sleeve wire rope free sample

Our fishing wire single crimp sleeves are made of quality aluminum. No burrs, no sharp edges, corrosion resistant and with high strength, they are nicely crafted. Light, small and cute thing to connect mono and wire leader or other leader materials. Once connected to the line or wire, it ensure a firm hold.

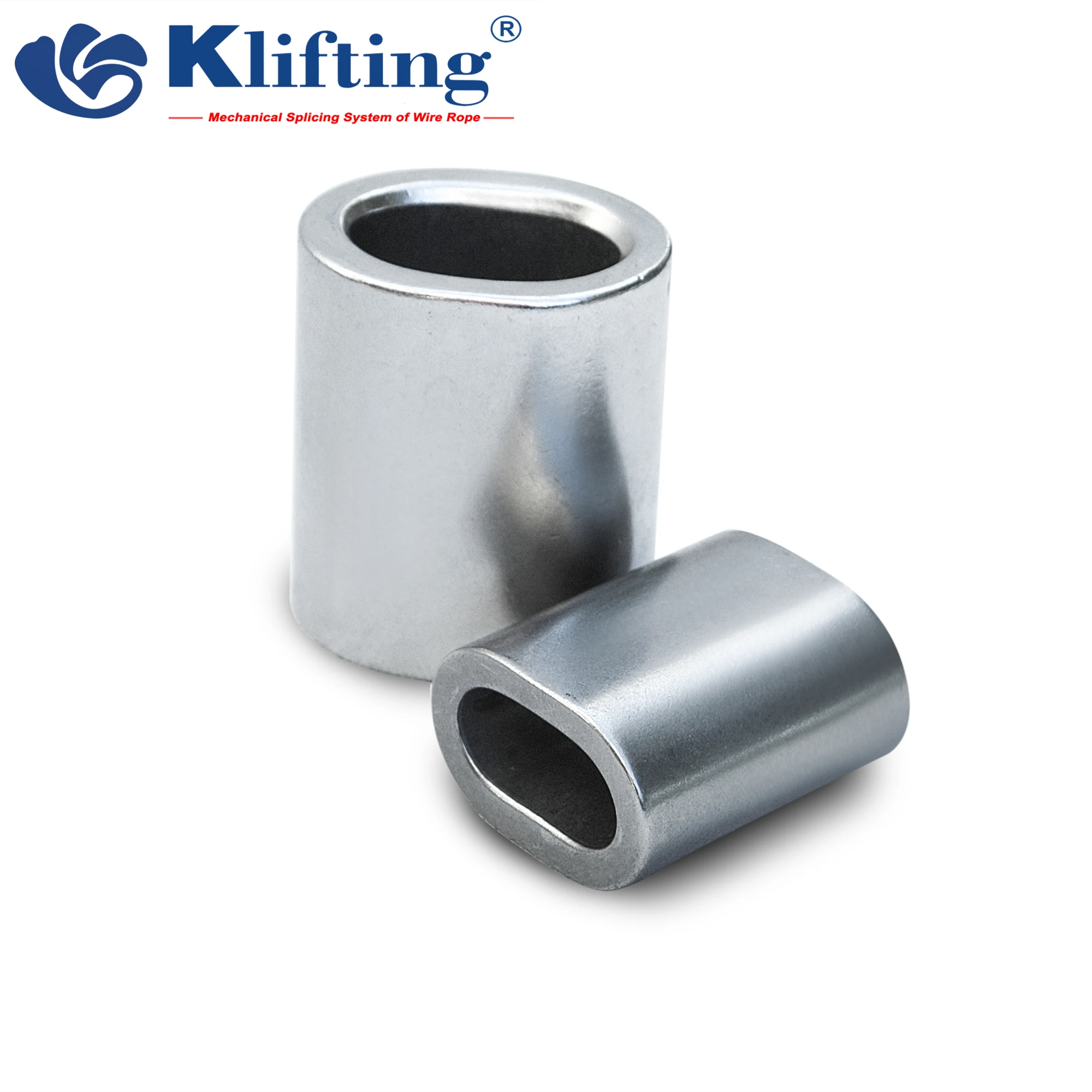

Sleeves are used to create loop ends on wire rope or fiber rope assemblies, often in conjunction with thimbles, and are useful for attaching assemblies. They are commonly designed to hold the nominal break strength of cable and wire ropes.

For use on hemp, manila, nylon, Dacron, cotton and all types of fiber, or synthetic ropes, bungee cord, and plastic coated cables. NOTE: We do not guarantee nor do we imply the holding strength of these sleeves because the breaking strengths of the various materials on which they are used, the physical properties, tensile strengths, hardnesses, stretch factors and end uses are too vast and varied to cover all applications. We will supply samples for you to test, or will perform tests if you supply samples of material on which you wish to use these sleeves and will determine maximum holding strengths for your specific application. Length can be extended to increase holding strengths.

Loos & Co., Inc’s wire rope terminals are domestically manufactured at our Naples, Florida facility. By purchasing from Loos & Co., Inc., you are guaranteed a well-crafted American made product, while directly supporting American jobs and the American manufacturing industry.

If you would like to speak with one of our wire rope terminals experts to learn more about our domestically made products, please contact us using any method below, and we will reach out to you directly.

(1) Cable laid and 6 x 19 and 6 x 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(c) Safe Operating Temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200o F. When nonfiber core wire rope slings of any grade are used at temperatures above 400o F, or below minus 60o F, the sling manufacturer"s recommendations shall be followed.

(3) Where rope clip attachments are used, they shall be made with U-bolts on the dead or short end of the rope and the saddle on the live end. The minimum number of clips for end attachments shall be not less than indicated in manufacturer"s tables, but in no case shall be less than three for any permanent installation. Clips shall be drop-forged steel. The clips shall be spaced at a distance equal to at least six times the diameter of the rope. All clip or clamp bolts shall be kept tight after tightening while rope is under tension.

(a) Wire rope slings must be made from new or unused regular lay wire rope. The wire rope must be manufactured and tested in accordance with ASTM A 1023-02 and ASTM A 586.

(f) You must install and maintain wire rope clips, if used, in accordance with the recommendations of the clip manufacturer or a qualified person, or in accordance with the provisions of ASME B30.26-2010.

(g) You must not use slings made with wire rope clips as a choker hitch.Note:If using wire rope clips under these conditions, follow the guidance given in Table 15.

•Slings made of rope with 6x19 and 6x36 classification.A minimum clear length of rope 10 times the rope diameter between splices, sleeves, or end fittings (see Figure 15, Minimum Sling Length) unless approved by a qualified person.

•Braided slings.A minimum clear length of rope 40 times the component rope diameter between the loops or end fittings (see Figure 16, Minimum Braided Sling Length) unless approved by a qualified person.

(3) Identification information. All wire rope slings must have legible identification information attached to the sling which includes the information below, see sample tag in Figure 17. For slings in use that are manufactured before the effective date of this rule, you must add the information below before use or at the time the periodic inspection is completed.

Figure 17 Sample Wire Rope Sling ID TagNote:Sample tag for a 1/2" single-leg sling 6x19 or 6x36 classification, extra improved plow steel (EIPS) grade fiber core (FC) wire rope with a mechanical splice (ton = 2,000 lb).

(iii) You must not repair wire rope used in slings, you must replace wire rope. Only end attachments and fittings can be repaired on a wire rope sling.

(c) For single- or multiple-leg slings and endless slings, you must proof load each leg according to the requirements listed in Table 18 based on fabrication method. The proof load test must not exceed 50% of the component ropes" or structural strands" minimum breaking strength;

Note: For mechanical splice, swaged socket and poured socket slings follow the rope manufacturer"s recommendations for proof load testing provided that it is within the above-specified proof load range, including (c) of this subsection.

(a) You must use wire rope slings within the rated loads shown in Tables 7 through 15 in ASME B30.9-2010. For angles that are not shown in these tables, either use the rated load for the next lower angle or have a qualified person calculate the rated load.

(g) Decrease the rated load of the sling when D/d ratios (Figure 19) smaller than 25 to one. Consult the sling manufacturer for specific data or refer to the Wire Rope Sling User"s Manual (wire rope technical board).

Basic guardrail components come in a variety of materials and configuration options. It is common for employers to use material available or produced at the worksite. Upright supports may be made from wood, formed metal, pipe, or composites. Wire rope is sometimes used for the top rails and midrails.

Premade guardrails are particularly susceptible to damage if not handled properly when disassembled and stored. Specific handling instructions are typically included in the manufacturer’s recommended procedures for disassembling and storing the guardrail components. If railing components are bent, broken, or missing, the guardrail may not be effective. Damage is more likely to occur if the components are dropped when disassembled, transported in vehicles, or stored in areas not protected from conditions that could cause corrosion or distortion.

Covers for permanent holes are typically built for a specific purpose (e.g., permanent access points, manhole covers, and trap doors) and are only effective when they are properly designed and secured in place.

A warning line system is a barrier erected on a flat or low- sloped roof to warn workers that they are approaching an unprotected roof side or edge (see 29 CFR 1926.500(b); 29 CFR 1926.501(b)(10); Figure 11). A warning line system includes a line (rope, wire, or chain) and supporting stanchions (see 29 CFR 1926.502(f)(2)).

PFAS components will be marked by the manufacturer with pertinent information specific to the equipment, such as warnings, serial/model number, capacity, and the materials used to make the component (see Figure 14). Information (e.g., proper use, maintenance, inspection) about fall protection components is typically provided in equipment manuals.

Many factors can contribute to a workers’ risk of falling from an elevated work area. Examples include precarious work positions, excessive leaning or reaching, improper work practices, unstable structures, trip hazards, slippery surfaces, and distractions.

When guardrails are not an option, personal fall protection equipment is helpful in some situations, but only when properly selected, worn, and attached to an adequate anchor point.

A lanyard is a flexible rope, wire rope, or strap which generally has a connector at each end for connecting the body belt or body harness to a deceleration device, lifeline, or anchorage point (see 29 CFR 1926.500(b)). Some manufacturers offer adjustable length lanyards. Effective lanyards are maintained in a clean, intact condition, and inspected prior to each use for wear, tear, and any obvious distortion or signs that the fall arrest (energy-absorbing) system has been activated (see 29 CFR 1926.502(d)(21)).

Lifelines function as an extension of an anchorage system, allowing an employee to move up and down (vertical lifeline) or back and forth (horizontal lifeline) across a work area. A sliding fitting (rope grab or shuttle) connects to the line and a lanyard connects the worker’s harness to that sliding fitting.

Ladder safety devices or systems are used to climb fixed ladders. The system includes a body harness, carabiner, carrier rail, and safety sleeve. Ladder safety devices are available as a cable (i.e., vertical lifeline) or fixed rail system (see Figure 16 and 29 CFR 1926.1053(a)(18), (a)(22), (a)(23)).

The worker wears a body harness attached to the system by a carabiner. The system uses a cable/safety sleeve, shuttle, or cable grab specifically designed to attach the climber to the vertical line or rail. The cable grab or shuttle freely travels up or down the lifeline/rail as the worker ascends or descends the ladder, allowing the worker to maintain full contact with the ladder. If the worker falls, a locking cam or friction brake in the cable grab or shuttle locks onto the cable or rail and arrests the fall.

Even when a PFAS works properly, the fallen worker is still in danger. The worker"s body weight places pressure on the harness straps, which can compress the veins, and cause blood to pool, in the lower extremities and reduce blood return to the worker"s heart (see Figure 17). This condition is called suspension trauma, also known as harness hang syndrome. In medical terms, this results in orthostatic intolerance. If the pressure is not reduced promptly, the worker can lose consciousness within minutes. (See Suspension Trauma/Orthostatic Intolerance, OSHA Safety and Health Information Bulletin.

With proper personal fall protection equipment, training and practice, a fallen worker can take steps to minimize suspension trauma. Self-rescue methods allow a fallen worker to temporarily relieve pressure on the legs or in some cases to even lower himself or herself to the lower level. Self-rescue methods are discussed in detail in Washington Industrial Safety & Health Division"s Fall Protection Responding to Emergencies.

Both a personal fall arrest system and a guardrail system with a minimum 200 pound top rail capacity (when the platform is supported by ropes); guardrail system only (when the platform is supported by the frame structure)

Often used by workers conducting foundation and formwork. The concrete anchor strap has a tough sleeve or wear-pad that protects it from abrasion where it contacts concrete. The strap loop slips over rebar and is left in place (with D-ring exposed) when concrete is poured. When no longer needed, the strap is cut flush with the concrete surface.

Rope lifeline attaches to an anchorage at the top and hangs vertically down through the work area. Movable rope grab attaches to the rope. Lanyard connects the rope grab to workers’ harness. To move up and down the work area, the worker can slide the rope grab up and down the lifeline, then relock it in place. If the worker falls, the rope grab locks onto the rope to break the fall. This system’s effectiveness depends on how well the worker is trained to reposition the rope grab while moving about. The grab can slide off the end of the rope if the rope is too short, if a knot is not tied near the end of the rope, or if the grab is not installed properly.

The lifeline is wound on a reel and automatically extends or retracts to take up slack in the line as the worker moves about. A sudden extension in the line activates a locking mechanism that typically includes a deceleration device. Some self-retracting lanyards can be set to restrict the distance traveled and so can also function as part of a properly designed fall restraint system.

Thimbles provide a protective interface between the eye of a rope loop and a connector. They are used to prevent pinching or abrasion of the rope. The thimble needs to be firmly seated in the eye of the rope loop.

Thank you for your interest in Allied Wire & Cable products. Please complete the form below to order your free sample. An Allied Sales Representative will contact you to discuss your requirements. During the regular business week, we do our best to respond within 24 hours. All samples will be shipped via UPS or another ground service unless otherwise specified.

Sleeves, when properly applied, are capable of holding the rated breaking strength of the cable to which they are applied. However, to determine the exact holding strength, we recommend pull testing prior to use. This step ensures the proper selection of materials, the correct pressing procedure and an adequate margin of safety for the intended use.

Due to the wide range of breaking strengths for the various synthetic and fiber ropes, samples are available for testing. PULL TESTING IS ESSENTIAL to determine holding strength of our standard length sleeve in your application. Sleeve length can be extended or multiple sleeves used to increase holding strength.

It has features of good corrosion, heat and cold resistance in application of various fields such as chemistry, fisher boat, automobile, aircraft, hardware used in family or stores. We has the capability to provide the rope in various types of material and structure with shiny surface to meet customers needs.

Vinyl/ PVC/PP coated wire ropes can be widely used in automobiles, ship building, construction industry and all the needs of outdoor applications or special working environment.

We"re well-known as one of the leading wire rope manufacturers and suppliers in China. Welcome to buy high quality wire rope at competitive price from our factory. Also, free sample is available for quality checking. Poly V-belt with steel core, Grade 30 welded link chains, Ratchet straps

8613371530291

8613371530291