stainless steel wire rope company supplier

Manufacturer and distributor of standard and custom industrial display hardware and accessories including wire rope cables. Cable types include galvanized steel cables, stainless steel cables, vinyl coated cables, nylon cables and nylon coated cables. Galvanized steel cables are available in dia. of 1/16 in. and feature maximum load capacities of 380 lbs. Stainless steel cables are available in dia. of 1/32 in. with maximum load capacities of 90 lbs. Vinyl coated cables are available in dia. of 1/16 in. with maximum load capacities of 150 lbs. Nylon and nylon coated cables are available dia. of 1/32 in. and 1/16 in. with load capacities ranging from 60 lbs. to 300 lbs.

Stainless steel ropes and cables are among the most popular in several industries especially those in which operations are performed under harsh or caustic environmental conditions such as pulp and paper or marine industries. This is because stainless steel, as the name would suggest, is a particular family of steel alloys that are produced with a heightened level of resistance to stains, wear, and corrosion while maintaining relatively the same fatigue strength as other materials.

Each of these factors is crucial in selecting the proper wire rope as these cables are often used as safety or control cables and mechanical failure can be costly and even deadly.

Other considerations include diameter, length, specific composition, resistance to crushing or flattening, and ductility. These should be examined with regard to the intended use of the cable which can range from supportive guy lines, hoist ropes, and cable railings to safety cables and braking mechanisms.

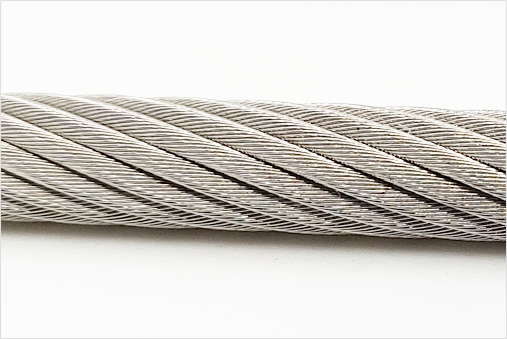

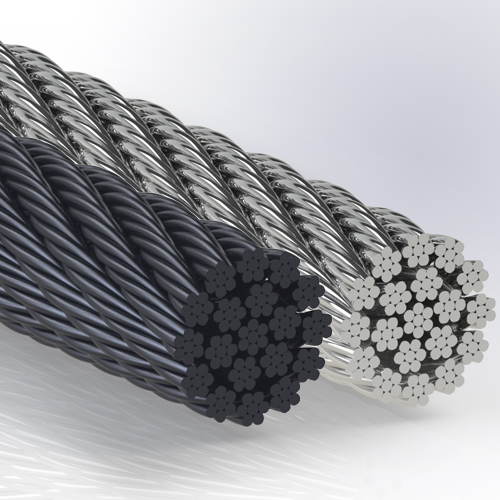

The particular design of a stainless steel cable should also be carefully considered. Like all wire ropes, these devices are composed of three main elements: filaments, strands, and cores. The filaments are the individual chromium steel wires which are often cold-drawn though may be produced in a number of ways.

Multiple filaments, which have a relatively small diameter, are twisted or braided together to form a grouping referred to as a strand. Most wire rope suppliers identify them by listing both the number of strands and the number of wires per strand. Strands are then helically wrapped around a core that may be stainless steel or an alternative material.

While alternative rope designs are available, the helical core design is often favored as it allows a wire cable to hold a lot of weight while remaining ductile.

The specific weight bearing and shock absorption abilities of a stainless steel cable depend on the particular alloy chosen. Grades 304 and 316 are the most popular types of stainless steel chosen for pulling, driving, and supporting applications.

Use our thorough list of wire rope manufacturers and suppliers in California to examine and sort top wire rope manufacturers with previews of ads and detailed descriptions of each product. Any wire rope manufacturers can provide wire rope products to meet your company"s specific qualifications. An easy connection to reach wire rope manufacturers through our fast request for quote form is provided as well. This source is right for you whether it"s for cable railing, marine rigging, or any other wire rope needs.

Type 302/304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine- and salt water.

Type 316 stainless steel is the standard high corrosion resistant steel for rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing and textile industries. It has the best pitting resistance in marine and salt water and can be used in temperatures up to 480°C (900°F).

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

Stainless Steel Wire Ropes are an important part of our core product range. We keep stock of AISI 316 Marine Grade Stainless Steel Wire Rope from 0.5mm up to 26mm in various constructions including: 1X19, 7X7, 7X19 and 6X36 wire core.

Providing high quality materials is an extremely important part of our ethos which is why our stainless steel wire ropes are produced in accordance with BSMA29 standards by one of the leading stainless steel wire rope manufacturers in the world.

Our ropes are used in demanding conditions and it is therefore vital that the tolerance and chemical composition of the material is as per the required AISI 316 requirements. Applications and markets include:structural and architectural, balustrade, yacht rigging and Stay Wire applications.

PersonalWe are on hand to personally guide you through the entire process, we translate the jargon, we recommend what’s best, and we are always here in person. No nonsense, just straight talking people who always exceed expectations through our extensive wire rope knowledge and superior service.

To accommodate for heavier weights and more heavy-duty applications, industrial wire ropes are available in different designs. Some of the most important elements to consider when purchasing wire rope for sale are:

Elite Sales offers a wide range of options for wire rope. Wire rope capacity can be adjusted based on your individual applications. Here are a few options to consider:

Material.Steel grades in wide use today are improved plow steel (IPS) or extra improved plow steel (EIPS); Stainless steel grades 302/304 and 316 are most common.

Industrial wire rope or cables are comprised of three key elements which all serve to support the rope’s strength and durability. It is important to understand the purpose of each of these components and the options available.

Wires: The most basic element of the wire rope are the individual wires used to form the cable. The thicker the diameter of the wire, the stronger it is, while thinner wires are more flexible.

Strands: A combination of multiple wires that are woven together form a strand. These strands are wrapped tightly together to maximize their strength and prevent uneven wear or breakage.

Fiber Core(FC) which can be made of natural or synthetic fibers that gives the wire rope some elasticity. However, it is not extremely strong nor is it optimal for high heat.

Wire Strand Core (WSC) consists of a singular wire strand which the other wires are wrapped around. This provides added stability while providing flexibility in the wire rope.

... outdoor with specific usual requests (highly agressive environments). Metallic central core, right hand laid. Construction 7x19. Available in diameter from 2.5 to 18 mm. Single stainless eye hooks are ...

... Tractel is a galvanized or stainless steel cable. The tool is designed 3 meters in length, and 8 mm of diameter. The tool is constructed using stainless steel or galvanized ...

The wire ropes, stainless steel rope components for the medical device, have excellent 1to 1 torque responsibility. Typical applications are endoscopic ...

... provides wire ropes that are suitable for every type of winch. There are two standard types, one with and one without a safety hook. The wire ropes come in a galvanized ...

CWI companies manufacture and stock the broadest range of domestic aircraft cable and wire rope in the USA, available to commercial and military specifications in stainless steel, galvanized carbon steel, and a variety of other alloys. We provide products "made and melted in America", "Made in the USA" through our United States based manufacturing facility that ensure your supply chain meets the Buy American Act or the Buy America Act when required. CWI is a fully integrated manufacturer: drawing wire, stranding cable, extruding jacketing material and providing custom products, configurations and processes when you require them.

Uses for stainless steel wires are incredibly diverse ranging from medical and dental tooling and apparatus to structural supports for construction and marine industries. Stainless steel wire is particularly well suited to such applications and others due to its hygienic, corrosion resistant, wear resistant and heat resistant qualities.

The high ductility, formability, weight to strength ratio and hardness of stainless steel alloys are also desirable traits of these filaments which may be used as such or combined through weaving, welding, twisting, braiding and more be made into complex products such as baskets, shelving or wire rope.

Along with the properties of a given stainless steel grade, the physical dimensions such as outer diameter, overall thickness or gauge, length and weight should be considered with regard for the final use of a rope to avoid potentially costly mechanical failure or inadequate performance. Steel service centers, wire rope manufacturers and other professionals should be consulted if uncertainty persists.

Rather than one specific steel alloy, stainless steel is a group of alloys whose compositions are primarily iron ore, but contain a minimum of 10% chromium. While other materials such as carbon, nickel, molybdenum, silicone and aluminum are present in various combinations, it is the chromium which gives the metals their name-sake non-staining, corrosion and wear resistant properties.

The chromium forms a protective layer of chromium oxide which provides the above characteristics. To create wires the alloyed material is first heated and then cast or otherwise formed into billets, ingots, rods or other stock shapes. One end of this form is then made narrower by hammering, filing, rolling or swaging so it will fit into a die. The pre-form for the wire is then pulled through the die, an action which decreases the overall diameter while increasing the length.

For thicker wire one die may be needed, but more often the strand is passed through a series of progressively smaller dies until the desired diameter and length are reached. Alternative processes such as extrusion, rolling or stamping may also be used in wire forming, though drawing is the most common among stainless steel wire manufacturers. Secondary treatments such as painting, annealing, coating and more are often made available to heighten the versatility of stainless steel wire both in terms of aesthetics and physical properties.

Sta-Lok stocks a comprehensive range of stainless steel grade 1.4401 (AISI 316) wire rope on 100,200 and 300-metre reels. Conforming to international standards, all wire is certified and fully traceable, in line with our quality systems and ISO 9001 accreditation. Learn how to choose the right wire rope here: Wire Rope Properties.

Stainless Steel Rod and Wire feature Type 316 composition, except for Double Spring strength which has an Elgiloy composition. All Stainless Steel Rod ...

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

8613371530291

8613371530291