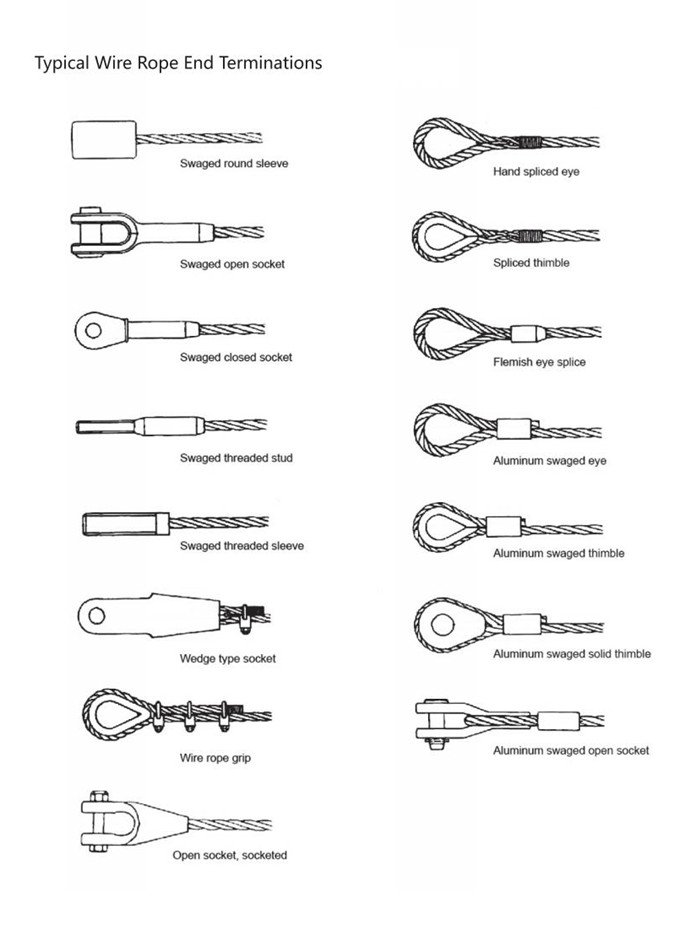

steel wire rope end terminations pricelist

The wire rope terminations that require fitting by using the Wirelock resin are the most commonly used kind of specifically terminating a wire because they are very safe and especially effective permitting long term exploitation.

When they were proof load tested these kinds of sockets (closed spelter socket) have reached a higher breaking force level compared to other kind of terminations.

They are fitted by rolling the wire rope"s end around the fixing wedge and then clipping the loose end of the wire rope with a wire clip. These sockets (closed wedged sockets) are most commonly used for mobile cranes.

The wire rope sockets (open wedged sockets) that are fitted by using an inside wedge are the easiest to fit of all this kind of wire rope terminations.

What works with thick wire is problematic when using wire rope: How can the rope end be equipped with a thread? To this purpose, "terminals" were invented. Architectural ropes that have been cut to size are provided with such a terminal on both ends. Analogous to tension ropes, the terminal has an external thread with which the cable is inserted into a mount and tightly tensioned from behind with the help of a threaded nut. In the case of high-grade tensioning cable systems, our competitors often work with sophisticated threaded and fork terminals. They are usually rolled with special machines and are correspondingly expensive. Alternatively, there are do-it-yourself terminals, in which the rope is fixed by grub screws transverse to the fiber direction; the cable end is then virtually part of the threaded rod. But even this solution remains price-intensive.

Therefore, Fassadengrün forgoes terminals altogether and has the ropes tensioned by hand, as described under our section on Installation. But how are the protruding cable ends then protected?

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. Wire rope comes in a variety of strand patterns including single layer, filler wire, seale, warrington, and combination. Wire rope strands can be laid around the core in different configurations including regular lay wire rope, lang lay wire rope, and alternate lay wire rope. There also many types of grades of wire rope, including: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). Some types of wire rope is preferred over others due to the unique properties, including: rotation resistant wire rope, compacted strand wire rope, swaged wire rope, plastic coated wire rope, plastic impregnated (PI) wire rope.

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.91, up from 374.68 last month and up from 317.27 one year ago. This is a change of 0.06% from last month and 18.17% from one year ago.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

Our partner companies give us the opportunity to offer a complete solution for your needs in steel wire ropes and accessories. Amongst our partners you will find steel wire rope, hoisting equipment and synthetic rope manufacturers. You can also find more information on our partnership with Hoist International, which specializes on hoisting equipment rental and inspections.

Wire rope end fitting, to join the end of wire rope to a metric screw thread. This fitting is for low-load applications, and provides an easy way to terminate the end of a stainless steel wire rope, using grub screws which are tightened to grip the end of the wire rope. The other end of the stainless steel fitting is a metric female thread for interfacing with a suitable metric screw / bolt / turnbuckle. These grub-screw fittings are not highly load-bearing so should only be used for low load and non-safety-critical uses.

8613371530291

8613371530291