skf wire rope lubricator quotation

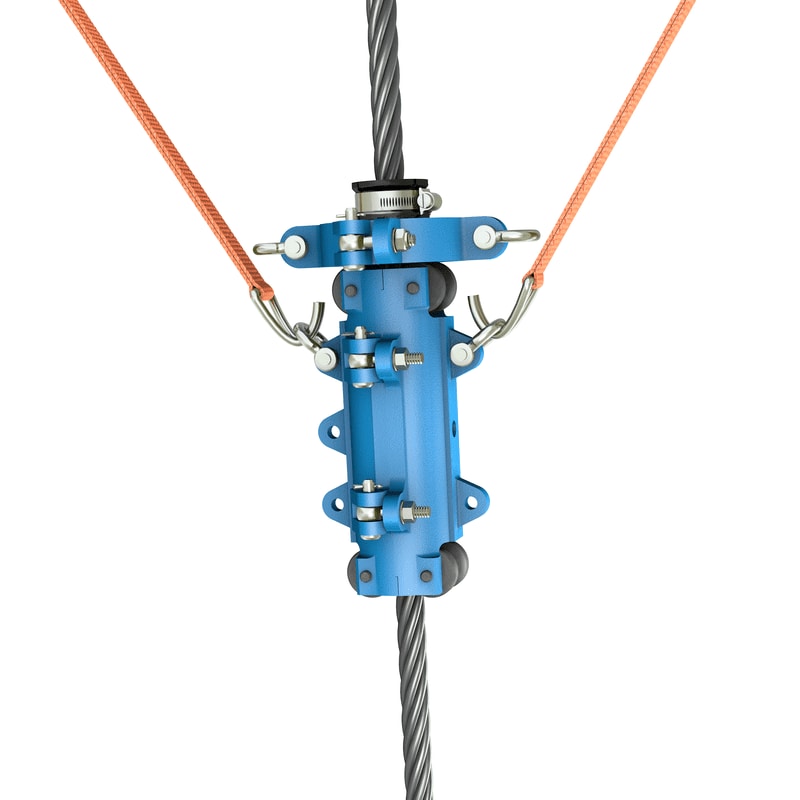

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

The service tool has been designed to deliver highly effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely operated vehicles and winding machines in mines. Used as part of the maintenance cycle, the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also dramatically reducing downtime.

Supporting all lubricants typically used with wire rope, the system ensures optimum lubrication by applying the exact amount of grease required and distributing it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it reduces lubrication time by up to 90 per cent compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

The easy to use wire rope lubrication system comes to the market following extensive field testing. It is ultra-reliable and features an extremely robust design, making it ideal for long-term use in even the most challenging environments and harsh conditions.

Commenting on the new Lincoln WRL, Tim Veal, Lubrication Systems Business Manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

The units are supplied ready-to-use straight from the box and filled with a wide range of high performance SKF lubricants. Tool-free activation and time-setting allow easy and accurate adjustment of lubrication flow.

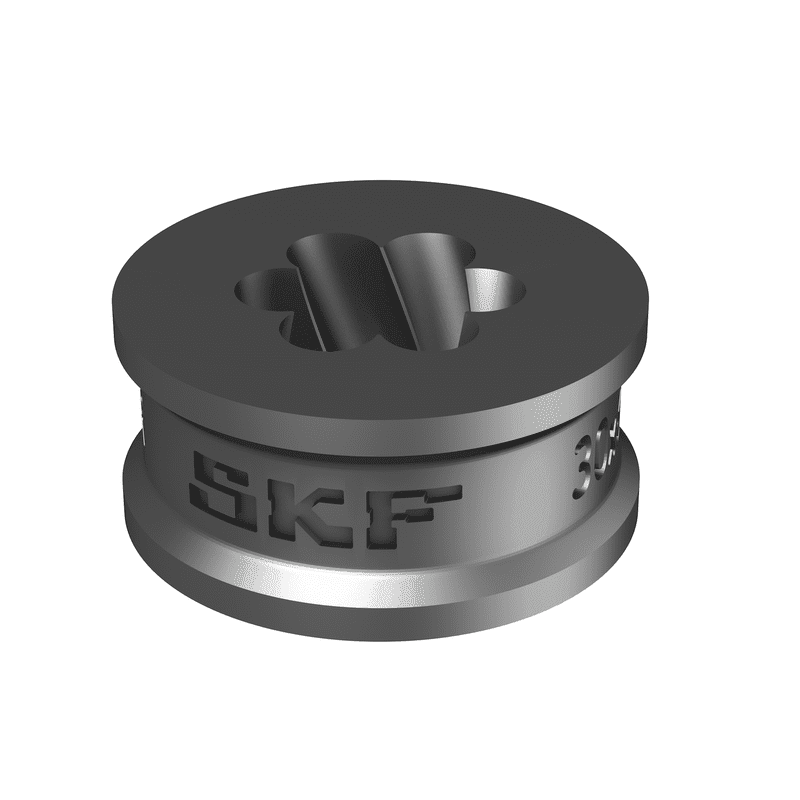

SKF LGMT 3 is mineral oil based, lithium soap thickened grease. This premium quality, general purpose grease is suitable for a wide range of industrial and automotive applications requiring stiff grease.

Lubricating with the aid of brushes, rags, gloves, or by other means is costly, risky, and ineffective. The lubricant forms a film on the surface which water vapour can penetrate, thus becoming trapped. Temperature changes cause condensation and rust then begins to form from the inside. A wire rope can appear to be in good condition, when in fact corrosion and friction are destroying it from the inside. Its useful life is shortened and it becomes potentially dangerous. Even factory lubricated wire rope requires regular relubrication.

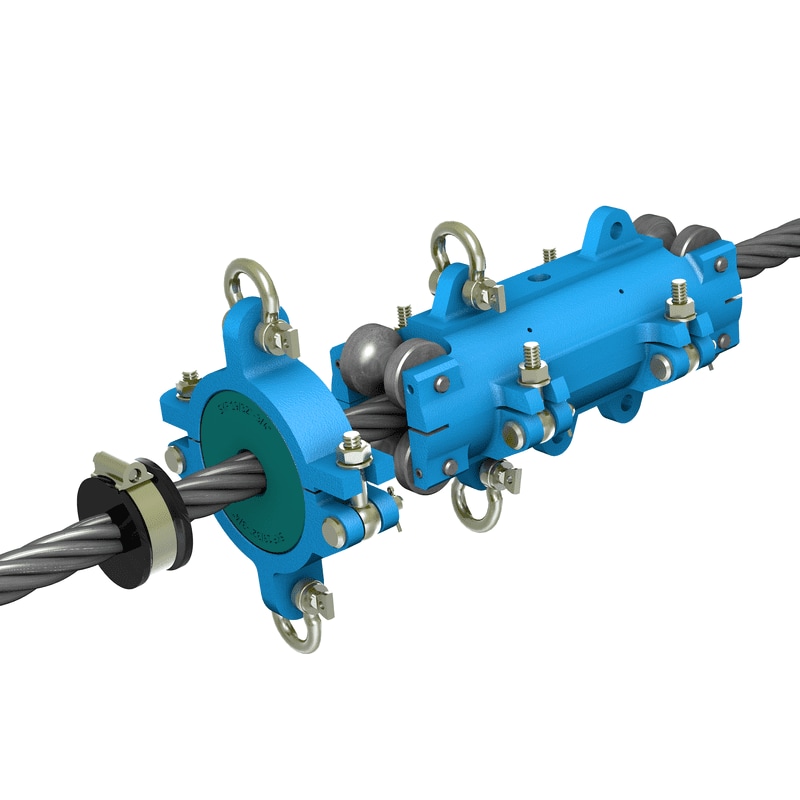

Only the Masto Lubricator penetrates under high pressure all types of wire rope, such as Non-rotating, Dyform, and Locked Coil with heavy grade lubricant. NB. To obtain total penetration through a compact rope the pressure must be minimum 20 bar (285 PSI) in the chamber. Even wire rope subjected to severe surface wear will have a longer life when lubricated with the Masto. Stainless steel, galvanized, and other special types of wire rope require just as much lubrication since friction is the same and corrosion can also occur.

If you start using the MASTO Lubricator, the best results are obtained with the highest quality Wire Rope Grease. If you use SWEPCO 150 Wire Rope Grease your wire ropes will be protected in an optimum way.

An impressive load wear index of greater than 75 and 4-ball weld load of 800 kg demonstrate the superiority of SWEPCO 150’s industry leading extreme pressure and anti-wear protection. The result is significantly longer service life for wire rope and wire rope system components.

Lubricating with the aid of brushes, rags, gloves, or by other means is costly, risky, and ineffective. The lubricant forms a film on the surface which water vapour can penetrate, thus becoming trapped. Temperature changes cause condensation and rust then begins to form from the inside. A wire rope can appear to be in good condition, when in fact corrosion and friction are destroying it from the inside. Its useful life is shortened and it becomes potentially dangerous. Even factory lubricated wire rope requires regular relubrication.

Only the Masto Lubricator penetrates under high pressure all types of wire rope, such as Non-rotating, Dyform, and Locked Coil with heavy grade lubricant. NB. To obtain total penetration through a compact rope the pressure must be minimum 20 bar (285 PSI) in the chamber. Even wire rope subjected to severe surface wear will have a longer life when lubricated with the Masto. Stainless steel, galvanized, and other special types of wire rope require just as much lubrication since friction is the same and corrosion can also occur.

If you start using the MASTO Lubricator, the best results are obtained with the highest quality Wire Rope Grease. If you use SWEPCO 150 Wire Rope Grease your wire ropes will be protected in an optimum way.

An impressive load wear index of greater than 75 and 4-ball weld load of 800 kg demonstrate the superiority of SWEPCO 150’s industry leading extreme pressure and anti-wear protection. The result is significantly longer service life for wire rope and wire rope system components.

We provide your company with the highest level of innovation, safety, and support for the care, and maintenance of your Wire Ropes. This generates longevity for your Wire Rope that no manual method used can achieve.

Since 1982, when we first introduced our products to the world market, we have consistently created the most advanced, safe, and well-supported method for Wire Rope Preventative Maintenance. Over the years since, our continued leadership has proven to make our Customers’ job much easier and cost effective on the broadest possible scale. In honor of this three-decade tradition, we will continue to announce further innovations, with several Patent Pending design features on the horizon. We never stop looking for improved design opportunities based on our own as well as our Customers’ first hand field experience.

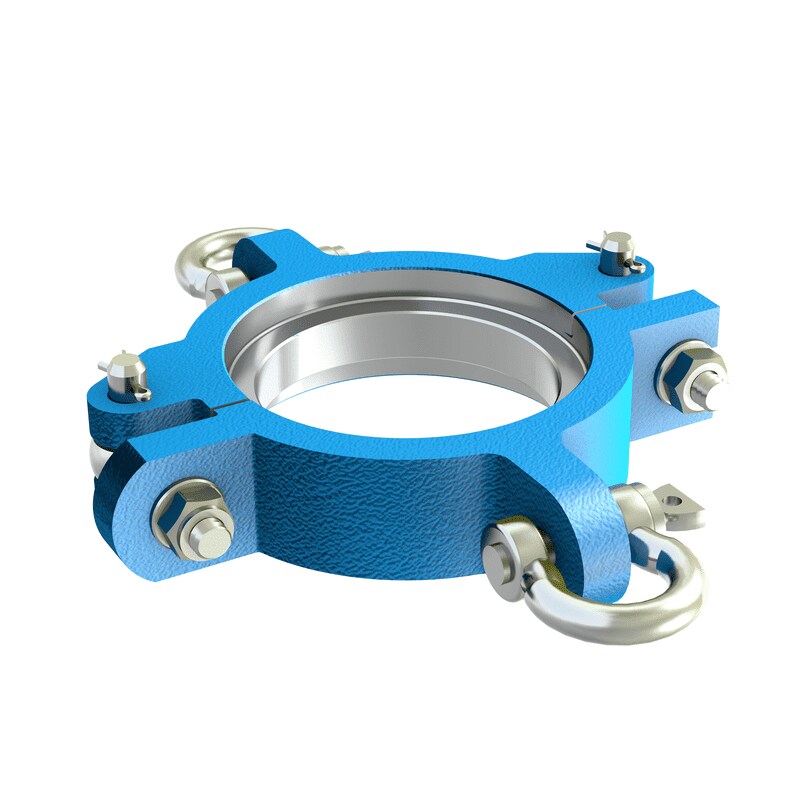

Kirkpatrick Wire Rope Lubrication System’s integrated design provides the most efficient way to field dress any configuration of Wire Rope in any Preventative Maintenance Schedule. Our Lubrication Systems accomplish this by scraping a Wire Rope’s Groove Pattern and outer circumference clean of debris while simultaneously applying a new coat of Wire Rope Lubricant under pressure to the surface and into the internal strands. This process is all accomplished in one pass, generating tremendous savings in time, labor costs, and Wire Rope Lubricant usage. Scraper Plates and Groove Cleaners used with the Kirkpatrick System are calibrated to fit the specific Diameter and match the number of outer strands and lay pattern of the Wire Rope for which they are used. An accurate fit to the Groove Pattern efficiently removes product build-up and debris within each distinct Groove Pattern. Our revolutionary proprietary laser created tooling makes the finished Groove Cleaners as close to a perfect fit as is possible.

Consequently, Dynagard™ Environmental Wire Rope Lubricants are uniformly applied to the newly cleaned surface, penetrating into any open spaces within the Grooves and inner strands that allow them to do so. The goal in this process is to maintain the structural integrity of the original factory applied lay-up material for as long as possible. Therefore, using a lubricant coating product such as Dynagard™ that marries well to the initial lay-up material substantially increases the working life of the layup material as well as the Wire Rope. Superior Wire Rope Maintenance happens because of the aforementioned and as the Wire Rope passes through a 100% pressurized immersion within the Lubrication Collar’s Seal Center Chamber. Surface and internal moisture (trapped within the strands) is displaced as the pressurized Wire Rope Lubricant coating is being applied. Our Wire Rope Lubrication Systems are functional with both low and high viscosity coatings.

Developed as a service tool, the Lincoln wire rope lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments, in general.

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste.

Dimensione, stato e previsione delmercato globale del lubrificatore per funi metalliche per il periodo 2022-2028.La ricerca approfondita è stata compilata per fornire le informazioni più aggiornate sugli aspetti chiave del mercato mondiale.Questo rapporto di ricerca copre i principali aspetti del mercato Wire Rope Lubricator, inclusi driver, restrizioni, tendenze storiche e attuali, scenari normativi e progressi tecnologici.Il ruolo dell’industria nell’epidemia di COVID-19 è stato studiato in modo completo.Durante un periodo specifico, sono state effettuate una valutazione completa dei rischi e raccomandazioni del settore per il lubrificatore a fune metallica.Questo rapporto confronta i mercati pre-COVID-19 e post-COVID-19.Nella ricerca si tiene conto anche dell’impatto del COVID-19 sull’economia regionale.

I principali attori di spicco sono:SKF, Viper WRL, Masto, Ferryl, Poseidon Marine Supplies, Kirkpatrick, Corelube Equipment, TST, MEP, Karmsund, LKS, Top Slings, Lubretec

Valutare i principali produttori del mercato globale Wire Rope Lubricator, compreso il loro panorama competitivo, analisi tra pari, matrice BCG e profilo aziendale.

Infine, i ricercatori hanno fornito informazioni sull’analisi precisa di Wire Rope Lubricator globale.Valuta inoltre i modelli e le piattaforme a lungo termine che supportano l’espansione del mercato.Il rapporto di ricerca valuta anche il livello di competitività.Il mercato è stato esaminato a fondo utilizzando l’analisi SWOT e la scansione dei cinque di Porter.Aiuta anche nella gestione dei rischi e degli ostacoli aziendali.Include anche una considerevole ricerca sulle tecniche di vendita

8613371530291

8613371530291