skf wire rope lubricator brands

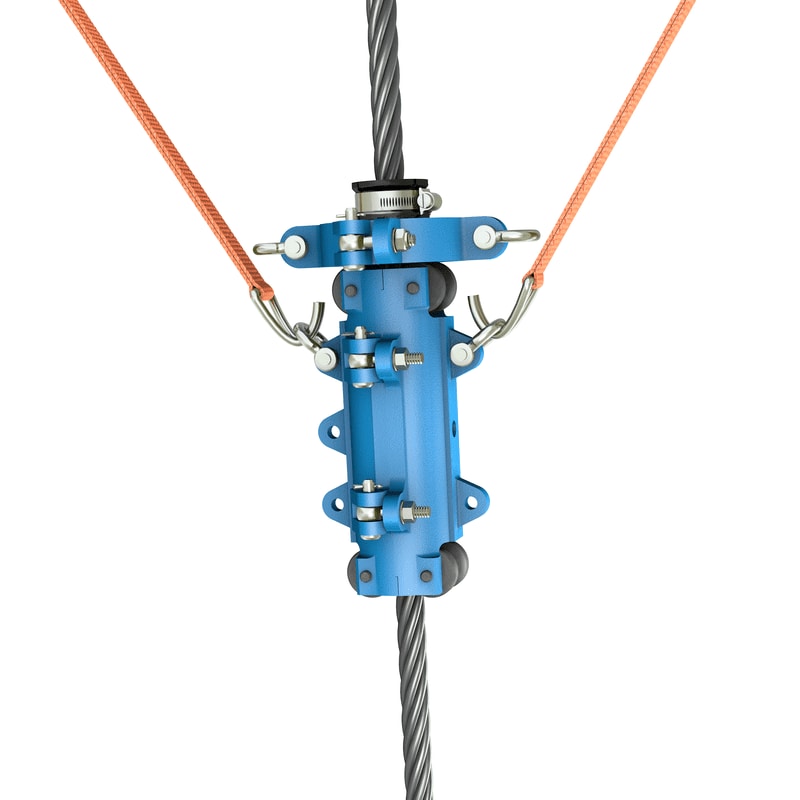

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Developed as a service tool, the Lincoln wire rope lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments, in general.

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste.

Beneits of wire rope lubrication Groove cleaner advantages The use of lubricant on a steel wire rope considerably reduces friction and, as a result, it minimizes the following two related factors: Regular lubrication helps to increase the lifetime of a steel wire rope signiicantly compared to a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general. The...

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste. Advantages: • Fast and eficient – reduces lubrication time by up to 90% vs. manual lubrication • Increases operator safety • Easy to use with any wire rope up to 2 in (52 mm) • Helps to prevent corrosion • Protects the wire ropes...

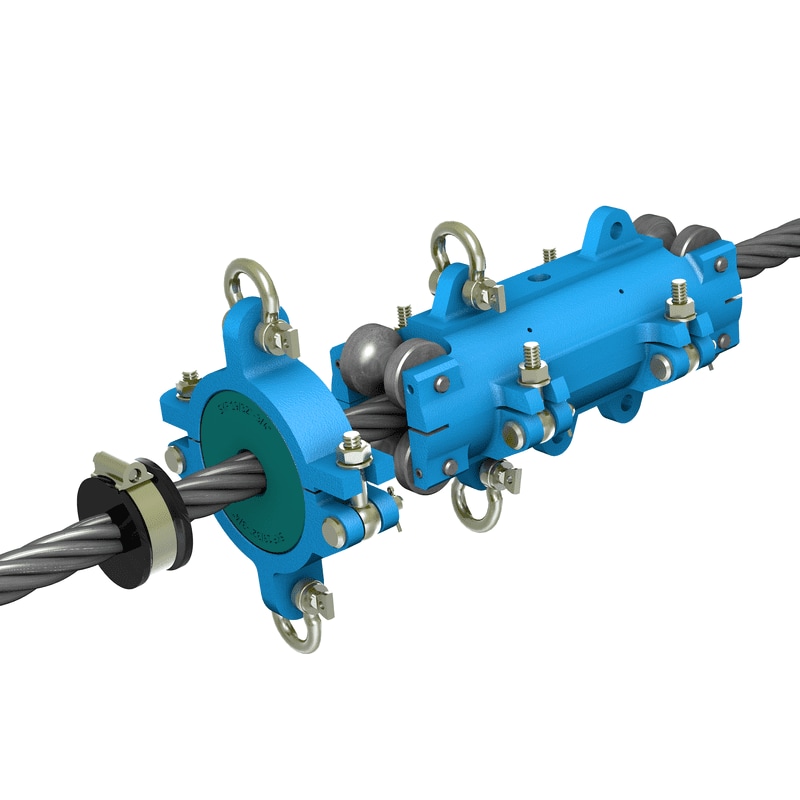

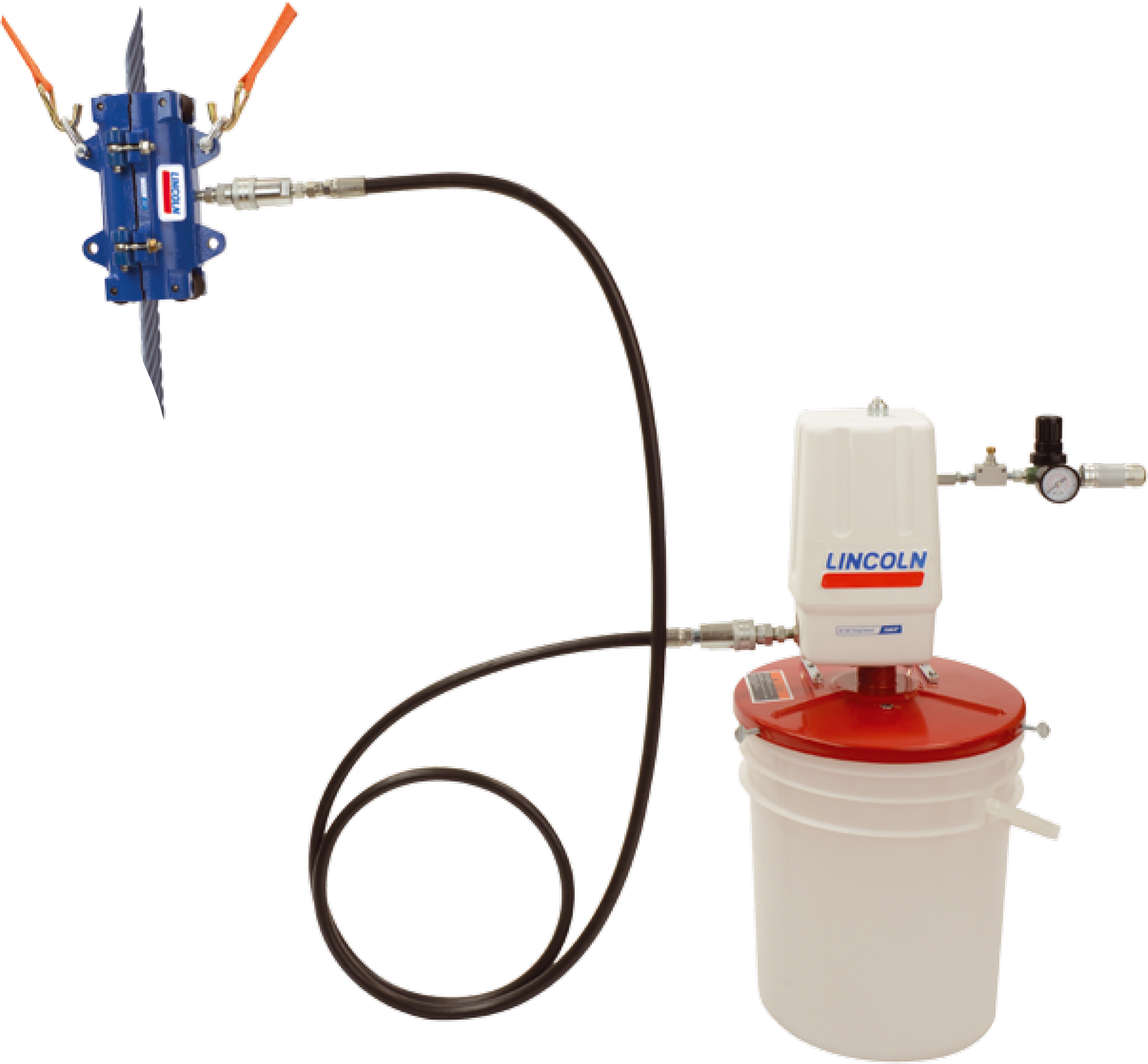

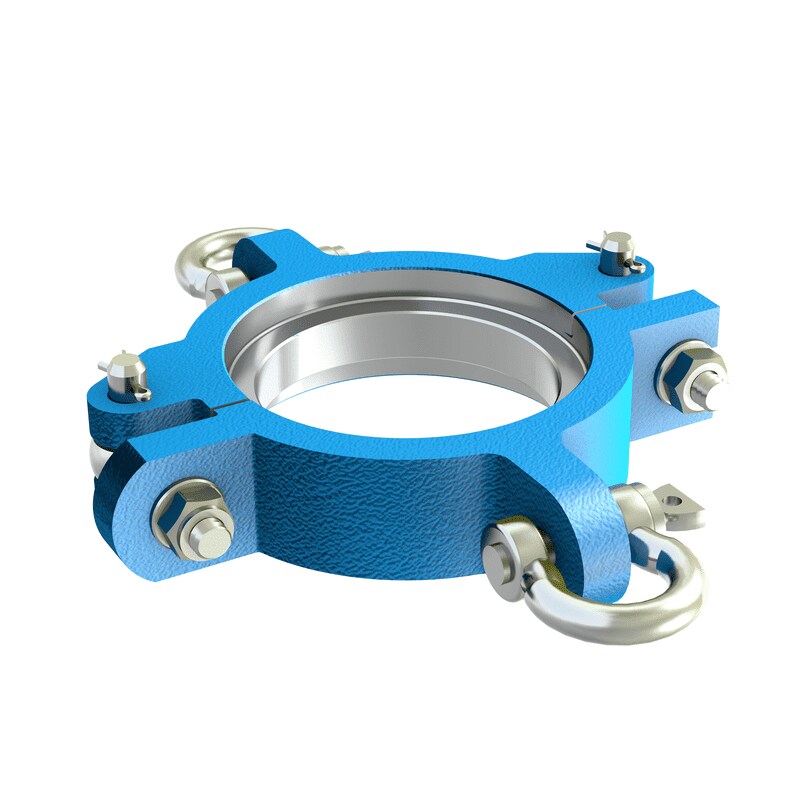

Typical wire rope lubrication system components Ordering wire rope lubrication (WRL) systems: 1 Select seal and roll kit to it the wire rope diameter. Interchangeable kits include seals and rolls to it wire rope diameters in their respective size ranges. Seal and roll kits Seal and roller kit model 3 Select pump and accessory package to it the required grease container size. Pump and accessory packages Nominal wire rope diameter 1) minimum maximum Pump and accessory package includes the Lincoln series 20 50:1 grease pump, air ilter, regulator, gauge, low control, WRL sling with ratchet,...

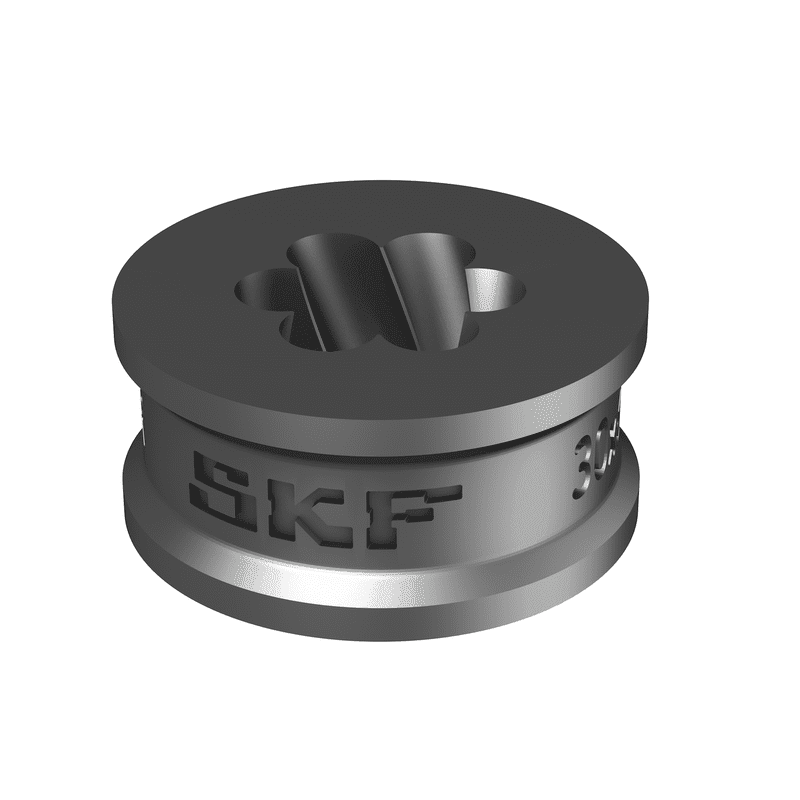

Groove cleaner helps extend wire rope service life Groove cleaner Separating bushing Designed to complement the Lincoln wire rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life. Each groove cleaner is produced individually based on rope speciications to make sure that the device proile matches accurately with the strands. The groove cleaner unit consists of a groove cleaner device, as well as...

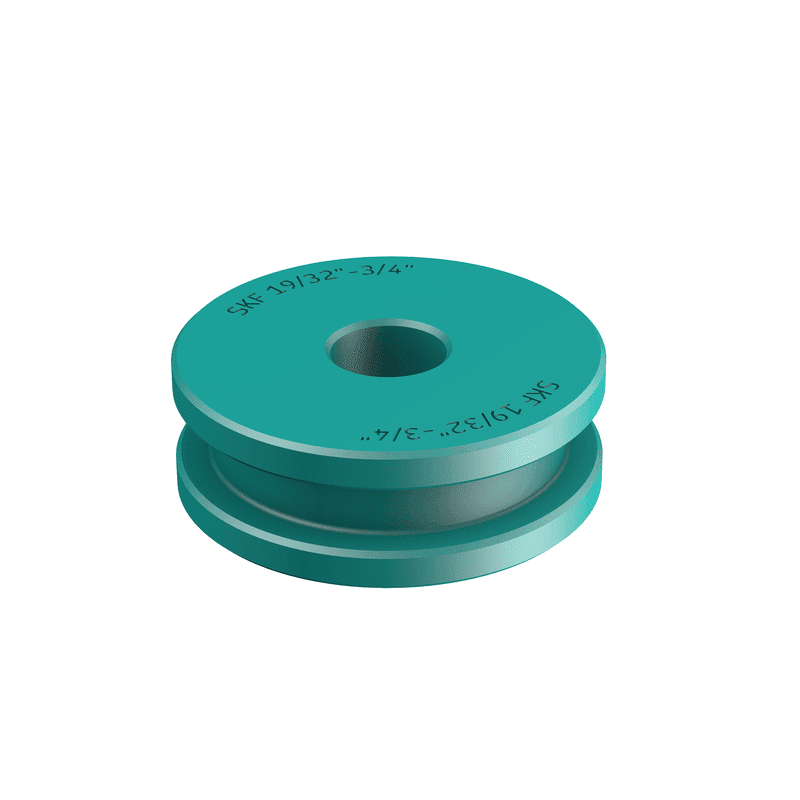

Groove cleaner and separating bushing identiication codes For the correct selection of a groove cleaner and separating bushing, the user must determine the accurate dimensions and type of wire. We recommend the following steps: A Measure the real diameter (A) of the wire rope with a caliper. Identify the number of outer strands. Determine the lay (right or left) of the wire rope strands. 4 Choose the separating bushing that its with the nominal diameter of the wire rope. Separating bushing Order no. Nominal wire rope diameter minimum maximum in For wire rope diameters 19/32" - 3/4" For wire...

6 The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope speciication, or send a sample. To ensure an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included). Groove cleaner element with breeze T-bolt clamp For rope strands with right lay Groove cleaner element with breeze T-bolt clamp For rope strands with left lay Order no. Wire rope diameter in Wire rope diameter in

skf.com/WRL | skf.com/lubrication | lincolnindustrial.com ® SKF and Lincoln are registered trademarks of the SKF Group. © SKF Group 2019 The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB LS/P2 17901 EN · August 2019 Certain image(s)...

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Herewith sharing an interesting story of a new Wire Rope Lubricator (WRL) body field trial test on a Container Terminal, one of the busiest & largest container ports in Europe;

We discussed our customers feedback with our factory & they worked in the design of a bigger WRL body of up to Ø3”. They manufactured a prototype WRL-3, that was send for a field test. Container Terminal has 2 different wire rope dimensions to lubricate in their cranes, Ø28mm & Ø30mm (both Right Lay & with 8 Strands).

From this 1st trial test, we had a lot of positive comments (Groove Cleaner worked perfectly with the new body, evenly distributed grease to the outside surface of the wire rope, higher speeds, etc.) coming from the experienced maintenance personnel of the terminal.

With the new WRL body we cover a wider range of wire ropes. So, the above problems are all solved, and our customers will lubricate more efficiently their wire ropes & with lower investment cost too!

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste.

SKF has launched a fast and efficient wire rope lubrication system to significantly reduce maintenance time and extend service life in a number of diverse applications. The Lincoln wire rope lubricator (WRL) has been developed to eliminate manual lubrication and is available in a range of models for use with any wire rope up to 52mm in size.

The service tool has been designed to deliver highly effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely operated vehicles and winding machines in mines. Used as part of the maintenance cycle, the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also dramatically reducing downtime.

Supporting all lubricants typically used with wire rope, the system ensures optimum lubrication by applying the exact amount of grease required and distributing it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it reduces lubrication time by up to 90 per cent compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

The easy to use wire rope lubrication system comes to the market following extensive field testing. It is ultra-reliable and features an extremely robust design, making it ideal for long-term use in even the most challenging environments and harsh conditions.

Commenting on the new Lincoln WRL, Tim Veal, Lubrication Systems Business Manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.”

Developed as a service tool, the lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate steel wire ropes. The Lincoln wire rope lubricator eliminates manual lubrication and, in turn, yields less downtime and longer service life. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation, which increases service life. The wire rope lubricator is easy to use and supports all types of grease lubricants typically utilized for this task.

• Modern wire rope was invented in Germany 180 years ago.• In the last half of the 19th century, wire rope systems were used for • cable cars • line shafts • elevators • draw bridges • suspension bridges

• Lincoln’s history with Wire rope systems • Wire rope lubrication products were made in the SKF, Rosiaro, Argentina facility • Sold only in Latin American region

Test Process:1. Lubricate 1” wire rope with brush – Check surface coverage – Open the wire rope to see if the lubricant reaches the core – Record rope speed

2. Lubricate 1” wire rope with WRL – Check that the entire wire rope surface is lubricated – Open the 1” wire rope to see if the lubricant reaches the core – Record rope speed

Test result:• With WRL • grease reached the core • wire rope speed was 25 meters/ 27 yards per minute• Manual w/ brush • grease did not reach the core • wire rope speed was 1.5 meters / 1.6 yards per minute

For this test, we only lubricated the lower section of the wire rope

WRL Installation step: Installed1. Attached WRL around the wire rope2. Secured WRL with the sling3. Connected the pneumatic pump SKF Pneumatic pump for 20kgs container ; Test only, replaced by SKF Lincoln brand pump for global markets

Transversal displacement of the wire rope

Wire rope lubricated with WRL, penetrates the strands Wire rope lubricated by brush on surface only

Model Description Wire rope diameter Inches mm 802175 Small WRL body 7⁄16-1 11.1 – 26.9 802180 Large WRL body 1-1⁄16- 2 28 – 52.3

• Lubrication benefits are: • Reduces friction • Protects against corrosion • Enables lubricant to adhere to each wire for long lasting protection

• Properly lubricated wire rope lasts 6 to 8 times longer than a wire rope that has not been lubricated.• Lubricating a wire rope while in service helps prevent corrosion• Corrosion can be internal and/or external ● It can be caused by acids, alkaline waters, salt air, humidity, fumes, abrasive and industrial environments• “Hands free” wire rope lubrication method reduces accidents

Features Benefits• WRL system developed by SKF • System meets customer WRL LBU knowledge and expertise requirements by penetrating wire rope core with grease for complete• Manufactured in SKF LBU lubrication vs. surface only facilities to strict SKF quality • Easy to install and set up standards • Easy to control • Confidence in quality and• LINCOLN BRAND Wire rope specifications lubricator body - robust design – • Long lasting in HD applications • Low cost of ownership• Pumps are proven Lincoln • Less down time Series 20 / Lubrigun design • No pump air valve packing to wear • High ratio and volume out • No springs to rust or fatigue • Supports all types of grease used • Hardened steel slide valve for wire rope lubrication

• The high pressure Lincoln wire rope lubricator • Eliminates manual lubrication • Forces grease through the entire wire rope to reduce friction for longer service life

• SKF & Lincoln have more than 100 years lubrication and friction control experience. We are applying this experience to wire rope lubrication.

• We have tested cleaners, but we are not ready to sell them yet. While competitive systems may clean the wire rope, they still leave waste behind

© SKF Group Slide 69 17 February, 2020 What is the indication the grease has reached the wire rope core? • OK if you see a small amount of grease bypassing seal when WRL is pressurized.

• One seal & roll kit cannot be used for different wire rope sizes unless they fall within the seal & roll kit measured size range on the chart.

Corelube designs, engineers & manufactures state-of-the-art, wire rope lubricators/lubricator & wire rope cleaning tools. Corelube has been solving wire rope maintenance problems for over 40 years.

The key to maintaining wire ropesis protecting the interior core wires from corrosion and wear with protecting the exterior from the elements and extreme wear conditions. Corelube Equipment has designed wire rope lubrication systems that address both of these issues.

We believe there is no one size fits all solution when it comes to wire rope lubrication. With 40 years of designing wire rope lubrication systems, we believe our systems are the most advanced/environmentally friendly systems out there.

Wire rope lubricants with good penetrating properties are key to preventing internal corrosion & wear. Corelube highly recommends wire rope lubricants that transition from penetrating oil to grease.

The Lincoln wire rope lubricator (WRL) has been developed to eliminate manual lubrication and is available in a range of models for use with any wire rope up to 52mm in size.

The service tool has been designed to deliver effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely-operated vehicles and winding machines in mines. When used as part of the maintenance cycle, SKF says the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also reducing downtime.

Supporting all lubricants typically used with wire rope, the system applies the exact amount of grease required and distributes it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it is said to reduce lubrication time by up to 90% compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

Tim Veal, lubrication systems business manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.”

8613371530291

8613371530291