steel wire rope load chart price

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.05, up from 373.69 last month and up from 316.95 one year ago. This is a change of 0.09% from last month and 18.02% from one year ago.

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

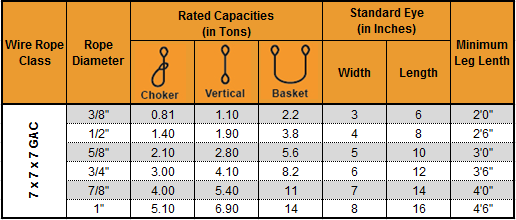

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

In selecting the right steel wire rope, it is important to determine how important the various properties are in relation to the application and then to assign priorities to these. It is also important to be aware of the relevant standards and regulations. If you are in any doubt, please contact our sales consultants or our Technical Department.

The tensile strength of the steel wire rope depends on the rope’s dimensions, the tensile strength of the wires and the construction. The minimum guaranteed tensile strength for the different kinds of rope is shown in the Randers Reb product catalogue.

The design of the steel wire rope does not significantly affect the tensile strength (up to approx. 5%). A change of core from fibre to steel makes slightly more difference (approx. 10%). The greatest change is achieved by changing the dimensions, usage of Compacted steel wire ropes or tensile strength of the wires (see also fig. 28).

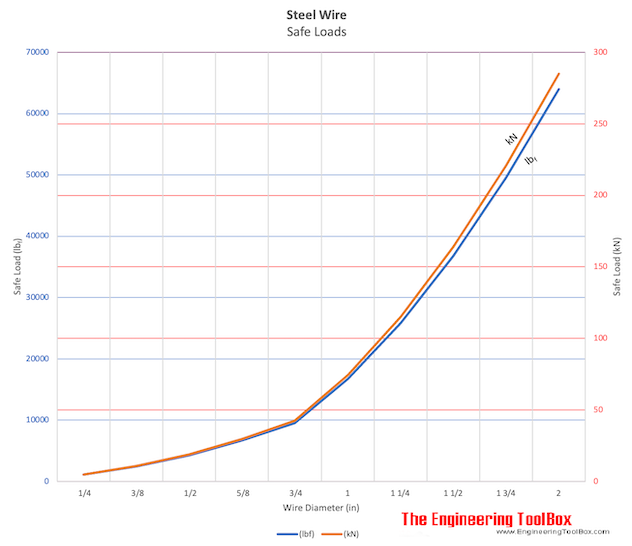

It is often required that the steel wire rope must have a specific SWL value (Safe Working Load), also known as a WLL value (Working Load Limit). This means the steel wire rope’s tensile strength divided by the safety factor required for the relevant application.

Steel wire ropes with thick outer wires (e.g. 6x7 Standard or 6x19 Seale) provide good abrasion resistance. Lang lay ropes provide better abrasion resistance than regular lay steel wire ropes (see also fig. 28). Abrasion resistance can also be increased by using wires with greater tensile strength.

The greater the number of wires in the strand, the greater the bending fatique resistance and flexibility. Lang lay ropes provide better bending fatique resistance than regular lay steel wire ropes. Bending fatique resistance can also be increased by using pre-formed steel wire ropes (see also fig. 28).

Galvanised and rustproof wires provide excellent protection against corrosion. Lubrication with special types of grease or oil will also increase resistance to corrosion. If the steel wire rope is subjected to significant corrosive influences, it is recommended that strands with thick outer wires are used.

Steel wire ropes with fewer wires (e.g. 1x7 Standard and 1x19 Standard) are subject to the least elongation (have the greatest elasticity modulus). This type of steel wire rope is ideally suited for guy ropes, but is not suitable to be run over sheaves/blocks. If only a small degree of elongation when running over sheaves is required, 6x7 or 6x19 steel wire rope should be used, in each case with a steel core or with certain special constructions. For larger dimensions, 6x36 steel wire rope with a steel core can also be used (see also Elongation and Pre-stretching, page 8-28).

Standard 6-lay and 8-lay steel wire ropes will rotate when they hang free and carry a load. Regular lay steel wire rope provides greater resistance to rotation than lang lay steel wire rope. A steel wire rope with a steel core rotates less than a steel wire rope with a fibre core. The type of rope that provides greatest resistance to rotation is, as the name suggests, low-rotation and rotation-resistant steel wire rope (special constructions, see also ”Low-Rotation and Rotation-Resistant Steel Wire Rope”, page 8-10).

A steel core provides better support for the strands than a fibre core, which is why the risk of flattening is less in a steel wire rope with a steel core. Strands with fewer, thicker wires have greater resistance to flattening/crushing. Also, a 6-lay steel wire rope has greater crushing resistance than an 8-lay rope (see also fig. 28).

Vibrations, from wherever they might come, send shock waves through the steel wire rope, which will be absorbed by the steel wire rope at some point, and in some cases they may cause localised destruction of the steel wire rope (not necessarily on the outside). This may, for example, be at places where the steel wire rope comes into contact with a sheaf/block, or enters the drum, and by the end terminals. In general, those steel wire ropes with the greatest flexibility also have the greatest vibration resistance.

Changes in the tension of a steel wire rope, depending on the size and frequency, will reduce the rope’s life expectancy. In general, steel wire ropes with the greatest flexibility can cope better with intermittent loading. Great care should be taken in the use of end terminals or fittings, as their pulsation resistance is equally as important as the selection of the right steel wire rope.

Lang lay steel wire ropes are the ones most suited to running over sheaves and are the most durable, but if they are to be used, three things must be observed:

The reason for Lang lay steel wire ropes’ excellent qualities of abrasion resistance and pliability is that the wires are affected/loaded in a different way and have a larger load-bearing surface than a regular lay steel wire rope (see fig. 29). Note that the largest wearing surface is on the Lang lay steel wire rope.

In the past (pre 19th century), most heavy haulage and lifting needs were met by bulky chains or big ropes made of fiber. In the early 1830’s, a mine in Germany dropped a mine conveyance full of ore to the bottom of their mine and it was found that the heavy chains they were using to haul the conveyance to the surface suffered from work hardening and became severely brittle, leading to its failure.

As time progressed, other nations and people began to experiment with the fabrication of wire rope and, initially, each of them were essentially drawing hot steel through some dyes to create wires which were then laid helically together to form the wire rope. The type of steel that was readily available at the time was the same steel used to create ploughs for agriculture; thus the “Plough Steel” designation was used to denote what grade of steel was used to fabricate the rope.

Improvements were made to the ingredients of Plough Steel that allowed for a higher tensile strength of the wire rope. This new grade was aptly named, “Improved Plough Steel” or I.P.S. for short. Improved plough steel became the de facto steel to be used until it was once again improved upon, to the point where it is actually difficult to find Plough Steel grade wire rope in inventory at a sling shop.

Speaking of improvements made to the already Improved Plough Steel, once the recipe was perfected and it was found that wire rope could be made to have some extra strength. What did the powers that be name this new and improved wire rope…You guessed it, “Extra Improved Plough Steel.” EIPS offers approximately 10-15% increases in tensile strength over the old IPS depending on diameter. The higher tensile strength improves the minimum breaking strength of the wire rope. This, of course, will change the breaking strengths of the rigging mines and other industrial uses. This makes it important to know what type of wire rope your rigging is constructed from. If for example, a worker is referencing a sling chart for minimum breaking strength of a sling they should:

Currently, most rigging shops have transitioned to EIPS or are in the process of doing so. EIPS wire rope should be the standard in a modern day rigging shop and used for rigging such as wire rope slings, winch lines, and wire rope assemblies.

Northern Strands has been a locally owned company for over 50 years. We carry the largest supply of wire rope and rigging in Saskatchewan. Contact us today for a rigging quote or visit our showroom.

8613371530291

8613371530291