shock loading wire rope manufacturer

Shock loading can occur in any situation where the load on the crane suddenly increases. The crane and accessories are designed to take up the weight of loads gradually and steadily. They are not designed to withstand sudden increases or decreases in the apparent weight of the load. Some examples of how shock loading can occur are shown below.

Operators and equipment owners should be aware of the causes and potential dangers of shock loading. Because the equipment is being used in a way that it is not designed for, shock loading can lead to damaging the equipment, the facility, or injuring personnel. Understanding the causes of shock loading will help to prepare operators to safely and accurately operate the equipment.

Skilled operators are a company"s first defense against shock loading. Lifting and lowering should always be done in slow speed until all slack has been taken out of the wire rope and any below the hook devices. Additionally, operators should be aware of their surroundings, making sure that the load they are lifting is not likely to snag on other pieces of machinery or the building itself. When lifting or lowering the load, operators should be careful to make sure the load is not bouncing as they operate the hoist. Additionally, operators should ensure that their loads are secure and well balanced.

Beyond operator training and best practices, features such as the HoistMonitor®assist operators in preventing shock loads. The HoistMonitor ensures that starting and stopping is initiated in slow speed, which helps prevent a jumping motion of the load. Sudden load supervision, also a standard feature of the HoistMonitor, prevents the hoist from continuing the hoisting motion when a load increase is suddenly detected, like if the load snagged on another item.

When overloads and shock loads occur in a rigging operation, the results can be deadly. A failure of gear or equipment can take place at the time the over/shock load happens or in many cases weeks, months or years later.

Most of us are familiar with the statistics used in rigging books and charts on the affects of shock loading. When a load of “X” pounds is allowed to free-fall or is popped off the ground, it introduces a load to the lifting device which can be two times or more its static weight. This compounding of weight takes its toll on the load’s internal and external structure, rigging attachment points, all rigging hardware, slings, hoist hook, running ropes, drum and entire hoisting system whether overhead or mobile crane.

A typical method of shock loading results from turning or flopping a load over from one plane to another. (Actual case) A coal-fired steam plant uses pulverizer journal assemblies to crush the coal into a fine talc - like powder for burning. The journals are awkward and difficult to handle with no available lifting lugs. After a journal is pulled from service and it has received maintenance, it is transported back to the pulverizer unit. A bridge crane picks up the journal from its vertical carrying cradle and sets the base on the floor. The crane then trolleys to pull or “flop” the journal over to a 45 degree angle. A special sling assembly is then used to hoist the journal into the pulverizer cavity.

During the “trolley and flop” movement, the slamming of the journal arms into their chain slings sends dust and dirt flying off the overhead bridge crane. How much weight in real pounds was introduced to the crane? Has anything happened to the crane’s structure? Does anyone suspect a broken weld, metal fatigue fracture or that damage has possibly occurred to the hoist system or wire rope? What if this happens twice a month for four years? Your imagination can provide many unwelcome answers to these questions.

Have you ever heard an employee say, “We were only lifting 2 tons on our 5 ton bridge crane and the whole thing came down on top of us!” Was it the 2 ton lift that caused the accident? Certainly not! It was the four years of repeated abuse, shock loading and structural damage which turned a fine bridge crane into a life threatening bucket of bolts.

If you have these situations in your operation, do everything possible to develop alternative rigging methods. Make a comprehensive inspection of all hoisting and rigging components. Using the proper procedures for each type of equipment perform load tests and make another inspection to ensure reliability. (Always check with the equipment manufacturer for testing procedures and limitations.)

Even with experienced crane operators, it can be challenging to lift a load without incurring stress to the crane, the load or the building’s structure. That’s because, before a load lifts off the ground, the rigging gear is loose and any upward hoisting would first move the rigging gear, not the load. Once the rigging gear is taut and the load is engaged, however, the hoist must be operated very slowly so as not to jerk the load into the air. Excess speed during the critical time of lifting the load off the ground can “shock” the crane system, causing high stress.

Konecranes has the answer: Shock Load Protection. With Shock Load Protection, the hoist drive monitors the load. If it is picked up too fast, the hoisting speed is automatically reduced until the load is in the air. This protects the crane, lifting load and the whole building from extra stress. This, in turn, provides lower maintenance costs for the crane and maximizes cycle times by reducing hoisting speed only during the critical moment of lift off.

Shock Load Protection is designed for smooth load pickups and works to prevent shocks to the load and the crane, extending the lifetime of the crane’s steel structure and mechanical parts. Shock Load Prevention is a feature of Konecranes Variable Frequency Drives for hoist control, and it works to eliminate shock loads automatically. With this automated feature, the operator can focus on controlling the load, monitoring his or her environment and ensuring that the load remains secure. Without the operator needing to purposely slow down operation as the hoist is raised, the crane can operate efficiently, speeding up operation while decreasing the mechanical wear and tear on the overhead crane.

Shock Load Protection is available for overhead cranes with, or with the capability of having, Variable Frequency Drives. Contact a Konecranes Representative to see if Shock Load Protection or any of our other Smart Features, can help your business.

Before we address shock loading let us take the time to understand the difference between static and dynamic forces. Static force is stationary. Static force usually refers to an object not in motion. Whereas dynamic force refers to an object that has unequal forces acting upon it. Rapid acceleration in lifting and rapid deceleration in lowering of a small or large load can result in what is often referred to as dynamic load.

Remember Newton"s second law? F = ma Force equals mass times acceleration. Acceleration refers to a change in the rate of velocity. Assuming we are referring to the same mass (size of the object), we see that the force exerted on an object is proportional to the acceleration it is given. This is the basis of the phenomena known as shock loading.

Generally speaking shock force or shock loading occurs when an operator takes up sling slack rapidly or suddenly releases the load creating a sudden jerk. Both rapid acceleration and deceleration of a load can create a shock force that far exceeds the working load limit of the wire rope. Always remember that the sudden release of a load can cause internal and external damage to a wire rope. Why is the safe working load limit of rigging slings and crane lines significantly lower than their minimum breaking strength? A safety factor must always exist. Remember that minimum breaking strengths are stated for static, straight lifts or pulls.

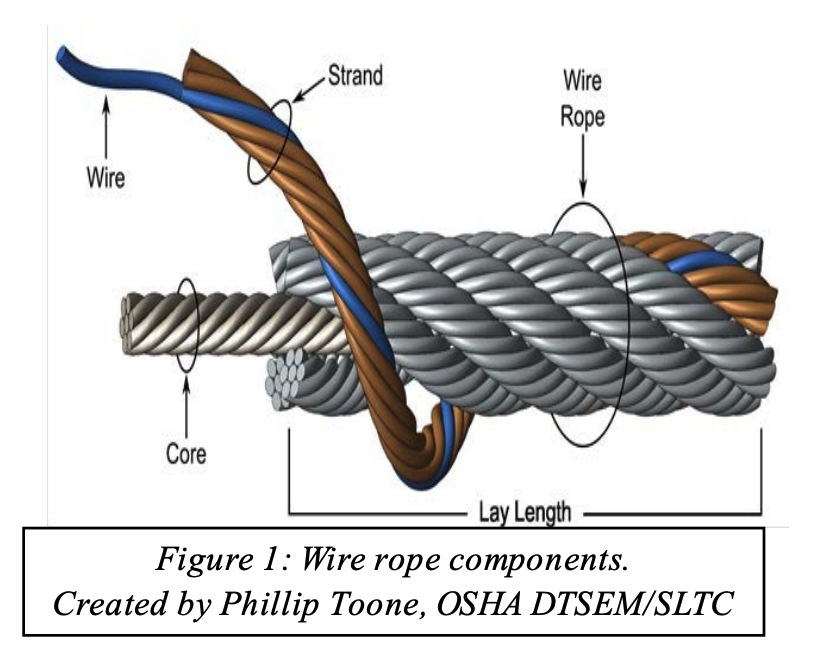

The four pictures in this post clearly illustrate what shock force or shock loading will do to a wire rope. Note the one strand has become unraveled from the other strands in forming the wire rope. Look closer and you will note broken wires at different points of the strand. Remember a series of individual wires make up each strand on a wire rope.

Done properly, it is better than standard lifting gear that is required and this must be compliant for a special lifting environment – another thing to remember!

Not really – a special lifting environment is a predictable scenario and should be accounted for… but if overloading occurs sometimes the after effects can look pretty similar. There are lots of reasons for shock loading, but there are basically two types of shock loading. These are:

There are two basic damage mechanisms. The simplest of these is overloading. At some point the ‘shock’ exerts a peak force that is sufficient to damage something.

- A jib arm might be built to resist downward loads very well, and although it should be built very stiff it will still deflect under load. This means that if the load is released rapidly, there is stored energy in the jib and it can flick back up – loading it in reverse!

- A lifting system might have different parts which share the load forces, but which react to those forces at different rates. A classic example being a rotation resistant rope. If the load share on the rope core is applied or released too fast then the core no longer shares load with the strands and the resultant imbalance can cause the rope to have a hernia – which we call a ‘birdcage’.

The right rigging gear, and the right advice is the starting point for safe lifting and avoiding many things which can lead to shock loading. Nobles can supply you with the right lifting gear, the best inspection and maintenance services, and the right advice. We also offer loadcells and engineering services to analyse the lifting gear design, the lift study, and (should the worst occur) the aftermath – with scientific investigation of shock load damage.

To understand shock forces you must know that there exists static (not in motion) forces, and dynamic (in motion) forces. In the real world we rarely have just simply static forces occurring during lifts. Even small amounts of speeding up or slowing down of the load result in dynamic loads. The very act of even slow lifting often results in some forces caused by movement such as swinging and drifting.

However, the force we are talking about it the one that occurs rapidly as opposed to slow dynamic forces. Shock force is more commonly referred to as shock load. This derives from the fact that engineers routinely refer to forces occurring in and on structural members as loads. In rigging a load is an object to be lifted or flown from one point to another point, hence the use of the phrase shock force in this article.

Shock forces can occur for any number of reasons, most notably; an operator taking up sling slack with a sudden jerk, the rapid acceleration or deceleration of the load, failure of fair leads or sheave guides to prevent the rolling out of a slack line.

The magnitude of a shock force can be many times that of the weight of the load be lifted. This is why the safe working load of rigging equipment is substantially lower than the minimum breaking strength. Minimum breaking strengths are stated for static, straight pulls. A factor of safety must therefore exist.

The amount of force created in a shock situation is dependent on, among other things, the weight of the load and the distance of travel. The exact determination can be quite complicated because the value of the load"s stopping distance is based on the amount of elastic stretch.

In order to precisely calculate the stopping distance we would need to know the exact composition of the wire rope, the equivalent cross sectional area, and the apparent modulus of elasticity of the wire rope composite, and then use a complicated formula to calculate the exact amount of elastic stretch*.

Many manufacturer"s websites state that there exists no practical method to estimate shock force. Gelrum** provides an example of a 75 foot long (L) 1⁄4 inch diameter galvanized cable sling subjected to a shock force by the sudden dropping of a 500 pound load 6 inches. The resulting shock force is 2,296 pounds, a value over 4 times the weight of the load!

*A free applet, or automated calculator, for wire rope elastic stretch is located online at:http://www.macwhyte.com/Technical/Metallic-Area-Elastic-Stretch-Calculator

Avoid shock loading to nylon or wire rope slings when beginning your lift. The crane or hoist should be engaged slowly until the load is suspended. The speed in which you lift or lower the load should be increased or decreased gradually. Sudden starts or stops place a heavy load on the slings and load line, up to 50 times the actual weight. Once any sling has been shock loaded it must be removed from service.

Manufacturers identify their classes of wire ropes beginning with two numbers such as 6x25. The "6" means that there are 6 strands or larger wires making up the wire rope and the second number "25" means that there are 25 smaller wires laid around each other to make up each strand. The other wires in some wire ropes are called filler wire. Wire fatigue resistance will increase as the number of wires per strand increases.

Known as the industry workhorse of wire ropes, the 6x25 Filler Wire maintains a good balance between resistance to abrasion and fatigue resistance. When both abrasion resistance and fatigue resistance are required, the 6x26 Warrington Seale is a better alternative.

Keep the wire rope lubricated so that rust and dirt will not weaken it by acting as an abrasive on the rope as it spools through the sheaves and drums. Lubrication of the rope allows individual wires to move and work together so that all the wires carry the load instead of just a few. Weather and other exposures can also remove

Natural and synthetic fiber rope offerings have expanded over the past years with the introduction of new materials such as Kevlar and other advancements that can provide a higher strength and a better

Recommended working loads will vary according to the rope size, type and manufacturer. Twisted rope is oftentimes has the working load listed between 10% to 15% of the tensile strength and braided rope is between 15% to 20%. Therefore, a braided rope with a listed tensile strength of 12,500 pounds might only have a safe working load of 1,850 pounds. Ropes have different qualities and you should carefully assess your rigging requirements. In example, Kevlar has a considerably higher breaking strength than most available products,

It is necessary to check with your cordage vendor to obtain the safe working load of your rope prior to purchasing it for any rigging or lifting purpose!

Many factors, including rope usage, load conditions and weather exposure affect the rope’s working load capabilities. You should inspect your rope daily for concentrated wear. It must be free of frayed strands and broken yarns, cuts and abrasions, burns and discoloration. If there is excessive soiling or paint buildup, place it out of service. Check for chemical or heat damage and ultraviolet deterioration. This type of degradation is indicated by discoloration and the presence of splinters and slivers on the rope surface. Do not use wire rope or V-belt sheaves for synthetic rope as the rope will be pinched inside.

The use of rope for any purpose results in friction, bending and tension. All rope, hardware, sheaves rollers, capstans, cleats, as well as knots are, in varying degrees, damaging to ropes. It’s important to understand that rope is a moving, working, strength member and even under the most ideal conditions will lose strength due to use in any application. Maximizing the safety of rope performance is directly related to how strength loss is managed and making sure ropes are retired from service before a dangerous situation is created. Ropes are serious working tools and used properly will give consistent and reliable service. The cost of rope replacement is extremely small when compared to the physical damage or personnel injury that can result from using a worn out rope.

There are basically three steps to consider in providing the longest possible service life for ropes, the safest conditions and long range economy: Selection, Usage and Inspection.

Selecting a rope involves evaluating a combination of factors. Some of these factors are straight forward, like comparing rope specifications. Others are less qualitative, like color preference or how a rope feels while handling. Cutting corners, reducing design factors, sizes or strengths on an initial purchase creates unnecessary replacements, potentially dangerous conditions and increased long term costs. Fiber and construction being equal, a larger rope will outlast a smaller rope, because of greater surface wear distribution. By the same token, a stronger rope will outlast a weaker one, because it will be used at a lower percentage of its break strength and corresponding Work Load Limit with less chance of overstressing. The following factors should be considered in your rope selection: Strength, Elongation, Firmness, Construction and Abrasion.

When given a choice between ropes, select the strongest of any given size. A load of 200 pounds represents 2% of the strength of a rope with a 10,000 Lbs. breaking strength. The same load represents 4% of the strength of a rope that has a 5,000 Lbs. breaking strength. The weaker rope will work harder and as a result will have to be retired sooner. Braided ropes are stronger than twisted ropes that are the same size and fiber type.

Please note that the listed break strengths are average break strengths and do not consider conditions such as sustained loads or shock loading. Listed break strengths are attained under laboratory conditions. Remember also that break strength is not the same as the Work Load Limit.

It is well accepted that ropes with lower elongation under load will give you better control. However, ropes with lower elongation that are shock loaded, like a lowering line, can fail without warning even though the rope appears to be in good shape. Low elongating ropes should be selected with the highest possible strength. Both twisted ropes and braided ropes are suitable for rigging. Size for size, braided rope has higher strength and lower stretch than a twisted rope of similar fiber. See page 390 for additional information on rope elongation.

Select ropes that are firm and hold their shape during use. Soft or mushy ropes will snag easily and abrade quickly causing accelerated strength loss.

Rope construction plays an important role in resistance to normal wear and abrasion. Braided ropes have a basically round, smooth construction that tends to flatten out somewhat over the bearing surface. Flattening distributes wear over a much greater area, as opposed to the crowns of a three strand or to a lesser degree, an eight strand rope.

All rope will be severely damaged if subjected to rough surfaces or damaging edges. All rope must be protected against damaging or abrasive surfaces. Wire rope will score and gouge chocks and bitts creating cutting edges that can damage synthetic ropes. Chocks, bitts, drums and other surfaces must be kept in good condition and free of burrs and rust. Weld beads on repaired capstans, fairleads, etc., are equally damaging, unless dressed down smoothly. Pulleys must be free to rotate and should be of proper size to avoid

Avoid using a rope that shows signs of aging and wear. If in doubt, do not use the rope. Damaged rope must be destroyed to prevent any future use. No visual inspection can be guaranteed to accurately and precisely determine the residual strength of the rope. When fibers show wear in any area, the damaged area must be removed and the rope should be re-spliced or replaced. Check regularly for frayed or broken strands. Pulled strands should be rethreaded into the rope if possible. A pulled strand can snag on a foreign object during usage. Both outer and inner rope fibers may contribute to the strength of the rope. When either is worn the rope is naturally weakened. Open the strand of the rope and inspect for powdered fiber, which is one sign of internal wear. A heavily used rope will often become compacted or hard, which indicates reduced strength. The rope should be discarded and made unusable if this condition is detected. See pages 395 and 396 for additional inspection information.

New rope tensile strength is based upon tests of new and unused spliced rope of standard construction in accordance with Samson testing methods, which conform to Cordage Institute, ASTM and OCIMF test procedures. It can be expected that strengths will decrease as soon as a rope is put into use. Because of the wide range of rope use, changes in rope conditions, exposure to the many factors affecting rope behavior and the possibility of risk to life and property, it is impossible to cover all aspects of proper rope applications or to make generalized statements as to Work Load Limits.

Work Load Limits are the load that a rope in good condition with appropriate splices in non-critical applications is subjected to during normal activity. They are normally expressed as a percentage of new rope strength and should not exceed 20% of the stated break strength. Thus, your maximum Work Load Limit would be 1/5 or 20% of the stated break strength.

A point to remember is that a rope may be severely overloaded or shock loaded in use without breaking. Damage and strength loss may have occurred without any visible indication. The next time the rope is used under normal Work Loads and conditions, the acquired weakness can cause it to break.

Normal Work Load Limits do not cover dynamic conditions such as shock loads or sustained loads, nor do they apply where life, limb or property are involved. In these cases a stronger rope must be used and/or a higher design factor applied.

Normal Work Load Limits are not applicable when rope is subjected to dynamic loading. Whenever a load is picked up, stopped, moved or swung there is increased force due to dynamic loading. The more rapidly or suddenly such actions occur, the greater the increase in the dynamic loading. In extreme cases, the force put on the rope may be two, three or many more times the normal Work Load involved. Examples of dynamic loading would be: towing applications, picking up a load on a slack line or using a rope to stop a falling object. Dynamic loading affects low elongation ropes like polyester to a greater degree than higher elongation, nylon ropes. Dynamic loading is also magnified on shorter length ropes when compared to longer rope lengths. Therefore, in all such applications, normal Work Load Limits do not apply.

Work Load Limits as described do not apply when ropes have been subjected to shock loading. Whenever a load is picked up, stopped, moved or swung, there is an increased force due to dynamic loading. The more rapidly or suddenly such actions occur, the greater this increase in force will be. The load must be handled slowly and smoothly to minimize dynamic effects. In extreme cases, the force put on the rope may be two, three or even more times the normal Work Load involved. Examples of shock loading are picking up a tow on a slack line or using a rope to stop a falling object. Therefore, in all applications such as towing lines, life lines, safety lines, climbing ropes, etc., design factors must reflect the added risks involved. Users should be aware that dynamic effects are greater on a low elongation rope such as manila than on a high-elongation rope such as nylon and greater on a shorter rope than on a longer one.

The shock load that occurs on a winch line when a 5,000 Lbs. object is lifted vertically with a sudden jerk may translate the 5,000 Lbs. of weight into 30,000 Lbs. of dynamic force, which could cause the line to break. Where shock loads, sustained loads or where life, limb or valuable property is involved, it is recommended that a much higher design factor than 5 be used.

Remember, shock loads are simply a sudden change in tension, from a state of relaxation or low load to one of high load. The further an object falls, the greater the impact. Synthetic fibers have a memory and retain the effects of being overloaded or shock loaded. Ropes that have been shock loaded can fail at a later time, when used within Work Load Limits.

Wire rope is extremely sturdy and can be used in many different applications. In order to withstand harsh conditions, wire rope has basic guidelines of inspection it must meet. Continue reading to find out the guidelines of inspection for wire rope.

Abrasion damage is usually caused by the rope making contact with an abrasive surface. It can also be caused by simply passing over the drum and sheaves during regular, continued use. To minimize this risk, all components should be in proper working condition and be of appropriate diameter for the rope. Badly worn sheaves or drums will cause serious damage to a new rope and will greatly diminish the integrity of the rope quickly.

Corrosion is hard to assess but is more problematic than abrasion. Corrosion is usually the result of the lack of lubrication. It will most likely take place internally before there are any apparent signs on the rope’s surface. One telltale sign of corrosion is a slight discoloration, which is generally the result of rusting. This discoloration indicates a need for lubrication which should be dealt with as soon as possible. Failure to attend to this situation will lead to severe corrosion which will cause premature fatigue failures in the wires and strands. If this occurs, the rope will need to be removed immediately.

Diameter reduction is an extremely serious deterioration factor and can occur for several reasons. The most common reasons for diameter reduction are excessive abrasion of the outside wires, loss of core diameter/support, internal or external corrosion damage, or inner wire failure.

Examining and documenting a new rope’s actual diameter when under normal load conditions is critical. During the life of the rope, the actual diameter of the rope should be regularly measured at the same location under similar loading conditions. If this protocol is followed correctly, it should divulge a routine rope characteristic—after an initial reduction, the overall diameter will stabilize, then gradually decrease in diameter during the course of the rope’s life. This occurrence is completely natural, but if diameter reduction is confined to a single area or happens quickly, the inspector must quickly identify the source of the diameter loss and make the necessary changes if possible. Otherwise, the rope should be replaced as soon as possible.

Crushing or flattening of wire rope strands can happen for many reasons. These issues usually arise on multilayer spooling conditions but can also develop just by using the wrong wire rope for the specific application. Incorrect installation is the most common cause of premature crushing/flattening. Quite often, failure to secure a tight first layer, which is known as the foundation, will cause loose or “gappy” conditions in the wire rope which will result in accelerated deterioration. Failure to appropriately break-in the new rope, or even worse, to have no break-in protocol whatsoever, will also result in poor spooling conditions. The inspector must understand how to correctly inspect the wire rope, in addition to knowing how that rope was initially installed.

Another potential cause for the replacement of the rope is shock loading (also known as bird-caging). Shock loading is caused by the abrupt release of tension on the wire rope and its rebound culminating from being overloaded. The damage that ensues can never be amended and the rope needs to be replaced immediately.

There are several different instances that might result in high stranding. Some of these instances include the inability to correctly seize the rope prior to installation or the inability to maintain seizing during wedge socket installation. Sometimes wavy rope occurs due to kinks or very tight grooving issues. Another possible problem arises from introducing torque or twist into a new rope during poor installation methods. In this situation, the inspector must assess the continued use of the rope or conduct inspections more often.

There are a lot of guidelines for troubleshooting wire rope. At Silver State Wire Rope and Rigging, Inc., we take these guidelines seriously, and so should you. All of our products are tested and guaranteed to be the best fit for your specific needs. We can also help you with your troubleshooting needs. Contact us today!

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that the load applied to the hook is centered in the base (bowl) of the hook to prevent point loading on the hook, unless the hook is designed for point loading,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Employers must not use improved plow-steel wire rope and wire-rope slings with loads in excess of the rated capacities (i.e., working load limits) indicated on the sling by permanently affixed and legible identification markings prescribed by the manufacturer.

An eye splice made in any wire rope shall have not less than three full tucks. However, this requirement shall not operate to preclude the use of another form of splice or connection which can be shown to be as efficient and which is not otherwise prohibited.

Except for eye splices in the ends of wires and for endless rope slings, each wire rope used in hoisting or lowering, or in pulling loads, shall consist of one continuous piece without knot or splice.

Wire rope shall not be used if, in any length of eight diameters, the total number of visible broken wires exceeds 10 percent of the total number of wires, or if the rope shows other signs of excessive wear, corrosion, or defect.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F (93.33 °C). When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F (204.44 °C) or below minus 60 °F (15.55 °C), recommendations of the sling manufacturer regarding use at that temperature shall be followed.

Wire rope slings shall have permanently affixed, legible identification markings stating size, rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, and the number of legs if more than one.

Employers must not use natural- and synthetic-fiber rope slings with loads in excess of the rated capacities (i.e., working load limits) indicated on the sling by permanently affixed and legible identification markings prescribed by the manufacturer.

In manila rope, eye splices shall contain at least three full tucks, and short splices shall contain at least six full tucks (three on each side of the centerline of the splice).

In layed synthetic fiber rope, eye splices shall contain at least four full tucks, and short splices shall contain at least eight full tucks (four on each side of the centerline of the splice).

Strand end tails shall not be trimmed short (flush with the surface of the rope) immediately adjacent to the full tucks. This precaution applies to both eye and short splices and all types of fiber rope. For fiber ropes under 1-inch diameter, the tails shall project at least six rope diameters beyond the last full tuck. For fiber ropes 1-inch diameter and larger, the tails shall project at least 6 inches beyond the last full tuck. In applications where the projecting tails may be objectionable, the tails shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F (-28.88 °C) to plus 180 °F (82.2 °C) without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under 1 inch (2.54 cm) in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope 1 inch (2.54 cm) in diameter and larger, the tail shall project at least 6 inches (15.24 cm) beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Employers must use natural- and synthetic-fiber rope slings that have permanently affixed and legible identification markings that state the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

MLA style: "Understanding shock loads.." The Free Library. 2013 United States Institute for Theatre Technology, Inc. 10 Dec. 2022 https://www.thefreelibrary.com/Understanding+shock+loads.-a0332379147

Chicago style: The Free Library. S.v. Understanding shock loads.." Retrieved Dec 10 2022 from https://www.thefreelibrary.com/Understanding+shock+loads.-a0332379147

APA style: Understanding shock loads.. (n.d.) >The Free Library. (2014). Retrieved Dec 10 2022 from https://www.thefreelibrary.com/Understanding+shock+loads.-a0332379147

Examine slings for wear, fatigue, crushed or broken wires, kinking, ballooning or "bird-caging", heat damage, etc. Check both before and after using slings to detect any damage or defects. See Hoist wire rope for more inspection tips.

8613371530291

8613371530291