steel wire rope construction pricelist

Cylinders can be found in almost all hydraulic systems and combustion engines, and they are among the most common industrial components around. While the shape of a cylinder is always similar, these parts are actually very diverse, and choosing the correct cylinder can make or break a repair job. Whether you"re engaged in motorcycle maintenance, fixing hydraulic doors, or replacing the cylinder on a drilling rig, Alibaba"s wholesale store is the place to search. Finding a construction rope prices couldn"t be easier, and every cylinder variety is easy to find.

Cylinders come in a massive range of forms, so using the search function at Alibaba is recommended. If you are looking for hydraulic versions, you"ll find cylinder components for doors, drills, pumping systems, bottle blowing machines, mechanical jacks, lifting platforms, passenger elevators and many more commonplace applications. They are in the hoists we use to lift rocks, forklift steering mechanisms and so much more. Match the specs of the machinery being fixed with the ideal cylinder and make whatever alterations need to be made. Refresh the piston on a plunge press, or stock up on construction rope prices components. Whatever you need, it"s here.

The same goes for automotive cylinders. Alibaba"s wholesale catalogue has all of the parts you need to fix engines and get vehicles back on the road and back to work. There are ignition lock gaskets, brake cylinder components, piston overhaul sets for bikes and autos, and all of the other parts needed. If you run a mechanics workshop or have a fleet of industrial vehicles to manage, Alibaba is the place to look. Find the ideal construction rope prices and don"t let a blown cylinder derail your plans.

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the wire rope price per meter you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal wire rope price per meter for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, wire rope price per meter will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

As a custom cable manufacturer, Sava knows firsthand how application design influences the cost of your products. From cable construction, to length tolerances, to the speed and reliability of production runs, count on Sava"s almost 50 years of engineering and production expertise to help you understand the key pricing factors that influence your budget.

Take a look at the cable costs, and considerations for designing and manufacturing your cable or wire harness assembly below or request a quote from our world-class, in-house engineering team.

How much does a wire rope sling cost? How much does a shackle or a web sling cost? These are legitimate questions that we hear every day from prospective customers looking to purchase rigging products for their next lifting project.

Rigging shops have long been the stalwarts of the lifting and rigging industries. Rigging shops typically have a showroom or storefront with a wide selection of sling hooks, shackles, chain, synthetic slings and wire rope. They also traditionally buy the raw materials for wire rope, webbing, steel and chain and have a shop where they can make the lifting and rigging products themselves.

If you’re looking for the added benefit and expertise of speaking with a knowledgeable salesperson, want to browse an extensive inventory, and may have an immediate need for a piece of rigging hardware, chain sling, roundsling, or wire rope, then a rigging shop might be your best bet.

A common 1/2” X 10’, 6 X 25 Wire Center, Wire Rope Sling comes in at $29.00, $43.00, and $67.00 from three different online retailers. So, why is there such a wide pricing range for what appears to be the same product?

Online suppliers with the more expensive wire rope and web slings tend to be larger catalog and supply houses that offer an impressive array of all types of industrial products, including rigging gear. They also offer the convenience of selling items like gloves, eye protection, spray paint, etc.—an added convenience factor that allows you to buy everything that you need from one source.

Size is always a factor when it comes to the cost of lifting and rigging products. For example, a 1-ton screw pin anchor shackle can be found for around $9.00 per piece, a 9.5-ton shackle sells for around $80.00 a piece, and a 25-ton shackle can run close to $300.00 per piece. Simply put, the more steel and more material required to produce the product, the more it’s going to cost you.

This is also true for lengths of wire rope and chain. Larger diameter wire rope, and larger and longer lengths of chain and wire rope, often fall out of the “standard” product range of suppliers other than rigging shops. If a shop has to special order a piece due to a non-standard size or length, that extra time and effort to acquire the piece will get passed on to the customers as a price markup.

High-performance and specialty items also cost more. For instance, 3/4″ 6 X 37 with wire center rope would cost around $2.50 per foot. A high-performance cable like a 3/4” Dyform 18 would cost about $4.50 per foot. But in the right application, the Dyform 18 will last much longer to justify the higher initial cost, and may also save labor costs because the customer won’t have to perform cable changes as frequently.

However, highly-trained lifting specialists are compensated for their time and knowledge applied to a lifting project and therefore will increase the cost of your rigging solution. Unfortunately, you’re not going to solve your problem by e-mailing a catalog house or e-commerce rigging website’s customer service team. Their businesses are built to move rigging hardware, wire rope slings, chain slings, and synthetic slings out the door in a quick and efficient manner.

Generally, imported products are cheaper in price, and in many cases, the quality is comparable to products made domestically. For instance, an imported 1/2” x 10’ 6 X 25 swaged wire rope sling would cost about $20.00—the same sling made by a company who manufactures their rigging gear in the United States would charge around $30.00.

E-commerce sites that offer deals like free shipping on lifting or rigging equipment seem to target the smaller end user—mostly contractors or small construction companies that make up a large portion of the rigging buyer’s market.

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We also have locations all across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

Our steel cable construction and wire rope assemblies offer a high strength to weight ratio, are long lasting, low maintenance, flexible and a cost efficient solution for many mechanical needs.

Commercial quality “aircraft grade” cable is made from galvanized steel wire or stainless steel wire. Galvanized aircraft cable provides high tensile strength and adequate corrosion resistance for most applications. Stainless steel wire cable provides slightly lower tensile strength, but greater resistance to corrosion.

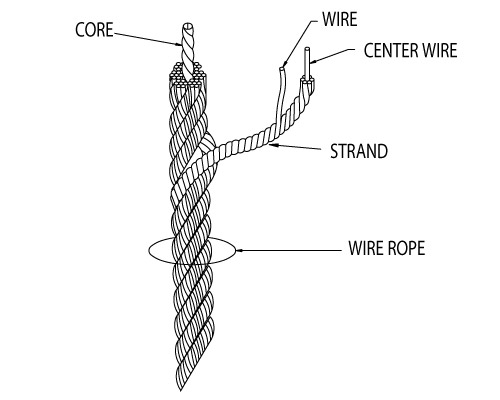

Industrial cable or wire rope is fabricated from individual wires put together in a uniform helical arrangement to form what is called a strand. A strand typically contains 7 wires (1x7) or 19 wires (1x19), although others are available. Cable or wire rope contains a varying number of these strands such as 7x7 and 7x19 (number of strands x wires per strand). The more strands and more wires per strand, the more flexible the cable and the higher the cost. The greater the cable diameter, the greater the diameter of each wire and the greater the breaking strength.

All steel wire cables can be coated with a number of different plastics such as vinyl (PVC) or nylon in various colors. Black, clear and white are typical stock colors but other colors can be ordered during the wire rope construction process.

The breaking strengths of various diameters of steel wire cable are listed here. Cable construction safety standards dictate a minimum of five to one safety factor when designing cables for most applications. If a cable is being designed for a 300 pound maximum weight load, then a 1/8 inch cable with a 1700 – 2000 pound breaking strength would be needed. For critical safety or shock load applications an 8 or 10 to one safety factor is needed. Request a quote on custom wire rope construction today and contact us with any questions about custom cable construction.

For more information or inquiries about our custom wire rope construction, get in touch with us today. Our team of experts are here to answer any of your questions. We look forward to hearing from you!

Each use for a custom wire rope cable assembly has its own unique purpose. We can assist you in designing a custom cable assembly to fit your specific needs.

The larger the diameter of cable, the less flexible it will be. Example: 1/8” 7 X 19 cable is more flexible than 1/8” 7 X 7 cable, but the 7 X 7 construction is more abrasion resistant.

Tyler Madison, Inc. specializes in cable size from 3/64" - 3/8" in diameter and 270 lbs. - 14,400 lbs. in breaking strength. We will put our years of experience to work in helping you design and produce exactly what you need. We have manufactured quality custom wire rope cable assemblies for leading companies in the following industries:Aerospace

Tyler Madison is an industry leading manufacturer of wire rope cable assemblies and custom wire and cable. Our knowledge and experience give us the capability to manufacture standard and custom wire rope assemblies and products for a variety of industrial clients. With in-house engineering and design services, you can get the exact kinds of wire rope assemblies and steel wire cable products that you are looking for from one place at an affordable price. Call us today to find out what types of cable assemblies we can do for you!

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.I UNDERSTAND STEELWIREROPESMANUFACTURERS Products

It’s not only the technical parameters that count. The cost effectiveness of the steel wire rope operated in the crane, too, may tip the balance when it comes to choosing the perfect steel wire rope. Opting for crane ropes made by Teufelberger-Redaelli substantially reduces the overall costs, since we know that the expense to be considered for a rope involves more than mere installation on the crane.

The Teufelberger-Redaelli rope experts will advise you competently. In case of trouble, we are always there for you 24/7 via a network of engineers and a 24-hour hotline. We take care that your downtimes are kept at a minimum and can be planned.

Designing a high performance steel wire rope requires detailed technological and production-related know-how. The PLASTFILL® technology developed by Teufelberger-Redaelli consists in covering the lubricated steel core in a compact synthetic coat. The SUPERFILL® compaction technology uses a special process to compact the individual strands of the steel wire rope.

Teufelberger-Redaelli offers a variation of rotation resistant and non-rotation resistant high performance steel wire ropes for construction cranes (building construction and deep foundation) excelling equally as boom hoist rope, hoist rope, trolley rope, or dragline.

United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand was 377.74800 Index Jun 1982=100 in March of 2022, according to the United States Federal Reserve. Historically, United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand reached a record high of 377.74800 in March of 2022 and a record low of 87.60000 in September of 1983. Trading Economics provides the current actual value, an historical data chart and related indicators for United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand - last updated from the United States Federal Reserve on December of 2022.

Understanding the basics of wire rope will help guide you on how to choose the right wire rope for your job. Application, required strength, and environmental conditions all play a factor in determining the type of wire rope that is best for you.

But when it comes to buying wire rope, the various numbers and abbreviations that describe the different types of wire rope can be confusing. EIPS wire rope, 6X19 IWRC wire rope, and lang lay wire rope are just some of the many variations available. But what does it all mean?

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available from 1/8” wire rope to 2-1/2” wire rope. Thicker sized wire rope has a higher break strength. For example, our Wire Rope has a 15,100 lb. break strength while our Wire Rope has a 228,000 lb. break strength.

The numbers indicate its construction. For example: in wire rope, as shown above the first number is the number of strands (6); the second number is how many wires make up one strand (19).

When it comes to wire rope basics, regular lay also refers to right lay or ordinary lay. This indicates that the strands pass from left to right across the rope and the wires in the rope lay in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

This term indicates that the wires twist in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Independent wire rope cores offer more support to the outer strands and have a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

Many of our customers use our rope and our wire rope clips to create rope assemblies. Check out of video blog on Wire Rope Clips to Wire Rope Assemblies to learn more.

For any questions on our wire rope products, call (877) 923-0349 or email customerservice@uscargocontrol.com to speak with one of our product experts.

Structural wire rope cables have played a major role in the engineering and architecture of many large structures and are widely used on projects involving bridges, vessels, stadiums and glass facade/membrane buildings to name a few. Using steel cables in the design of such projects has proved more cost effective than solely using raw materials such as Iron or concrete and is now very much the preferred choice within the construction and engineering sector.

The starting point for FATZER products is high-tensile steel wire. Fabricated into steel wire ropes, it enables architects, engineers and contractors to create technically sophisticated rope architecture.

FATZER manufacture a wide range of rope diameters, suitable for use on the most complex of projects. The performance parameters of all products are monitored and confirmed by independent test bodies.

It goes without saying that steel wire ropes must meet the highest safety requirements. What sets them apart though, is the way they provide freedom for aesthetically creative design. It is the elegant HYEND series of end connections, in particular, which turns these technical products into true “design objects”.

Spiral strand and fully locked coil ropes are manufactured in Switzerland in FATZER"s own factory. This covers the whole process including stranding, pre-stretching, marking and in some cases socketing. Handling customised product solutions is a challenge we tackle on a daily basis. In all cases rope assemblies arrive on site ready for installation.

All materials are fully certified and has full traceability in line with our ISO9001 procedures. The most common constructions of wire rope used for structural purposes are: Spiral strand ropes and fully locked coil rope (EN 1993-1-11:2006). All ropes are available with HYEND fittings to guarantee the best quality and safety standard (EN 13411-4).

SWR have the capacity to design and manufacture these assemblies, and can provide structural advice on load ratings and fixing terminals should this be required. Both galvanised and stainless steel can be used depending on the location and specification of the project.

One of the first things to consider when purchasing industrial cable for projects or construction is the material it is made of. Cable is generally made of steel, as this type of metal is strong and very durable.Industrial cable is sold in two types:galvanizedandstainless steel.

For instance, ais made of seven strands which are composed of 19 wires woven together and galvanized.is also made of the same number of strands and wires – but they are made of different material.

Galvanized steel cable is made of traditional steel which is coated in a thin layer of zinc. This coating helps to protect the steel from corrosion, as untreated steel has iron will rust if it is exposed to water or moisture.

Steel cables may also beelectrogalvanized, which creates a very thin layer over the metal via an electric current. The zinc solution conducts this electricity, which positively charges the ions and attaches to the steel. This creates an extremely thin layer that has been mechanically-bonded.

Stainless steel cable is made of ancontaining at least 10.5% chromium and may also be mixed with nickel, silicon, manganese, nitrogen, or carbon. This chromium is naturally corrosion-resistant, so stainless steel does not require an additional galvanized coating for protection.

Stainless steel is produced by melting together all of the raw materials for 8 to 12 hours until it is completely molten. The excess carbon is then removed by pouring the molten metal into an Argon Oxygen Decarburization (AOD) converter. Additional elements may also be added in the converter.

Molten stainless steel is then tuned, which helps to improve the consistency by stirring the metal and maintaining an even temperature until it is ready to be formed.

Cutting – stainless steel may also be cut after being formed into sheets by using sharp knives, saws, high-speed blades, flame cutters, or ionized gas.

In addition to the chemical composition and finishing processes, there are some important differences to note between galvanized steel and stainless steel.

First, is theprice. Galvanized cable is typically less expensive than stainless steel because the process is much quicker and involves less steps. Stainless steel is also more expensive because of the added elements, which increases the cost.

Another difference isstrength. Stainless steel is significantly stronger than galvanized steel, which has a lower breaking point. The exterior layer of zinc may wear off over time if the cable is exposed to a lot of friction, which weakens the steel beneath.

The next major difference iswear resistance. Although stainless steel is exceptionally strong, the mixture of nickel actually softens the metal and will present signs of wear and tear sooner than galvanized cable would. The shiny exterior also shows scratches and dents more than galvanized metal does.

Theappearanceof both metals is also different. Galvanized steel is not as shiny as stainless steel and appears to be a bit duller and streakier. While the appearance of cable is typically not incredibly important, it may matter in some applications.

Since galvanized metal is not as strong as stainless steel, it is commonly used for lighter-duty applications that do not require extremely heavy weights. It is also far more cost-effective, so it is typically used when budgets are tight.

7×7 galvanized cables are often used in construction for towing equipment or building materials. 7×19 galvanized wires are used for heavier purposes, since it is more flexible and can handle higher levels of stress without snapping.

Since stainless steel cable is extremely strong, it is largely used in more heavy-duty applications to secure heavier weights. It is also best in more moist environments as it is extremely rust resistant.

Stainless steel also tends to last longer than galvanized steel in certain environments. Therefore, the higher cost ends up evening out as it does not need to be replaced as quickly.

As with galvanized cable, 7×7 stainless steel cable is used when flexibility is not necessary. 7X19 stainless steel cable is best for heavier applications that involve more movement and friction.

The most important thing to keep in mind when you need to buy stainless steel cable or galvanized cable is to choose a manufacturer that offers high-quality products. Quality is key, and it can ensure that your application is far safer and lasts longer.

You can trust Elite Sales to be your provider for any and all industrial hardware equipment. We offer a wide variety of industrial cable, as well as wire ropes, chains, and other products in numerous sizes and finishes.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Cables designed with 3×7, 7×7 and 7×19 construction provide for increasing degrees of flexibility but decreased abrasion resistance. These designs would be incorporated where continuous flexing is a requirement.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

8613371530291

8613371530291