steel wire rope ferrules free sample

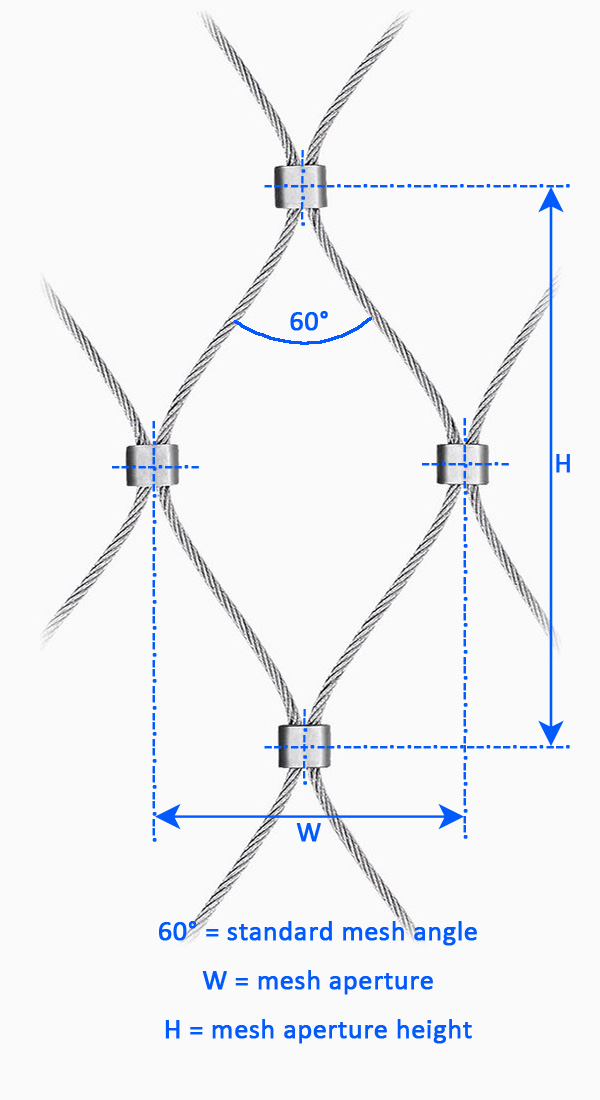

Stainless steel wire rope mesh is custom manufactured to suit your balustrade, railing or architecture application ;Finished diamond mesh style when it is stretched at 60 degree angle ;

Stainless steel ferrule rope mesh is also called stainless steel ferruled rope mesh. The only difference with stainless steel knotted rope mesh is that the two neighboring ropes of stainless steel ferrule rope mesh are combined by ferrules to form diamond openings. Stainless steel ferruled rope mesh is very flexible, and its width and length can be modified.

Our stainless steel ferrule rope mesh are mainly manufactured from high tensile stainless steel AISI 304, 304L, 316 or 316L. The rope construction is 7 × 7 or 7 × 19, making stainless steel ferrule rope mesh very soft. Therefore, it can be curved and folded easily, which makes it effortless to transport. And this property also makes it easy to install. The diameter of the stainless steel rope is from 1.2mm to 3.2mm.

Stainless steel ferrule rope mesh has diamond-shaped openings and ferrules, making it have great perspectivity and pretty appearance. Therefore, it is widely used as bird aviaries, animal enclosure, animal cages, building decoration and so on. And the stainless steel ferrule rope mesh itself is a big landscape.

1. Light weight and high flexibility. Stainless steel ferrule rope mesh is light, and its width, length, rope diameter and opening size can be modified.

2. (A) All goods supplied by us shall remain the sole and absolute property of us until such time as the customer shall have paid us the agreed price together with the full price of any other goods the subject of any other contract with us.

8. If the buyer shall make default in or commit a breach of the contract, or of any other of his obligations to the seller, or if any distress or execution shall be levied upon the buyer’s property or assets, or if the buyer shall make or offer to make any arrangement or composition with creditors, or commit any act of bankruptcy, or if any petition or receiving order in bankruptcy shall be presented or made against him if the buyer is a limited company and any resolution or petition to wind-up such company’s business (other than for the purpose or amalgamation or reconstruction) shall be passed or presented, or if a receiver of such company’s undertaking, property or assets or any other part thereof shall be appointed, the seller shall have the right forthwith to determine any contract then subsisting and upon written notice of such determination being posted to the buyer’s last known address any subsisting contracts shall be deemed to have been determined without prejudice to any claim or right the seller may otherwise make or exercise.

2. (A) All goods supplied by us shall remain the sole and absolute property of us until such time as the customer shall have paid us the agreed price together with the full price of any other goods the subject of any other contract with us.

8. If the buyer shall make default in or commit a breach of the contract, or of any other of his obligations to the seller, or if any distress or execution shall be levied upon the buyer’s property or assets, or if the buyer shall make or offer to make any arrangement or composition with creditors, or commit any act of bankruptcy, or if any petition or receiving order in bankruptcy shall be presented or made against him if the buyer is a limited company and any resolution or petition to wind-up such company’s business (other than for the purpose or amalgamation or reconstruction) shall be passed or presented, or if a receiver of such company’s undertaking, property or assets or any other part thereof shall be appointed, the seller shall have the right forthwith to determine any contract then subsisting and upon written notice of such determination being posted to the buyer’s last known address any subsisting contracts shall be deemed to have been determined without prejudice to any claim or right the seller may otherwise make or exercise.

Our fishing wire single crimp sleeves are made of quality aluminum. No burrs, no sharp edges, corrosion resistant and with high strength, they are nicely crafted. Light, small and cute thing to connect mono and wire leader or other leader materials. Once connected to the line or wire, it ensure a firm hold.

European foreword ................................................................................................................................................................ 4

5.2 Ferrules ..................................................................................................................................................................... 10

5.3.2 Matching of ferrule to wire rope ...................................................................................................................... 11

A.3 Ropes for this design of ferrule ........................................................................................................................ 17

A.3.2 Rope types ................................................................................................................................................................ 17

A.3.4 Rope grade ............................................................................................................................................................... 17

A.3.5 Types of rope lay .................................................................................................................................................... 17

A.6 Matching wire rope to ferrule ........................................................................................................................... 21

A.7.3 Ferrules after pressing ........................................................................................................................................ 25

For Stainless Steel Wire Rope Ferrule Mesh, the wire ropes are neither knotted nor crossed, it is a construction of stainless steel wire ropes that lie parallel in pairs, connected and reciprocally curved by stainless steel Ferrules. The wire rope construction is either 7 x 7 or 7 x 19. The standard mesh angle is 60°. All the components are made from either AISI 304 or AISI 316 material group.

The mesh construction can be pulled apart like an accordion, producing a spring force that varies depending on the mesh aperture and wire rope thickness. The Ferrule Mesh is a vibrant, premium-quality product. The mesh aperture and wire rope diameter determine its functionality and aesthetics.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

8613371530291

8613371530291