single wire rope sling quotation

M-sling Standard Eye Wire Rope Slings are popular at construction sites because of their low cost and resistance to abrasion in rugged work environments. These Mechanical Spliced Eye to Eye Wire Rope slings are the most economical wire rope sling designed for general purpose applications.

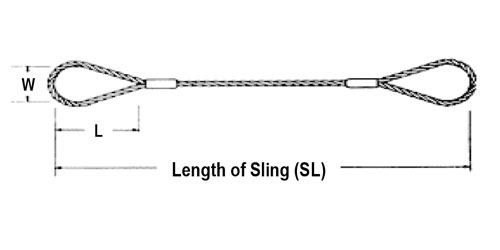

Single Leg Wire Rope Slings otherwise known as eye/eye or Eye & Eye slings are manufactured from high-quality wire rope that has been engineered and mechanically spliced to form the non-reinforced soft eyes found at each end.

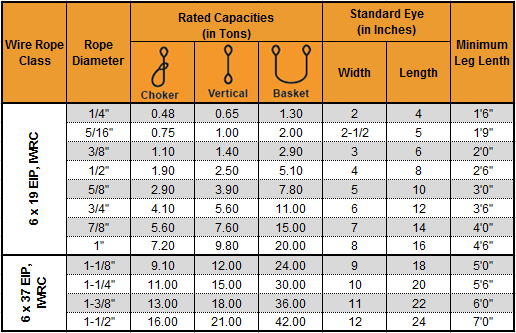

Available online with diameters up to 1inch and capacities up to 9.8Tons and lengths of 20ft as well as larger sizes offline. Single body wire rope slings are also offered with various different end terminations like thimble eyes and hooks to suit a variety of industries such as offshore, engineering, automotive, recycling, oil & gas and many others.

Proudly assembled in the USA, our slings are fitted with a robust identification tag displaying the unique serial number and Working Load Limit. Made from an Independent Wire Rope Core (IWRC), our wire slings offer resistance to crushing and less stretch whilst still manageable and flexible. Manufactured from Extra Improved Plow Steel (EIPS).

For further information, advice and quotations on multi-leg or larger sizes of Single Leg Eye & Eye Wire Rope Slings please contact a member of our sales team who will be happy to help.

IMPORTANT: All of our Wire Rope Slings & Chokers are manufactured on demand (extremely quickly) to your exect order, right here in Houston, TX. The date of manufacture is also stamped on each sling tag, for these reasons all sling sales are final and cannot be returned or exchanged once ordered.

All Commercial Group riggers are trained to fabricate wire rope slings and bridles with a mechanically spliced flemished eye. The ends are secured by pressing a metal sleeve over the ends of the strands of the splice.

We supply Wire Rope Slings that are manufactured to order in the UK. Our range is so vast with various different types of wire rope avaliable at custom lengths with your desired end terminations such as thimble eyes, sling hooks, C-hooks and more.

Our sales team are here to help you select the right wire rope sling and provide an offer and design that meets not only your expectations but also the budget you have in mind. We ship direct from manufacturer to end user to ensure costs are kept to a minimum saving you time and money. Call today for a free Wire Rope Sling quotation.

Wire rope sling assemblies are the most common and rugged slings used today that can be made in single, double, triple and quadruple leg configurations. In addition to meeting the demanding environments as a standard sling, wire rope sling assemblies can also be braided into multiple parts making them more flexible and able to handle higher capacity by increasing the diameter of the sling. Together, all Bishop Lifting Products riggers are trained to fabricated wire rope slings with a flemished eye, not a Texas tuck or turn back eye splice.

Our sling catalog makes ordering easy to select sling sizes and lengths by dimensions or capacity. For information and pricing, contact sales@lifting.com.

Single leg wire rope slings are just as they sound- they are comprised of a single length of wire rope. Also sometimes known as one leg wire rope slings or single leg cable slings, these heavy duty lifting slings offer some versatility as they can be manufactured with a variety of end configurations.

An eye loop is formed using a flemish eye splice, in which the rope is separated into two parts. One part contains three strands and the other three strands plus the core. These two rope parts are then re-laid back into the opposite direction, forming an eye. The entire area is then secured by a metal pressed sleeve.

Thimble & Thimble Sling: Similar to a traditional eye & eye sling but fitted with protective thimbles on each eye. A thimbled protects the eye from pressure, wear, and tear, to extend the working life of the sling.

Sliding Choker Wire Sling:Sliding choker wire rope slings are made of 6 x 19 EIPS wire rope and have a sliding choker hook between the two eyes that slides from one end to the other for easy hook-up. Sliding wire choker slings feature a regular eye for the top portion of the lifting sling and a thimbled eye for the portion of the sling that loops back to attach to the sliding hook. This helps prevent wear and tear on the sling eye by protecting the steel cable rope from rubbing on the hook. Our sliding wire rope choker slings are also available with a latched choker hook by special order.

Ultra Flexible Cable Laid Sling: Cable laid wire rope slings are manufactured using an ultra-flexible 7 x 7 x 7 galvanized aircraft cable to offer more flexibility than a standard steel wire cable sling. Though the cable laid sling is weaker in strength than the standard wire rope, it offers excellent corrosion resistance. Our standard cable laid metal slings have eyes on both ends but other fittings are also available, including thimbles, hooks, crescent thimbles, and slip-thru thimbles to create the custom steel strand lift sling you need.

As with all lifting slings, the rated capacities of single leg wire slings will vary based on the type of wire rope, as well as the direction and angle of the pull.

Proof testing certificates can be supplied with your order for a nominal fee and must be requested at the time of order. Proof tests are performed in the factory where the sling is pull tested to 2x the vertical rating and officially recorded as proof for governing bodies. During the standard manufacturing process, only random slings during a production run are tested for compliance; in order to provide proof testing certificates with your order, every sling must be pull tested at the time of manufacture.

Wire rope lifting slings, bridles and assemblies provide great durability and high tensile strength for lifting heavy loads. In addition, wire rope lifting slings are lighter in weight and more cost efficient than chain slings. Wire rope slings, sometimes referred to as wire slings, or cable lifting slings, are constructed using a variety of different styles and sizes of steel wire rope. Every style and size of wire rope offers different properties and benefits such as:

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel IWRC (independent wire rope core) core.

Wire rope lifting slings, bridles and assemblies are highly customizable, so if you are unable to find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

The durability of steel cable lifting slings is also put to the test in the harsh environments seen in steel mills and forging facilities. Every steel wire rope configuration will offer different properties and will be better equipped to handle certain applications. Generally, a smaller number of large outer wires will provide more wear, corrosion and abrasion resistance. Conversely, a larger number of smaller outer wires will provide better flexibility and fatigue resistance.

After you decide what construction and size of wire rope fits your application, you must configure the entire sling. Wire rope bridles and assemblies are available in single-leg, double-leg, triple-leg, and quadruple-leg configurations. They most commonly have 2 eyes and are constructed using a mechanical flemish splice. Wire rope lifting slings can be used in vertical, choker and basket hitches. They can also be equipped with a variety of attachments and fittings to accommodate almost any overhead lifting application.

Although wire rope sling fittings and attachment can be reused, the wire rope itself is not repairable. If a wire rope sling fails an inspection, it is to be properly destroyed and disposed of

It is important to inspect wire rope slings regularly and to keep a record of all sling inspections. At Tri-State Rigging Equipment we offer a full range of rigging inspection and repair services. The standards that govern wire rope sling inspection are OSHA 1910.184 and ASME B30.9. It is recommended that wire rope rigging slings first undergo an initial inspection when you receive the lifting sling from the manufacturer. The purpose of this initial inspection is to:

Wire rope slings, bridles and assemblies should also be inspected by a designated and qualified individual every day before use to make sure that the sling is in working condition and will lift its rated capacity. The person performing the inspection should examine all the wire rope, fastenings and attachments on the wire rope sling. The inspector is looking for visual indications of any defects, deformities and general damage that might affect the integrity of the sling.

Depending on your application, it may be recommended that you perform these visual inspections more than once a day. If the wire rope sling is used many times throughout the day, by multiple individuals, across multiple shifts, it is imperative that the sling be inspected before every shift change and before any change in lifting application.

ASME standards further require a thorough periodic inspection to be performed at least once a year by either a professional service provider, or by a Qualified Person. In addition, written records must be kept until the next periodic inspection. The rejection criteria for periodic wire rope sling inspections are as follows:

10 or more randomly distributed broken wires in one rope lay, or 5 or more broken wires in one strand in one rope lay, for strand-laid grommets and single part slings.

If your wire rope sling shows any of the rejection criteria above, you must remove the sling from service, and it must be destroyed. Properly destroying rigging equipment is imperative because you can be held accountable for damage done by people who find and use your discarded slings. Therefore, lifting slings deemed not suitable for service must be destroyed beyond use and beyond repair. The process for destroying a wire rope sling is as follows:

The purpose of daily and periodic wire rope sling inspections is not to get anyone in trouble but rather to gain knowledge of the frequency of use, severity of conditions, and nature of lifts, and consider how all these factors affect your wire rope sling. The most important reason to perform daily and periodic wire rope sling inspections, however, is to keep you and your coworkers safe.

Tri-State Rigging Equipment is a custom manufacturer, service provider and distributor for all wire rope lifting slings serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use.

Specific inspection intervals and procedures are required by the Occupational Safety and Health Act (OSHA) and by ANSI B30.9 Regulations, and the responsibility for performance of inspections is placed squarely upon the sling user by Federal Legislation.

As a starting point, the same work practices which apply to all “working” wire ropes apply to wire rope which has been fabricated into a sling.Therefore, a good working knowledge of wire rope design and construction will be not only useful but essential in conducting a wire rope sling inspection.

But because wire rope is a rather complex machine, no precise rules can be given to determine exactly when a wire rope sling should be replaced. There are many variables, and all must be considered.

Broken Wires: For single-part slings. 10 randomly distributed broken wires in one rope lay, or five broken wires in one strand on one rope lay. For multi-part slings these same criteria apply to each of the component ropes.For the inspection, a broken wire shall only be counted once; that is, each break should have two ends.

Metal Loss: Wear or scraping of one-third the original diameter of outside individual wires. This is quite difficult to determine on slings and experience should be gained by the inspector by taking apart old slings and actually measuring wire diameters.

Distortion: Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope. Slight bends in a rope where wires or strands are still relatively in their original positions would not be considered serious damage. But good judgement is indicated.

Metal Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light rusting usually does not affect strength of a sling, however. In addition to these seven conditions specified by OSHA, the following are also important:

Pulled Eye Splices: Any evidence that eye splices have slipped, tucked strands have moved, or pressed sleeves show serious damage may be sufficient cause to reject a sling.

Unbalance: A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

Disposition of Retired Slings: the best inspection program available is of no value if slings which are worn out and have been retired are not disposed of properly. When it is determined by the inspector that a sling is worn out or damaged beyond use, it should be tagged immediately DONOTUSE. This sling should then be destroyed as soon as possible by cutting the eye and fittings from the rope with a torch. This will help assure that an employee will not mistakenly use a sling which has been retired from service.

Wire rope slings are widely used in the lifting applications and engineering industries for extremely heavy loading. They can be used on wire rope hoist, pulley and block, crane and winch pulling equipment at dockyards and large construction sites.

They are available in single leg or multi legs like the chain slings, however, the wire rope slings are more safety than chain slings for wire rope sling can still hold the load if 1 or 2 wires are broken, while the chain sling will fail for 1 link broken result to the whole chain sling failed.

Usually, we use a less flexible or a stiffer wire rope to assembly for they are more crush and abrasion resistance than a very flexible one since wire rope slings are used in a straight line for lifting connect with a master link on one end and a hook or hooks on the other end, need more load strength than flexibility.

We offer Wire Rope Sling that are mainly used for transporting and shifting of load.These are highly acclaimed for features like durability, hardness and tensile strength. The sling is used in construction, marine and automobile industry. The range is also customized as per specification of client.

8613371530291

8613371530291