stainless steel wire rope netting free sample

As a building material, stainless steel wire rope mesh is widely used in zoos, bird parks and various building protection projects. Such a safety-related material is costly, but its performance is what every customer cares most. There is no basis for trust for suppliers who are cooperating for the first time, and perhaps a small sample can be the beginning of trust.

Weiyue Stainless Steel Wire Mesh Factory provides customers with free samples and promises that the samples are consistent with the quality of the products placed. However, since the sample itself is provided free of charge, the cost is limited and the freight is required by the buyer.

If you are interested in our products, but because we have not cooperated in the past, if you want to know if our products meet international standards, then you can contact us at any time to get samples of the specifications you need. After testing, you will realize that you have obtained a very high quality stainless steel wire mesh product.

Looking for cable mesh netting? Go online and check out for cable mesh netting at Raffles Wire Mesh Pte. Ltd. Explore http://www.rafflesmesh.com for more info. #cablemeshnetting

Aviary Wire Netting by Yuntong made from stainless steel wires, and has skin-like characteristics. It can form a plane surface but can also be tensioned into three-dimensional forms featuring funnel-like, cylindrical or spherical.

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Jakob products are manufactured in Switzerland using only high-quality AISI 316. Whether your project needs stainless steel fittings, stainless steel fasteners or any stainless steel hardware, you won"t find a better product anywhere in the world.

This section includes stainless steel railing balustrades and guardrail created with our wire rope wire mesh netting, rods, fittings, and other INOX Line components manufactured by Jakob, Inc.. Components provided by Jakob, Inc. are fabricated from chromium-nickel austenitic stainless steel with low carbon content and containing molybdenum for greater corrosion resistance. These stainless steel, corrosion resistant, low maintenance, high tensile strength products provide design flexibility, durability, high strength to weight ratio, functionality, and impressive aesthetics.

** NOTE TO SPECIFIER ** It is the Architect"s responsibility to design the stainless steel wire rope railings including supporting posts, frames, and anchorage method to comply with applicable codes and regulations. Consult load tables contained in the manufacturers product data for required data. The following paragraphs identify typical code conditions, edit as required to suit actual requirements. Delete if data is indicated on the Drawings.

A.Structural Requirements: Provide wire rope railings systems capable of withstanding the effects of gravity loads and the following loads and stresses within limits and under conditions indicated on the Drawings:

** NOTE TO SPECIFIER ** It is the Architect"s responsibility to design the stainless steel wire rope railings including the height of railings, size and clearance of handrails, size of openings in guardrails, and other attributes to comply with applicable codes and regulations. The following paragraphs identify typical code conditions, edit as required to suit actual requirements. Delete if data is indicated on the Drawings.

C.Wire rope railing systems shall be designed, fabricated, and installed to accommodate expansion and contraction of metal components without causing undue stress, buckling, opening of joints, and distortion.

4.Where materials or fabrications are indicated to comply with design loadings, include material and safety factor properties, and other information needed for structural analysis.

A.Manufacturer Qualifications: Company specializing in manufacturer of stainless steel wire rope, fittings, and other stainless steel components with 10 years minimum successful experience.

A.Acceptable Manufacturer: Jakob Rope Systems, which is located at: 2665 N.W. 1st Ave.; Boca Raton, FL 33431; Toll Free Tel: 866-215-1421; Tel: 561-330-6502; Fax: 561-330-6508; Email: request info; Web: https://www.jakob-usa.com

** NOTE TO SPECIFIER ** Select wire rope paragraph(s) required and delete those not required. 6x7 wire rope is used for most railing applications due to ease of use and flexibility to accommodate stairs and curves. 1x19 has higher tensile capacity and is more resistant to bending and deformation under load. Typically 3 mm (1/8 inch) to 6 mm (1/4 inch) is used for cable infill. The type and size of wire rope to be used can be selected by Architect from Jakob product literature and load tables. Contact Jakob for assistance in determining the correct cable size and end fittings for your application.

A.Material: ASTM A 492 and ASTM A 555, Type 316 stainless steel. Fabricate wire rope with integral colored filament designating specific manufacturer.

** NOTE TO SPECIFIER ** Wire netting is a flexible, extendable, stainless steel wire mesh that when stretched between perimeter supports accommodates stretch and tension forces in three dimensions. Use the following paragraphs if Webnet is to be used as infill for guardrails. Delete if not required.

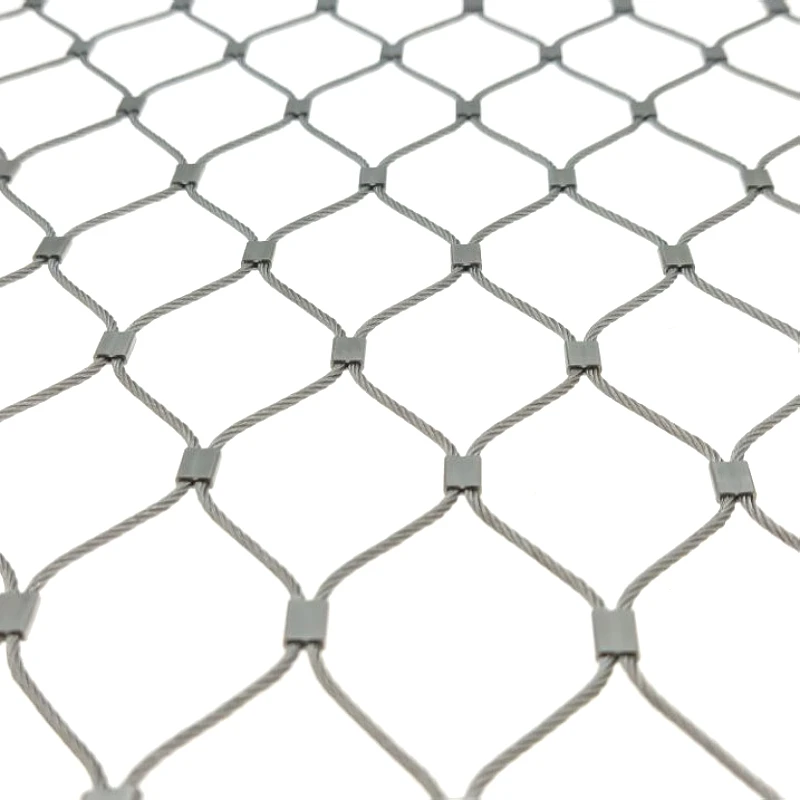

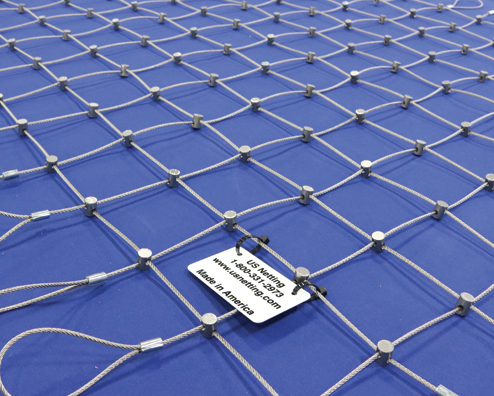

A.Material: Webnet as manufactured by Jakob, Inc. Parallel stainless steel wire ropes connected by reciprocally curved offset sleeves or clamps such that ropes are neither knotted nor crossed. Wire rope shall be fabricated from cold-drawn, AISI Type 316 stainless steel wire complying with ASTM A 492 and ASTM A 555.

** NOTE TO SPECIFIER ** The type and size of wire netting to be used can be selected by Architect from Jakob product literature and load tables. Contact Jakob for assistance in determining the correct cable size and end fittings for your application.

** NOTE TO SPECIFIER ** Guardrails can be infilled with vertical solid stainless steel rod spindles. Edit and include this article if rod spindles required. Contact Jakob for assistance in determining the correct rod size and end fittings for your application. Delete if not required.

** NOTE TO SPECIFIER ** Stainless steel rods are available in eight standard diameter sizes as listed in the following paragraph. Select the diameter required and delete those not required.

** NOTE TO SPECIFIER ** Stainless steel rods can be shop swaged with end connectors or rolled with external threaded connectors for on-site attachment. Select the rod termination required and delete those not required.

** NOTE TO SPECIFIER ** Guardrails and infill require fittings for attachment and connection of stainless steel wire rope wire netting and metal rods to support framework and substrates. Edit the following paragraphs as required. Contact Jakob for assistance in determining the correct end fittings for your application.

** NOTE TO SPECIFIER ** Fitting strength is typically a percentage of the wire minimum breaking strength. Depending on type of fitting, breaking strength can vary from 40 to 120 percent of wire rope minimum breaking strength.

C.Types: Fabricate from AISI Type 316 and 316L stainless steel complying with ASTM F 1145; INOX Line Fittings as manufactured by Jakob, Inc. Provide sizes and types as required to meet project design conditions specified and indicated on Drawings and reviewed shop drawings including:

** NOTE TO SPECIFIER ** Jakob, 1nc. manufactures numerous stainless steel fittings for wire rope ends, for attachment to different substrates, and for connecting wire rope segments. To ensure structural compatibility it is important the Jakob wire rope only be used with Jakob fittings. Typically required fittings will be determined by manufacturer to accommodate Project conditions and loadings. Edit the following to indicate basic type of fittings required for specific project. Delete the fitting type paragraphs not required.

1.Shop applied swaged rope ends: Threaded external and internal swivel ends, turnbuckles, tensioning screws, end stops, clevis ends, eye ends, loop ends, and end cones.

2.Screwed rope ends for on-site assembly: Threaded external and internal swivel ends, turnbuckles, tensioning screws, end stops, clevis ends, eye ends, loop ends, and end cones.

5.Anchoring systems: Studs, clevis, eye end, eye bolt, slotted, spacer baskets, radial clevis holder, cross clamp with support disk, slotted rope deflector, ball cage.

D.Accessories: Provide threaded couplings, tensioning screws, cover disks, eye bolts, eye nuts, carabiners, shackles, clips, welded rings, screws, washers, lock nuts, hexagonal nuts, dome nuts, wall anchors, screws, and wire endcaps as required to complete the installation.

E.Coordinate requirements, dimensions and spacings of wire rope railing system to ensure required factory drilled holes in supporting framework are correctly located.

C.Verify supporting posts and framework for stainless steel wire rope railings are prepared for attachment of anchors, fittings, wire rope, and wire netting and transfer of calculated loads.

Since the development of X-TEND® in 1990, Carl Stahl has continuously improved and further developed the cable mesh. X-TEND® is now produced in the United States and in Europe.

In Europe, the mesh is produced under European conditions in the Carl Stahl facility in Süssen, Germany, and has European quality certificates and quality marks.

Our cable mesh is made of stainless steel AISI316. This is also known as material class 1.4401 or A4 quality. We can guarantee this quality 100% through European certificates. If necessary, static calculations are made to demonstrate that our cable mesh meets your requirements.

Architectural rope Mesh, also called rope wire mesh, similar to architectural expanded mesh and architectural ring mesh, is one type of decorative wire mesh. Stainless steel architectural cable mesh for tensile architectural projects that combines protection and aesthetic design.

Generally, the architectural rope mesh is made of stainless steel but aluminum is also available. It is a product made of high-quality raw material and weaved, stretched and stamped through a special process. Stainless steel rope mesh has unique characteristics that allow design flexibility in architecture. It incorporates the tensile strength of the indestructible stainless steel and aesthetically diamond openings which is graceful and beautiful and is a perfect combination of modern science and art.

Stainless steel rope mesh is light, robust and transparent, and it can stand up to heavy loads, and now it has been widely used as balustrade infill systems, zoo enclosures, tensile facade, safety netting and green wall systems.

BMP is a leader in the flexible stainless steel cable netting industry. We are specialized in the development and production of stainless steel wire rope mesh products, with more than 20 years of experience. According to the different connection modes of stainless steel wire cables, stainless steel wire cable nets are mainly divided into stainless steel wire cable braided nets and stainless steel wire cable ferrule nets, both of which are diamond nets. Stainless steel wire braided net is to wind and cross stainless steel wires together without additional steel ferrules. It has a more straightforward structure, lighter weight, more beautiful and durable. Our company specializes in developing and producing stainless steel cable braided mesh. Stainless steel braided wire rope net will replace stainless steel ferrule net because of its many advantages and has broad development prospects.

Flexible stainless steel cable netting, also known as stainless steel cable net, wire rope woven mesh, stainless steel cable ferrule mesh, etc., is 304 / 316 stainless steel material. It is a metal net with extraordinary elasticity and high flexibility. The shape of the grid is diamond. The commonly used mesh angles are 60 ° and 90 °.

Wire Cable mesh can customize mesh size and wire rope thickness according to different applications. This is an innovative product born in the 1990s. It is durable and corrosion-resistant, fully reflecting the super toughness and plasticity of authenticating stainless steel. As soon as it was born, it was quickly accepted by the global market and became the favorite building material for architects and designers…

We can judge from the name that the two meshes are composed of stainless steel wire and cable, but the processing technology is different. Mesh knots (grids) are fixed in different ways.

The application of these two kinds of cable nets is very similar. They can be used as zoo fence net, Birdhouse net, safety net and railing net. The last difference is that the ferrule mesh is limited to fixed mode and cannot form a small mesh aperture. The mesh size of rope woven mesh can have a higher customizable range, and the minimum mesh aperture of rope woven mesh can be 15 mm (0.6 “).

The rope woven net of the invention has a more straightforward structure, higher light transmittance and better transparency effect in visual effect. It is easier to be ignored and has a negligible visual impact on people. It is almost invisible from a distance. The rope woven net has a simple structure; the net is more firm and will not deform. The ferrule mesh will lose the fixed steel sleeve due to slight differences in processing technology, resulting in mesh deformation. From the product quality perspective, rope woven bird aviary mesh has a more stable product quality. Another difference between rope woven net and ferrule net is the difference in weight. The weight of steel wire rope, woven mesh and ferrule mesh with the same area and thickness is different. The unit weight is heavy because the ferrule is fixed by steel ferrule. This means that the woven rope net with the same weight can have tremendous bearing pressure. In other words, the rope woven net is lighter at the same strength.

Stainless steel cable mesh adopts 304 / 304L 316 / 316L general stainless steel. 304 / 304L and 316 / 316L stainless steel sheets are stainless steel grades produced according to American ASTM standards. They have excellent corrosion resistance, easy formability, high toughness and safety. They are widely used in equipment and mechanical parts requiring corrosion resistance in the food and medical industries. To maintain the inherent corrosion resistance of stainless steel, they contain 18% or more chromium and 8% or more nickel. Stainless steel wire rope mesh is safe and reliable, corrosion-resistant, high toughness, soft and flexible, environmental protection, and has a long service life

304 steel has excellent mechanical properties. It has considerable corrosion resistance, high-temperature resistance, strong plasticity and stamping ability. It is usually used for tableware, furniture, equipment and medical equipment.316 steel increases nickel content and molybdenum element based on 304, which can significantly improve its acid, alkali and high-temperature resistance. It is usually used in the environment where the acidic solution comes into contact with seawater, also known as marine steel. In addition, 316 steel has a remarkable feature, that is, there is no thermal expansion and thermal shrinkage, which is very important for precision parts

The low carbon content ensures the intergranular stability of the material at high temperatures. 304L / 316L is suitable for high chlorine environments, high-temperature environments and places requiring welding. Intergranular corrosion of stainless steel corrosion resistance of austenitic stainless steel comes from the chromium oxide protective layer formed on the metal surface. Suppose the material is heated to a high temperature of 450 ° C to 900 ° C or in a high chlorine environment. In that case, the material structure will change, and chromium carbide will form along the edge of the crystal. Therefore, a chromium oxide protective layer cannot be formed at the edge of the crystal, resulting in reduced corrosion resistance. This type of corrosion is called “intergranular corrosion. “This led to the development of 304L and 316L stainless steels to resist this corrosion. 304L and 316L stainless steels have low carbon content. Due to the reduction of carbon content, chromium carbide will not be produced, and intergranular corrosion will not occur.

After years of R & D investment, Boss metal mesh has matured the dyeing process of stainless steel wire rope mesh. Our company adopts the chemical oxidation coloring method to form an oxide film on the surface of stainless steel wire rope mesh, which can protect stainless steel materials while forming different colors and is more resistant to corrosion, heat and ultraviolet rays. The color dyed by this process is uniform and bright, does not fade and fall off, and the effect is much better than that of coating and electroplating. It is reported that “austenitic stainless steel is exposed to the industrial atmosphere for six years, exposed to the marine atmosphere for 1.5 years, soaked in boiling water for 28 days, or heated to about 300 ° C. its color does not change.”

The super sizeable monocular panel can form a better visual effect and reduce the installation steps and difficulty compared with other products. The optional wire rope diameters are 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.2mm and 4.0mm. The mesh sizes selected are 15mm, 20mm, 25mm, 30mm, 38mm, 51mm, 60mm, 76mm, 90mm, 100mm, 127mm and 152mm. Classification according to different wire rope diameters is usually more intuitive. The diameter of the wire rope determines the maximum force of a single wire rope in the grid. It is imperative to determine the thickness of steel wire rope according to the service situation. The size of the grid depends on the purpose of the grid installation, such as keeping animals in captivity or preventing animals. The mesh size is determined by the size of the animal or object being processed.1.2mm diameter is usually used for birds and cages, and 1.6mm diameter is usually used for large birds, and small animals.2.0mm and 2.4mm diameter can be used for some medium-sized animals or large birds.3.2mm diameter can be used for large animals…

Stainless steel wire rope mesh is a multi-purpose mesh suitable for various places. It is divided according to the thickness of wire rope and the size of the mesh, forming a large number of product specifications. You can customize the specifications of the desired grid. Thanks to the processing method, the size of our products can also be customized. One-piece can reach 3000 square feet.

Handwoven Stainless Steel Netting is hand-woven from Material 304 or 316 stainless steel ropes by molds. It is a creative product that perfectly replaces the fences and bars used in zoological gardens, so it is called zoo mesh by clients. Stainless steel wire rope mesh for enclosure fences (alternate names: stainless steel cable mesh, flexible metal mesh, stainless steel wire rope woven mesh, stainless steel knotted rope mesh, stainless steel wire mesh, hand-woven stainless steel netting, stainless steel rope mesh).

HEBMETALMESH is a stainless steel wire mesh manufacturer from China, being a professional Handwoven Stainless Steel Mesh supplier. We are the zoo fence, enclosure factory supplier. Our products are widely used in zoos and therefore referred to by our customers as Zoo mesh. Our products are known as zoo fence, enclosure fence & birds aviary mesh, and so on.

Stainless Steel wire rope mesh enclosures zoo fencing produced by Hebmetalmesh is safety-certified, simple in structure, easy to install. Beautiful in appearance, highly durable, and maintenance-free (alternate names: hand-woven stainless steel netting, stainless steel wire mesh, flexible metal mesh, stainless steel cable mesh, stainless steel knotted rope mesh, handwoven multiple wire mesh).

Stainless steel ferrule rope mesh is also called stainless steel ferruled rope mesh. The only difference with stainless steel knotted rope mesh is that the two neighboring ropes of stainless steel ferrule rope mesh are combined by ferrules to form diamond openings. Stainless steel ferruled rope mesh is very flexible, and its width and length can be modified.

Our stainless steel ferrule rope mesh are mainly manufactured from high tensile stainless steel AISI 304, 304L, 316 or 316L. The rope construction is 7 × 7 or 7 × 19, making stainless steel ferrule rope mesh very soft. Therefore, it can be curved and folded easily, which makes it effortless to transport. And this property also makes it easy to install. The diameter of the stainless steel rope is from 1.2mm to 3.2mm.

Stainless steel ferrule rope mesh has diamond-shaped openings and ferrules, making it have great perspectivity and pretty appearance. Therefore, it is widely used as bird aviaries, animal enclosure, animal cages, building decoration and so on. And the stainless steel ferrule rope mesh itself is a big landscape.

1. Light weight and high flexibility. Stainless steel ferrule rope mesh is light, and its width, length, rope diameter and opening size can be modified.

Black stainless steel cable mesh is a special process surface treatment of stainless steel rope woven mesh, made of 304/316 stainless steel, in the original stainless steel color on the basis of the surface into a black, used in animal cages can absorb the strong sun Light, in the hot sun to protect the animal vision is not strong light, reflected light stimulation, play a certain shade effect. But also for the black oxide treatment of stainless steel rope net, the deeper play a preservative effect, combined with a unique aesthetic sense, compared to the original color stainless steel rope netting product performance quite, but the black stainless steel rope braid mesh is more design sense.

Black stainless steel cable mesh, stainless steel rope braid mesh, we also called wire rope cable netting, black wire cable net, black wire rope mesh, black wire rope zoo mesh, the use field is very broad, in addition to the zoo animal fence, zoo cage mesh, zoo wire cable fence netting, but also widely used in playground fence, stadium fence, staircase protective Fence, green plant climbing netting, indoor exhibition hall decoration, etc.

Manufacturers customized black stainless steel cable mesh, stainless steel rope braid mesh, no brokers, directly provide the lowest factory price to customers.

8613371530291

8613371530291