shell wire rope grease for sale

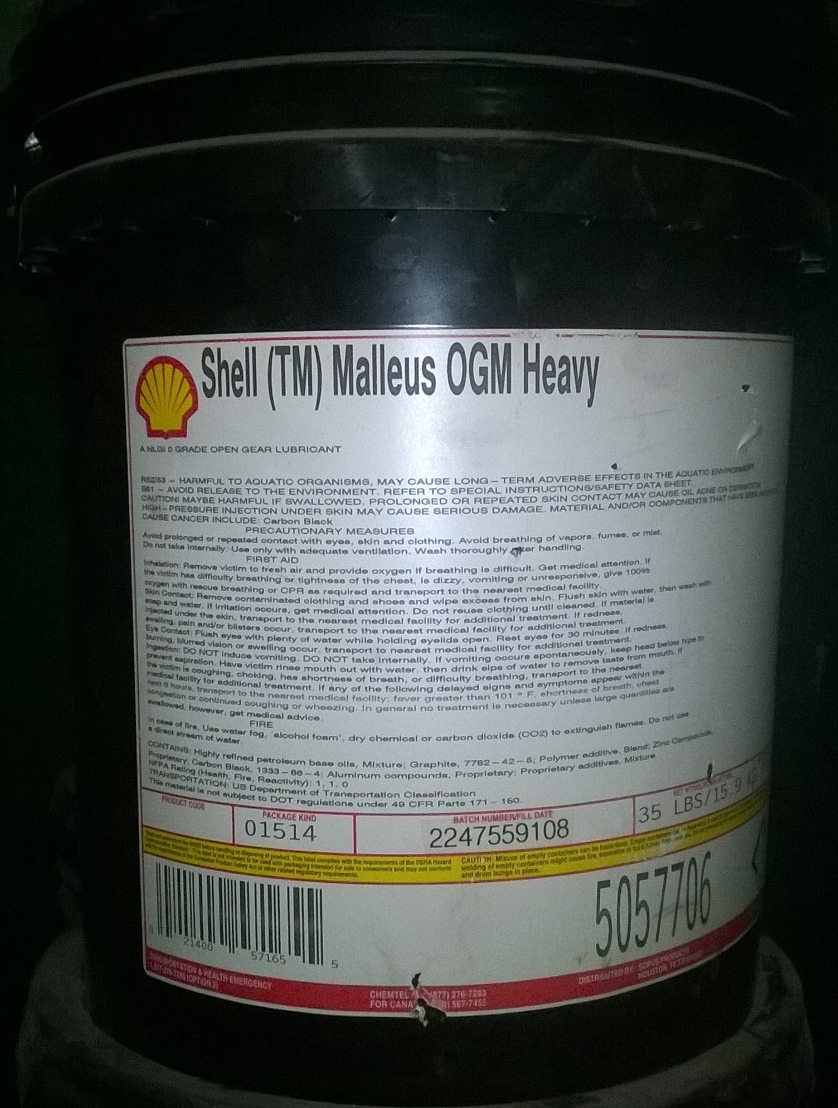

At working temperatures, speeds and pressures, Shell Gadus S2 OG 40 forms a protective cushion between the large gear (girth, bull etc) and pinion teeth.

Heavily loaded open gears, particularly those found in grinding mills, kilns, shovels, draglines, ship loaders, stackers and reclaimers and excavator applications. When choosing a product to suit your ambient temperature conditions, always consult with your Shell representative for the appropriate grade.

Multi service lubricant that can be used as the one grease (multi-purpose and open gear) for the entire machine on most shovels, excavators and draglines (excluding electrical motors bearings).

Shell Naturelle S2 Wire Rope Lubricant A is a high performance fully biodegradable grease for use on open gears, wire ropes and cables. Supplied in an 18kg Pail.

Shell Naturelle S2 Wire Rope Lubricant A is designed for wire ropes, open gears and other deck equipment. It has excellent adhesion properties and is formulated with a selected blend of additives to offer superior extreme-pressure and anticorrosion protection in the most challenging of environments.

Low-cost lubricants can be poor value if they fail to stay where you need them. Shell Naturelle S2 Wire Rope Lubricant A offers high resistance to water wash-off owing to its outstanding adhesion properties. This can help to cut product consumption and labour costs, thereby reducing the cost of keeping your mooring and crane wires protected and working efficiently.

Shell Gadus S3 Wirerope A Grease is specially developed for the lubrication and rust inhibition of steel armoured ROV cable operating in saltwater environment in arctic as well as tropical climates. The product can also be used for other types of wire and chain where excellent adhesion, rust inhibiting and water repelling properties are requested. The grease can be applied using central lubrications systems of the type " Masto ".

Lubricant Supplies are a specialist distributor for quality branded lubricants, grease, chemicals and adhesives associated with engineering essentials to all sectors of industry throughout the UK.

You’ve come to the right place! We are now offering a hefty discount on a variety of industrial, bearing, automotive, construction and other hard to find greases. Lithium complex grease, moly grease, clay bentonite and lithium 12-hydroxystearate soap thickened grease drums are up to 30% off for a limited time!

These Premium, Heavy Duty greases offer enhanced load carrying capacity and are ideal in severe operating conditions. Suitable in off-highway and construction applications where resistance to water is essential!

Shell Gadus S3 Wirerope grease is a tacky, high quality, lithium soap-based grease incorporating multifunctional, extreme pressure additives, finely dispersed graphite and molybdenum disulphide. Shell Gadus S3 Wirerope grease exhibits outstanding load-carrying capacity in bearings operating up to the maximum rated speed for grease lubrication in the temperature range -150C to 700C. The temperature range can be increased 900C for bearings operating at 75% of the maximum rated speed.Heavy Duty Protection

We can give you the best cost prices to buy Gadus S3 Wirerope compared to all dealers, suppliers, vendors, wholesalers, retailers, traders, resellers and distributors in Mumbai, Navi Mumbai, Bhiwandi, Thane in Maharashtra and all India.

We can also ship Gadus S3 Wirerope to all these states of India Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Andaman and Nicobar Islands, Chandigarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Jammu and Kashmir, Ladakh, Lakshadweep and Puducherry.

This grease remains stable and in place under high pressure, heavy loads, and shock loads. It"s often used for demanding mining, construction, and automotive applications.

NLGI viscosity grade is a rating of a grease"s consistency. NLGI 1 is about the consistency of tomato paste. NLGI 2 is about the consistency of peanut butter.

Weld load measures a grease"s ability to withstand pressure in kilograms of force (kgf). The higher the rating, the more pressure the grease can withstand.

Grease lubricates most efficiently within the listed temperature range. Melting temperature is the point at which grease will fail and run out of equipment, leaving it to run dry.

This grease comes in cartridges that only work with our Controlled-Use Food-Grade Lever-Grip Grease Guns to make sure that the right grease is used in food-processing areas. It is NSF registered H1 for incidental food contact.

Whitmore and Shell Lubricants Announce Definitive Agreement to Form Joint Venture to Provide Industrial Products and Services to North America Rail and United States Mining Customers

DALLAS, Jan. 22, 2021 (GLOBE NEWSWIRE) -- CSW Industrials, Inc. (NASDAQ: CSWI) and Pennzoil-Quaker State Company dba SOPUS products (“Shell”), a wholly owned subsidiary of Shell Oil Company that comprises Shell’s United States (“U.S.”) lubricants business, announced today the execution of a definitive agreement under which Whitmore Manufacturing, LLC (“Whitmore”), a wholly owned subsidiary of CSWI, and Shell will form a joint venture (“JV”) to market, distribute, and sell lubricants, greases, coolants, reliability products, and related industrial services to the North America rail and U.S. mining sectors. The JV, which will be named Shell & Whitmore Reliability Solutions, LLC, is expected to be owned fifty percent by each of Whitmore and Shell.

The JV will combine the strengths of Whitmore and Shell to offer multi-sector expertise; advanced equipment technologies and services; and an integrated product portfolio that meets the unique needs of companies engaged in North America Class I, II, and III rail (excluding municipal transit systems) and U.S. mining (excluding quarries).

Joseph B. Armes, CSW Industrials Chairman, President, and Chief Executive Officer, commented, “Today’s announcement represents a first step toward offering a comprehensive portfolio of products and solutions to rail and mining customers. When Shell first approached us about this opportunity to form a partnership, our team quickly realized the value in an expanded commercial relationship with a world class organization to drive accretive growth for shareholders, promote proprietary products and technologies to customers, and increase capacity utilization at Whitmore’s existing manufacturing facility.”

“Whitmore and Shell customers are at the heart of the rationale for creating this JV,” noted Machteld de Haan, President of Shell Lubricants Americas. “The resilient B2B sectors are key pillars for the future of Shell Lubricants, where we see a lot of opportunity for growth to support the market. Partnering with Whitmore, a leading provider of reliability products, high-performance greases, friction modifiers, and rail products, in creating this JV helps us to progress toward the execution of this strategy.”

The JV will be staffed by Whitmore and Shell sales and technical professionals with extensive experience in the rail and mining sectors, enabling the successful transfer of relationships, technical knowledge, and sector expertise. The products manufactured and sold by the JV will benefit from Shell’s and Whitmore’s proprietary industrial lubricant and grease formulations and technologies.

A key part of the JV’s success will be its manufacturing agreement with Whitmore. The JV’s production assets will be co-located at Whitmore’s Rockwall, Texas facility and operated by Whitmore, where the JV will benefit from Whitmore’s scale and expertise. This structure is expected to optimize Whitmore’s existing manufacturing capacity through increased production output to be contributed by both Shell and Whitmore, and to position the JV for future growth.

An additional benefit of the companies’ collaboration is an expanded commercial relationship between Whitmore and Shell, which is expected to significantly broaden the reach of Whitmore’s reliability products through Shell’s extensive distribution channels throughout the Americas (excluding the JV’s business sectors).

Armes added, “Through this JV and our expanded distribution relationship with one of the premier brands in the reliability industry, we expect to expand our reach across the Americas and to enhance utilization at our world class Whitmore Manufacturing facility in Rockwall, Texas. We look forward to strengthening our partnership with Shell, while supporting the effort with our decades of experience in the production of small batch customized products for specialized applications.”

The JV is subject to customary closing conditions and expects to commence operations in the first half of calendar 2021. As Whitmore and Shell work toward the successful formation of the JV, each company’s representatives will provide separate communications to respective in-scope customers with key information regarding the potential transition of business to the JV.

The term ‘Shell Lubricants’ collectively refers to the companies of Royal Dutch Shell plc that are engaged in the lubricants business. Shell Lubricants companies have led the global lubricants industry by volume for more than 14 consecutive years.* The companies manufacture and blend products for use in consumer, heavy industrial, and commercial transport applications. The Shell Lubricants portfolio of top-quality brands includes Pennzoil®, Quaker State®, FormulaShell®, Shell TELLUS®, Shell RIMULA®, Shell ROTELLA® T, Shell SPIRAX®, Shell Gadus®, and Jiffy Lube®. http://www.shell.us

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions, including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Most wire ropes are lubricated during the manufacturing process, but this lubricant will not last the entire life of the rope. When looking for a lubricant to relubricate your wire rope, choose one that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, can penetrate between wires and strands, has high fluid film strength, resists oxidation and remains pliable. It is important to remember that most wire ropes fail from the inside out. Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

Because most wire ropes fail from the inside, it is critical to ensure the center core receives sufficient lubricant. LE recommends a combined regimen in which a penetrating lubricant is used to saturate the core, followed by a coating lubricant to seal and protect the outer surface. LE offers several penetrating and coating type wire rope lubricants to suit your specific needs.

Penetrating lubricants contain an evaporative solvent that facilitates migration of the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film that protects and lubricates each strand.

Wirelife Almasol Coating Grease (451-453) is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Wirelife Almasol Coating Lubricant (2002) is a fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust – even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

Wirelife Almasol Syn Coating Lubricant (2022) is an extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength. Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol, LE’s exclusive wear-reducing additive.

Wirelife Monolec Penetrating Lubricant (2001) has excellent corrosion resistance and high load-carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core. Available in bulk sizes or in an aerosol version.

Typical Applications: All stationary or moving wire ropes or cables under heavy loads; chains of all sizes; mining and construction applications such as standing and running lines, draglines, cranes and derricks; marine applications such as cranes, hoists and drilling rigs; any other application that requires excellent rust protection for steel parts.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife Low Tox Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Earthwise EAL Wire Rope Grease (3353) is recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation.

Typical Applications: Applications near or around waterways including: Wire rope; chain links, pins and bushings; cable sheave bushings, bearings and strands; open and closed silent and roller chains. Ideal for use in automatic lubrication systems.

LE is happy to offer industrial lubricant and reliability recommendations for a variety of applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our wire rope lubricants, wire rope lubricators as well as our other enhanced lubricants and lubricant reliability products, please

8613371530291

8613371530291