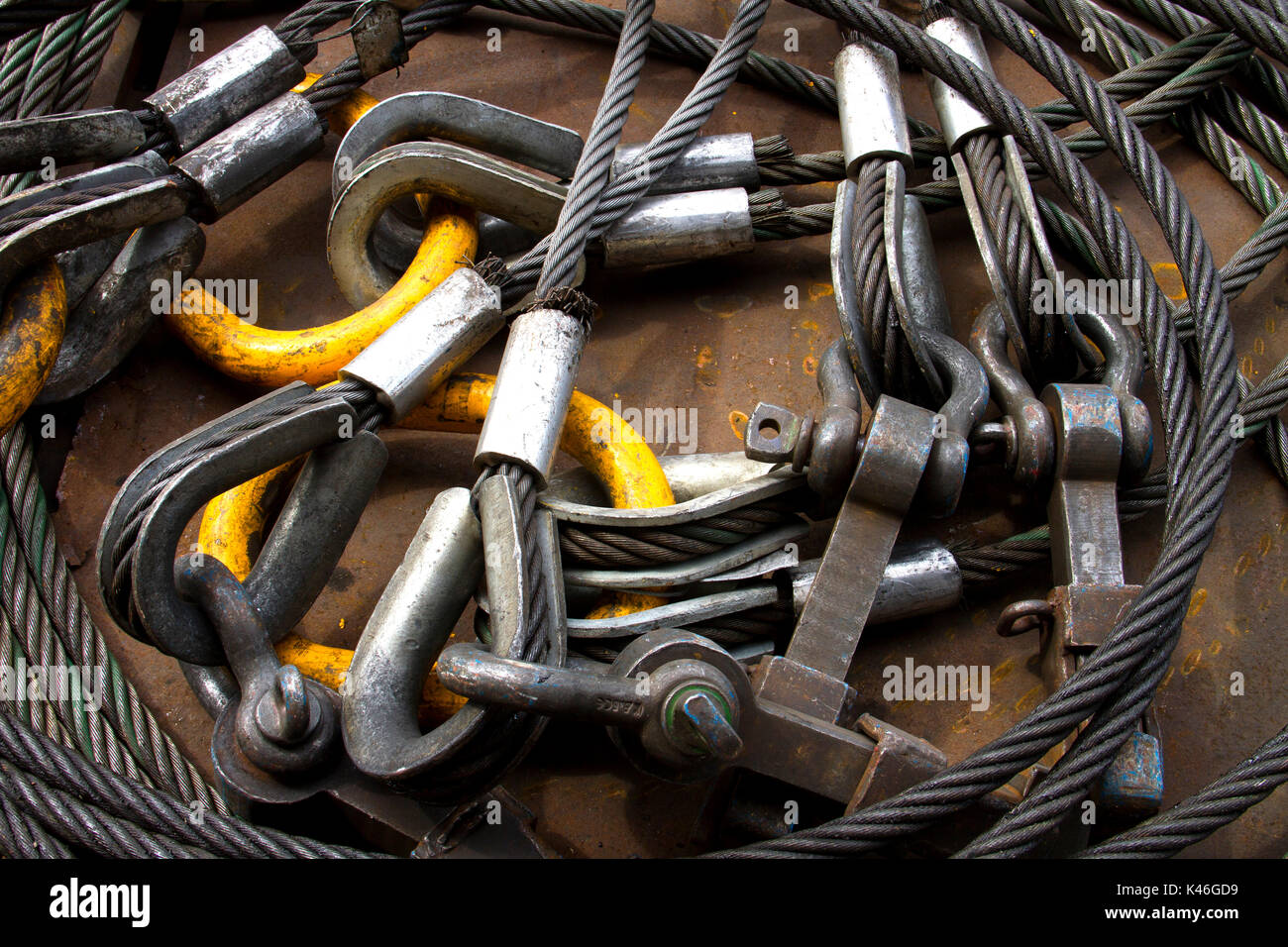

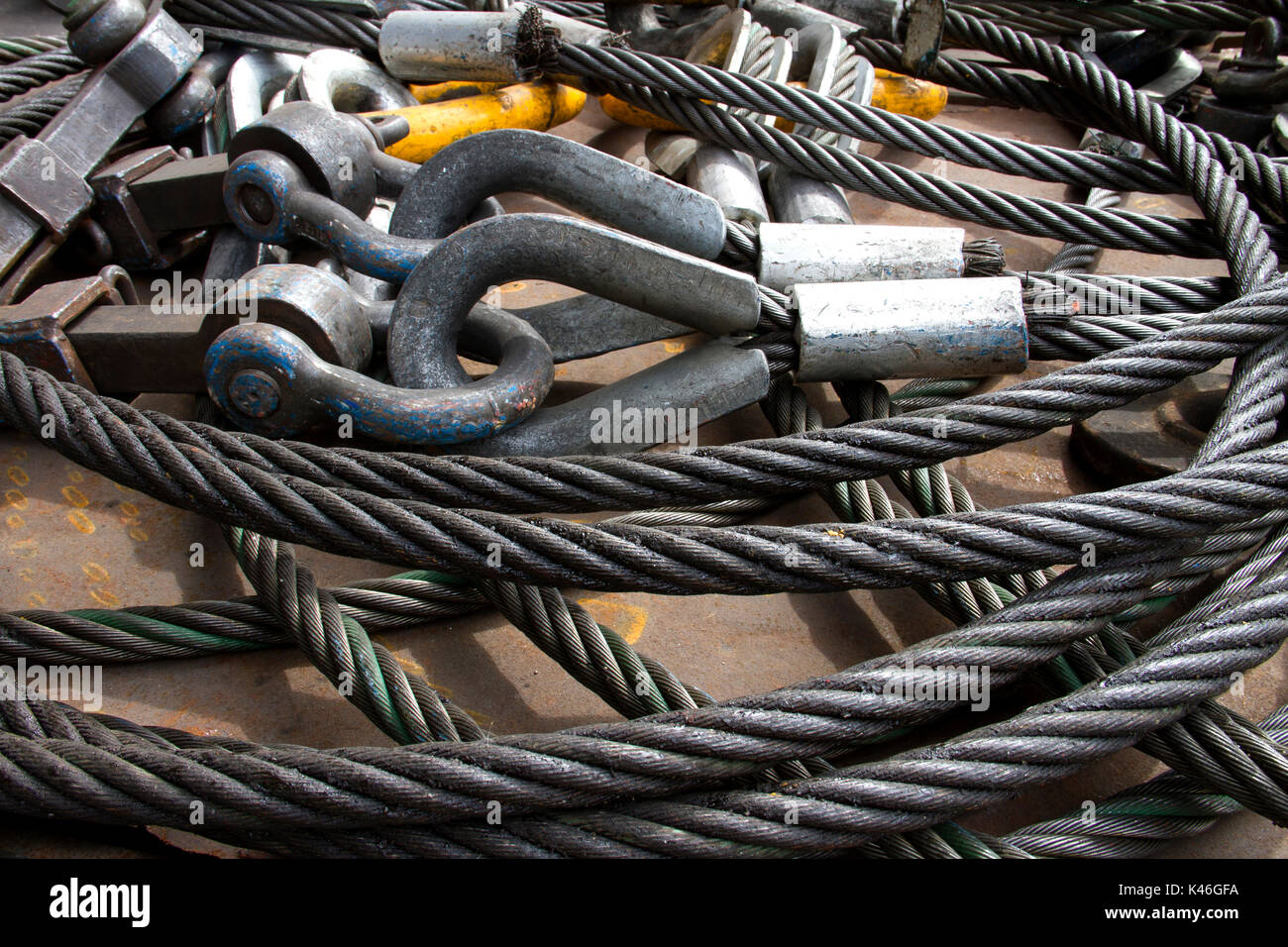

steel wire rope construction in stock

Stainless Steel Wire Ropes are an important part of our core product range. We keep stock of AISI 316 Marine Grade Stainless Steel Wire Rope from 0.5mm up to 26mm in various constructions including: 1X19, 7X7, 7X19 and 6X36 wire core.

Providing high quality materials is an extremely important part of our ethos which is why our stainless steel wire ropes are produced in accordance with BSMA29 standards by one of the leading stainless steel wire rope manufacturers in the world.

Our ropes are used in demanding conditions and it is therefore vital that the tolerance and chemical composition of the material is as per the required AISI 316 requirements. Applications and markets include:structural and architectural, balustrade, yacht rigging and Stay Wire applications.

Steel Wire Rope Ltd have specialised in supplying multi stranded galvanised steel wire rope since 1989. We stock from 0.5mm up to 64mm in various constructions including 1X19, 7X7,6X19, 7X19, 6X36, 8X19, 8X36, 19X7 and 35X7 with both Fibre Core and Steel Cores. In addition to these conventional steel wire ropes we can offer special wire ropes from high quality manufacturers.

Most wire ropes operate in demanding conditions and must resist crushing, bending fatigue and abrasion. We recognise that it is vital that all of our wire ropes need to perform to the highest levels to maximise service life therefore increasing productivity for the end user. With our technical experience we have worked hard with our partners to ensure that all material is manufactured to the very best standards in the steel wire rope industry.

Each steel wire rope can be supplied fully assembled complete with end terminals such as a thimble eyes, swaged ends and wedge sockets as well as many other solutions. These cable assemblies are manufactured in house by our team of engineers complete to your specifications.

Stainless Steel Wire Ropes are an important part of our core product range. We keep stock of AISI 316 Marine Grade Stainless Steel Wire Rope from 0.5mm up to 26mm in various constructions including: 1X19, 7X7, 7X19 and 6X36 wire core.

Providing high quality materials is an extremely important part of our ethos which is why our stainless steel wire ropes are produced in accordance with BSMA29 standards by one of the leading stainless steel wire rope manufacturers in the world.

Our ropes are used in demanding conditions and it is therefore vital that the tolerance and chemical composition of the material is as per the required AISI 316 requirements. Applications and markets include:structural and architectural, balustrade, yacht rigging and Stay Wire applications.

Each use for a custom wire rope cable assembly has its own unique purpose. We can assist you in designing a custom cable assembly to fit your specific needs.

The larger the diameter of cable, the less flexible it will be. Example: 1/8” 7 X 19 cable is more flexible than 1/8” 7 X 7 cable, but the 7 X 7 construction is more abrasion resistant.

Tyler Madison, Inc. specializes in cable size from 3/64" - 3/8" in diameter and 270 lbs. - 14,400 lbs. in breaking strength. We will put our years of experience to work in helping you design and produce exactly what you need. We have manufactured quality custom wire rope cable assemblies for leading companies in the following industries:Aerospace

Tyler Madison is an industry leading manufacturer of wire rope cable assemblies and custom wire and cable. Our knowledge and experience give us the capability to manufacture standard and custom wire rope assemblies and products for a variety of industrial clients. With in-house engineering and design services, you can get the exact kinds of wire rope assemblies and steel wire cable products that you are looking for from one place at an affordable price. Call us today to find out what types of cable assemblies we can do for you!

Hold everything together with the Jumbl 316 Grade Stainless-Steel Wire Rope, 1,000 Ft. Use this heavy-duty rope when working with hefty materials. This stainless-steel wire rope is great for fencing and hanging things you want to stay perfectly in place. With a breaking strength of 1,510 lbs., this is the type of reliable rope you do not have to worry about snapping.

Viable anywhere needed, use this stainless-steel cable indoors or outdoors. Stick with Jumbl to get strong, sturdy wire rope you can depend on for all your renovating and construction needs.

Braided to last longer – This durable wire rope is made up of 7 x 7 stainless-steel strands. These strands are braided together to create rope built to last.

For construction needs – Great for making renovations inside or outside the home. Hang up your heavy tools or thread the railing of your stairs with this rope.

Plenty to go around– Use this 1,000-foot-long rope for multiple application. Cut the rope and use some for fencing and the rest for hanging materials.

ROPETEX steel wire rope products are developed by Axel Johnson International – Lifting solutions group (LSG) and sold through companies that belong to the group.

In the ROPETEX product range, our decades of experience and extensive knowledge have been brought together to bring you steel wire rope products with an excellent price / quality ratio.

The production of ROPETEX steel wire ropes takes place in carefully selected production centres that continuously meet our strict requirements with regard to technology, quality, social responsibility and sustainability.

The product range is constantly under development and currently consist of General Purpose wire ropes, PVC coated steel wire ropes in several colors and high quality stainless steel wire ropes as well. Browse them below - and use the filters above if needed.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

Global Steel Wire Rope Market is Segmented By Material(Carbon Steel, Stainless Steel, Alloy Steel), By Lay Type(Regular Lay, Lang Lay), By End-User(Marine, Sports and Leisure, Oil and Gas, Industrial, Mining, Construction, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) – Share, Size, Outlook, and Opportunity Analysis, 2022-2029

[210 Pages Report]The Global Steel Wire Rope Market size was worth US$ YY million in 2021 and is estimated to reach US$ YY million by 2029, growing at a CAGR of YY% during the forecast period (2022-2029).

Steel wire rope is made from several strands of metal wire twisted into a helix to form a rope in a pattern known as laid rope. The wire rope diameter consists of multiplying the strands of such laid rope in a pattern known as cable laid. In the initial days, wrought iron was used for wire ropes; however, steel is exclusively used for making wire rope in the modern age due to the corrosion-resisting properties of steel. Galvanized steel and stainless steel are some forms of steel used to make wire ropes.

Historically, wire rope evolved from chains made of wrought iron, which had a high mechanical failure rate. Structural flaws in the chain links or solid steel bars can lead to complete and catastrophic failure, whereas flaws in the wire rope made of steel are less critical since the other wires easily bear the load. Friction between the individual steel wires and strands causes mechanical wear and tear over the rope"s service life and helps compensate for minor failures during service life.

Wire ropes were developed for hoisting mining loads in the 1830s. Today, wire ropes are used for dynamic lifting and hoisting in industrial cranes and modern elevators and mechanical power transmission in belt drive systems. Wire ropes transmit force and motion in mechanisms such as controlling an aircraft connected to levers and pedals in the cockpit. Static wire ropes support structures such as suspension bridges or as support to towers. A suspension monorail relies on a wire rope to support the carriage upside down. High corrosion resistance, good thermal stability and high stress and strain bearing capacity are some of the desired characteristics of steel wire rope.

Increased infrastructural and construction activities mainly drive the demand for steel wire rope is a key driver for the market. The growing adoption of synthetic and composite ropes is a key factor in limiting the growth of this market.

Rapid urbanization and industrialization are occurring globally, particularly in emerging markets. People migrating from rural to urban areas to seek better opportunities have increased urbanization and city population. Better infrastructure is required to accommodate the growing urban population. Strong economic growth has led to better socio-economic outcomes and rising disposable incomes. The above factors, ease of financing and increased government investment have led to the residential and commercial construction boom.

New residential apartments, recreational centers, commercial spaces, bridges, stadiums, tunnels and mass transit systems are under construction globally. The building and construction industry is experiencing an unprecedented boom, which has created strong demand for good quality, high-performance building materials. Steel wire rope is used in commercial construction suspension bridges and industrial cranes. Almost all modern elevators use steel wire ropes for operation. Therefore, the increase in infrastructure and construction is a key driver for the growth of the global steel wire rope market.

Recent years have seen a rise in innovation in the wire rope industry. Companies use new materials and rope construction methods to increase product value and drive growth. The industry is witnessing the growing adoption of synthetic and composite materials for wire rope making.

Synthetic materials are cheaper to manufacture than steel. Synthetic ropes also float on water due to their low density, making them ideal for marine applications. Synthetic ropes are also corrosion-proof since they are made from non-metals. The use of carbon fiber composites is also increasing since carbon fiber has twice the strength of steel with half the corresponding weight. The rising use of synthetic and composite ropes is a key challenge for the growth of the global steel wire rope market.

The global steel wire rope market experienced uneven impacts on value chains in production and sales in 2021 due to the COVID-19 pandemic. Construction and industrial applications saw steep declines since government-imposed lockdowns and restrictions brought a prolonged halt to manufacturing and office work globally.

China, a major market for the construction industry, emerged from the lockdown relatively early, in June 2020 and demand showed encouraging signs of recovery towards the end of 2020. However, North America and Europe were hit by the second wave of the pandemic, thereby depressing demand. The global demand is expected to recover by early 2021. Many small and medium scale companies in the supply chain were facing bankruptcy due to a collapse in demand. Global demand is expected to recover by the end of 2021 fully. The short-term impact of the pandemic has been mild for the steel wire rope market. The demand for steel wire rope remains strong and is expected to grow gradually in the coming years.

The global steel wire rope market is segmented into material, lay type, end-user and region. The steel wire rope market is segmented into regular and lang lay based on lay type. The regular type leads this segmentation since it has the largest applications. Lang lay is generally only used for specialized high load-bearing applications.

Asia-Pacific is leading in the global steel wire rope market. Due to major ongoing large-scale infrastructure projects, the region has the largest market share. China is also the largest market for steel wire rope in the world. China has the largest construction industry in the world and is expected to add US$1.2 trillion to global construction output by 2030. Residential and commercial construction has seen a tremendous increase in China in the last two decades.

China is also funding the Belt and Road Initiative (BRI), undertaking large-scale infrastructure projects throughout the Asia-Pacific. Residential and commercial construction has seen a tremendous increase in China in the last two decades. India is also undertaking massive commercial construction to drive infrastructure-led economic growth.

China also is the largest producer of construction equipment in the world. Steel wire ropes have extensive use in construction equipment, such as elevators and industrial cranes. The Asia-Pacific will continue to have the largest market share in the global steel wire rope market in the coming years.

The global steel wire rope market is competitive due to the availability of a wide variety of wire ropes that cater to different types of end-use applications. Some of the major players contributing to the growth in the segment are Bekaert S.A., Cortland Limited, Samson Rope Technologies, Southern Ropes, Marlow Ropes, Teufelberger, WireCo World Group, Gustav Wolf GmbH, Lanex A.S. and Jiangsu Langshan Wire Rope Co., Ltd. The major market players adopt growth strategies such as new product launches, patenting new technologies, joint ventures and collaborations, contributing to the growth of the global industry.

Overview:Bekaert S.A. is a major steel processing company interested in wire transformation and coatings. The company operates in 45 countries globally. Bekaert S.A. was founded in 1880 and is headquartered in Zwevegem, Belgium.

Product Portfolio:Flexisteelis a durable high tensile steel wire rope designed for an elevator hoisting application. A thermoplastic coating is applied to the rope to ensure noiseless elevator operation.

Key Developments: In February 2020, Bekaert S.A. and AGRO started a joint venture in Colombia. AGRO is a major producer of high-quality springers that merged with Bekaert S.A. to produce high-end steel wire systems. The merger is expected to increase the supply of steel wire ropes in South America.

Visualize the composition of the steel wire rope market segmentation by the material, lay type, end-user and region, highlighting the critical commercial assets and players.

Dy-pac® 18 The 18 series is a compacted rotation resistant rope construction consisting of a inner part with an outer layer of strands spun in the opposite direction.

Wire rope construction: veropro 10 is a very flexible 10-strand, non-rotation resistant rope with compacted strands and a rope core covered with a plastic layer.

30 NORTH GOULD STREET, WYOMING, UNITED STATES, August 26, 2022 /EINPresswire.com/ -- The new report by Expert Market Research titled, ‘Global Steel Wire Rope Market Size Report and Forecast 2021-2026’, gives an in-depth analysis of the global steel wire rope market, assessing the market based on types of lay, strand patterns, steel types, coating types, applications, and major regions.

The global steel wire rope market is being driven by the increasing demand from major application sectors, such as oil and gas and heavy machinery. The Asia Pacific is one of the leading regions in the global steel wire rope industry. Steel wire rope consumption and sales are extremely high in the Asia Pacific, especially in China, Indonesia, and India.

The steel wire rope industry in China has grown significantly over the last decade owing to the growing production of steel and rising investments in infrastructure activities involving lifting and motion applications. The increasing construction activities in China are expected to provide enhanced growth opportunities to the market in the forecast period.

A steel wire rope, which is composed of wires, strands, and a core made of steel and fibre, is a machinery commonly used in construction, mining, oil and gas, and marine sectors, among others. The function of the core is to sustain the external strands and protect them as they function. The wires, which are primarily made of stainless steel and high carbon steel, are twisted into strands to finally produce steel wire ropes.

The steel wire rope industry is expected to witness a healthy growth as a result of the product’s expanding applications in various sectors such as marine and fishery, and industrial and crane, among others. Steel wire ropes are light, strong, corrosion resistant, have low specific gravity and excellent elasticity, and are easy to mould.

These ropes are favoured in these sectors because of their excellent impact resistance, longevity, high strength, abrasion resistance, and corrosion resistance. In the coming years, the rapid urbanisation and industrialisation and the growth of these sectors, particularly in emerging nations, are expected to drive the market growth.

The major players in the market are Cortland Limited, Anchor Industries Pty Ltd, Samson Rope Technologies, Inc., Chung Woo Rope Co. Ltd, Teufelberger Holding AG, Fasten Group, and Bekaert Group, among others. The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

EIN Presswire"s priority is source transparency. We do not allow opaque clients, and our editors try to be careful about weeding out false and misleading content.

As a user, if you see something we have missed, please do bring it to our attention. Your help is welcome. EIN Presswire, Everyone"s Internet News Presswire™,

Shree Steel Wire Ropes Limited is an India-based company, which is engaged in the business of production of steel wire ropes and allied products. The Company is engaged in the manufacturing of wire rope, wire rope allied products and railway overhead equipment (OHE) products. The Company"s steel wire ropes are used in general engineering, shipping, fishing, mining, oil well exploration, construction, aerial application, and deep-sea exploration. The Company is a supplier to railways, port trusts, ONGC, Oil India, defense, steel plants, department of atomic energy, cold fields, and other projects. It produces various engineering components and parts from 50 grams to 10 kilograms per piece as per the customer’s drawings and specifications with international standards. It also produces non-ferrous castings, aluminum alloys, aluminum bronze, and brass. It company has production of approximately 1000 kilograms per day.

8613371530291

8613371530291