steel wire rope end terminations quotation

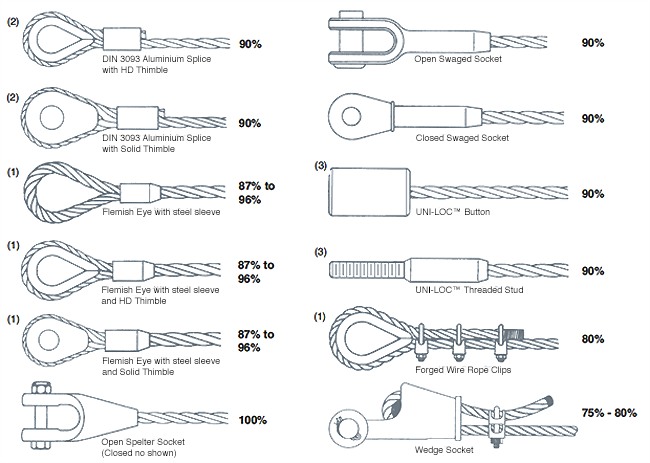

• Based on the catalog breaking strength of wire rope, Crosby wire rope clip have an efficiency rating of 80% for 3-4mm to 22mm sizes, and 90% for sizes 24-26mm through 90mm.

• Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these wire rope clips meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

Spelter socket terminations have an efficiency rating of 100%, based on the catalog strength of wire rope. Ratings are based on the recommend use with 6×7, 6×19, or 6×36, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope. Strand constructed with minimal number of wires (e.g. 1×7) requires special consideration that socket basket be five (5) times the strand diameter or fifty (50) times the wire diameter, whichever is the greater.

Wedge socket terminations have an efficiency rating of 80% based on the catalog strength of XXIP wire rope.Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these sockets meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide fo r Certification of Cranes.Basket is cast steel and individually magnetic particle inspected.Pin diameter and jaw opening allows wedge and socket to be used in conjunction with closed swage and spelter sockets.Secures the tail or “dead end” of the wire rope to the wedge, thus eliminates the loss or “punch out” of the wedge.

Eliminates the need for an extra piece of rope, and is easily installed.The TERMINATORᵀᴹ wedge eliminates the potential breaking off of the tail due to fatigue.The tail, which is secured by the base of the clip and the wedge, is left undeformed and available for reuse.

Utilizes standard Crosby Red-U-Bolt® wire rope clip.The 9-10mm through 28mm standard S-421 wedge socket can be retrofitted with the new style TERMINATORᵀᴹ wedge.Available with Bolt, Nut, and Cotter Pin. US patent 5,553,360, Canada patent 2,217,004 and foreign equivalents.Meets the performance requirements of EN 13411-6: 2003.

We use Talurit press dies and ferrules for complete compatibility. The ferrules are totally traceable and validated to EN13411-3 standards. This consistency in process and parts ensures that our products achieve the designed wire strength efficiencies and enjoy full coverage under Talurit’s Product Liability Insurance.

Our standard steel thimbles are manufactured according to BS 464, FF-T-276b Type III (G414) or JIS B2802 (Type A) specifications. Our solid thimbles are built to JIS B2802, JIS F3403 or DIN 3091 standard.

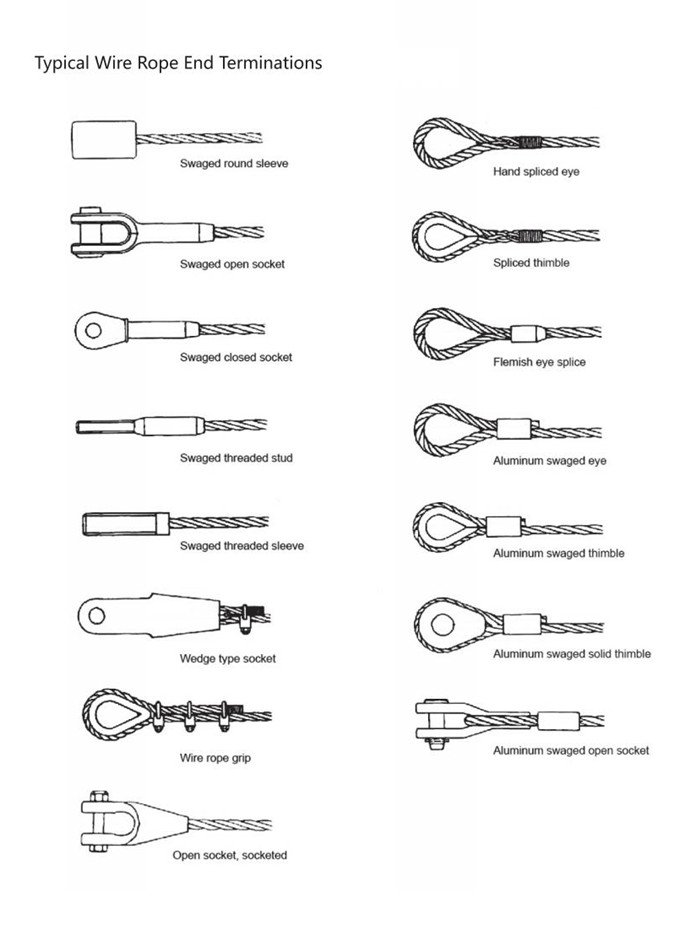

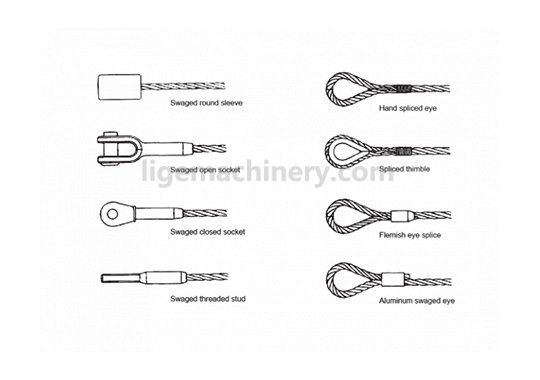

For crane wire ropes many different types of sockets are used: open and closed spelter sockets, open and closed swage sockets, wedge sockets and Nemag rope pear sockets.

A wedge socket termination reduces the wire rope efficiency to 80%, but the wedge socket remains a popular choice because it is easy to install and can be attached after the wire rope is reeved.

The Nemag rope pear socket when paired with the Nemag quick release link forms an unbreakable connection between two ropes. Together, they enable quick and straightforward coupling and uncoupling of grabs on cranes. Made from high grade austenitic manganese steel, these Nemag fittings generally outlast the wire rope.

Our Spelter sockets and Nemag rope pear sockets are poured with Wirelock, the original cold socketing resin and the first socketing system to meet the performance criteria of DNV for offshore wire mooring rope, currently the DNV-OS-E304 standards. Wirelock produces a void free socket for 100% efficiency and safety, and is unparallel in dependability and fatigue performance.

Our sockets are made of high quality cast steel supplied in hot dipped galvanised finish and comply with EN10204 3.1/3.2, JIS F3432 or RR-S-550D, Type B standard.

Whether you are looking for an item to add class to celebrations with loved ones, or for the business owner to get client’s attention, our wholesale wire rope end terminations features an assortment of decanters that will do just that. It includes a wide range of crystal wine decanters, scotch decanters, and crystal whiskey decanters.

wire rope end terminations is a versatile item; it can be used for any type of beverage. It comes in different sizes and designs to fit your customer’s tastes and fits any narrative that they want to create. Personalized decanter sets also come with many different caps. Some people prefer simplicity, then a minimal round cap fulfills the task. However, if they want something that stands out, just imagine having a majestic reindeer’s mighty horns as a decanter cap. Whatever the impression they want to convey, wire rope end terminations can help them get there.

These items are versatile, whether drink lovers prefer scotch or liquors, our decanters will meet their needs. Liquor decanters are specially crafted to optimize the experience of drinking liquor, while the whiskey decanter set is a good fit for barley lovers. The delicate combination of clear crystal and shine of amber-colored whiskey is a delight to behold. The enjoyment of wines and spirits just feels incomplete without a proper decanter.

What is a thimble end fitting?A thimble is a special type of heavy duty, grooved metal end fitting. Its goal is to protect the fastening loop of a wire rope.

We define “at-risk loops,” by loops that are at risk of bending under the weight of a load or are under the forces of abrasion. Thimble for wire rope is installed on the inside of a loop, protecting the cable from abrasion and preserving the loops open shape.

How does Tyler Madison secure thimble end fittings?Thimbles are fashioned inside the loops by including them in the looping process. They are wrapped tightly inside once the expanding sleeve is swaged using a hydraulic swage machine.

What materials does Tyler Madison use to produce standard thimble end fittings?We make our thimble endings out of cold rolled steel (AN100 type), galvanized steel or stainless steel.

However, thimble end fitting applications rely on strength, corrosion resistance, abrasion resistance and durability. Few materials outside of the steel family meet all of these qualifications without great manipulation or alteration.

Thimble end fittings work very well on cable railing, stainless steel medical cables and wire rope tethers, and anything that is under large consistent tension forces.

Nevertheless, the only way to know for sure whether or not thimble end fittings are right for your application is by talking over your specifications and requirements with a member of our staff. Give us a call today, and we will steer you in the right direction.

Just a handful of industries in which you can use thimble end fittings include: construction and building, agriculture and farm equipment, marine and boating, material handling, industrial machinery manufacturing and automotive manufacturing and repair.

Who is Tyler Madison?Tyler Madison is a leading American wire rope manufacturer based out of Apple Valley Minnesota. We create high quality wire rope fittings, wire rope lanyards, cable railing, wire rope tethers and countless standard and custom wire rope cable assemblies.

Why choose Tyler Madison?Tyler Madison is energized by challenges! We have the capabilities and know-how to create wire rope assemblies for high-stake applications. These include aircraft cable assemblies, military cables, stainless steel medical cables and push pull control cables. From start to finish, we create your wire rope assemblies using the latest technology and the best quoting practices.

Large structures and equipment needing stabilization and support require specially-fabricated wire rope products. These assemblies usually fit swaged or poured terminations to wire rope. Assemblies like these used on boom cranes are referred to as either pennant or boom lines. Similarly-made products are also frequently used in structures such as large awnings and support cables for bridges.

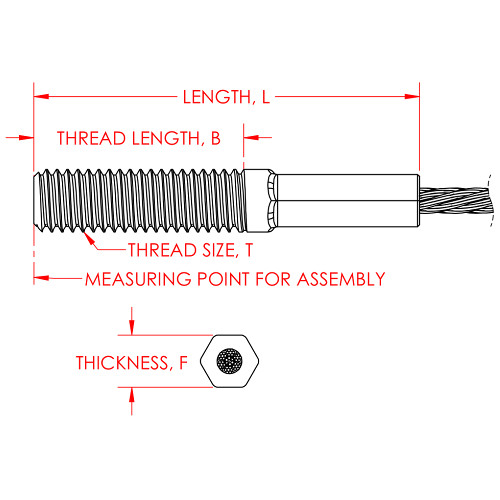

The proper application of these types of assemblies requires careful consideration of capacity, length, plane, and type of termination. The capacity of the socketed assembly will be determined by the diameter and grade of wire rope. Trinity Sling offers a wide variety of wire ropes suitable for socketed and threaded wire rope terminations. The length of a socketed or threaded wire rope assembly requires exacting measurements. These usually are ordered in pairs and require length matching. Due to the differences in stretch inherent in different batches of wire rope, it is not recommended that new socketed slings be matched to used assemblies. The lengths will be mismatched under load.

At Trinity Sling we have years of experience with the various types of socket terminations. The terminations most commonly come with one of three types of connections; open socket (female), closed socket (male), and threaded ends. An open socket looks like a fork with a pin that can be inserted to close and secure the end fitting to the opening of the fork. A closed socket has an eye. The eye of the closed socket is designed to accept the pin of the open socket so they can be linked together. Threaded wire rope end fittings can be made with any type of thread pitch or thread length required for the application.

With open and closed socket wire rope terminations the plane of the attachment to the wire rope is also important. The plane of the assembly is determined by the degree relative to each end to which the terminations are attached. Consult the diagram from the Wire Rope Sling User’s Manual for reference to same and opposite planes.

Whether a job requires poured sockets or swaged sockets, well-built assemblies will carry up to 98% of the rated break strength of the rope. Poured sockets are usually set with an epoxy covering the broomed wires inside the socket, while swaged end fittings are attached by forming the shank of the end fitting over the wire rope with a press. Poured socket wire rope end fittings feature flexibility of assembly.

With a properly-trained person and the right equipment, poured sockets can be made in the field. Field installation should not be used in critical or overhead lifting or supporting applications, however, as those applications cannot be proof tested in the field.

As for all products fabricated by Trinity Sling we use only the highest quality materials and industry-recommended manufacturing techniques for our end fittings. Trinity Sling’s high capacity test bed is available for proof loading and recertification of all type of pennant lines and socketed end fittings. Trinity Sling can also offer tagging and asset tracking of each assembly with the InfoChip tagging and tracking system.

With the assistance of our trained sales personnel Trinity Sling can help design and fabricate specialty swaged end fittings to meet your specific needs. Such specialty end fittings are often used in military applications or in specialty manufactured goods. Trinity offers a wide variety of custom and standard fittings to accommodate most any rigging situation. Rigging experts with decades of experience in the industry are available Monday through Friday from 8-5 CST to answer questions, provide quotes, or satisfy hard-to-fill spec requirements for jobs across the U.S. and Canada, often from existing inventory. Call 1-877-589-2404 for more information or to place an order.

Lexco® Cable provides a full line of fork ends and jaw ends for use in a wide range of applications, from military and marine to industrial and architectural and more.

The term “fork/jaw ends” describes clevisesthat swage directly to the cable. In some respects, a fork/jaw end can be thought of as a two-in-one fitting, because a more rudimentary approach to fork/jaw end functionality is a cable loop with a shackle secured to it. This two-part configuration works perfectly well in many instances where a flexible cable construction can be used. However, in other situations, a rigid cable is advantageous. Typically, this is the case when minimizing stretch and modulus of elasticity are predicated on providing structural support. Where a cable is too rigid to form a thimble loop, the need for an inline fitting, such as a fork/jaw, is born.

Our fork and jaw end fittings must be machine swaged for proper hold strength. Lexco takes pride in our assembly work and will quote any assembly you need per your specification or design print.

MIL SPEC and Naval spec fork and jaw end fittings do not include clevis pins (must be ordered separately). All other fork ends and jaw ends include clevis pins.

Note:The hold strength of a fork end or jaw end is affected by the construction of the cable to which it is attached. A fork/jaw end installed on a 1x19 cable may yield a different holding strength than an identical fork/jaw end installed on a 7x7 cable, for example."

When referring to “fork ends” and “open swage sockets,” it is inferred that the clevis end of the fitting is fixed to the swage area. In other words, both portions of the fitting are one continuous piece.

Lexco® Cable supplies both commercial grade and MIL SPEC (MS20667) fork ends. Typically machined from 304 stainless steel, they are available in various sizes to accommodate cable from 1/16” to 1” in diameter.

Commercial and military grade fork ends must be machine swaged for proper hold strength. Please contacta Lexco® sales representative to receive an assembly quote.

Note:A fork end’s hold strength is affected by the construction of the cable to which it is attached. For example, a fork end installed on a 7x7 cable may yield a different holding strength than an identical fork end installed on a 1x19 cable.

All Muncy Machine and Tool™ fittings are machined from carbon steel specially selected for swaging. Aluminum and stainless steel available upon request.

CAUTION: SB buttons are modeled after Wire Rope Technical Board’s Specifications. SB buttons are recommended for use with 6 x 19 or 6 x 37 IPS or XIP, EIP, RRL, or IWRC wire ropes. Before using an SB button for any other type lay, construction, or grade of wire rope, it is recommended that the termination be proofloaded to prove the adequacy of the assembly. Item numbers are designed to indicate the wire rope size for the particular fitting. For instance, SB-5 is for the 5/32″ wire rope.

Among the wire rope hardware and cable assemblies we offer, we have a large inventory of wire rope threaded cable end fittings and end stops. Our threaded wire rope end fittings inventory consists of 144 different threaded plugs. Our plugs are made from stainless steel, plated steel, and brass. Each wire rope threaded stud, end stop, and threaded cable clamp comes in many different sizes and is built to accommodate a variety of different uses. See the exact spec of all of our cable plugs below, and contact our team to get a quote.

These threaded steel cable ends can achieve the desired break strength, and serve the cable needs of many different industries, including aircraft cable and medical cable.

Wire rope swage sleeves and fittings are used to terminate the ends of wire ropes to prevent fraying, and to securely form lifting eyes in wire ropes. Cable swage sleeves and wire rope end fittings are very versatile and are an essential part of many wire rope rigging applications.

Here at Tri-State Rigging Equipment we pride ourselves on providing only the highest quality swage sleeves and wire rope end fittings to our customers, from only the most reputable manufacturers. We can provide you with any rigging equipment on the market, so if you cannot find what you are looking for or don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

Wire rope swage sleeves, sometimes referred to as cable ferrules or duplex / crimp sleeves, are used to form eyes on the end of wire ropes. Wire rope swage sleeves are a more secure and more permanent alternative to wire rope clips. Cable swage fittings and sleeves are available in a variety of materials to fit any wire rope rigging application:

To properly fit and secure a cable swage sleeve, most use a hydraulic swaging press, while others can be hand crimped using a special hand swage crimping tool. Cable swage sleeves are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

These wire rope end fittings are used to allow wire rope to be used in a large variety of rigging applications. Wire rope end fittings are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

Tri-State Rigging Equipment is a service provider and distributor for all wire rope cable swage sleeves and wire rope end fittings for rigging and lifting serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

There are many different types of wire rope sockets, some of them specific to a particular kind of job or application, others designed to match certain sizes or types of wire rope. It’s especially important to match the socket to the rope correctly when replacing components.

Open and Closed Sockets–Most wire rope sockets come in open or closed varieties. Open sockets have a pin or bolt to accommodate a hook block or other type of fitting. Closed sockets form a hole designed to accept a pin or bolt.

Swaged Sockets– This type of socket is mechanically pressed onto wire rope using special dies. They are resistant to wire fatigue and breakage at 100% of the rope’s strength but must be professionally crimped and secured with the correct size dies.

Spelter or Poured Sockets–Spelter, also known as poured sockets, attach onto the end of a wire rope cable with molten zinc or resin. Once it hardens, the socket stays firmly welded onto the end of the cable. These are one of the most efficient types of wire rope end attachments with close to 100% efficiency.

WedgeSockets – Wedge sockets secure the rope to the end attachment by passing it around a grooved and wedge-shaped piece of steel. This type of socket is popular because it can be installed and adjusted in the field, providing 80% efficiency. Wedge sockets are common for construction and mining applications where the wire rope may be subjected to high stress and abrasion.

Wire rope and termination sockets are an essential component of construction and mechanical systems that require tension or support. As long as they are matched correctly to the size and material of wire rope and professionally installed, they form part of a strong mechanism for lifting, hauling, and supporting heavy loads.

If you need assistance correctly matching your wire rope and termination sockets, you can count on our team at Certified Slings and Supply® to help. We have a full inventory of the highest quality products, more than sixty years of experience at our disposal, and regularly perform on-site inspections for rigging equipment of all kinds. For help keeping your construction operations running smoothly and your workers safe on the job site, give us a call at 1-800-486-5542 today.

Our range comprises stainless steel cables in diameters from 0.62 mm up to 26 mm in various configurations:Single-strand constructions: 1 × 7, 1 × 19, 1 × 37

Wire ropes and rods can be assembled with thread ends in different designs and configurations, including:Standard external and internal thread ends, swaged

able and tie rod assemblies need a tensioning device on at least one end. If this is not possible, we can supply a range of turnbuckles that can be inserted between the ends.

Swaging is a method of pressing an end fitting onto the end of wire rope permanently. Our 316 stainless steel swage terminals have been designed for use with 1×19, 7×19, 7×7 and compacted strand stainless steel wire rope from 3mm (1/8”) to 26mm (1”) diameters, and can be terminated using all types of swaging machines.

Sta-Lok swage terminals have been designed for use with 1×19, 7×19, 7×7 and compacted strand stainless steel wire rope and can be installed using all types of swaging machines.

Swage sockets incorporate a reduced machined area of the shank which is equivalent to the proper “After Swage” dimension. Before swaging, this provides for an obvious visual difference in the shank diameter. After swaging, a uniform shank diameter is created allowing for a QUIC-CHECK® and permanent visual inspection opportunity.

Designed to quickly determine whether the socket has been through the swaging operation and assist in field inspections, it does not eliminate the need to perform standard production inspections which include gauging for the proper “After Swage” dimensions or proof loading.

NOTE: S-502 Swage Sockets are recommended for use with 6 x 19 or 6 x 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope. Before using any National Swage fitting with any other type la , construction or grade of wire rope, it is recommended that the termination be destructive tested and documented to prove the adequacy of the assembly to be manufactured. In accordance with ASME B30.9, all slings terminated with swage sockets shall be proof loaded.*

Wire rope thimbles also known as cable thimbles, are used for making reinforce loop(eyelet) with grips, clips or clamps by preventing fraying caused by friction at the bearing anchor point to protect and extend the service life of the wire rope or sling. They are just one of the many types of wire rope fittings (ferrules, wire rope clips, terminals, etc.).

Wire rope thimbles are available in a variety of strengths and materials(carbon steel and stainless steel, see our post on Surface Finish: 4 Common Types You Should Know) but mainly they come in two different duty grades.

If you use it in high moisture or corrosive environments, recommend our stainless steel wire rope thimbles which can offer resistance to corrosion on the surface, particularly in marine applications.

Simply wrap the end of the wire rope around the outer groove of the thimble, lace the dead end of the wire rope past the U-bolt of the wire rope grips or a wire rope ferrule crimp to hold onto the bearing anchor point at the end of the thimble to prevent fraying caused by friction.

Once in place, put another wire rope clip as near the loop you just wrapped over the thimble. Turn nuts firmly but do not yet tighten to the proper torque, we recommend using a crimping/swaging tool to compress the ferrule firmly onto the rope to hold your thimble loop securely.

Alternatively, you can use a wire rope ferrule crimp to secure your thimble in place. this method is quick and easy to install. For further information on installation using a wire rope ferrule please – click here

Wire rope thimbles are used in conjunction with cable and rope to protect the eyes and will allow for smooth rope guiding around natural curves. So that the most important thing is to make sure the thimble eye securely fastened. Here are some tips for correctly using wire rope thimble:

Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized rigging fittings.

While you are using a vinyl coated cable, you should multiply the actual size of the cable, usually use a larger size thimble than normal, for the actual diameter is the thickness of the vinyl coating plus the inside wire rope diameter. For example, if you are using a 5/16″ vinyl coated cable that is coated to 3/8″ diameter, you’d want to use a 3/8″ wire rope thimble.

8613371530291

8613371530291