steel wire rope mesh in stock

Custom-made steel wire net with high mechanical load capacity for industry, construction sites and the public sector. Enter the desired dimensions in the appropriate fields above. Net area and price will be calculated and displayed automatically.

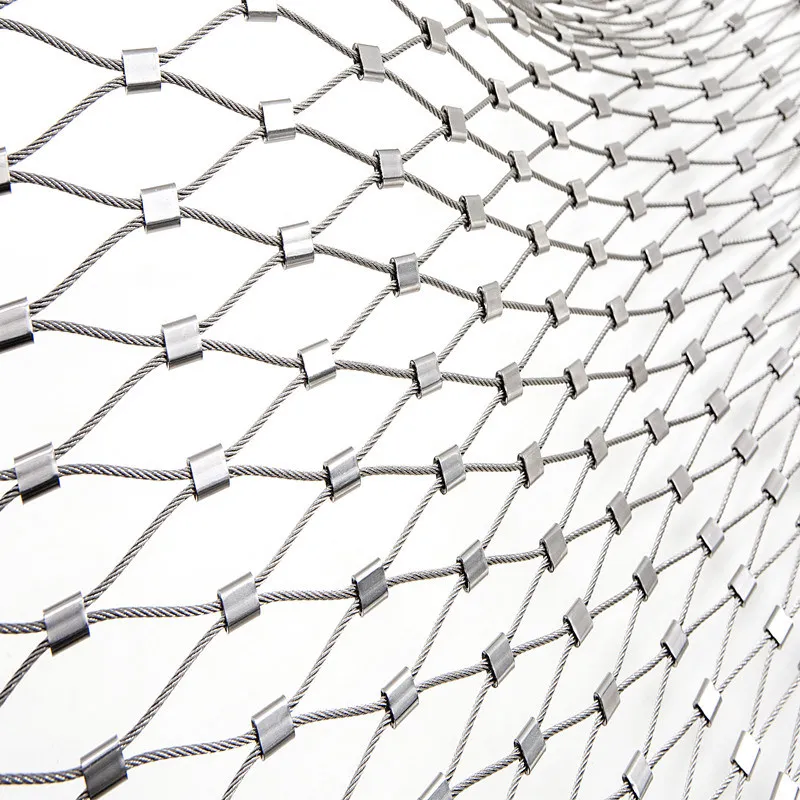

The ropes are running in vertical and parallel lines and are fixed at the crossing points using stainless steel cross clamps. The clamps are pressed to a permanent connection. The rounded shape of the clamps ensures good haptics and minimizes the risk of injury.

The steel wire mesh is highly resilient and weather-resistant, making it suitable for continuous use. Please note, that the steel wire mesh is a rigid network. In contrast to textile nets the energy consumption is more erratic. Depending on the nature of load on the network, the specified slip resistance of the wire connectors is also relevant beside the breaking force of the ropes.

Steel wire nets should be installed with a slight tension, which reduces the effectiveness of an impact. It should be noted that the loops can distort under load when they are attached at certain points and can therefore change in length. In this case, the dimension of the netting should be reduced accordingly. Manufacturing tolerances are subject to change depending on the design and type of fastening.

The specified mesh size describes the dimension between the inner edges of the wire ropes. The size of the meshes and especially the edge meshes is adjusted so that they match the size ordered and the type of edge design and can therefore vary slightly.

The edges of the net are designed as loops as standard. Due to the meandering course of the ropes, the net has a loop on every second stitch. Depending on the number of individual strands, the start and end point of a rope can be pressed to a loop, converted in the direction or executed as a thimble. Depending on the overall size and aspect ratio, the net can consist of one or more individual steel cables.

The loops on every second mesh serve as an attachment point. For example, they can be mounted directly to a substructure with hooks or eyes. Another option is to mount the net with rigid profiles (profiles or pipes made of steel or aluminium). Alternatively, an additional steel cable can be used, which is threaded and tensioned through the edge meshes.

Attention: The wire rope nets must not be pinched or warped during assembly. Pinched or warped nets have a considerably lower strength due to increased shear forces or additional tension in the edge area.

Attachment made of galvanized steel or stainless steel with an open thread. Different diameters and lengths are possible depending on the rope strength.

Since the development of X-TEND® in 1990, Carl Stahl has continuously improved and further developed the cable mesh. X-TEND® is now produced in the United States and in Europe.

U.S. mesh production began in 2016 in order to focus on Made in USA and Buy America project requirements. Our production facility is located in Woodridge, IL just outside of Chicago.

In Europe, the mesh is produced under European conditions in the Carl Stahl facility in Süssen, Germany, and has European quality certificates and quality marks.

Our cable mesh is made of stainless steel AISI316. This is also known as material class 1.4401 or A4 quality. We can guarantee this quality 100% through European certificates. If necessary, static calculations are made to demonstrate that our cable mesh meets your requirements.

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Stainless Steel Wire Rope Fence Mesh material is producing by high quality stainless steel wire cable, the stainless steel grade includes type 304, 304 L, 316 and 316L. The structures of Stainless Steel Wire Rope Fence Mesh have 7 x 7 and 7 x 19. The standard Stainless Steel Wire Rope Fence Mesh diameter includes 1/8", 3/32", 1/16", and 3/64", the standard mesh opening size includes 2" x 2", 3" x 3" and 4" x 4".

Stainless steel wire rope mesh are mainly used in the hotels, shopping malls, supermarkets, office, indoor decoration, mechanical protective cover, electrical ventilation, aquaculture and many other industries.

Stainless steel rope net products are used in animal cages, bird nets, animal fences and garden decorations in zoos, marine parks and other similar environments, parks, community protection, doors and windows, etc., and can also be applied to building reinforcement, lifting goods, car sealing and capping, high-grade decoration, sports, acrobatics, home decoration, architectural decoration, fence fence, also used in mine support, slope protection, security burglar, etc.

Cable mesh, made of high quality stainless steel, is a fabric of particular resilience and flexibility. Invented in 2000, it opens up a new world of spatial possibility using cables. And not doubt, it sweeps across the global market quickly thanks to its high strength, durability as well as corrosion resistance.

Boegger, as one of the leading manufacturers of cable mesh in the Asia, provides various cable mesh mainly in three styles: knotted cable mesh, ferrule type cable mesh and square cable mesh as shown in the right picture.

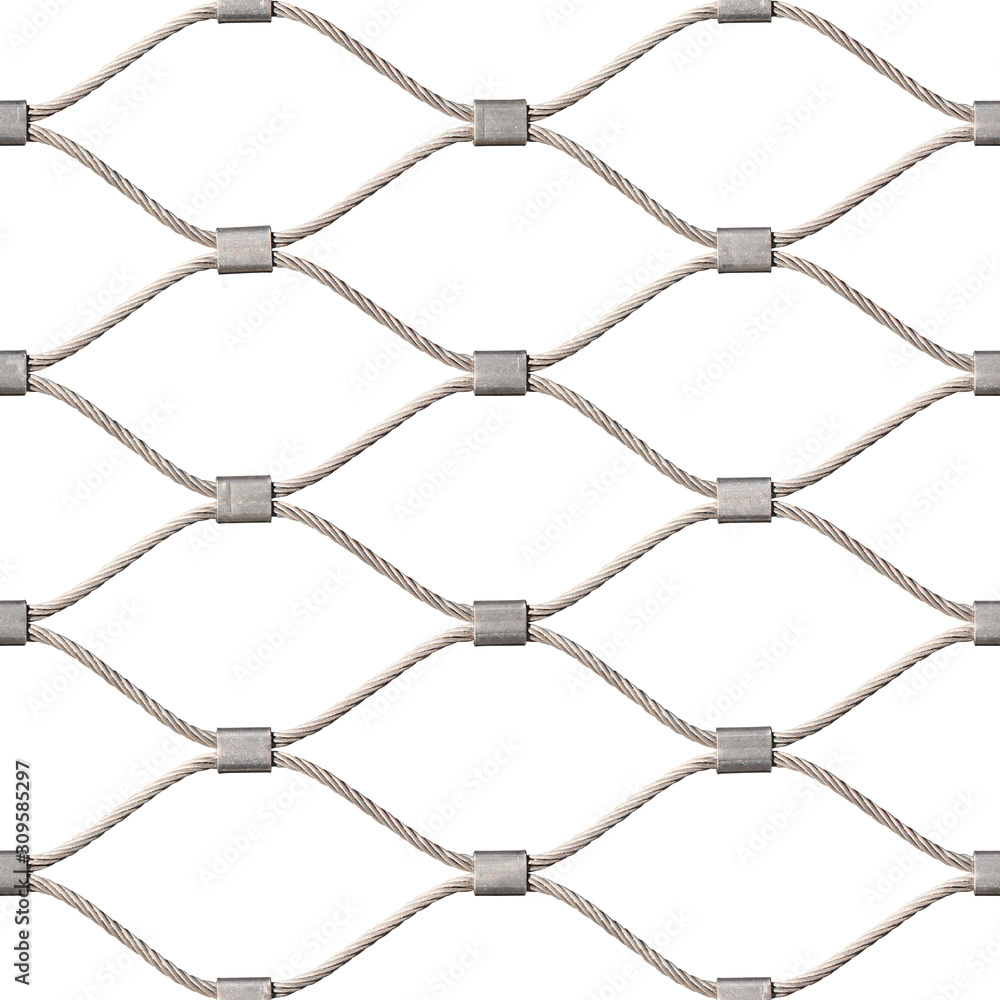

Both knotted and ferrule type cable mesh feature rhombic patterns, but they are different in the combination way of cables. The cables of former one are inter-woven together, in contrast, the latter one gets its name for seamless ferrules for combining. As to square cable mesh, no less than six types can be supplied by our company to suit different needs of your projects. Normally, the knotted type and clamp type in the right picture are more welcomed by our customers.

Our range of cable meshes are manufactured from high tensile stainless steel AISI 304, 304L, 316 or 316L. Meanwhile, these cables are available in constructions of 7 × 7, 7 × 19 or 1 × 19 and in diameter from 1mm to 4mm. Other specifications can also be manufactured to match your design requirement.

Stainless steel mesh balustrade for bridge, stairs and paths. With high strength and impact resistance, these meshes effectively minimize potential fall accidents.

Also known as zoo mesh and aviary netting, stainless steel cable mesh is perfect for animal and bird enclosure as it is flat and flexible to prevent impact damages.

Stainless steel cable mesh is also used as a garden fences, safety fence in stadium, partition fence and safety net that prevents suicide to the largest extent.

If your are interest in our products or want learn more about its specifications, material and prices, please email us directly at flegal@cable-mesh.com. We are more than happy to answering your questions.

RME0YAGG–Sep. 09, 1969 - Sitting On 400,000 Volts. Electricity Board linesman, Ted Malpass, yesterday demonstrated the effectiveness of a suit of stainless steel wire mesh and cotton, which took two year to perfect at the central Electricity Generating Board"s laboratory at Leatherhead, Surrey, and which enables repair and maintenance work on pylons sat on 400,000 volts, when he demonstrated the suit"s effectiveness when he demonstrated the suit"s effectiveness when he changed a conductor spacer between pylons at Odiham, Hampshire

1. Knotted mesh is a kind of plain weave,each warp wire rope crosses alternately above and below each weft wire rope.Warp and weft wire ropes generally have the same diameter.

2. Ferruled mesh is of the same physical properties with the knotted mesh,the only difference is in the combination style,the stainless wire rope are combined by the ferrules which are made of the same grade stainless steel.

Stainless steel wire mesh, specifically Type 304 stainless steel, is the most popular material for producing woven wire cloth. Also known as 18-8 because of its 18 percent chromium and eight percent nickel components, 304 is a basic stainless alloy that offers a combination of strength, corrosion resistance and affordability. Type 304 stainless steel is normally the best option when manufacturing grilles, vents or filters used for the general screening of liquids, powders, abrasives and solids.

Woven wire mesh products, also known aswoven wire cloth, are woven on looms, a process that is similar to the one used to weave clothing. The mesh can consist of various crimping patterns for the interlocking segments. This interlocking method, which entails the precise arrangement of the wires over and under one another prior to crimping them into place, creates a product that’s strong and reliable. The high-precision manufacturing process makes woven wire cloth more labor-intensive to produce therefore it is typically more expensive thanwelded wire mesh.

Wire openings and sizes range broadly. Marco Specialty Steel offers many different weave patterns and pre-crimp styles. Below are examples of crimp and weave styles that are available. See our Crimp and Weave Styles page for more detailed information.

Lock crimp: Lock crimp is comprised of pre-crimped wire featuring the formation of knuckles or bumps over intersecting sets of wires. This locks the mesh in place to create an extremely rigid product.

Intercrimp: Commonly used for screens and architectural applications, intercrimp woven wire mesh provides superior strength and stability, while offering a rigid mesh solution.

Plain/Double:This standard woven wire cloth weave type produces square openings where the warp wire alternately passes over and under the fill wire at right angles.

Twill Square:Typically used for applications that require managing heavier loads and finer filtration, twill square woven wire mesh exhibits a distinctive parallel diagonal pattern.

Twill Dutch:Twill Dutch is known for its superior strength, which is achieved by packing a high volume of wire in targeted areas of the weave. This woven wire cloth style can also filter particles as small as two microns.

Plain Dutch: The Plain Dutch style features diagonally slanted openings that are difficult to see, but produces a strong, compact wire mesh that works well for filtering cloth applications.

If you can’t find the right woven wire mesh product in our extensive stock inventory, just let us know. What makes us one of the best woven wire mesh suppliers in Texas and beyond is our willingness to work with our customers to provide the perfect product for their needs. Our 35,000-square-foot facility includes a fabrication shop fully-equipped with expert fabricators who have the necessary tools to transform any of our in-stock products into a custom-tailored creations that solve a unique problem quickly, efficiently and affordably.

As one of the leading woven wire cloth suppliers in Texas and beyond, you can trust Marco Specialty Steel for helpful advice in selecting the best product for your applications.

We’ll assist you in evaluating all the factors that go into the decision-making process. These include determining the ideal mesh size (diameter of the openings in the mesh), mesh count (the number of wires found within each linear inch) and weave type (this will affect the filtering capabilities of the mesh). You’ll be able to move forward on your projects with total confidence.

As one of the world’s leading wire mesh suppliers, Marco Specialty Steel, Inc. is your headquarters for a wide range of high-quality steel mesh products. We can also provide custom woven wire cloth solutions for your specific applications. With more than a quarter-century of woven wire mesh expertise and a large inventory of stock products, you can count on us for the best solution for your company.

We’re also known as a customer-focused metal/steel company that is willing to do whatever it takes to achieve total customer satisfaction. Fast turnaround times are our specialty – we understand the importance of keeping your projects on schedule, and we make every effort to deliver our products as quickly and efficiently as possible.

Many years ago now, CARL STAHL ARCHITECTURE came up with an innovative construction element that combines protection with aesthetic design: X-TEND. The potential applications for stainless steel mesh are exceptionally varied both indoors and outdoors. Amongst other things, it is used as balustrade in-fill, horizontal or vertical fall protection, dividers, façade cladding, green wall systems or simply very flexible design elements. Architecturally ambitious zoolutions such as lightweight, free-flight aviaries or big-cat enclosures with three-dimensional, curvilinear geometries are also built using X-TEND stainless steel netting. They are just one of the many specialities of CARL STAHL ARCHITECTURE’s experienced planners and wire rope specialists.

8613371530291

8613371530291