and electrical components and systems.

Loos & Co’s Seismic Bracing Cable Assemblies are the very best cable sway braces! Loos & Co. manufactures the most cost-effective, code-compliant seismic bracing system on the market today. The system installs in half the time of conventional rigid pipe bracing systems. The AISI Standard for structural cable includes a requirement for pre-stretching cable, a requirement for using permanent end fittings that are recommended by a cable manufacturer, and a requirement that permanent end fittings develop the break strength of the cable. The Loos & Co., Inc. Seismic Bracing Cable products satisfy these requirements and, therefore, may be used with the best safety factor. This reduces the sizes required to carry the earthquake loads and the smaller sizes employ less expensive end fittings that are faster to install.

Manufacturer and supplier of custom and standard wire and cable, cable assemblies and wire harnesses. Custom wire and cable can be provided with many different jacket and insulation materials and various conductor and shielding options. Standard wire and cable offerings include commercial, Mil-Spec, UL/CSA approved wire and cable, molded cord sets, and tubing/sleeving/wire management. Custom assemblies include cable assemblies, wire harnesses, box builds, cable jumpers, overmolded cable assemblies, and wire lead manufacturing. Full engineering and design services available. Certified woman-owned business/women"s business enterprise (WBENC), ISO 9001 certified, and ITAR registered.

Discover at Ben-Mor our wide selection of products for seisms: bracing cable, looped cable, sway bracing cable, wire rope cutters, swagers and Kwic-locs. Click on the products below for more information.

For over 60 years, Loos & Co., Inc. has pioneered and thrived in the highly critical profession of wire, wire rope, and hardware manufacturing for use in applications where critical outcomes are directly at stake. This valuable experience has taught us “the ropes” about what a difference quality and performance make in your applications. Now, we can help make the difference for you with your pulley and sheave applications, too.

We’re proud to offer a wide variety of military specification and commercial wire rope, aircraft cable, and fittings to compliment your complete sheaves or pulley system. These products are the perfect compliment to the high performance products offered by esheaves.com. Pairing Loos & Co., Inc. tools, hardware, and accessories with the highest quality pulleys and sheaves will repay you with the performance you have come to expect from our products.

The major portion of our manufacturing is devoted to the production of Military Specification wire rope fittings, connectors and terminations. These products are on the QPD (Qualified Producers Database) for the US Government. Several hundred product numbers are manufactured and warehoused in our Naples facility. Additionally, we manufacture the swaging machines and tools needed to connect our manufactured hardware to the various types of wire rope. We are proud to be able to offer fast turnaround and complete delivery from our large supply of finished inventory.

We have become a major supplier of UL Listed Seismic Bracing Products to the construction industry. Loos’ Seismic Cable Bracing is fast becoming the preferred product for mechanical contractors in many types of commercial construction projects all over the world.

We are the first ISO accredited PCA ISO-17065, third-party certification body for special seismic certification of non-structural building components and their mounting configurations by the ICC’s International Accreditation Service.

We are the only ISO 17025:2005 Accredited Seismic Simulation Test Laboratory with a triaxial shake table owned and operated by California licensed Structural engineers.

Bloomingdale, NJ – July 27, 2007 – VMC Group, a world leader in innovative shock, seismic, vibration and noise control products, today announced that their Wire Rope division, Aeroflex International Isolators, has joined forces with IDC International, Inc. headquartered in Puerto Rico. A definite agreement was signed in June 2007 consummating the deal, which is phase one of a multi-phase agreement. This transaction, which is another key component of VMC Group’s strategy to deliver engineered solutions to its ever-growing global client base, positions VMC Group with an even larger market share of the wire rope isolator industry. With this expansion, VMC Group will be able to reunite with some of the original customer base of their Aeroflex International Isolators division and will offer a more extensive wire rope isolator product line. VMC Group will be relocating their wire rope manufacturing operations to Puerto Rico. The wire rope line will remain a key component of VMC Group’s product offering.

"We are pleased to have completed this transaction and be aligned with this particular group, IDC International, Inc.," said John Wilson, Jr., Chief Executive Officer, VMC Group. IDC International, Inc. is a leading company in the industry and IDC’s President, Johnny Ramos, is one of the pioneers of the Wire Rope industry. “After months of working closely together and having first-hand knowledge of IDC International’s operation, we are pleased that Mr. Ramos will remain as President of the Puerto Rico facility and join forces with VMC Group,” states Mr. Wilson.

Both entities will unite their wire rope sales and manufacturing operations. Combining and streamlining the manufacturing process will enable both entities to continue to deliver the product line in a cost-effective manner. “IDC International’s next generation of wire rope products will complement Aeroflex International Isolators’ 45-year history of quality wire rope isolators and enhance VMC Group’s current portfolio and position as a global leader in the industry,” states Mr. Ramos, President of IDC International. Mr. Wilson adds, “we are in an excellent position to serve our customers with the highest of standards.”

Headquartered in Bloomingdale, NJ, VMC Group is comprised of four leading global brands that together represent the state of the art in shock, vibration, seismic and noise control. VMC Group works closely with their customers to deliver product and engineering solutions across a broad range of industries including HVAC, commercial construction, architecture, military, defense, aerospace, marine, vehicular, electronics and power generation. For more information on VMC Group, visit www.thevmcgroup.com.

Aeroflex International Isolators has provided mission critical products and solutions to leading military, aerospace and defense companies for more than 35 years. Aeroflex International Isolators was the original patent holder of wire rope isolators for the shock and vibration industry.

IDC International, Inc., located in Caguas, Puerto Rico, has over the past 25 years built over 1 million wire rope isolators for many defense applications. Additionally, IDC provides turnkey electromechanical and mechanical products and solutions including platforms and rail systems.

IDC International, Inc. is the premier manufacturer for shock and vibration wire rope isolation systems. IDC has the latest state of the art CNC equipment as well as inhouse processes to meet their customers’ expectations for quality, price and delivery schedules.

nVent CADDY cable bracing is a simple seismic bracing method for mechanical, electrical, plumbing (MEP) and fire sprinkler systems, including CPVC pipe systems. Cable bracing is the only option when brace lengths exceed the brace length limitation of 9"-7" (3 m) for strut or when confined/crowded spaces make rigid systems difficult to install. The system includes steel cables complying with the ASCE® 19 pre-streching requirements, attachment fittings, swaged oval sleeves & related tools, as well as pre-assembled kits.

Seismic bracing products can be categorised in two distinctive types: Rigid Braces and Steel Wire Rope Braces. A single rigid brace can work under tension or compression loading and they are very popular with fire fighting and sprinkler installers. Having said that steel wire ropes offer cost effective solution even though they can only resist tension loads and two braces are required at single restraint point. Where vibration isolation is of a concern rigid bracing can not be used and the only alternative is steel wire ropes. They are quick to install and offer great flexibility. Seismic bracing is most commonly used in protecting suspended MEP services (ducts, pipes, cable trays…) and equipment (fans, AHU, FCU…).

ST. LOUIS — Vibration and Seismic Technologies (VST) has been awarded an exclusive license to manufacture and market the Seismic Wire Rope/Cable™ Bracing products previously manufactured by Loos & Co. The product line is used to brace a range of non-structural building components, including HVAC equipment. The cable bracing line is said to meet all current building codes and standards.

The patented cable bracing system was developed by Dan Duggan Sr. and Mike Werner of Duggan-Werner Inc., which has granted the exclusive license to VST. In addition to offering the Seismic Wire Rope/Cable Bracing product line and associated tools, VST also offers seismic engineering services for mechanical, electrical, and plumbing construction projects.

All VST seismic bracing products are UL listed and comply with the International Building Code and its referenced standards, including ASCE 19-10, which prohibits the use of cable clips and wedge type end fittings that can loosen and damage the cable over time.

VST will sell the cable bracing system through select original equipment manufacturers, as well as through manufacturer’s representatives and distributors. The company is currently seeking sales reps and distributors in several areas. For more information, call 844-734-7642 or visit www.vstseismic.com.

8613371530291

8613371530291