splicing steel wire rope in stock

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

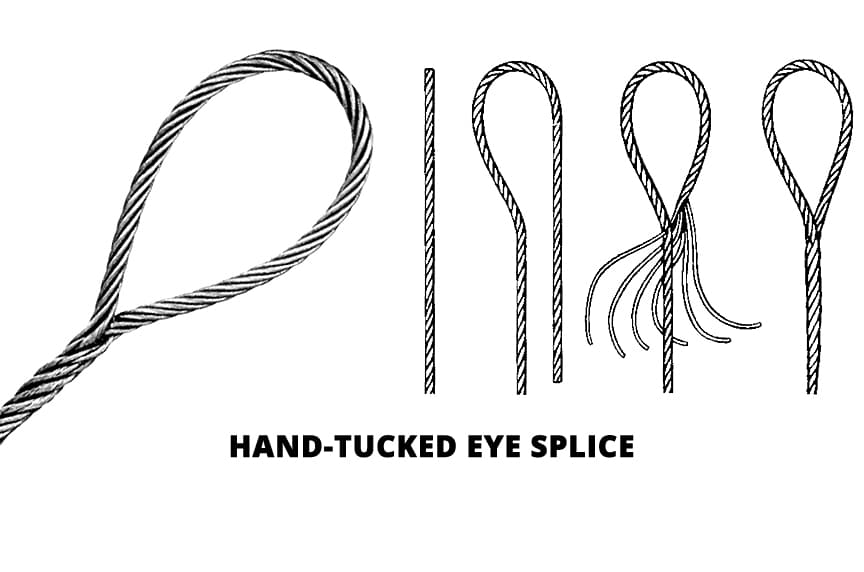

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

Manufacturer of aluminum swage sleeves including hour glass, oval, thin wall, combo & fiber rope sleeves. Hour glass sleeves range in rope & sleeve size from 1/32 to 1/2, width from .090 to 1.062, height from .136 to 1.625, hole width from .040 to .562, length from 1/4 to 2. Oval sleeves have a rope & sleeve size of 1/16, width of .172, height of .250, hole width of .078 & length of 3/8. Thin wall sleeves range in rope & sleeve size from 3/32 to 5/32, in width from .226 to .375, height from .372 to .562, hole width from .118 to .200 & length from 1/2 to 11/16. Combo sleeves are available with rope & sleeve size of 1/8 x 1/16, width of .343, height of .500, hole widths of .156 & .078 & length of 5/8 or sleeve size of 3/16 x 1/8, width of .430, height of .656, hole widths of .160 & .320 & length of 1. Fiber rope sleeves range in rope & sleeve size from 1/8 to 7/16, width from .250 to .855, height of .388 to 1.35, hold width from .160 to .525 & length from 1/2 to 1 1/4.

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

Alibaba.com offers a classic collection of steel wire rope splicing machine machines that are powerful, sturdy, and loaded with unique sets of features for more enhanced performances. These modernized machines can contribute to all types of heavy-duty lathe requirements involving metal, leather, etc. These technically-advanced steel wire rope splicing machine are equipped with a broad spectrum of fascinating features that offer superior precision and consistent performance level. Leading steel wire rope splicing machine suppliers and wholesalers on the site offer these premium machines for competitive prices and intriguing deals.

The incredibly powerful steel wire rope splicing machine are not only made up of sturdy materials such as metal and FRP but also very sustainable against all kinds of usages. These machines are ideal for use in the manufacturing industry due to the wide variety of purposes that they cater to. The steel wire rope splicing machine on the site are available in both semi-automatic and automatic versions depending on your requirements. Coming with distinct capacities and max spindle speeds, these steel wire rope splicing machine are well efficient in processing distinct workpieces such as shafts, discs, and rings.

Alibaba.com boasts of multiple steel wire rope splicing machine available in various designs, shapes, colors, and sizes depending on your specific requirements and the models are chosen. These superior-quality steel wire rope splicing machine are ideally used for distinct purposes such as drilling, reaming, tapping, and knurling in accordance with your preferences. The products available here are provided with a centralized automatic lubrication guide to reduce heat distortion and offers better stability. These steel wire rope splicing machine are also equipped with low noise generating technology for soundless performance.

At Alibaba.com, you get to select among distinct steel wire rope splicing machine depending on your specific budget and requirements to purchase these products without having to spend excessive money. These products are ISO, CE certified and are available as OEM orders. Customizing is also an option when you are buying these machines in bulk.

Flemish Eye Splice–In the standard flemish eye mechanical splice, wire rope is separated into two parts—3 adjacent strands, and 3 adjacent strands and core. These two parts are then re-laid back in opposite directions to form an eye, and the ends are secured with a swaged metal sleeve.

This splice is a version of the "Flemish Reduced Eye splice" intended for use on a winch drum. The reduced size enables it to pass through heel blocks and gin blocks on a ship"s derricks. Caution! The splice is unsafe unless it has at least 3 to 4 turns on the winch drum, it is not intended to have the full load applied to the splice, nor is it intended or approved for use in "running rigging" where rotation of the wire rope may occur.It has been used extensively in the logging industry, out of sight of safety inspectors.

I am an 80 year old former Able Seaman, and qualified Port of Melbourne Rigger/ Wire Splicer, with comprehensive experience in splicing wire ropes used in the Ports large wharf cranes and slipways. I have never used a Flemish Eye because of the safety issues. There is an alternative splice which I used but this would be outside the capabilities of an untrained person. I would advise the novice to use at least three bulldog grips, but first make sure the saddles are placed on the live standing part and the u-bolts on the cut end, to avoid distortion of the main load bearing part of the wire.

This splice is a version of the "Flemish Reduced Eye splice" intended for use on a winch drum. The reduced size enables it to pass through heel blocks and gin blocks on a ship"s derricks. Caution! The splice is unsafe unless it has at least 3 to 4 turns on the winch drum, it is not intended to have the full load applied to the splice, nor is it intended or approved for use in "running rigging" where rotation of the wire rope may occur.It has been used extensively in the logging industry, out of sight of safety inspectors.

I am an 80 year old former Able Seaman, and qualified Port of Melbourne Rigger/ Wire Splicer, with comprehensive experience in splicing wire ropes used in the Ports large wharf cranes and slipways. I have never used a Flemish Eye because of the safety issues. There is an alternative splice which I used but this would be outside the capabilities of an untrained person. I would advise the novice to use at least three bulldog grips, but first make sure the saddles are placed on the live standing part and the u-bolts on the cut end, to avoid distortion of the main load bearing part of the wire.

Want to do your own rigging and splicing of ropes? We have made more than 30 rope splicing instruction videos. For example, how to make an eye-splice in modern ropes? Or how to make soft shackles from ropes with Dyneema® fibers? Watch our video"s! The reference numbers correspond to the chapters of "Handbook Splicing Modern Ropes".

Want to start with splicing? Check out our wide range of splicing tools. And do you already have our Rope Splicing App on your phone? All splicing instructions in your pocket and easy to use off-line!

If your rope does not hold in jammers or clutches, splice an extra cover or add an extra core. Chafing covers from Technora or Dyneema®are great to extend the life of your ropes.

Splicing modern braided ropes of super fibres is quite fun and easy to learn. Premiumropes has uploaded various splicing tutorials, such as eye-splices, soft shackles, taper sheets or make a continuous furler line. Make sure you have enough space to work and an anchoring point for your rope. If you are on board, you can use a winch in case you need extra force. Choose a fid that matches the diameter of the rope, or even one that is slightly thinner. Never use pliers to pull out a fid from the rope - you will damage it! Do you know what the construction of your rope is? Check our table what splicing technique to choose for which type of rope. The core material largely determines the type of splice, whether it is core dependend or if you need to use the cover in the eye-splice too.

8613371530291

8613371530291