southwest wire rope company quotation

Southwest Wire Rope"s Engineering Services Department provides engineered lifting devices, lift plans, and engineered load testing services under the leadership of experienced Professional Engineers with extensive experience in heavy lifting.

Since 1966 Southwest Wire Rope has expanded to become a recognized global wire rope supplier serving diversified markets with material handling, lifting & mooring products at five full-service locations. Large, full-range inventory includes their trademark “Gold Strand” wire rope; bright, galvanized, stainless steel & vinyl coated cable; plus wire rope slings & a variety of fittings & hardware.

Manufacturer & distributor of wire rope for the offshore oil exploration industry, heavy lifting & rigging use, subsea hoists & chains & safety equipment, including synthetic & poly rope & load cell testing

Wire rope, nylon slings, synthetic rope & related hardware, including web & round slings, high performance synthetic ropes, shackles, thimbles & sockets

Looking for business intelligence data on Southwest Wire Rope LP or other suppliers of Wire Rope Slings? Set up your free account with IndustrySelect.

Omni Cable Corporation entered into a definitive asset purchase agreement to acquire Southwest Wire Rope Business of Houston Wire & Cable Company (NasdaqGS:HWCC) for $5 million on January 13, 2021. The consideration is subject to a working capital adjustment. The sale excludes approximately $2.6 million of trade accounts receivable, which HWCC will retain. HWCC expects to use the net sales proceeds and accounts receivable collections to further reduce Revolver debt. The transaction is subject to customary closing conditions and is expected to close in the first quarter.

Omni Cable Corporation completed the acquisition of Southwest Wire Rope Business of Houston Wire & Cable Company (NasdaqGS:HWCC) on March 12, 2021. The sale excluded approximately $2.9 million of trade accounts receivable, which HWCC retained. HWCC used the net sales proceeds of approximately $3.4 million to further reduce revolver debt.

Omni Cable Corporation entered into a definitive asset purchase agreement to acquire Southwest Wire Rope Business of Houston Wire & Cable Company (NasdaqGS:HWCC) for $5 million on January 13, 2021. The consideration is subject to a working capital adjustment. The sale excludes approximately $2.6 million of trade accounts receivable, which HWCC will retain. HWCC expects to use the net sales proceeds and accounts receivable collections to further reduce Revolver debt. The transaction is subject to customary closing conditions and is expected to close in the first quarter.

HOUSTON, Jan. 13, 2021 (GLOBE NEWSWIRE) -- Houston Wire & Cable Company (Nasdaq: HWCC) today announced that it has entered into a definitive asset purchase agreement for the sale of its Southwest Wire Rope business, a leading provider of lifting slings and wire rope and rigging products, for a purchase price of $5 million, subject to a working capital adjustment. The sale excludes approximately $2.6 million of trade accounts receivable, which HWCC will retain. HWCC expects to use the net sales proceeds and accounts receivable collections to further reduce Revolver debt. HWCC has already reduced Revolver debt to approximately $21.4 million as of January 13, 2021, from a peak of $95.2 million in the first quarter of 2020.

James L. Pokluda III, HWCC President & CEO commented, “Southwest Wire Rope is a company that for over fifty years has been a leading supplier of quality lifting slings, wire rope and rigging supplies to the lifting industry. We wish them much success in the future. Proceeds from the sales of Southern Wire and Southwest Wire Rope allow us to reduce debt, which lessens financial risk in these uncertain times.”

With 45 years’ experience in the industry, Houston Wire & Cable Company, an industrial distributor, is a large provider of products in the U.S. market. Headquartered in Houston, Texas, the Company has sales and distribution facilities strategically located throughout the United States.

Standard stock items available for immediate delivery include continuous and interlocked armor cable; instrumentation cable; medium voltage cable; high temperature wire; portable cord; power cable; primary and secondary aluminum distribution cable; private branded products, including LifeGuard™, a low-smoke, zero-halogen cable; mechanical wire and cable and related hardware, including wire rope, lifting products and synthetic rope and slings; corrosion resistant fasteners, hose clamps, and rivets.

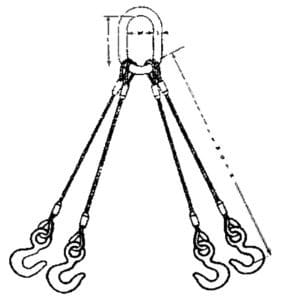

Manufacturer of material handling, lifting and mooring products required by industries along the Gulf Coast. The company"s products include wire rope slings, nylon slings, round slings, chain, shackles, thimbles, sockets and other related products.

When considering complaint information, please take into account the company"s size and volume of transactions, and understand that the nature of complaints and a firm"s responses to them are often more important than the number of complaints.

Take a look at Vitalife Wire Rope Lubricant, a lubricant designed for BIG jobs. It"s been lubricating the Brooklyn Bridge since the late 1800s!https://wireropelube.com

Founded in 1992, Ashley Sling has been serving in the Atlanta area and beyond for 30 years. Ashley Sling, Inc. is a proud leader in the wire rope and rigging industry. Our primary mission is to provide customers with the highest quality lifting products and services. We continuously deliver on that promise and surpass industry standards with our fabricated lifting products and rigging products.

Rope serves a wide variety of industries all over the world, but it is especially useful in the rigging, safety, arborist, construction, products manufacturing, recreation, hobby, marine (watercraft mooring), defense contracting, and sporting goods industries.

We’re not sure when rope first came into being. The earliest evidence we have of what is likely rope made by humans comes from Europe about 28,000 years ago. This evidence is simply the impression of cordage on pit fired pottery. Another example of prehistoric rope was found in the famous Lascaux Cave in France. There, archaeologists discovered fossilized fragments of two-ply rope that was about 7 mm in diameter. It dates back to about 15,000 BC. Prehistoric people hand twisted and braided very early rope like this from plant materials, like grass and vines.

The first people to really develop ropemaking as a craft were the ancient Egyptians. Between around 4000 and 3500 BC, they used special tools to construct ropes made from a variety of materials. This tool consisted of what was likely a weighted wooden object, such as a paddle, tied to a stick. To use it, ropemakers tied fibers to the weighted object and spun it around the stick. This allowed the fibers to twist into strands. They would then spin the new strands in the opposite direction, in order to twist them together into rope. The Badarian culture of Upper Egypt made the earliest of these ropes from water reed fibers. Other fiber materials that Egyptians used to make cordage include date palm, papyrus, rushes, wild reeds, halfa grass, esparto grass, and flax. Occasionally, they used animal fibers like camel hair or leather. Egyptians used their ropes for a variety of tasks, but they’re most well-known for using hoist rope to lift stones during monument building.

The next people to make secure a line in rope history were the ancient Chinese. They popularized the hemp rope, which they first started making around 2800 BC. By around 1000 AD, the native peoples of the modern-day American Southwest were also making rope. They used a process quite similar to that of the Egyptians.

During the Middle Ages, people used rope extensively. We do not know a lot about their methods, though, because they were made by guilds that guarded their craft as secrets. Based on an artist’s rendition of ropemaking from 1393, we believe that the first step to ropemaking at this time was spinning yarn. We do know many of the applications for which they used rope, though. Some of the most common rope applications of the Middle Ages and Renaissance included rope bridges, ropewalks, and sailing. Also, by this time, sailors and shipping merchants knew how to splice ropes.

In 1792, British inventor Edmund Cartwright invented the Cordelier, a ropemaking machine. His invention was not an isolated idea, though, and many other people of the Industrial Revolution made their own rope machines.

Since then, rope continues to be important. One of the biggest differences between modern rope and rope of earlier times is the fact that manufacturers can make it with so many different materials. While natural ropes are still somewhat common, steadily since the 1950s, they have largely been replaced by ropes made with synthetic materials designed to better weather their applications. Modern rope materials can resist all sorts of perils, like rot, corrosion, unraveling, and weakening from the sun. Modern ropes are also quite strong and light.

Rope suppliers craft rope from a variety of different synthetic and natural fibers. Examples of synthetic rope fibers include nylon, polyethylene, polyester, polypropylene, Kevlar and the like, and examples of natural fibers include sisal, jute, manila, linen, and cotton. They can also be made from metal wire. Material variety like this allows rope suppliers to make ropes that fit many different application requirements related to stretch, resilience, and chemical and exposure resistance.

There are two main types of rope construction: braiding and twisting. Though historically twisting has been the most common form of rope construction, over time, rope braiding has risen to the top spot. This popularity is due to its ability to stay true to its form, rather than spin or untwist, while holding a load. Rope may be braided using one of these styles: diamond with cores, hollow diamond, and solid braid. A diamond braid core is solid material positioned in rope’s center, underneath its braid, that increases rope strength.

Hollow diamond braid ropes do not have this core, but are rather manufactured simply through the weaving of strands over and under each other. Solid braided rope has a tightly woven lock-stitched construction that resists unraveling, even when cut. Finally, double braided ropes have both a braided rope and core. They are the strongest and most expensive braided rope available.

Note that neither solid braid nor diamond braid cores can be spliced. The second rope construction method, twisting, involves coiling, or twisting, three-plus strands tightly in the same direction, using strand fibers that are twisted in the opposite direction. Counter-twisting is healthful, reinforcing strength and creating a balanced rope that will hold together without kinking. After the strands are twisted, rope suppliers fuse each rope end to deter unraveling.

When designing rope or helping customers select a rope, manufacturers consider application specifications like the physical environment in which you will use the rope (in saltwater, during mountain climbing, in the hot sun, etc.), how you plan to use the rope (hoisting, tying, anchoring, etc.), how often you will use the rope, the maximum and minimum loads you will put on your rope, and the safety requirements of your rope. Based on these specifications, they will decide on things like rope material, elasticity (static rope vs dynamic rope), rope construction, rope weight, and rope length.

Nylon rope, not be confused with elvenhair rope, offers high elasticity, good shock absorption, high strength, and longevity. In addition, it is resistant to damage from the sun, chemicals, and abrasive action. For these reasons, it’s quite popular with applications related to lifting and towing.

Polyester rope is less elastic, less shock absorbent, and has a shorter lifespan than nylon rope. However, since polyester has a superior chemical damage resistance, weathering resistance, and abrasion resistance, polyester rope is one of the most commonly used ropes in the boating industry.

Polypropylene rope stands alone as the only synthetic rope variety that floats, and is therefore used widely in watersports, light watercraft mooring, and in pools. However, polypropylene rope cannot be used for more heavy-duty tasks because propylene has the lowest melting point and UV resistance of all rope material types.

Polyethylene rope is a synthetic rope known for resistance to abrasion, and similar to polypropylene rope, its ability to float. It is mainly used in fishing.

Sisal rope is a medium tensile strength natural fiber rope made from agave fibers. It is used for gardening, bundling, and other knot-holding related applications.

Manila rope, made from abaca leaf fibers, is much stronger than sisal rope. Because it is hard, resistant to sunlight, stretches minimally, and does not melt, it is very popular in construction. It’s also very resistant to saltwater, which lends it to some marine tasks.

Cotton rope is weaker than most other ropes, both natural and synthetic. However, it is soft, pliable, and easy to handle, making it perfect for small and light-duty applications.

Wire rope is a type of rope made from metal alloys like steel. Steel wire rope is the most common wire rope type, as most alloys in the steel family are strong and corrosion resistant. To qualify as wire rope, the rope must be at least ⅜ inch. If it is any smaller than this, then you should call it a cord or a cable. Also, to qualify as wire rope, it must meet certain lbs weight restrictions.

Rope suppliers manufacturer some speciality ropes that are application-specific, rather than fiber specific, such as twine, marine rope, elastic cord, and stair rope.

Twine, or rope twine, is a thin, twist rope usually made from natural fibers like linen or cotton. Twine is commonly found around the house as clothesline or package typing rope and at butcher shops, where it is used to tie stuffed poultry together. It may also be used to make sporting goods like basketball nets.

Marine rope is used for water, most often saltwater, related applications, like docking, boating, and pontooning. A good example of marine rope is watercraft mooring rope. Marine rope must be made from material that stands up against salt, water, and other elements, like nylon.

Stair rope is rope used for bannister or handrail applications. It may help people climb stairs, or it may just be there for decoration (e.g. rope lights). If the stair rope is made from metal, it may be called a cable railing.

To offer you the best service possible, ropes come with a variety of accessory products. Examples of these products include rope clips, rope storage bags, and steel carabiners.

To make sure a rope lasts and maintains both its usefulness and its safety, users must treat it with proper care. Care for your rope, and it will prove itself time and time again. Proper care for ropes entails a number of things, including proper usage, storage, and damage checks.

• Usage—Never put an amount of strain on your rope for which it is not equipped. Likewise, do not use your rope in environments for which it was not designed to endure.

• Storage—Always store your rope products in a dry and dark environment, up off of the ground. Prolonged exposure to either moisture or sunlight can weaken your rope over time or cause damage. When you store it, in order to avoid tangles, make sure to fold it in gentle loops; never just shove it in a corner.

• Damage Checks—Whenever you get out your rope, take some time to check it over for damage. Damage could be any number of things, but some of the common issues you may encounter are cuts, breakages, rot, or unraveling strands. If the cuts are small, you can likely still use your rope, but you may need to repair it first. To fix a cut rope, you can remove the damaged section with a knife or a pair of sharp scissors, or you can melt the cut with a candle or lighter. However, if your rope has a cut in the middle, you will likely have to replace it.

Ropes are subject to different safety, quality, and characteristic standards, per their application and the location(s) in which they will be used. ASTM International, for example, puts out standards in regards to the characteristics of stranded carbon steel wire rope used for general applications. In the European Union, ropes must have the CE mark. In the United States, rope used for emergency services must be certified by the NFPA (National Fire and Protection Association). Also, in the U.S., ropes used in the workplace must also meet the standard requirements of OSHA (Occupational Safety and Health Administration). To learn about what safety standards your rope must meet, talk to your industry leaders and applicable governmental offices.

To get rope that is safe and meets your standard requirements, you need to work with an experienced rope manufacturer, such as those we’ve listed on this page. The best way to approach your search is to start by writing down your specifications, requirements, questions and concerns. Don’t forget to include aspects like your budget, when you need the rope, and your delivery preferences. Once you’ve got your list, browse the rope suppliers we’ve sandwiched in between these information paragraphs. Based on your list, pick out three or four that you think could be right for you. Discuss your application with each of them, compare and contrast your conversations, and pick the one with whom you want to work. It’s as simple as that.

When you need to move heavy equipment, materials, or your entire plant to a new location anywhere in the world, we can help! As a company, we’ve been awarded by the Specialized Carriers and Riggers Association for Best Hauling Job Award. Our locations in the United States and Mexico and our contacts all over the world make hauling what to different places across the world easy and efficient.

Whether you’re adding new equipment, relocating to a new plant, or building a new facility, we can haul materials and machinery wherever you need them to go. This includes heavy military armor and aerospace support being transported around the globe. Whatever the job, you make the right decision when you give Southwestern Industrial Contractors and Riggers a call.

Headwinds for Houston Wire and Cable Company (NASDAQ:HWCC) end markets have depressed revenues and earnings for the current year. The stock is trading at a historical 52/week low and has pushed the company in a deep undervaluation. Headwinds are temporary and there is an ever increasing demand for HWCC"s products. In 2-3 years there will most likely be mean reversion, letting the company trade at a much higher multiple.

HWCC operates its business in the energy, utility, infrastructure and the industrial markets. They have been around since 1975 and have a very broad wire and cable product offering. As a business, they help customers that require multiple cables and complex engineering requirements or electrical codes. HWCC sells over 30,000 products on an annual basis, has over 44,000 SKUs and has offices all over the US. What makes them stand out from their competition is that they have a huge array of inventory (most of the times they have ~$100mm in inventory), a ton of different cables and they specialize in hard to find items.

HWCC is a microcap company with a very easy to understand business model. There is a clear absolute undervaluation, high cash flow and the company is trading near a 52/week low. However, there are industry headwinds, a decent amount of debt and the company has a strategy of keeping hardly any cash on the balance sheet. Despite the former, you can pick up a decent 7.67% sustainable dividend yield coupled with a clear undervaluation. Market Cap 103.92 M Cash N/A

Moving on, we can see that HWCC would have been more profitable in the first six months of 2015 if it wasn"t for a non-cash impairment charge. Their newly acquired business, Southwest Wire Rope (bought in 2010), had a non-cash goodwill impairment charge of $2.6mm recorded in Q2. Investors should remember that this was just a non-cash charge, which had no effect on operating results or cash flow.

From around 2010 until 2014, revenues have pretty much bounced around $390mm. If you go back to 2010, you can see that revenues jumped up around $90mm, from an improving economy and more importantly from the investment into Southwest Wire Rope. Up until late 2014, the company performed at pretty much the same rate (revenues were around the same each year and so were margins, to an extent). Then the O&G sector got hit by a plunging price of oil. Capex from customers slowed and industrial projects were put off. As I have stated before, revenues dropped a good 25%, earnings took a beating and investors rapidly sold off their shares.

You may notice that so far this year EPS has been at a historical low; industry headwinds and impairment charges on goodwill can do that. However, if you look at HWCC from another perspective (FCF), you can see that the company has been performing very well despite the headwinds. Cash flow is up a ton so far this year. Looking at the free cash flow statement, you may think to yourself that FCF is up due to abnormally high changes in working capital. This is true, but what it interesting is that cash provided by operating activities clocked in ~$22mm in the first six months of 2015. So yes, FCF is high due to larger changes in working capital accounts, but also from high cash provided by operating activities as well.

Another item that stands out on the free cash flow statement is higher than normal capex. One question investors may have is; why is capex up when the industry is down? It does seem counterintuitive, but capex is up in order to realize more savings going forward. Expenditures are up in 2015 due to the renovation of a facility associated with the Southwest business segment (one-time expense). The renovation is slightly expensive at first, but it will save the company ~$400,000/year (four existing Southwest locations are being moved to the renovated location).

Based on the company"s contractual obligations, and its historical FCF, the company will have plenty of liquidity going forward. The company has enhanced their FCF and are in the final draft of getting a new credit facility established, that will be valid up until September of 2020.

In 2014, the board of directors authorized a share repurchase program of $25mm. So far the company has spent $10.1mm on repurchases and bought back 4.8% of the shares outstanding. This share repurchase program has no expiration date and based on the company"s strong/enhanced FCF, I am going to assume that the company will continue incrementally buying back shares. In fact, I hope that the company continues to buy shares at these low levels.

As for the dividend, in 2014, 2013 and 2012, the company spent $8.2mm, $7.4mm and $6.3mm on stock dividends. Because of the rapid drop in the share price, the yield looks rickety. In reality, the dividend is currently sustainable (as long a FCF holds its ground). Management has even stated in their recent quarterly reports that they plan to continue paying the dividend going forward. However, I wouldn"t count on them raising it until these headwinds become tailwinds.

So far this year, FCF has clocked in at ~$20mm, OCF in at $30.13mm and LFCF at $28.69mm. HWCC is a very good generator of cash, and their business really is not in any danger from these headwinds. Analysts believe that HWCC will start to generate higher revenues in 2016 (around $324mm), based on the headwinds subsiding. Right now you can pick up HWCC at a historical low not seen since the depths of 2009 and lock in a 7.67% sustainable dividend. The company is in deep value territory (EV/EBITDA and EV/Revenue of 6.71 and 0.42, respectively), there is a program addressing cost management and the company returns tons of wealth to shareholders every year (very good management team). I have provided the steps below on how I figured out the forward FCF for 2015.

What really stood out to me after reading the company"s annual reports is its ability to outperform manufacturers. The way they do this is by keeping a huge amount of inventory on their balance sheet. Thus, no manufacture can compete with HWCC when it comes to the inventory the company has (this makes same day shipping possible, a thing manufactures can"t do). What is interesting is that ADDvantage Technologies (AEY) also utilizes the same strategy of keeping a high amount of inventory on their balance sheet to give customers one day shipping (I found both of these companies using the same screener). Although, the bad part of keeping a huge amount of inventory is the risk of an inventory write-down (will talk about later in the risks section).

What is also very interesting is that there is no on-site labor costs associated with HWCC"s business model. The company buys wire, then sells it. Gross margins have been able to stay relatively around 21.7% despite industry headwinds. Manufactures also can"t offer services such as custom cutting, cable coiling, custom slings and harness, etc. This gives HWCC an advantage over wire manufactures.

This allows the company to give very good customer service and also goes back to the same day shipping value it can provide. All in all, HWCC has >6,300 customers, >10,500 different customer locations and there wasn"t one customer that accounted for over 10% of consolidated net sales.

HWCC is the leading supplier in the US of the low-smoke, zero halogen products, there are critical barriers to entry in the industry (LifeGuard products), there is an estimated $1.4bn market for this specific product and it is accepted by over 300 end users. The company has a leading market position in this product line and in other product lines as well. As the construction market continues to grow, the LifeGuard product will continue to see demand (proprietary product in construction).

James Pokluda is currently the CEO and President of HWCC. His career at HWCC started in 1987 as an Account Manager. Before becoming the CEO, Pokluda was the VP of Sales and Marketing, and he held other senior leadership positions in the company.

From studying microcap stocks this past year, I have come to realize that when management guides for earnings and revenues going forward, they really are not doing shareholders a favor (especially when the company misses guidance). Digging into management and HWCC, I have noticed that management does not provide forward guidance when it comes to future revenues and earnings. Not providing guidance is an item that I like about a management team.

There have been some authors on HWCC in the past that suggested that margins will stay the same across the whole board, despite how much the company sells and how weak the industry may be. I think the former can be argued. First, we can see in Q2 that revenues have fallen, but sales and commissions (as a percentage of revenues) have went up. Secondly, when prices of copper, steel, aluminum and petrochemicals rise, so does the cost of buying wire. Finally, if the cost of these four former byproducts of wire decline, so will the value of the inventory. All three of these former examples can squeeze margins. Investors should realize that gross margins may be able to hold steady, but other margins do have a potential of being squeezed.

The biggest risk in HWCC"s business model is the cynical end markets that the company serves. Pretty much all of HWCC"s end markets are very cynical. A downturn in one of these markets will also put the company in a downturn (as what is happening in the O&G industry right now).

Investors should realize that HWCC has been a company for 40 years now. They have survived the ups and downs of many different troubled economic time periods. The worst time period was probably the Great Recession, in which the company survived. HWCC is a company that has potential to be around for a long time (due to the simple business model, the continual demand for its products and the great management team).

If you want to buy a company near a 52/week low that has a bright future, HWCC may be the company you are looking for. There are many things to like about the company; a great management team, the simple business model, a clear absolute undervaluation, and history of providing shareholders value (dividends and repurchases). When the company survives this downturn, they will continue to provide value for the huge market that they serve (infrastructure, utility and industrial markets are $73bn, $30bn and $219bn markets, respectively). Lock in that sustainable 7.67% dividend and patiently wait for mean reversion.

8613371530291

8613371530291