stahl wire rope hoist manufacturer

STAHL Crane Systems wire rope hoists range in capacity from 500 kg to 160,000 kg. STAHL wire rope hoists have a compact, sturdy construction which is extremely low-maintenance. The reliability, power and long service life of Stahl hoists are above average. The particularly smooth, precise starting and braking characteristics are common to all. Tri-State Overhead Crane is your go-to Stahl hoist parts distributor.

The STAHL CraneSystems AS7 wire rope hoist is an innovative choice in lifting and crane technology. The low-maintenance components and modular system are appreciated by users, crane and system manufacturers.

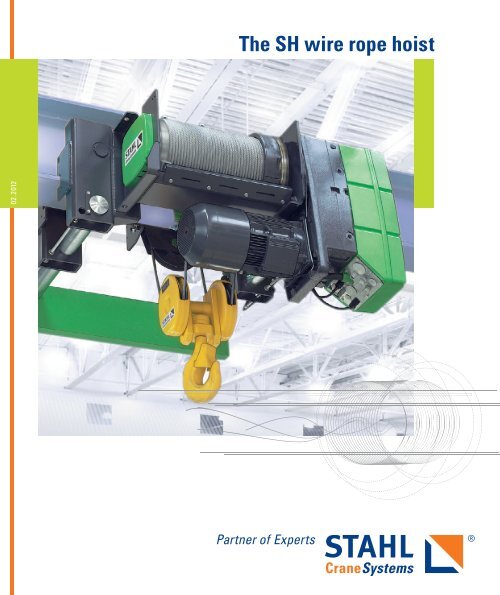

The STAHL SH wire rope crane hoist has been the standard in lifting and crane technology around the world for years. The modular system allows for practically unlimited combinations to meet any of your lifting needs.

TSOC sells, services and provides parts for STAHL wire rope crane hoists; serving clients from coast to coast, Canada, Mexico and especially focused in Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

What’s special about this: we can com- bine the individual components at will so that each of our wire rope hoists is ideally designed for your requirements. Regard- less of whether it’s a standard or an indi- vidually customised product.

The SH wire rope hoist from STAHL CraneSystems is one of the best hoists in the world. The SH Compact, powerful and particularly maintenance-friendly modular system permits practically unlimited combinations of the individual components. Five frame sizes, 26 S.W.L. variants between 500 kg and 28,000 kg: this makes the SH wire rope hoist the best hoist both for standard and off-standard solutions.

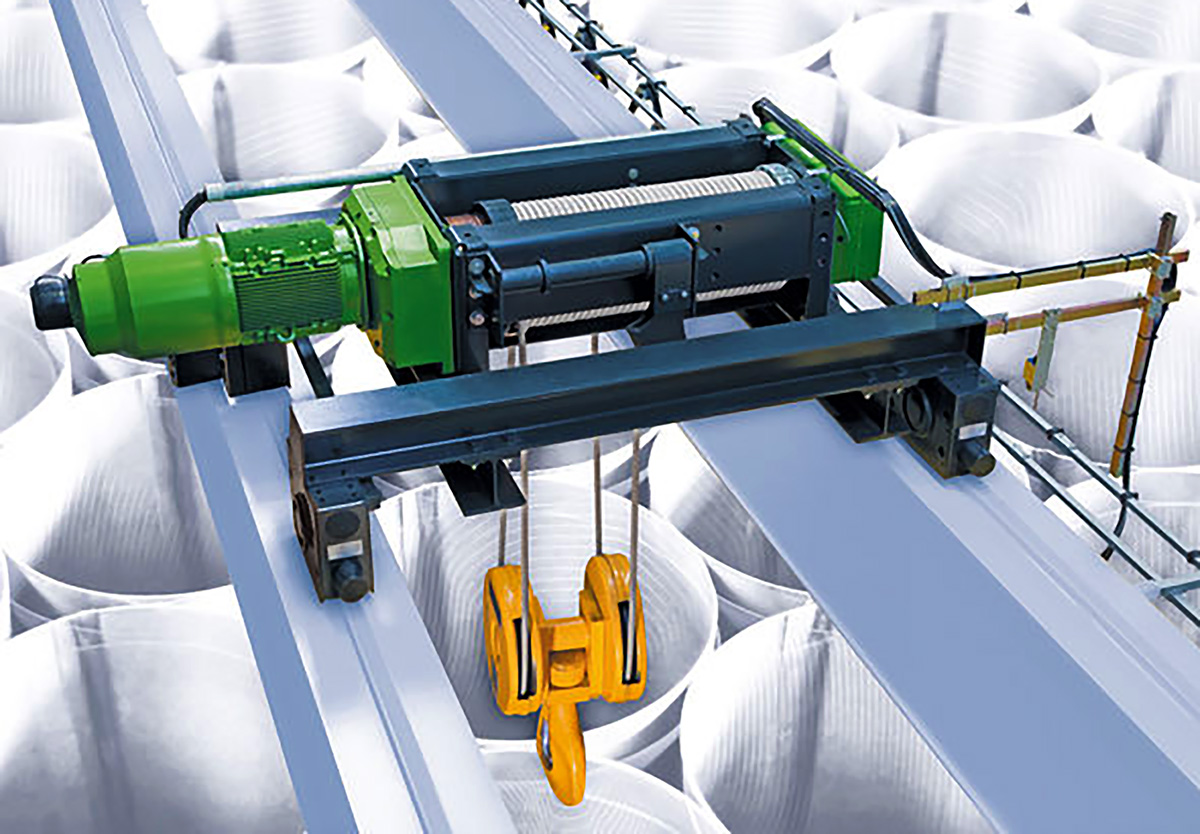

The AS 7 range supplements the SH series in the upper S.W.L. range up to 125,000 kg. Its compact construction makes it particularly suitable for systems manufacture and applications in restricted spaces. The AS 7 wire rope hoist is used either as stationary hoisting or towing equipment or mounted on crabs on double girder cranes and systems.

The combination of two AS 7 wire rope hoists as a twin hoist offers an interesting alternative to comparable hoists in a similar load class as regards technology and price. As a twin hoist, the AS 7 wire rope hoist has a higher hoisting speed than conventional hoists, considerably greater lifting heights and maximum safe working load of 125 tonnes.

STAHL winches lift heavy loads up to 160 t. Their powerful hoist motors and robust, low-maintenance design make them perfectly equipped for rugged everyday work.

In contrast to wire rope hoists, winches require only a low number of rope reevings even for heavy loads, this makes them particularly compact and cost-effective

STAHL wire rope hoists is designed from a technically mature modular system that guarantees cost- effective production at the highest level of quality.

We can combine the individual components at will so that each of our wire rope hoists is ideally designed for any of your special requirements : an individually customised product will be delivered to your specifications from standardized, field-proven components.

The SH Series is a heavy-duty, compact, low maintenance wire rope hoist from STAHL. Providing load capacity ranges from 1 Ton to 15 Tons. Standard dual speed motor for smooth lifts with speed options. The STAHL SH wire rope hoist can be used by itself or together with a trolley for standard cranes. Optional short headroom monorail trolley and double girder trolley available. IP 66 protection for outdoor use without a protective roof.

The SH wire rope hoist programme has been the embodiment of perfection in lifting and crane technology all over the world for many years. Compact, high-performing and particularly maintenance-friendly. Users, crane manufacturers and system manufacturers appreciate the modular system based on field-proven, low-maintenance components. Series manufacture of the standard components means economic advantages for you. And this combined with precise manufacture of off-standard components makes the SH wire rope hoist a widely acknowledged top quality product. The modular system permits practically...

The SH wire rope hoist The models and travel carriage variants Different types and variants of travel carriage for the SH wire rope hoist open up the most varied applications. Individually tailored to your specific requirements as stationary hoisting or towing equipment, for use with a trolley or crab, or for systems manufacture. The travel carriages are equipped as standard with two travel speeds. But in this matter too we are open to your requirements. Other speeds are available as options. Our wire rope hoists are known worldwide for their flexible and versatile use. Compact dimensions...

Cram S/stems Stationary model The SH wire rope hoist can be used as stationary hoisting or towing equipment, for example in systems manufacture. Depending on the application, the rope lead-off angle, the attachment of the hoist and the mounting position of the hoist motor can be varied. OE double rail crab The OE double rail crab is intended for use on double girder overhead travelling cranes. The extremely compact construction makes very low approach and headroom dimensions possible and the available space can thus be used to the full. The double rail crab is available with various track...

The SH wire rope hoist It’s reassuring to know what convincing technology is concealed in the SH wire rope hoist. The largely maintenance-free components of the modular wire rope hoist are optimally matched to each other. They guarantee constant performance, high efficiency and long service life. The standard safety components such as gear limit switch, motor temperature control and overload device, or even an optional additional brake, increase workplace safety. ■ Highly flexible special rope with long service life ■ Field-proven enclosed rope guide in spheroidal graphite cast iron has no...

■ Low-maintenance asbestos-free brake; needs no adjustment ■ Long service life thanks to generously dimensioned brake ■ Brake easily accessible for inspection from outside ■ Motor management ensures low wear ■ IP 65 protection ■ Special-purpose motor for hoisting applications ■ Classified according to ISO, high duty cycle and switching operation frequency ■ IP 55 protection, thermal class F ■ Motor outside rope drum, highly efficient motor cooling, maintenance-friendly ■ Temperature control by ptc thermistors ■ Optimised ratio of drum to sheave diameter ensures low wear on rope ■ Flexible...

The SH wire rope hoist There’s always room for improvement. Although it is already first-class in standard design, you have the alternative of making your SH wire rope hoist even safer, even more cost-effective, even more convenient by selecting from numerous mechanical, electrical and electronic options. As a welcome side-effect, the service life of the wire rope hoists is prolonged. The extensions to the programme increase the performance of the wire rope hoist and adapt it to your individual requirements. Here we show you some examples of the options available. If you need further...

■ Continuous load monitoring by overload cut-off even if hoist is at a standstill ■ Overload protection with ALC automatic load control ■ Load spectrum memory for load-related operating time summation ■ Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles ■ Data exchange with PC possible ■ Travel limit switches on trolley/crab for cross travel, optional ■ Limiting for both directions of travel ■ Switchover from "fast/slow" (predisconnect) ■ Switch contacts designed for control current ■ IP 66 protection ■ SLD four-digit 7-segment load...

The SH wire rope hoist | The options ■ The brake release device permits the hoist brake to be released manually and thus the load to be lowered during a power cut. ■ As an option, every hoist can be equipped with this supplementary equipment to the standard brake. ■ Redundant brake system provides increased safety ■ Intercept and holding brake, prevents the load falling even if the gear should break ■ Control is effected with a centrifugal switch or safety PLC Frequency control ■ Smooth starting and braking characteristics ■ Load swing greatly reduced ■ Fast, precise positioning of the...

The SH wire rope hoist Engineering means innovation and individuality. Constantly redefining the lifting and transporting of loads for complex requirements even in explosive areas is a job for our experts. Drawing on one of the widest product ranges of standard components, they regularly develop modern, individual off-standard and customised solutions. Hardly any other manufacturer of lifting and crane technology can offer you this diversity of precisely designed top quality customised solutions with maximum cost-effectiveness. The SH wire rope hoist programme forms the basis for a wide...

Example 1 TDC Twin Drive Concept The TDC Twin Drive Concept TDC is the uncompromising solution for hoists complying with DIN EN 14492-2, Annex B. Hoists in TDC design are intended for transport of molten metals and for use in high-risk applications: acids, alkalis, gases or transport over gas and acid pipelines. They are equipped as standard with two motor-gear units. Both motors are always synchronously controlled. The brakes mounted on the two motors are designed so that in an emergency each one is capable of braking or holding the load by itself. The two brakes are activated in...

The SH Series is a heavy-duty, compact, low maintenance wire rope hoist from STAHL. Providing load capacity ranges from 1 Ton to 15 Tons. Standard dual speed motor for smooth lifts with speed options. The STAHL SH wire rope hoist can be used by itself or together with a trolley for standard cranes. Optional short headroom monorail trolley and double girder trolley available. IP 66 protection for outdoor use without a protective roof.

STAHL CraneSystems’ wire rope hoists cover the S.W.L. range from 500 kg to 125, 000 kg. They are based on a technically mature modular system that guarantees cost-effective production at the highest level of quality. What’s special about this: we can combine the individual components at will so that each of our wire roperead more...

The STD dual chain hoist was developed specifically for long material and loads that need to be picked up at two points. It is equipped with two load chains, which are moved synchronously by a hoist motor. The hookread more...

ElectroMech is the exclusive India partner for STAHL Crane Systems, Germanys range of Explosion protected crane and crane components. Explosion protected crane technology is used in industries such as chemicals, oil & gas, paints and pharmaceuticals. STAHL Crane Systems is the pioneer for explosion-protected craneread more...

With a wide range of wire rope and chain hoists from Stahl we offer you the greatest variety of hoists in the world. That means flexibility for your logistics tasks. Every material flow requirement, however unconventional, can be solved individually and at a particularly favorable ratio of performance and cost-effectiveness.read more...

STAHL Wire Rope Hoists are designed for safe working loads upto 100, 000 kg-available as a modular system in various ratings from 320 to 100, 000 kg. with 6 frame sizes and 26 SWL variations permit practically unlimited adaptability to all customer-specific applications. In addition they have low headroom and short approachread more...

Columbus McKinnon Corporation, a designer and manufacturer of motion control products, technologies, and services for material handling, offers the AS7 electric wire rope hoist as an addition to its advanced hoist product portfolio. STAHL CraneSystems, a wholly owned subsidiary of Columbus McKinnon, developed the AS7 as a cost-effective, specialized solution for users, crane manufacturers, and system manufacturers.

“As part of Columbus McKinnon’s wire rope hoist product family, the AS7 modular system offers practically unlimited component combinations to produce ideal application solutions for our Channel Partners,” said Carlos Bassa, North America product manager, wire rope hoists. “Minimal-maintenance components are optimally matched to provide continuous productivity, high efficiency, and long service life.”

The AS7 is assembled with German-made components in two designs, a deck mount configuration for stationary hoisting or towing equipment and a double girder trolley configuration for double girder overhead traveling cranes. Both designs have a maximum load capacity of 85 tons, with customization available for higher capacities upon request. The AS7 is also available in a twin drum configuration, which serves the same applications, but offers a load capacity up to 135 tons, greater lifting height, faster hoisting speed, and precise load positioning.

A variety of models and trolley options for the AS7 and ASR7 wire rope hoist systems can be tailored to specific requirements for stationary hoisting or towing equipment. Options to further customize these wire rope hoist systems include pendant pushbutton controls, radio remote controls, emergency hoist limit switch, SMC multicontroller, load display, signal transmitters, brake release device, rope drum brake, and adjustable frequency drives. These options boost productivity, extend service life, and customize the hoist to specific requirements.

Columbus McKinnon also offers custom-made AS7 designs with lifting technology and components that comply with ATEX and IECEx approvals for EX Zone 1, Zone 2, Zone 21, or Zone 22 hazardous locations. ATEX compliance, required in the European Union, certifies that the AS7 is safe to use in potentially explosive areas with flammable gases or dust. IECEx equipment certification signifies that the AS7 conforms to international safety standards for environments where a potential exists for explosions. All equipment for the AS7 is available in an explosion-proof design.

The SH wire rope hoist programme has been the embodiment of perfection in lifting and crane technology all over the world for many years. Compact, high-performing and particularly maintenance-friendly. Users, crane manufacturers and system manufacturers appreciate the modular system based on field-proven, low-maintenance components. Series manufacture of the standard components means economic advantages for you. And this combined with precise manufacture of off-standard components makes the SH wire rope hoist a widely acknowledged top quality product.

The modular system permits practically unlimited combinations of the sub-assemblies to produce your individual solutions. The SH series from STAHL CraneSystems is available for the load capacity range from 500 kg to 25,000 kg in five frame sizes with 26 load capacity variants. The wire rope hoists can be used as stationary models or together with a trolley or crab in standard cranes, off-standard cranes or systems manufacture. If your requirements are exceptional, the experts in our engineering department will develop customised solutions tailored to them.

Various off-standard designs are available for use in particular conditions. IP 66 protection for example is required for outdoor use without a protective roof or if the hoist is exposed to water jets. If there is a danger of the formation of condensation, or in arctic temperatures, space heaters are required. Even in explosive atmospheres you do not have to manage without the SH wire rope hoist. On request, the entire wire rope hoist programme is available in explosion-protected design for Zone 1, Zone 2, Zone 21 or Zone 22. It’s no coincidence that we are market leader for explosion-protected lifting technology and crane components.

If you thought the SH series was great just wait until you read about the AS7 hoist as it comes with standard lifting option up to 125 tonnes in capacity. If you’re looking for wire rope electric hoist manufacturers who design powerful lifting equipment for compact spaces then you’ve come to the right place. This hoist can be foot mounted or fixed to a motorized trolley and is suitable for double girder top running overhead cranes. It"s built with a powerful motor and braking assembly for both strength and safety.

MANUAL RELEASE OF HOIST BRAKE:The brake release device permits the hoist brake to be released manually and thus the load to be lowered during a power cut. As an option, every hoist can be equipped with this supplementary equipment to the standard brake.

ROPE DRUM BRAKE:Redundant brake system provides increased safety. Intercept and holding brake, prevents the load falling even if the gear should break. Control is effected with a centrifugal switch or safety PLC.

FREQUENCY INVERTERS FOR “LIFTING”:Smooth starting and braking characteristics. Load swing greatly reduced. Fast, precise positioning of the load, corrective switching operations rarely necessary. The reduced dynamic load means a longer service life for hoist motor and gear and reduces stress on the whole system.. ESR function (Extended Speed Range) for higher hoisting speeds with partial load. Worldwide approvals for all frequency inverters. Certified in compliance with DIN ISO 9001.

TWIN DRIVE CONCEPT:Prevents sagging of the load even when the gearbox fails. Permanent brake, drive and load monitoring. Two synchronously controlled hoist motors and brakes. Two manually releasable brakes for emergency lowering. Robust, completely encapsulated system. Service and safety brake of identical design. Up to 60 % higher load capacities when transporting non-molten metals.

LOAD DISPLAY:SLD four-digit 7-segment load display (Stahl Load Display), large format, luminous red, available with various interfaces including CAN. Choice of 60, 100 or 150 mm digit height. No additional sensor is required as the standard load sensor is used.

SMC MULTICONTROLLER:Continuous load monitoring by overload cut-off even if hoist is at a standstill. Overload protection with ALC automatic load control. Load spectrum memory for load-related operating time summation. Monitoring of the motor temperature of the hoist motor and travel motor. Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles. Data exchange with PC possible.

EMERGENCY HOIST LIMIT SWITCH:In standard version, the hoist is equipped with a gear limit switch for top and bottom hook position and an operational limit switch for top hook position. As an option, up to eight switching elements can be fitted to the switch. This permits for example further stopping positions and operational limiting in bottom hook position.

8613371530291

8613371530291