steel wire rope construction free sample

Barbed wire fencing strong sharply pointed element twisted around art pattern industrial barbwire protection concept design modern metallic sharp element for area protection

Nantong Fasten Metals Products Co., LTD is located in the coastal open city—Nantong which is in the lower area of the Yangtze River. We are a professional corporation which produces a variety of standards and types of galvanized steel wire rope, ungalvanized steel wire rope, steel-wire, stranded wire and spring steel wire. Our products mainly exported to Southeast Asia, the United States, Europe, the Middle East, Africa and other countries.

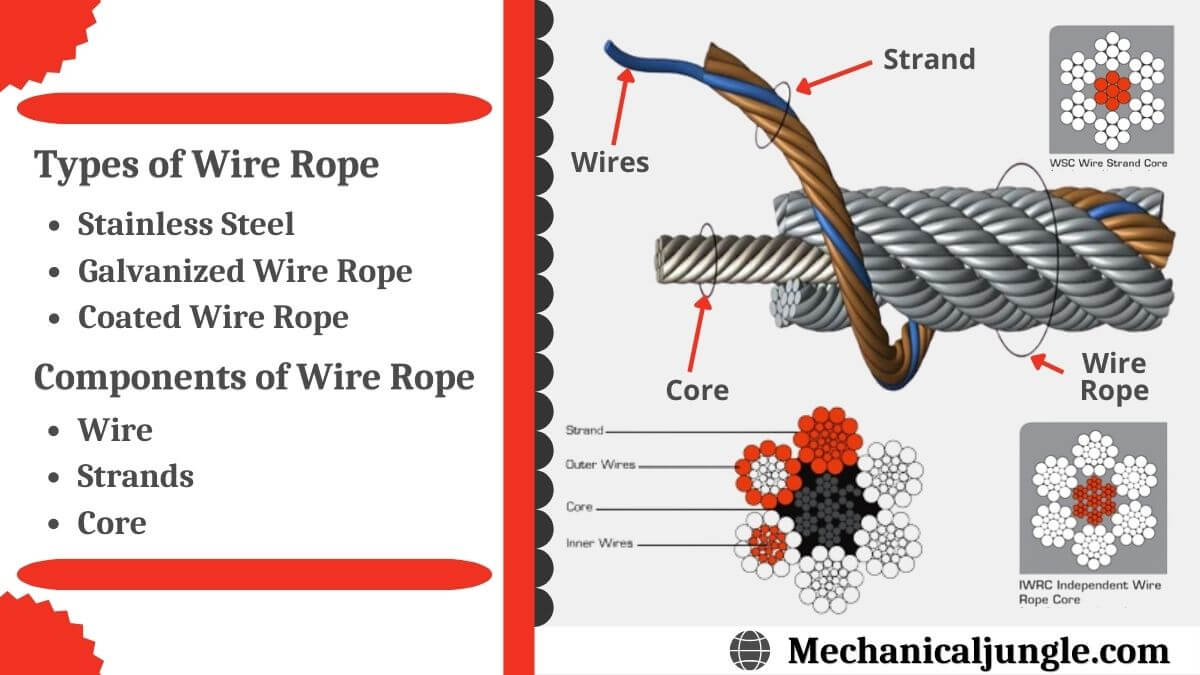

Asteel wire rope is defined not only by its basic elements (wires, strands, core), but also by the way in which the individual wires are laid together to create a strand and the way in which the strands are laid around the core, etc. The steel wire rope’s construction is defined when the following criteria have been determined:

The steel wire rope is designated according to the number of strands, the number of wires in each strand, the design (type) of the strand, and the type of core.

The number of wires in a strand varies between three and approx. 139, although there are most commonly 7, 19, 24 or 36 wires. The number of wires and their thickness depend on the design of the strand and affects the characteristic of the steel wire rope.

The type of strand is characterised by the way in which the wires in the strand are arranged. There are four basic types of strand design that are used in all steel wire ropes, either in their original form or as a combination of two or more types. The four basic types are:

The Standard construction (fig. 3) is characterised by the fact that all wires are of equal thickness, although the core wire may be thicker. The wires are also laid together in such a way that all of them, with the exception of the centre wire, are of equal length. In this way all the wires are subjected to an equal distribution of load when pulled straight.

The geometric wire distribution consists of one centre wire, onto which one or more layers are laid. Each layer is produced in a separate operation. If there are several layers, the number of wires increases by six for each layer.

The designation for a Standard strand with e.g. seven wires is (1-6), i.e. one centre wire with six external wires in one operation. If there are 37 wires it is known as (1-6/12/18), i.e. one centre wire with six external wires from the first operation, 12 from the second operation and 18 from the third operation.

The Seale construction (fig. 5) is characterised by the way in which the strand consists of two layers of wire produced in one operation. Also, the number of wires in the first and second layer is identical.This construction is somewhat stiffer than a corresponding Standard construction (with the same number of wires). This is because the outer wires in the Seale construction are considerably thicker.

The Filler construction (fig. 7) is characterised by a strand consisting of two layers of wires produced in one operation. Also, the number of wires in the second layer is twice the number in the first layer. This is, however, only possible if filler wires are inserted between the first and the second layers, to prevent the strand becoming hexagonal in shapes.

This construction is more flexible than a corresponding Standard construction and considerably more flexible than a corresponding Seale construction (with the same number of wires excluding filler wires).

A Filler strand with e.g. 25 wires (including 6 filler wires) is known as (1-6+6F-12), i.e. one centre wire with six wires in the first layer and 12 wires in the second layer. There are six filler wires between the first and the second layers.

The Warrington construction (fig. 9) is characterised by a strand consisting of two layers of wire produced in one operation. The second (outer) layer contains wires of two dimensions, and the number of wires in the second layer is twice the number in the first.

This construction is very compact and flexible. A Warrington strand with e.g. 19 wires is known as (1-6-6+6), i.e. one centre wire with six wires in the first layer and a total of 12 wires of two dimensions in the second layer. The centre wire may be replaced by several wires or a fibre core (fig. 10).

The Warrington-Seale construction is characterised by a strand consisting of three layers of wire produced in one operation. The number of wires in the third (outer) layer matches the number of wires in the second layer. Also, the layers below the outer layer are built as a Warrington construction.

A Warrington-Seale strand with e.g. 36 wires is known as (1-7-7+7-14), i.e. one centre wire with seven wires in the first layer, 14 wires made up of two dimensions in the second layer, and 14 wires in the third layer.

The strands and the wires in the strands do not necessarily have to be round. Examples of this are shown in fig. 12. The strands are special strands (i.a. with profiled wire), designed to meet extremely unusual requirements.

The number of strands in a steel wire rope varies between three and approx. 36, although most commonly there are six strands. The more strands a steel wire rope contains, the more rounded and flexible it is, although the wires in the strand are also thinner (less durable).

Fibre cores are the most commonly used, as not only do they provide a good, elastic base but also enable lubrication of the rope from the inside, since it is possible to add oil and/or grease to the fibre core during production. This reduces the risk of rust attacking from the inside. The fibre core is normally produced from polypropylene (PP) or sisal. PP can withstand weaker acids and alkalis and it does not rot. The advantage of a sisal core is that it can absorb oil/grease to a greater degree for lubrication of the steel wire rope from the inside.

Randers Reb recommends the use of a steel core, in the event that it is not certain that a fibre core will provide satisfactory support for the strands, e.g. if thesteel wire rope is spooled on to a drum in several layers under a considerable load, or at high temperatures.

The word “lay” has more than one meaning in this context. It is used to describe the process of interweaving the wires and strands and also to describe the appearance of the finished steel wire rope. The four most common terms to describe the lay of a steel wire rope are:

Right hand regular lay steel wire rope. In this instance the wires in the strand are laid in the opposite direction to the strands in the rope. The wires are laid helically left, while the strands are laid helically right (see fig. 13).

Right hand Lang lay steel wire rope. Here the wires are laid in the same direction as the strands in the rope. The wires in the strands and the strands are laid helically right (see fig. 15).

Multi layer steel wire rope (low rotation/rotation resistant). Here there are usually two layers of strands, the inner layer as a rule a left hand Lang lay, while the outer layer is a right hand regular lay.

Cable laid steel wire rope. The strands are normally 6-lay steel wire rope with a fibre or steel core. The core is a fibre core or a 6-lay steel wire rope with a fibre or steel core.

Flat braided steel wire rope. This steel wire rope is flat braided from strands or consists of parallel strands or steel wire ropes that are bound together by sewing (belt strap).

Right hand lay steel wire rope is also known as Z-lay, and left hand as S-lay. Similarly, a right hand lay strand is known as z-lay and left hand as s-lay. Fig. 17 shows why. Of the types of lay described, right hand regular lay is the most common.

“Preformed” refers to steel wire ropes in which the strands have been permanently formed during the laying process (see fig. 18), so that they are completely stress-free within the unloaded steel wire rope.

All Randers Reb steel wire ropes are supplied preformed, with the exception of certain individual special constructions (e.g. low-rotation/rotation resistant).

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for 3mm-5mm Pvc Plastic Coated Wire Rope, Steel Wire Strand, Gym Cables, The principle of our company is to provide high-quality products, professional service, and honest communication. Welcome all friends to place trial order for creating a long-term business relationship.

The plastic-coated steel wire rope is made of phosphate-coated steel wire rope, galvanized steel wire rope, and stainless steel wire rope. The steel wire rope is coated with plastic, usually PVC or PU coating. The plastic material includes domestic steel wire rope plastic and imported steel wire rope. plastic. The colors of the plastic-coated steel wire ropes are transparent white, black, yellow, green, red, etc., and can be painted with different plastic colors according to customer needs; the surface of the plastic-coated steel wire rope looks more beautiful, and the structure of the steel wire rope is more stable to a certain degree of relaxation Vibration and anti-extrusion effects can extend the service life of the wire rope

Coated Steel Wire Cables are widely used in Guardrail, cannery lines, closelines, abattoir wire, barrier ropes, computer security cables, gym cables, lock cable system, catenary systems, horticultural application, running cable applications.

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Free sample for Wholesale Pvc Coated Wire Rope Steel - Plastic coated steel wire rope – Bangyi , The product will supply to all over the world, such as: Benin, Romania, Poland, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let"s enjoy it!" Change for the better! Are you ready?

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We"re seeking forward in your check out for joint development for China Stainless Wire Rope 7x19, Coated Stainless Steel Wire Rope, China Steel Wire Rope Galvanized, Customers" benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

Natural core steel wire ropes use natural fiber rope cores such as jute, sisal, etc. This kind of rope core has a lot of oil storage, the steel wire rope is soft and not resistant to corrosion;

Synthetic core steel wire rope is a fiber core made of chemical synthetic materials, such as polyethylene, polypropylene, nylon, etc. This kind of rope core has less oil storage, and the steel wire rope is hard and corrosion resistant.

2. The steel core wire rope has better impact resistance and pressure resistance than the fiber core wire rope. The steel core wire rope is suitable for multi-layer winding;

3. Steel core wire rope is higher than fiber core wire rope in terms of high temperature resistance. Steel core wire rope is generally selected for high temperature occasions;

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for Free sample for China Galvanized Steel Wire - Steel wire rope with fiber core – Bangyi , The product will supply to all over the world, such as: Paris, Bandung, Montreal, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay. (The rope in the left hand lay photo shows one left hand lay rope from left to right and top to bottom, with 5 right hand lay strands, and part of a sixth in the upper left. It is not 5 right hand lay ropes adjacent to each other.)

Ordinary and Ducay"s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used, first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand. (On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang"s lay they are cross at an angle of about 45�.) Lang"s laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. For this reason, swivel termination units can be dangerous.

The specification of a wire rope type � including the number of wires per strand, the number of strands, and the lay of the rope � is documented using a commonly accepted coding system, consisting of a number of abbreviations.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Cables designed with 3×7, 7×7 and 7×19 construction provide for increasing degrees of flexibility but decreased abrasion resistance. These designs would be incorporated where continuous flexing is a requirement.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

Asahi Intecc started in 1976 as a manufacturer of custom stainless-steel cables solutions and monofilament stainless wire, including small wire rope, strands and cables, plastic coated miniature cable, and miniature stainless cable assemblies for both medical device and non-medical applications.

1. IWSC (Independent Wire Strand Core): The core consists of a strand made of the same material as the outside strands of the wirerope. These strands are combined in configurations such as 3x7, 7x7 and 7x19. This structure can be used universally as a mechanical element and features excellent axial rigidity and bending flexibility.

2. IWRC (Independent Wire Rope Core): The core consists of a wire rope, around which the outside strands are twisted. The core wire rope and strands are combined in configurations such as {(7x7)+(1x19)x8} and others. This structure is used for mechanical elements that require high flexibility. As durability in the original form is low due to easy deformation under contact stress, these types are usually coated with a synthetic resin such as nylon.

In order to ensure the highest quality, we draw our own wire material in-house. Besides regular SS304 and SS316, Asahi also has its proprietary WHT (high-tensile strength) stainless-steel. We also work with tungsten and nitinol.

Asahi wire rope has been specifically designed for high flexibility and high strength. Different structure options give the possibility to meet your need as closely as possible. Example applications are angulation wires in endoscopic scopes, medical robotics forceps, etc.

The global steel wire market size was USD 91.33 billion in 2018 and is projected to reach USD 112.14 billion by 2026, exhibiting a CAGR of 2.7% during the forecast period.

The demand for steel wire is driven by the increased spending by governments of emerging countries for the development of infrastructure. steel wire in the form of mesh and ropes are used for reinforcement, to provide strength to the structure. Their properties include high strength, lightweight, shock and wear resistance, and resistance to deformation. Furthermore, rising construction activities in the residential sector to provide housing for the growing population is another factor growing the demand.

Governments are investing massive amounts in developing the infrastructure of the country. Construction of suspension bridges to improve the connectivity and infrastructure has led to increased consumption of steel wire. Suspension bridge incorporates suspended steel wire ropes to support the roadway, and any load applied on the bridge gets converted to the tension on the steel cables. These wires are used in cables of suspension bridges as they offer properties including higher tensile strength, flexibility, endurance during tough conditions, and higher load-bearing capacity. This is projected to further propel the steel wire market trends during the forecast period.

The steel wire market driver includes the growth of the construction industry in the analysis period for developing countries. The market is expected to advance due to rising commercial, residential, and infrastructural construction by government and private firms. The development of schools, hospitals, and the residential sector has increased demand. The steel wire has applications such as reinforcement, and binding of rebar to keep the structure of the building intact as they have high strength, abrasion resistance, and resistance to corrosion and deformation. Mesh made from steel wire is the backbone of all modern constructions. Moreover, large scale structures such as bridges, towers, and dams also incorporate steel wire for reinforcement. Hence, the growing construction industry will drive the market in the forecast period.

Steel rope is several strands of steel wire twisted together in the helix formation. The historic review of teel ropes is used for applications, including lifting in cranes & elevators and transmitting mechanical power. One of the major factors restraining the growth of the market is the replacement of steel ropes by plastic ropes for various applications. Replacing steel ropes by plastic ropes has resulted in the reduction in weight of the machine, providing stability, and reducing the axle load. The plastic ropes can tolerate a tough environment during the installation, handling, and maintenance operations. The use of plastic ropes in mobile cranes is increasing as they offer better lifting efficiency, lower maintenance cost, and extend the life of the rope, thereby restraining the steel wire rope market.

Based on grade, the market is segmented into carbon steel, stainless steel, and flat steel, alloy steel. Amongst these, carbon steel grade dominated the market. Wires made from Carbon steel have high tensile strength and are used for applications such as construction where strength is required. Technological advances, leading to improved strength, wear and shock resistance, and lightweight, has been instrumental in the dominance of carbon steel grade in the global market.

The stainless steel segment is projected to register a significant CAGR during the forecast period. Incorporation of stainless steel for applications in automotive, aerospace, and surgical tools and equipment are factors anticipated to fuel its demand. Moreover, properties such as high strength, temperature resistance, recyclability, and long life, will drive the market during the forecast period.

Based on end-use industry, the market is segmented into automotive, construction, energy, agriculture, and others. Amongst the end-use industry, construction holds the major share of this market. The rising construction activities related to residential and commercial spaces, and infrastructure will influence the demand for steel wire. Moreover, the construction of bridges, dams, airports, and others to develop the infrastructure of the country is promoting the steel wire market growth.

The automotive segment is estimated to register substantial growth during the forecast period. This is attributed to its properties, such as heat resistance, abrasion resistance, flexibility, and lightweight.

The steel wire market size in North America stood at USD 8.24 billion in 2018. The market in the region is characterized by high demand for construction applications. The market in Europe and Asia-Pacific is projected to register a significant CAGR during the forecast period. The presence of major automotive manufacturing companies in Europe has increased the demand for steel wire for automobile applications. Growing construction and infrastructural activities in the developing countries of Asia Pacific, such as China and India, will drive the demand in Asia Pacific during the forecast period. The growth of the market in Latin America is attributed to the demand for mining applications. This, coupled with the rising ore extraction and mining activities in Latin America will drive the regional market. The Middle East & Africa, on the other hand is expected to show slow growth during the forecast period. This is attributable to the growing number of oil & gas exploration activities in this region.

The competitive landscape of steel wire depicts a fragmented market. The dominance of a company is dependent on the diversified product portfolio of steel wire for a variety of applications. Furthermore, constant innovations by the key players to improve the strength to weight ratio and tensile strength of the steel wire is expected to widen the presence of the company in the market. The rise in demand for these wires from the construction and automotive industry has encouraged companies to implement various growth strategies such as expansion, joint venture, and acquisition.

February 2018 –Optimus Steel acquires Gerdau SA’s Beaumont wire rod mill and two downstream facilities located in Texas for about USD 92 Million. The Beaumont steel mill has a melting capacity of about 700 KT per year and a rolling capacity of 800 KT per year. The mill produces coil rebar and wire rods.

March 2019 –WireCo. Introduced TURBOLITE M, a new 8 strand steel rope for underground mining applications. The TURBOLITE M offers better strength to weight ratio and is lightweight than standard steel ropes.

The steel wire market report provides future analysis of the market and focuses on key aspects such as leading companies, product types, and leading applications of the product. Besides this, the report offers insights into the market, current market trends, the impact of COVID-19, and highlights the key industry developments. In addition to the aforementioned factors, the report encompasses several factors that contribute to the growth of the market over recent years.

8613371530291

8613371530291