steel wire rope uses in stock

Sought out for its strength and flexibility, wire rope is an integral part of a plethora of industries. Modern wire rope has been around since the mid-1800s and has snaked its way into many different sectors for its ability to lift loads safely and reliably. It is also used as a reinforcement for concrete and to run machines. The following are a few of the many industries that use wire rope in one way or another.

The aerospace industry needs parts that are strong, reliable, and corrosion and heat resistant so is it any wonder why wire rope is a staple in this industry? Not only is wire rope used inside planes and rockets to control the levers and pedals that move the aircraft, but it is used in the building of the massive machines as well.

Heavy-duty wire rope is used throughout the automotive industry because of its versatility and strength. It is used for raising windows and opening and closing sunroofs. Tow trucks use wire rope to tow vehicles. Wire ropes are also used in the manufacturing of automobiles in cranes and hoists to move heavy car parts around the factory.

Wire ropes are used daily on construction sites to move heavy loads vertically and horizontally. Construction workers rely on wire rope for its sturdiness and endurance.

In the construction of buildings and bridges, wire ropes are used to reinforce structural strength in security fences and to reinforce concrete in buildings and bridges. It is also used extensively in suspension bridges.

Wine barrels and large containers of ingredients are being moved around with wire rope in the Food and Beverage manufacturing industry. In processing, it is used in conveyor belts to move the products from one machine to the next, for instance, in moving the chocolate along to the box area to be packaged.

Wire rope is used for towing and mooring boats and in the building of ships and the lowering of lifeboats. It is also used extensively in sailboats to lift and lower the masts. This industry relies on wire rope because it resists corrosion in the salty, misty, sea air, and for its flexibility.

Special underground mining ropes are required in deep shaft mining. These wire ropes must be extremely strong and reliable to safely lift and lower materials and personnel from and to deep underground.

Wire rope shines in harsh, hazardous environments, making it ideal for use in the oil and gas industry. Wire ropes are used as drilling lines in the oil rigs and because they can withstand huge amounts of pressure and stress and extensive temperatures, they are widely used in the oil derricks out at sea and on land in all types of weather.

Wire rope was used early on in the rail industry underneath the road for pulling cars up unimaginably steep hills or to guide them along city streets with the use of overhead line conductors. Wire rope is still used in trains and to lift and lower freight into and out of railroad cars.

Wire ropes are an integral part of the theater industry. Wire rope and rigging is an essential part of raising and lowering stage curtains. Heavy, bulky backdrops and scenery pieces to “set the scene” are moved around with the help of wire rope and actors fly over the stage with harnesses connected to cables to keep them safe.

Stunt rigging is vital in the film industry to get that perfect take and to keep the stunt people from getting hurt. In this industry, people’s lives are literally on the line so they use wire ropes for their strength and versatility.

In the ski industry, wire ropes hold the cars or chairs to shuttle skiers to the top of the mountain. These strong cables carry people back and forth up and down the mountain in extreme weather and need to be durable enough to hold up in these conditions.

Amusement parks have been using wire ropes since the beginning of amusement parks. They are used to pull cars to the top of rollercoasters, hold swings that fly through the air, and to pull cars around a track through a haunted house. Wire ropes are versatile, strong and easily replaced when needed. They are also used in carnival rides because of their strength and for ease of removal and replacement during travel.

Silver State Wire Ropesupplies wire rope to Nevada and beyond. Although we specialize in entertainment and stage rigging and mining rigging, Silver State Wire Rope manufactures wire rope for whatever industry you’re in as well.Contact ustoday and we’ll help you find the wire rope you’re looking for!

Steel wire rope is several strands of metal wire twisted into a helix forming a composite “rope”, in a pattern known as “laid rope”. Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as “cable laid”.

In stricter senses the term “steel wire rope” refers to diameter larger than 3/8 inch (9.52 mm), with smaller gauges designated cable or cords. Initially wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, steel wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Steel wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than steel wire rope. For example, aircraft cables are available in 3/64 in. diameter while most wire ropes begin at a 1/4 in. diameter. Static wire ropes are used to support structures such as suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern steel wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany. It was quickly accepted because it proved superior to ropes made of hemp or to metal chains, such as had been used before.

Wilhelm Albert’s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further. In America wire rope was manufactured by John A. Roebling, starting in 1841 and forming the basis for his success in suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal owners[9] of the Lehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk, Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, steel wire rope systems were used as a means of transmitting mechanical power including for the new cable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

The steel wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

As of 2017, the consumption and sales of steel wire ropes is high in Asia Pacific, especially in China, Indonesia and India. North America and Europe are key regions for the global steel wire rope market as they are prominent end users of the oil and gas industry. Manufacturers of steel wire ropes are largely based in China, India, the U.S., Germany and Japan.

During the forecast period, the steel wire rope market in Asian countries such as China, India, Indonesia, Thailand and Malaysia is expected to witness a high growth trend. Since the last decade, China has been witnessing major growth in the steel wire rope market, which can be attributed to the growth of steel production and investment in infrastructure where lift and motion applications are involved.

Oil and gas, marine and mining industries drive the global steel wire rope market. During the forecast period, the mining industry is expected to witness a stable growth trend as government regulations for mining activities have limited the application of steel wire ropes.

Manufacturers of steel wire ropes are expected to focus on economies with significant steel production and import. In addition, developing economies such as India, Brazil and GCC countries are expected to play a key role in the growth of the steel wire rope market.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A fiber core can be made of natural or synthetic polypropylene fibers. Fiber cores offer greater elasticity than a steel core but are more susceptible to crushing and not recommended for high heat environments.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

At Carl Stahl Sava Industries, our steel mechanical cable choices include 304 and 316 stainless steel and galvanized steel cable. Sava is both a wire rope supplier and a wire rope manufacturer that is able to work withexotic steel alternatives upon request, both stainless steel and galvanized steel mechanical cable offer distinct benefits, depending upon the application. Read on to learn the differences between galvanized vs. stainless steel wire ropeand determine which custom wire rope will better serve your application requirements.

One of the greatest benefits of stainless steel wire rope is that it is suitable for nearly any application. While it may have a slightly higher cost than galvanized steel cable, stainless steel cable provides customers with greater ROI and maintains its high-strength qualities over its lifespan under most conditions. While not as strong as tungsten or tolerant of excessive temperatures, stainless steel mechanical wire rope is an incredibly effective cable construction material.

Stainless steel has high corrosion resistance due to it being treated with chromium. This additional element makes stainless steel suitable for use in moist environments, even when harmful salty conditions are present. Specifically in marine environments, for instance, stainless steel wire rope can be used for years without corroding. And in the medical devices field, stainless steel is commonly the metal of choice for many medical device instruments like endoscopes because of its high sanitization level and durability over many cycles makes it ideal.

Galvanized steel is steel that has been dipped in a zinc coating, which gives it good corrosion-resistant qualities. But even with the addition of zinc, galvanized wire rope’s strength is weaker than stainless steel because of the presence of chromium, making the cable stronger and more tolerant of corrosive elements like saltwater. Galvanized cable will rust and corrode if salty wet conditions are present. And like stainless steel, galvanized steel cable ends will also weld together if they make contact with one another.

Galvanized steel cable is often found in industrial applications, since items may brush up against the wire rope in the field, which again, are environmental conditions that galvanized steel tolerates quite well over time. For this and other reasons, Galvanized steel wire rope works exceptionally well in aerospace applications.

Stainless steel wire rope is a cost-effective solution that works across a range of applications, is impervious to salty wetness and is stronger than galvanized steel cable. But galvanized steel wire rope is corrosion-resistant, except when salt is present and tolerates contact with itself far better than stainless steel cable.

It"s important to remember that since each application has unique needs, these comparisons are general guidelines. Contact Sava today to discuss your project, so we can help you determine whether a stainless steel wire rope or galvanized steel wire rope is best for your cable manufacturing needs.

When it comes to choosing the right wire rope, you need to ensure you choose the materials best suited to meet your application’s needs, while also being sensitive to budget. This requires working with the right stainless steel wire supplier that meets ISO 9001 requirements. Stainless steel wire rope manufacturers like Carl Stahl Sava Industries know that it is cost-effective, strong, durable, corrosion-resistant, and heat resistant. This makes stainless steel among the more popular cable rope materials that Sava works with precisely due to its wide range of applications and affordability.

Stainless steel wire rope suppliers often recommend it over other cable construction materials because of its cost-effectiveness. But what’s interesting about stainless steel stranded wire is that its affordability, as compared with more expensive alternatives like tungsten for example is rooted in its low maintenance, longevity, availability and ease of use and installation. Therefore the material’s mechanical malleability, including its lifespan, combined with how readily available it is, makes stainless steel ideal in many use cases.

As a stainless steel wire rope supplier & manufacturerSava typically works with industry-standard stainless steel, such as 303, 304 and 316 stainless steel. However, we can work with any stainless steel a customer needs,and through our stainless steel wire fabrication process we provide a product other wire rope manufacturers, suppliers, and stainless steel wire rope factories cannot. We are a wire rope supplier of over-the-counter stainless steel cable and manufacture an entire family of cable fittings to create your custom cable assembly.

Another reason stainless steel is an industry-standard is because of stainless steel wire rope’sstrength and durability. It is an exceptionally strong wire.

For example, Grade 301 and 304 stainless steel possesses a tensile strength of up to 1300 MPa in strip and wire forms. Galvanized steel, with a tensile strength of up to 550 MPa, comparatively, makes stainless steel remarkably strong.

Consequently, stainless steel has a long lifespan, although not as long as tungsten due to the latter’s tolerance of more intense temperatures. Even so, stainless steel is effective in a wide range of applications over many cycles, making it ideal across many applications.

As mentioned, tungsten is preferable in extremely hot environments that require a long life span, because it heats up quickly but dissipates the heat equally as fast. However, stainless steel can perform at these same levels of extreme heat and at a lower cost, but over less cycles. But that it doesn’t last as long as tungsten under extreme conditions doesn’t rule it out. For instance, if you have an operation that needs a high lifecycle, but it’s not being used as frequently, stainless steel mechanical cable might be perfect. If cycles are less frequent, then it’s possible stainless steel will last as long as the application requires and again, under the same hostile temperatures that gives tungsten all the glory.

So, while tungsten certainly has its benefits, stainless steel mechanical cable is a strong alternative that will provide similar, if not the same, results for most applications.

Another feature that makes stainless steel cable advantageous is that it’s easy to work with, compared to other materials. It is very easily formed, especially in the small-diameter wires inside the cable as well. What’s more, stainless steel mechanical cable is also easy to lay into the appropriate shape when stranded.

When the stainless steel cable is manufactured with a nitinol core, the results possess seemingly magical easy-to-use properties. Known as a memory alloy, nitinol “remembers,” so-to-speak, the shape it was in, allowing the stainless steel cable housing the nitinol core wire to traverse winding and twisting pathways like arteries and other narrow vessels. In such surgical applications, this nitinol core wire is the center of the stranded cable otherwise comprised of stainless steel. So when paired with nitinol, stainless steel cable becomes a flexible, memory-based solution for a wide array of medical devices that use medical cable assemblies, and medical grade stainless steel wire. But as nitinol is not used to comprise the entire stranded cable used in these elegant medical devices, stainless steel remains the best material to work with when bending is critical, but cost is equally important.

If your application requires sensitivity to corrosion, such as weather or water, salt or otherwise, stainless steel cable is an excellent choice. The material’s tolerance of harsh environmental conditions ensures the cable can take a beating over a long period of time by moisture. Comparatively speaking, galvanized steel, another steel cable Sava manufacturers, is vulnerable to applications where corrosive variables are present, like marine or submerged saltwater uses.

If you are looking for a stainless steel cable supplier and manufacturer, our USA based manufacturing team can help you decide which stainless steel wire rope is right for your application. Visit our contact page to get in touch with a Sava team member and inquire about your stainless steel wire rope options!

Did you know wire ropes were used as far back as the 1830s for mining hoist applications? Nowadays, we can use steel ropes for many different applications such as lifting and hoisting in elevators and cranes, and for mechanical power transmission. US Cargo Control’s wire rope slings are an excellent choice for heavy-duty jobs as their fabrication offers excellent abrasion resistance and heat resistance for extreme conditions.

Although these slings are beneficial for the lifting and rigging industry, there are a few specifications to know before purchasing them. Continue reading what is wire rope, what are important specifications to look for, and how it’s different from cable rope.

These slings carry different properties that can determine their performance. Wire rope is constructed where a strand consists of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Once the wires are formed, they all come together to create greater strength and flexibility.

These slings work well for lifting, hoisting, towing, or anchoring loads. They’re manufactured in a variety of configurations, with 6×19 and 6×36 being the most common. When you see 6×19 or 6×36 from our website, these numbers represent the number of wires making up the strand and the number of strands wrapped around the core.

For example, a 6×19 indicates that there are 19 wires making up a strand, and 6 strands wrapping around the core. To learn more about our 6×19 wire ropes, look into our bestselling 1/2″ Galvanized Wire Rope EIPS IWRC, 1/2″ Stainless Steel Wire Rope IWRC T304, and 1/2″ Bright Wire Rope EIPS FC.

The configurations will offer different benefits for certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance. Continue reading to learn which wire rope fits your job.

There are different versions of wire rope slings, ranging from single leg to 4 legs, as well as braided wire rope and domestic wire rope slings (manufactured in the U.S. with Crosby® hardware). When looking at the types of slings we offer at US Cargo Control, be sure to consider how much versatility and capability you need.

For example, a braided wire rope has increased flexibility and friction to grip loads over a regular wire rope. Adding an additional leg to the sling can add additional versatility and strength.

This is the measurement of the rope’s diameter and can be displayed in inches or millimeters. These sizes commonly display different strand patterns where the number of layers, wires per layer, and size of the wires per layer all affect the strand pattern. Wire rope can be constructed using one of the following patterns below or using two or more patterns.

Warrington – this construction has two layers of wires around a center with one diamter of wire in the inner layer, and two diameteres of wire alternating large and small in the outer layer.

The type of lay refers to the way the wires are laid to form a strand. They’re how the strands are laid around the core which can be regular lay, long lay, or alternate lay.

The wires line up with the axis of the rope. This is where the wires are twisting in one direction, and the strands in the opposite direction create the rope. Regular lay is less likely to untwist and less likely to crush.

This is the opposite of regular lay where the wires form an angle with the axis of the rope. The wires and strands spiral in the same direction and run at a diagonal to the centerline of the rope. Lang lay is more flexible and resistant to abrasion than regular lay wire ropes. The only con is this type of lay will be more likely to twist and crush than the regular lay.

Sometimes known as reverse lay, this type of lay consists of alternating regular lay and long lay strands. This unites the best features of both types, and it’s using relatively large outer wires to provide an increase of abrasion resistance.

This refers to the protective coating that’s applied to the wire rope. There are three types of finishes which are galvanized (zinc-coated), stainless steel, and bright (unfinished steel).

The grade of the rope means the grade of steel being used. The plow steel strength calculates the strengths of most steel wire ropes. Some classifications include Improved Plow Steel (IPS), Extra Improved Plow Steel (EIPS), Extra Extra Improved Plow Steel (EEIPS), Galvanized Improved Plowed Steel (GIPS), and Drawn Galvanized Imrpoved Plow Steel (DGEIP).

EIPS is 15% stronger than IPS, and EEIPS is 10% stronger than EIPS. Along with that, GIPS and DGEIP wires can add corrosion resistance to your application, but DGEIP wires have a higher break load than GIPS.

The type of core is what makes up the center of the wire rope. There are three types of core: Fiber Core (FC), Independent Wire Rope Core (IWRC), and Wire Strand Core (WSC).

A fiber core can be made of synthetic polypropylene fibers. The fiber cores offer greater elasticity than a steel core, but are more susceptible to crushing. This isn’t recommended for high heat environments.

A steel core can either be an independent wire rope or individual strand. The steel cores can provide adequate support, or in an operating environment where temperatures can exceed very high heat.

Wire and cable ropes are terms that are often interchangeable but do have one varying difference. Wire rope refers to the diameters that are larger than 3/8 inch. Sizes smaller than this are classified as cable rope or even cords. Regardless of the size difference, cable and wire rope are still classified as a “machine.” Even a group of strands laid around a core would still be called a cable or wire rope.

Wire rope is used by both private and public sector organisations that engage in construction, rigging, automotive, aerospace, manufacturing, marine, mining, military, natural resources, chemicals, manufacturing, warehousing and rail activities.

Available in various constructions, sizes and finishes, wire rope is a versatile material that can be used to (among other things) lift, hoist, separate, position, secure, remove, repair, readjust, support and brace items in a safe and effective manner.

Wire rope was initially designed to assist in the mining industry. Removing minerals from the earth required heavy duty cables that could be sent towards the core of the earth and extract deposits for fuel, manufacturing, construction and fashion purposes. Nowadays, wire rope serves an important role across many industries because of its features and properties.

Wire rope can be fabricated to minimise torsion, withstand high temperatures, carry very heavy loads, be suspended in water or chemicals for long periods of time, suffer continuous vibrations or ad hoc shocks and much more. The diverse application of wire rope makes it an ideal choice in various commercial and industrial operations.

We stock a wide range of wire rope to suit your exact needs and requirements. Instead of making a decision from a limited selection of wire rope, we stock all kinds so that you do not settle for anything less. We stock stainless steel wire rope 0.30mm-20mm, galvanized wire rope 1.6mm-48mm and PVC & nylon coated wire rope in various diameter at competitive prices to suit your specific needs. Our wire ropes and stainless steel cables are sourced from reliable suppliers and are tested to comply with the relevant Australian standards.

Construction is one industry that continues to use wire rope extensively. Whether that be during construction of a building, the lifts that operate in a building, window cleaning equipment, supporting utility equipment, operating doors, securing shafts, bracing, anchoring, restraining and many more, wire rope is a common construction material.

Each application has its own requirements. For example, wire rope that is used to suspend lift cars and the external window cleaning and maintenance equipment must be able to withstand heavy loads and also not twist under stress.

The lifting industry comprises cranes and hoists, both mobile and fixed. You will see these lifting apparatuses at warehouses, ports, construction sites, infrastructure build sites, and other venues that require heavy and/or bulky loads to be lifted, positioned and moved.

The wire rope for these applications need to be designed to suit the exact requirements of the activity so that they operate effectively while in use. Lifting, positioning and moving heavy items needs to be done safely, so the wire rope needs to be sturdy, resist torsion, not snap, have enough flex and withstand a shock or sudden impact.

The mining industry was the primary user of wire rope, and continues to be a major contributor to wire rope consumption in Australia. Wire rope would be used in the lift shafts, to extract minerals, provide essential supplies down below the ground to the mining team, install equipment, secure stairwells and in many other applications.

Together with other stainless steel components, wire rope is an essential material to secure, fasten, position and brace equipment used for mining and natural resource activities.

The manufacturing industry uses wire rope in its assembly lines and facilities to manufacture goods for the Australian and overseas economies. Whether the wire rope is fitted in a conveyor belt, hoist, manufacturing equipment or other device, without an easy to install and maintain component the manufacturing industry would not be flourishing today.

Items always need to be moved around and wire rope makes it easy to lift, pull or push items no matter how small or large with precision and without human effort. With automation, wire rope continues to play an important role in operating robotics.

The automotive, aerospace and rail industries continue to use wire rope in various ways. Each application of wire rope has different requirements so that it can function appropriately. While wire rope is common in pedals for cars, trucks, trains and aeroplanes, the latter form of transportation requires heat resistant and corrosion resistant cables due to travel at high altitudes and fast speeds. There are many moving parts in transportation and each mechanical part relies on a system of components which commonly include wire ropes or steel cables.

At Keble’s Trading, we are a wire rope and stainless steel cable supplier who stocks a wide range of wire rope for your review and selection. We are one of the leading suppliers of galvanised, stainless steel and PVC & nylon coated wire rope and cable in Australia. If you would like to enquire about our wire rope or stainless steel cable products, or place an order with us, please contact us on 1800 067 687.

Stainless Steel Wire Ropes are an important part of our core product range. We keep stock of AISI 316 Marine Grade Stainless Steel Wire Rope from 0.5mm up to 26mm in various constructions including: 1X19, 7X7, 7X19 and 6X36 wire core.

Providing high quality materials is an extremely important part of our ethos which is why our stainless steel wire ropes are produced in accordance with BSMA29 standards by one of the leading stainless steel wire rope manufacturers in the world.

Our ropes are used in demanding conditions and it is therefore vital that the tolerance and chemical composition of the material is as per the required AISI 316 requirements. Applications and markets include:structural and architectural, balustrade, yacht rigging and Stay Wire applications.

Steel Wire Rope Ltd have specialised in supplying multi stranded galvanised steel wire rope since 1989. We stock from 0.5mm up to 64mm in various constructions including 1X19, 7X7,6X19, 7X19, 6X36, 8X19, 8X36, 19X7 and 35X7 with both Fibre Core and Steel Cores. In addition to these conventional steel wire ropes we can offer special wire ropes from high quality manufacturers.

Most wire ropes operate in demanding conditions and must resist crushing, bending fatigue and abrasion. We recognise that it is vital that all of our wire ropes need to perform to the highest levels to maximise service life therefore increasing productivity for the end user. With our technical experience we have worked hard with our partners to ensure that all material is manufactured to the very best standards in the steel wire rope industry.

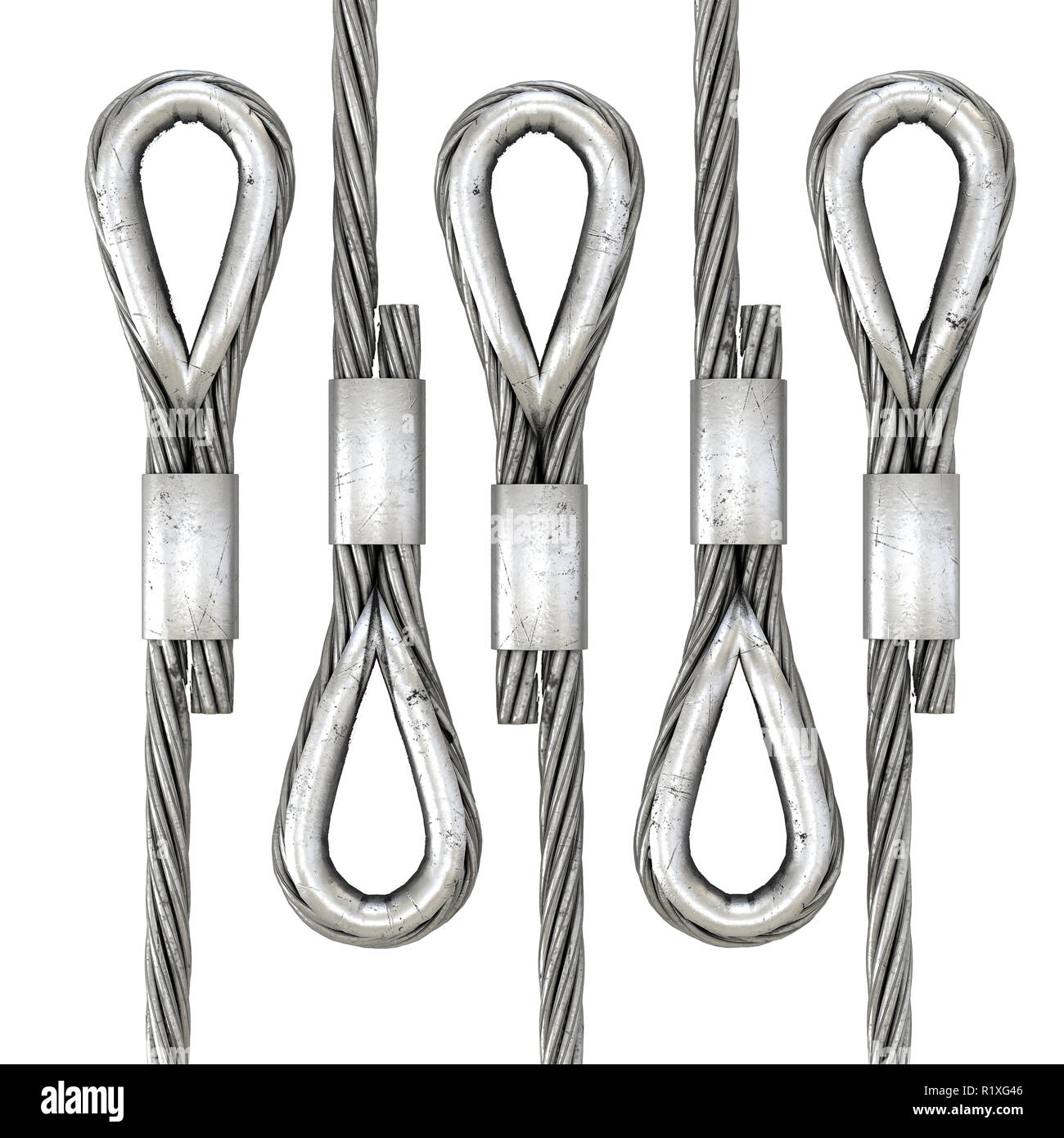

Each steel wire rope can be supplied fully assembled complete with end terminals such as a thimble eyes, swaged ends and wedge sockets as well as many other solutions. These cable assemblies are manufactured in house by our team of engineers complete to your specifications.

Although simple in its appearance, wire rope is a complex mechanical device that makes lifting, moving or supporting a load simple. Wire ropes are available in various compositions to suit different purposes. For example, wire rope can be rigid, flexible, restrict rotation and have features that limit corrosion, abrasion and crushing. In particular, it is common for wire rope to be fabricated from stainless steel or galvanised steel.

Stainless steel wire rope is very common and used in many commercial and industrial applications. Stainless steel has chromium added to the steel to provide some degree of protection against rust and corrosion. Stainless steel is not immune to those environmental effects but is better protected than pure non-treated steel. Stainless steel wire rope is used predominantly in applications where it is not exposed to the outdoor elements to avoid rust or corrosion damaging the wire rope.

Stainless steel wire rope is available in grades 304 and 316. 304 grade stainless steel is standard whereas 316 grade stainless steel is ideal for use in and around marine locations. 304 grade stainless steel contains approximately 18% chromium and 8% nickel while 316 grade stainless steel contains 16% chromium, 10% nickel and 2% molybdenum. The molybdenum is added to help resist corrosion to chlorides (like sea water, chlorides and de-icing salts).

Galvanised wire rope is steel wire rope coated in a layer of zinc. The coating helps protect the steel from moisture in the air to prevent the wire rope from being susceptible to rust. This type of wire rope is ideal for use in marine locations where the wire rope is exposed to wet, damp and humid conditions. Galvanised wire rope helps to prevent the inner steel degrading from rust deposits.

While galvanised wire rope provides this benefit, it is not ideal for use in certain circumstances. These circumstances include: applications in and around salty sea water, use where corrosive chemicals are being handled, when food or medical products are being handled, applications where aesthetics are important and a shine is required, and others. In these circumstances it is preferable to use stainless steel wire rope.

The main difference between stainless steel and galvanised steel wire rope is the tensile strength. Given stainless steel is steel combined with chromium when the steel is in liquid molten state, this provides additional strength compared to galvanised wire rope composed of steel and a coating of zinc. Stainless steel wire rope is favoured by many for this very reason and during the wire rope’s service life, if maintained well, it performs highly effectively in various applications.

Galvanised wire rope is steel wire hot dipped in zinc or electro-galvanised to protect the steel from rust and corrosion. This treatment provides a coating only and protection to the internal steel wire will no longer exist if the coating is breached. We stock galvanised wire rope available in fibre core or steel core, in 6x7, 6x19, 6x24, 6x25, 6x36, 7x7, 7x19 constructions.

Each type of wire rope construction is suited for different purposes and it is important that you check your standards, regulatory requirements and industry codes to ensure the correct wire rope is used. A wire rope with a thicker diameter will be more abrasion and crush resistant, whereas a thinner diameter will provide flexibility, bendability and not suffer fatigue.

Fibre core wire ropes are used where flexibility in handling, moving or supporting a load is required. Fibre core wire ropes are not suited for applications where there is prolonged outdoor exposure or crushing against other objects. On the other hand, steel core wire ropes have a higher tensile strength and are better suited to applications where there will be abrasions and crushing.

We stock stainless steel wire rope available in grades 304 and 316 in 1x19, 7x7 and 7x19 constructions. Each type of wire rope construction is suited for different purposes and it is important that you check your standards, regulatory requirements and industry codes to ensure the correct wire rope is used.

- 1 x 19 construction: this type of wire rope consists of a single strand with 19 wires. Given the number of wires formed into the rope, it offers a high breaking load and is the least flexible wire rope construction. It will not bend around corners or angles and is ideal for straight line applications to support objects.

- 7 x 7 construction: this type of wire rope consists of 7 strands of 7 wires. It is not as flexible as the wire rope with a 7 x 19 construction but still has bendability characteristics.

- 7 x 19 construction: this type of wire rope consists of 7 strands with 19 wires each. This combination offers the greatest flexibility and is the most common and versatile in industrial and commercial applications. The wire rope is ideal for applications where there are bends and turns in the system. This type of rope also has some stretch in it.

Stainless steel wire ropes are more than just elegant; they are also an ideal alternative over traditional materials limited in functionality and style. When using stainless steel wire ropes, you get a wide range of options and benefits. Using stainless steel offers an amazing advantage to the ornamental and architectural industry. This material"s main benefits include high corrosion resistance that allows the material to function and survive harsh environmental conditions. Stainless steel wires are also great at resisting heat and fire, which helps them to resist scaling while also retaining strength during high temperatures.

Stainless steel wire rope is commonly used because it offers both horizontal and vertical choices. Horizontal rope railings are highly specific. On the other hand, vertical wire ropes offer a more attractive alternative that is great for architecture. These ropes have a clean and minimalist appearance when compared to horizontal ropes.

If your application needs sensitivity to corrosion (water, weather, salt, etc.), stainless steel cables could be your best choice. The material is known for its strong work in harsh environmental conditions. Cables can take a beating and still be reliable. A galvanized stainless steel wire rope is vulnerable to corrosion, and as such, it should not be used under these conditions. When working in marine settings, stainless steel wire ropes and nylon slings should be your first choice.

Renowned for having one of the most comprehensive and robust inventory of wire rope, TEHO Ropes stocks steel wire ropes from some of the best manufacturers in the industry.We are stringent that our wire ropes are true to their technical specifications, principally those of BS 302, BS EN12385, ISO 2408:2004, JIS G3525 and API-9A.

The TEHO steel wire rope product range include general purpose steel wire ropes, stainless steel wires, PVC coated wires, rotation-resistant and non-rotating wire ropes which can be used for mooring, lashing, hoisting and luffing applications.

A wide selection of applications for usage are lashing wires, fire wires, mooring wires, accommodation ladder wires, Hose Handling Crane wires, Overhead Crane wires, Freefall boat davit wires.

In addition to the general purpose steel wire ropes, we also stock a wide variety of high performance crane cables in 4 strand, 8 strand and multistrand type with plastic infiltrated core.

Selecting the most suitable wire rope for mooring is essential for optimum performance and safety. It is crucial for very large and ultra large vessels whose numbers are increasing.

OCIMF strongly recommends the use of 6 × 36 class drawn galvanised wire rope with Independent Wire Rope Core (IWRC) as mooring lines. TEHO’s range of 6 × 36 class wire ropes strictly follows the EN10264-2 standard for galvanisation, as well as the other OCIMF guidelines.

Most cranes come with a recommended range of wire ropes to use on the different functional components. Proper application of the wire rope to each crane function is necessary to extract best performance, and to prevent accident and avoid damage to the equipment.

In this full length handbook, learn the basics of wire rope including how to choose and measure wire rope. Additionally, you will understand the fundamental mechanics behind our most popular rope constructions and classifications. Finally, you will learn the proper way to care for and use your wire rope, including end treatments, inspection, and removal criteria.

Twisted hoist lines can bring a construction project to a sudden halt, resulting in downtime. But the good news is that you can minimize block rotation through proper installation, handling and corrective measures. In this reference document, you will better understand torque and gain tips on how to reduce block rotation.

Our galvanized strand products meet or exceed ASTM specifications A475 and ASTM A363. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn what the strands are tested for. Additionally, a chart detailing the physical properties of zinc-coated steel wire strand is included.

Our industry has its fair share of terminology and phrases. In this reference document (an excerpt from the Wire Rope Users Handbook), you will be provided a comprehensive glossary of all Wire Rope words. From “Abrasion” to “Warrington”, your questions are answered here.

How long will your rope last? While there is not a simple answer, there are several factors involved. In this reference document (an excerpt from the Wire Rope Users Handbook), you will the factors affecting the longevity of your ropes life. Additionally, information regarding the cleaning and lubrication of your ropes is included.

There is a correct methodology behind measuring of wire rope diameter. Learn this methodology in this reference document (an excerpt from the Wire Rope Users Handbook). Also, the definition of design factor is available. And finally, detailed information regarding metric conversion and equivalents is included.

Yes, there is a RIGHT way to unreel, uncoil and store a wire rope. Learn the proper steps in this reference document (an excerpt from the Wire Rope Users Handbook). Additionally, the three stages of kinking are vividly displayed.

Wires are the basic building blocks of a wire rope. And, a rope core will greatly impact the performance of your rope. Learn how the number of wire strands and construction determine a wire rope classification. In this reference document (an excerpt from the Wire Rope Users Handbook), you will become familiar with the standard rope classifications and special rope constructions.

The types of wire, lay and performing greatly affect wire rope performance and operation. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the basic types of wire used in ropes, the common grades of wire rope and the meaning of “lay”.

In this Product Bulletin, you will learn about the new rope description format that WireCo WorldGroup will follow in all of our product descriptions. This format will adopt symbols and designations that are part of ISO, ASTM, and other industry standards and specifications.

Rotation-resistant ropes can frequently provide the best and most economical service in specific applications, when you choose, handle and use them properly. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the difference between Category 1, Category 2 and Category 3 Rotation-Resistant Rope.

Previously known as “aircraft” cable, and now known as “utility cable, these small diameter specialty ropes are used in a variety of applications, including control cables, window and door closures, different kind of remote control systems and boat riggings. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn how Union specialty small ropes are engineered and fabricated, and the special lubrication and testing they require. Additionally, a minimum breaking force and weights for 7x7, and 7x19 utility cable is included.

Our industry has its fair share of abbreviations. In this reference document (an excerpt from the Wire Rope Users Handbook), you will be provided a comprehensive glossary of all Wire Rope words. From “PRF” (preformed) to “XIP®” (Extra improved plow steel), your questions are answered here.

Swaged ropes and “Double-Swaged” ropes provide excellent strength for some specific applications. In this reference document (an excerpt from the Wire Rope Users Handbook), you will find the definition of swaged and PowerFlex (aka double-swaged) ropes. Minimum breaking force and weights charts for 6x19, 6x36, PowerFlex, 3x19 and 3x36 ropes are included.

Our most popular Tech Report, this Wire Rope Inspection Tech Report explains why periodic inspection of wire ropes are necessary. Learn how to properly inspect wire rope, what tools are necessary for inspection, and how to use inspection forms. Additionally, you will learn how often you should inspect your wire rope, what your ‘critical’ points are, how to inspect your end attachments, how to make an internal rope examination, how to inspect sheaves, and how to evaluate drums. Finally, you will understand how to properly measure rope diameter and rope lay.

In applications where a specific length is critical, the constructional stretch can be minimized by prestretching the rope prior to installation, HOWEVER, learn why WireCo WorldGroup advises against prestretching Tuf-Kote/PFV rope. After reading this product bulletin, you will understand the rationale behind WireCo WorldGroup’s recommendation against prestretching Tuf-Kote/PFV Rope.

Engineering and producing wire rope slings for your application is a highly specialized field - with exacting standards that we gladly live by. In this marketing flier, learn the different Union Wire Rope Sling constructions. Additionally learn more about Union Spelter Sockets (both open and closed). There are capacity and diameter charts associated with each product.

In this Product Bulletin, learn the various definition of "US made wire rope" including references to the Buy American Act and the Buy America Requirement. Additionally, learn how Union wire rope meets these definitions.

Most ropes are shipped with the ends seized as they are prepared for cutting, however, in some cases, the rope requires special end preparations. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the two chosen methods for seizing cut ends of your wire ropes. Illustrations and step-by-step instructions are included.

All wire ropes will wear out eventually and gradually lose work capability throughout their service life. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn why periodic inspections are critical. The purposes for inspection, guidelines around timing and choosing the right person to inspect are included. Additionally, illustrations regarding “what to look for” in a wire rope is available.

There is obvious evidence of wire rope wear and abuse, and specific criteria regarding removal of your wire rope. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the various types of wear and abuse (illustrations included) and the exact removal criteria. A chart on when to replace your wire rope – based on number of broken wires is included.

In this product bulletin, learn why WireCo WorldGroup refers to XLT4 as a low-torque rope and not a rotation-resistant rope. Also included are the definitions of ASTM A1023 and ASME B30.5.

8613371530291

8613371530291