small wire rope sheaves manufacturer

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Primarily, we are an engineering firm. We take your technical requirements for wire rope sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application.

For years, Sheaves Inc. (Esheaves) has been the number one source for the wire rope industry, developing and providing custom engineered wire rope QSheaves™ that meet your specific needs and rigors of your application. We also supply a large inventory of stock sheaves from the best known brands in the industry.

Our expertise is based on decades of engineering and supplying leading manufacturers, from the simplest applications to the most demanding. We’ve supplied sheaves for a range of applications, from industrial machines, manufacturing equipment, and military applications, to recreational equipment, theater rigging, and large commercial boat lifts.

We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs; achieved, for example, in our patented line of steel sheaves that allow us to provide an extensive range of 6” to 12” QSheaves™ to be shipped the same day.

Designed for cables 1/2″ and under, eSheaves Small Cable Sheaves offers an in-stock, ready to ship solution for almost any application. Whether you select steel or stainless steel, all small cable sheaves are turned from drawn bar stock to provide strength and durability. All bearings are engineered for high load applications running at medium speed. Oil impregnation provides permanent self-lubrication. Learn more about applications and available configurations below.

Don’t see what you need? No Problem! Additional modifications are available upon request to meet your requirements. Simply complete a request for small cable sheave quotation and we will provide a price and delivery.

Our team understands that choosing the right cable assembly manufacturer, and pulleys for your cable assemblies requires thoughtful consideration, from bearing life, to minimum pulley diameter. Let Sava"s engineering expertise guide you toward the best selection of wire rope pulley wheels.

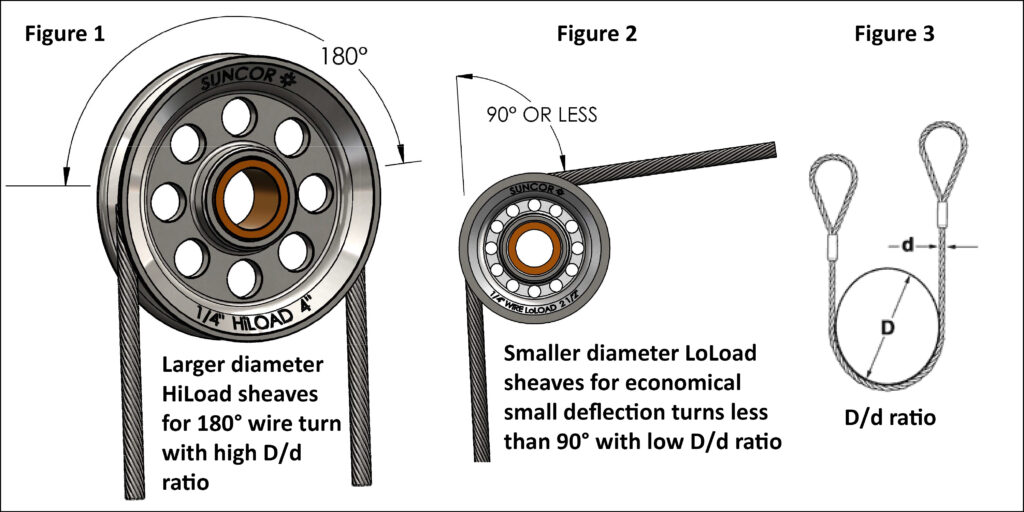

When cable is used over pulleys, the cable life can be significantly prolonged by proper pulley groove design. Laboratory tests on wire rope pulleys prove that improper groove design reduces cable bending life up to 90%. These same tests show that doubling a pulley diameter can increase cable bending life up to thirteen times what is otherwise typical. Also, pulley diameters less than sixteen rope diameters fall into a range in which cable life is relatively low.

Johnson Wire Rope Sheaves are industry proven and are available in sizes ranging from 3" to 108", in over 250 standard models. Cost efficient, custom designs are available, with no upfront tooling or pattern charges and no premium price for small order quantities. 16" to 108" O.D. Sheaves have flame hardened, precision grooves for slow, even wear and long rope life. The integrity of Johnson’s single disc forged steel construction provides sheaves with superior strength.

A large variety of wholesale wire rope sheaves can be found at Alibaba. The stainless-steel license frame with an aluminum sheet shines brilliantly on the back of the vehicles, making them noticeable and remarkable on the road. The license plate bracket is designed to hold the license frame on the front of the vehicle.

We also have wire rope sheaves that can be customized with different designs, logos, and tags. The personalized license plate frames are very appealing to company owners such as car dealers because they can market their trademarks using customized wire rope sheaves on their professional vehicles. For luxury and prestigious models, we recommend wire rope sheaves like rhinestone license plate frames, silicone license plate frames, and diamond license plate frames. The vintage license plate frames add a retro aesthetic to vehicles. Explore more stylish license frames available at amazing bargains.

Bairstow Lifting Products supplies and distributes lift assistance products from some of the very best, quality manufacturers such as McKissick, Johnson, RopeBlock, Skookum, Harrington Hoists, Tractel, CM, Coffing, Lug-All, Little Mule, Caldwell, VersaBar, TandemLoc, Lettelier and more. Our pulley blocks and sheaves for wire rope are made from the highest quality materials.Browse our industrial pulley systems below and find the ideal product for your specifications.

Not only does Crosby stock key materials, it has the manufacturing capacity to provide short deliveries, as well as operational and technical support. This enables every team to learn more about the product and material they will be handling. Crosby offers roll forged sheaves that provide an upset meta flow without creating a stress zone at the splitting point. The dome-reinforced sheave design provides for a continuous weld in a circular pattern.

Sheaves produced come in: 30, 35, and 45-degree profiles. The McKissick roll-forged sheave is available in the following: plain bore, bronze bushed, roller bearing, tapered roller bearing, lubrication thru hub, key ways, set screws, full complement bearing.

All products have been tested for underwater and hard environment uses, giving the client confidence in using sheaves for all applications. In addition, Crosby has achieved API Q and TS29001 statues and are licensed to manufacture sheaves to API 8C and provide to API, DNVA, and ABS requirements.

Crosby Roll-Forged Sheaves have a reputation of reliability you can depend on. First, teams must know which type of sheave needs to be used on the job. The type of project, duration, and environment all determine the type of sheaves that is required, as well as the maintenance schedule for the product.

All wire rope and fittings should be thoroughly inspected before use and replaced if found defective. Any alteration to Block Division’s products will void all said or implied warranties, guarantees, and liabilities.

Selecting the right size for sheaves will help prevent frequent wire rope damage which in some instances occurs after just one run. Many common operational issues including the wireline getting dislodged or losing its strength are caused by improper sheave sizing and alignment problems. Our experts offer 3 valuable tips to eliminate stress failure, improve equipment safety and efficiency, as well as increase the lifespan of your sheaves and wire rope.

Pay attention to sheave groove size and diameter: When sheaves for your wire rope are too large or too small, there is greater stress on both resulting in spooling trouble and premature wear. For instance, grooves that are too large have proven to cause the wire rope to flatten and unbalance leading to the wire breaking. When properly sized, the groove provides maximum support to the rope lowering the sheave bearing pressure and increasing sheave and rope lifespan. Typically the groove diameter should exceed that of the wire rope by 5% while groove depth should be one-and-a-half times the rope diameter. A groove angle between 30° and 45° offers the best support for the wire rope. Specific dimensions and angles may vary depending on your application.

Ensure sheave groove hardness: The hardness of sheaves is a factor that is often overlooked. Since the wire rope is hard, the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To avoid this, ensure your steel cable sheaves are flame hardened. (A simple way to determine if your grooves are worn out is by using a sheave gauge.) At Rockett Inc., we can provide flame hardening for wear resistance along the contact area.

Correct sheave groove alignment: Poor alignment of your sheaves wears out the wire rope and sheave flange. This is because the rope comes into constant contact with the flange creating stress on the rope, abrasion damage and fatigue breaks. Any alignment issues should be corrected immediately.

To avoid operational problems, opt for custom made steel sheaves. This way the sheaves for your wire ropes are tailored to your specific requirements instead of the other way around. As an experienced sheave manufacturer with a state-of-the-art facility in Mississippi, Rockett Inc. offers comprehensive custom solutions for diverse industrial and commercial needs.

Should you have a specific requirement, our experienced engineers can work closely with you to design and manufacture the product your application requires. Precision engineering and state-of-the-art metal fabrication equipment result in a closer tolerance fit to the wire rope to reduce fatigue and wear. Inspection at every stage of our manufacturing process ensures that the final output meets your specifications.

Need assistance with designing sheaves for wire rope? We are always happy to help. Our team can work directly from your drawings and specifications, or offer 3D CAD design and engineering support optimized for practical, cost-effective results. Over the years, we have produced the most diverse range of custom steel cable sheaves for our clients across the globe. Having the ISO 9001:2008 Certification means we take pride in quality and customer satisfaction.

McKissick® Tapered Bearing Sheaves are designed to operate on shafts machined to +/- .0005 of the indicated shaft size. Applications should provide for tightening separator plates against bearing cones to adjust and insure proper function of bearing. For sizes not listed, McKissick® Finished Bore Sheaves can be equipped with tapered Bearings at an addtional charge.

8613371530291

8613371530291