wavy wire rope quotation

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Wire Rope 1x19 Stainless Steel AISI 316Most commonly used wire rope for yacht rigging. Wire rope with a high breaking load. Is generally used for shrouds, stays or guard rails. Also used for other applications.

Other sizes and information about 1x19 wire rope on request.Custom madeWant to make a quotation for your total rigging yourself? This is possible within the wire rope 1x19 section by following these 6 easy steps:

Eyes are mainly used as an attachment to rigging screws or forks. Eye terminals are engraved with the wire size and swage depth, making them easier to work with and to press or swage onto the wire.

Forged from low carbon stainless steel AISI 316L every Petersen Forged Swage Eye is increadibly strong and light. Petersen swage eyes can be used with many different wire-rope constructions.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

The "T" Terminals all features, engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. Be aware t-terminal fitting is mast brand related, exact dimensions are critical for proper function.

Be aware Stemball terminals are mast brand related, exact dimensions are critical for proper function. Stemball terminals can be used in combination with Blue Wave Cups.

Swage Stemballs from Petersen are forged from low carbon stainless steel AISI 316L and is incredibly strong. Petersen swage stemballs can be used with many different wire-rope constructions.

Thread Terminals UNF all feature engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. The UNF thread is more refined compared to metric and has a longer life span.

Metric thread is less refined compared to UNF thread and more subjected to wear. In general the thread terminal on the wire side is right-handed, thereby left-handed thread is the exception.

Nicopress Copper and Zinc-Plated Copper Oval/Duplex Compression sleeves (sometimes called ferrules), are used for making eye and lap splices on wire rope. They are economical and can hold approximately 100% of the cable"s rated breaking strength, depending on the cable size and type used and conform to MS51844. We have determined through pull-testing that Nicopress Oval Sleeves will hold military specification grade aircraft cable in tension until it breaks, when the cable is made to military specifications for 3x7. 7x7, 7x19 and 6x19 IWRC and correctly applied with Nicopress Tools. Here used in combination with a thimble.

Wire Rope 7x19 Stainless Steel AISI 316Very flexible Stainless Steel Wire Rope. Is used for halyards but can also be used for many other applications.

Other sizes and information about 7x19 wire rope on request.Custom madeWant to make a quotation for your total rigging yourself? This is possible within the wire rope 7x19 section by following these 6 easy steps:

Eyes are mainly used as an attachment to rigging screws or forks. Eye terminals are engraved with the wire size and swage depth, making them easier to work with and to press or swage onto the wire.

Forged from low carbon stainless steel AISI 316L every Petersen Forged Swage Eye is increadibly strong and light. Petersen swage eyes can be used with many different wire-rope constructions.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

The "T" Terminals all features, engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. Be aware t-terminal fitting is mast brand related, exact dimensions are critical for proper function.

Be aware Stemball terminals are mast brand related, exact dimensions are critical for proper function. Stemball terminals can be used in combination with Blue Wave Cups.

Swage Stemballs from Petersen are forged from low carbon stainless steel AISI 316L and is incredibly strong. Petersen swage stemballs can be used with many different wire-rope constructions.

Thread Terminals UNF all feature engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. The UNF thread is more refined compared to metric and has a longer life span.

Metric thread is less refined compared to UNF thread and more subjected to wear. In general the thread terminal on the wire side is right-handed, thereby left-handed thread is the exception.

Nicopress Copper and Zinc-Plated Copper Oval/Duplex Compression sleeves (sometimes called ferrules), are used for making eye and lap splices on wire rope. They are economical and can hold approximately 100% of the cable"s rated breaking strength, depending on the cable size and type used and conform to MS51844. We have determined through pull-testing that Nicopress Oval Sleeves will hold military specification grade aircraft cable in tension until it breaks, when the cable is made to military specifications for 3x7. 7x7, 7x19 and 6x19 IWRC and correctly applied with Nicopress Tools. Here used in combination with a thimble.

The lifetime of wire rope is crucial in industry manufacturing, mining, and so on. The damage can be detected by using appropriate nondestructive testing techniques or destructive tests by cutting the part. For broken wires classification problems, this work is aimed at improving the recognition accuracy. Facing the defects at the exterior of the rope, a novel method for recognition of broken wires is firstly developed based on magnetic and infrared information fusion. A denoising method, which is adopted for magnetic signal, is proposed for eliminating baseline signal and wave strand. An image segmentation method is employed for parting the defects of infrared images. Characteristic vectors are extracted from magnetic images and infrared images, then kernel extreme learning machine network is applied to implement recognition of broken wires. Experimental results show that the denoising method and image segmentation are effective and the information fusion can improve the classification accuracy, which can provide useful information for estimating the residual lifetime of wire rope.

Wire ropes play an important role in many fields such as cranes, oil drilling rigs, elevators, and mine hoist. The safety of wire ropes is closely related to people’s life and resources loss as well as the normal operation of industry. Because of the complex structure of wire ropes and the diversity of application environment, it is difficult to evaluate the health of wire ropes in service [1, 2]. Thus, it is necessary to effectively and accurately perform the quantitative nondestructive testing (NDT) of wire rope by adopting proper methods.

At present, the NDT methods of wire rope include electromagnetic [3, 4], X-ray [5], acoustic [6–9], and optical [10] method [1]. X-ray apparatus has radioactive contamination; acoustic method detects wire rope by striking, which is simple but one-sided; CCD camera optical testing method can directly show the real defects through imaging, but it is susceptible to oil pollution; because of high sensitivity, high speed, and low cost, electromagnetic NDT method is widely used [11–14]. However, no single nondestructive testing technique can identify all kinds of defects. Infrared nondestructive testing does not contain dangerous radiation and has characteristic of noncontact; thus, it has widely applied in solving real problems in numerous areas [15].In addition, its popular application areas contain building sector [16, 17], aeronautics and astronautics [18], chemical industry [19], food [20], cultural heritage [21], and so on. Munoz et al. [22, 23] determined heat source dissipation from infrared thermographic measurements based on the heat diffusion equation provided by thermodynamics principles and identified damage evolution in carbon fibre reinforced composites combing acoustic emission and infrared thermography.

Magnetic flux leakage (MFL) detection of wire rope mainly includes the forward calculation model of MFL detection, pretreatment of MFL signal, and inversion of defect [24]. For example, Yan et al. [25] employed a three-dimensional finite element method (FEM) to analyze MFL signals. This method provided theoretical guidance for detection signal analysis and hardware design. Based on the magnetic dipole model, Yang [2] created the leakage magnetic field analysis models of single wire fracture, surface broken wire, and internal broken wire of wire rope, which provided the theoretical basis for the quantitative analysis of wire rope. Zhao and Zhang [11, 12] made FEM on the distribution of magnetic flux leakage of typical broken wire defects in steel cables, and obtained the relationship between MFL and detection distance, damage size, and internal broken wire. In [13, 14], a magnetic dipole model was established to design the prototype, which provided a theoretical basis for the quantification of defects. Through the FEM model of wire rope and the FEM simulation under different broken wires, DU et al. [26] studied the influence of different broken wires on the safety coefficient of wire rope.

Because actual MFL detection signals are polluted by many noise sources, it is necessary to preprocess the signals in order to reconstruct the defects. Zhang et al. [27, 28] utilized wavelet based on compressed sensing to denoise the strand wave, but it restored a lot of noise; then, they combined the Hilbert-Huang Transform (HHT) and Compressed Sensing Wavelet Filtering (CSWF) to reduce various background noises. Zheng and Zhang [29] exploited wavelet soft threshold to inhibit the noise; nevertheless, the denoising effect is poor. Then Zheng and Zhang [30] implemented Variational Mode Decomposition (VMD) and a wavelet transformation to remove noise from the raw MFL signals, which can effectively eliminate noise. Hong et al. [31] proposed an adaptive wavelet threshold denoising method based on a new threshold function, which achieved good denoising effect on the MFL signal of wire rope. To realize the visualization of defects, Zhao [13] utilized an adaptive notch filtering algorithm for suppressing wave noise.

To visualize and quantify defects and realize quantitative detection of broken wires, researchers need to implement defect inversion. In order to perform defect inversion, numerous scholars have used various methods. Through adopting the wavelet super-resolution reconstruction technique, the resolution of defect grayscale was improved in [32]. Zhang and Tan [33] proposed a super-resolution (SR) reconstruction method based on Tikhonov regular multiframe, which can effectively remain image features of defects while the axial resolution was reduced and circumferential resolution was increased. In [28, 32], researchers implemented classification of defects by adopting back propagation (BP) neural networks. However, BP was easy to fall into local minimum, which can lead to problems such as network underfitting and insufficient generalization ability. Wan et al. [34] investigated the theory on optimal wavelet packet with the Least Squares Support Vector Machine (LS-SVM) to diagnose elevator faults, which was then validated by the experiment. Zheng and Zhang and Qin et al. [29, 35] took the Support Vector Machine (SVM) with a radial basis function classified to conduct the fault pattern recognition, whereas this method was not very effective.

The researchers [15, 36] investigated the failures of steel ropes and defect of ferromagnetic specimens by means of thermovision. In [15], since the measurements required extremely sensitive thermovision technology, the method can detect the tight of ropes at certain conditions. In [34], the researchers developed a new active thermography technique, which can detect the defect in ferromagnetic steel specimens. The fusion of infrared and other information is effective and widely used. Kee and Oh et al. [16] combined air-coupled impact-echo and infrared thermography. It can improve effectiveness of the individual test data. Data fusion of ground-penetrating radar and infrared thermography improved the accuracy of detecting defects [37]. The researchers [38] combined finite element analysis with experimental data from infrared thermography, which provided accurate means to assess quantitatively the size and position of thermal imperfections. According to these, it is demonstrated that data fusion is effective. In this paper, fused data based on infrared thermography and magnetic is utilized to detect the number of broken wires.

Electromagnetic NDT for wire rope is susceptible to hardware design and magnetic signal processing. In [13, 14], the location and number of sensors can affect the quality of acquisition signal. Insufficient quantity will lead to the serious loss of MFL signal, while dense placement of sensors can lead to serious signal interference, resulting in difficulty of noise reduction. Meanwhile, the small broken wire defect information may be drowned out by noise. However, thermal infrared is a visualization method, which can intuitively grasp the surface damage state of wire rope and be closer to the actual damage pattern than magnetic data. Meanwhile, it is without the shortcomings of magnetic detection method and it can make up for the loss of small defects in magnetic information. Thus, the combination of the two methods supply more information for the damage and can avoid the loss of defect information.

To improve classification accuracy of broken wires and provide a reference for evaluating the service life of wire rope, the combination of infrared information and magnetic information is put forward for the first time to perform quantitative identification of wire rope. To processing magnetic signal, an algorithm based on Wavelet Total Variation (WATV) is proposed to remove noise from the raw MFL signals. The noise from high-frequency magnetic leakage, baseline drift, and strand waves can be suppressed by the proposed algorithm. To separate defects from infrared images, an image processing method based on distance is presented. After extracting statistical texture, invariant moment characteristics, and color moment, a fusion method based on kernel extreme learning machine (KELM) of decision level fusion is proposed to combine magnetic and infrared information. Experiment results show that the information fusion based on magnetic and infrared can improve the recognition rate of broken wires.

In the next sections, the platform to get data, the processing for magnetic data, steps for extracting infrared information, and recognition for broken wires after information fusion will be introduced in turn. In this paper, major innovations are as follows: (1) the proposed denoising algorithm based on WATV can eliminate noise generated by channel imbalance, the structure of wire ropes, and so on; (2) an infrared image segmentation algorithm based on distance is presented; and (3) information fusion combined magnetic with infrared to perform classification is firstly adopted.

In this part, through processing and fusing magnetic signal and infrared image, the classification for six kinds of broken wires is implemented. In this experiment, the number of broken wires is one, two, three, four, five, and seven. Many wires are wound into a strand, then it is wounded into a wire rope. The damage of the wire rope is related to the geometry and winding mode of the wire rope [1, 2, 13]. As shown in Figure 1, the structure of the wire rope is with a diameter of 28 mm. The length of the wire ropes is 6.5 m. The specimens used are 185, where the number of training samples is 139 and testing number is 46. The number of broken wires is from 1 to 5 and 7 wires, where the number of every samples set of broken wires is 30, 30, 32, 34, 35, and 34. The width of samples contains 2 mm, 5 mm, and 1.5 cm. The depth of defects is 1 mm. The type of defect is shown in Figure 2.

When there is no defect on wire rope and materials of the wire rope are uniform and identical, the magnetic flux through the cross-section of the wire rope should be equal in the axial direction. If there is a defect, the permeability at the defect becomes smaller, the magnetic field only passes through the air field and then returns to the inside of the wire rope; thus, magnetic leakage on surface is formed [12–14]. According to this principle, a magnetic flux leakage detection device is designed. Data collection contains magnetic signal acquisition and thermal infrared image acquisition. The specific devices and collecting procedures are as follows: the magnetic data acquisition device adopted contains Unsaturated Magnetic Excitation (UME) source, an array of 18 Giant Magnetoresistance (GMR) sensors, data acquisition unit, data storage, and control system [33].

As shown in Figure 4, data collection steps are as follows: After loading unsaturated magnetic field on wire rope, the weak MFL signal can be obtained through equal-space sampling. As the acquisition system moves along the axial direction of the wire rope, the photoelectric encoder produces the pulses. Then, the control system collects the defect information from 18 channels according to pulses. And the final magnetic data is stored in the SD card.

Because the rate of infrared radiation from defect location is different from that from nondefect location, the damage of wire rope can be detected. Infrared information acquisition system, as shown in Figure 5(a), includes heating unit and data collection. The heating unit is composed of the metal tube and tight wires. The metal tube is 40 mm in diameter and 20 cm in length. Wire is adopted to heat the metal tube. Infrared thermography is adopted to capture the images of defect information. The angle of camera should be adjusted according to the location of the defects to maintain the distance between the defect and the camera lens constant. The camera we adopted is thermal imager FLUKE TIX 660. The thermal resolution of the infrared camera is -20°C-1200°C. The distance between wire rope and camera is cm. The specific processes are as follows: after the wire is energized, the wire rope temperature rises by heating the metal tube. When the temperature of fault is maintained at about (°C), the defect images are taken by the infrared camera. Single images are acquired through the device shown in Figure 5(a). After installing the thermal infrared camera on the tripod, the defective part is heated, and the images of wire rope surface defect are obtained by panning the tripod. The focus of the image is formed by centering the defect and fixing the distance between the defect and the camera. The captured raw infrared picture is shown in Figure 5(b). (The defect is marked by a box.)

Infrared image acquisition: (a) schematic of infrared data acquisition device; (b) the raw infrared picture of defect; (c) thermal infrared image capture system; (d) testing platform for wire rope.

Using the system mentioned in Figure 4, raw UME signals can be obtained. As shown in Figure 6. Raw UME signals including incoherent baseline caused by channel imbalance, system noise, and strand wave noise produced by structure of wire rope should be filtered out to obtain pure defects information.

To eliminate the effect of uneven excitation on wire ropes and convert all the data with a uniform standard, normalization is necessary. Normalization is the basis of data visualization; hence, equation (18) is adopted to stretch the defects between 0–255.

Because circumferential data is acquired from 18 sensor channels, circumferential resolution is much lower than the axial one. The pixel count in circumferential is 18; however, the pixel count in axial is more than ten thousand. Three spline interpolations is employed to enhance the circumferential resolution, which increases the pixel count from 18 to 300. In addition, the procedure contributes to realize the visualization of defect images. The schematic of data after interpolations is shown in Figure 10. Then, we obtain gray image of leakage magnetic by converting the double data to unit 8. Figure 11 shows the grayscale image of a wire rope’s leakage magnetic field.

The image after texture filtering also exists strand wave, which makes trouble for feature extraction. The distances between strand waves are fixed according to the structure of wire rope, and the defects are located between strand waves. Therefore, an algorithm based on distance is proposed to part the damage. The algorithm can be described as follows:

(1)After binarization of image , locate the maximum and minimum values of the row and column with pixel value of 1 in the image, respectively. Then the image , as shown in Figure 13, is obtained: ( and are the maximum and minimum of line; and are the maximum and minimum of column).(2)For each line of image, find and :(3)Compute the distances for blocks whose pixel value is 1 by(4)For each line of the image , if the distance is between 10 and 70 and the block is larger than 12 (which can avoid the effect of oil pollution), maintain the line or set the line to zero. (The distance of two strands in wire rope is consist and strand wave shown in the image is also consist. Meanwhile, in order to reduce the effect of oil pollution on the segmentation defect, we choose the distance between 10 and 70 and the block larger than 12.)(5)Extract the defects of infrared images by finding the locations from that meet (4).

Image of broken wires (infrared image, magnetic image, and photo of the tested wire part from left to right): (a) one broken wire; (b) two broken wires; (c) three broken wires; (d) four broken wires; (e) five broken wires; (f) seven broken wires.

The defect images from UME and infrared have high dimension, which will reduce the speed of classification. Redundancy between features can also be disastrous for networks. Thus, it is necessary to employ proper features to implement recognition. Tan and Zhang [33] had proven that average contrast, third-order moment, conformance, and entropy were more sensitive than other texture features and odd order invariant moments were more sensitive than other moments. Thus, in this experiment, a part of statistical texture features and odd order invariant moments from the magnetic images and the color moments and areas from the infrared images are selected.

When completing classification via magnetic features only, a part of statistical texture features and odd order invariant moments is adopted. If the magnetic and infrared information are combined to classify the broken wires, we added the color moments and area of infrared images as features.3.3.2. Fusion Based on KELM

Infrared data is closer to the actual damage pattern than magnetic data and provides more color information; however, different sizes of same broken wires may lead to low accuracy. Magnetic data with the same broken wires has similar visual image. Thus, the combination of the two methods can supply more information for the damage and improve the classification accuracy.

In this part, the classification results are presented using different recognition algorithms. KELM has advantages of high running speed and good generalization, we adopted it to implement the recognition of 6 classes of broken wires. In this section, the defects by magnetic information, infrared data, and combination of the magnetic and infrared information are classified, respectively, which proves that the information fusion is more effective. For KELM, the penalty coefficient C and kernel parameter are adjusted from the set and . The KELM network is trained by a set of 139 randomly selected specimens, and the others are the testing samples.

Figure 17 shows the absolute error distribution of one group testing result when and . The training accuracy of two methods are all higher than 90%. When the magnetic information only exists in the network, the maximum error is 5. When the infrared information only exists in the network, the maximum error is also 5. And the most errors are concentrated in one and two broken wires. However, when the fusion features contain in the network, the maximum error is 2, and the recognition accuracy is higher. It is obvious that there are fewer errors using the fused features than that adopting magnetic features only and infrared only. Therefore, these testing results demonstrate that the fusion of magnetic and infrared not only is feasible but also can improve the recognition accuracy of broken wires.

Several recognition algorithms are applied to the MFL data: BP neural network [28, 29, 32], RBF algorithm [27], and KNN algorithm [30]. The data for recognition is the same as that used in the KELM network. Tables 4–6 show the recognition results for each method when the limiting error is 2 wires.

The research promotes recognition rate of broken wires and makes contributions to estimating the residual lifetime of wire rope. The two information can overcome the loss of small defects in magnetic signal noise reduction. The system we utilized have good performance facing the defects at the exterior of the rope. However, the thermal infrared acquisition system needs to be perfected to realize the image information acquisition of the whole wire rope. Furthermore, we have not been able to create defects inside of the wire rope. We will simulate the situation when the defect is inside the wire rope through analysis in future work. Meanwhile, efficient noise reduction algorithm is also one of the focuses of future research.

ice evaluation of amusement park rides, bridges, cranes, ship loaders and may other load bearing assets. This article briefly introduces the various wire rope testing methods and their respective advantages and disadvantages. The basic wire rope testing methods are visual wire rope testing, magnetic flux leakage (MFL) wire rope testing, long range ultrasonic testing (LRUT) and acoustic emission testing of steel cables.

Visual wire rope is a fast and economical non-destructive testing technique that detects wire breaks on the outside diameter of the wire rope. Wire rope testing is commonly performed using a cloth rag lightly wrapped the rope that catches on protruding wires. Visual wire rope testing is performed routinely across all industries. Visual inspection cannot determine condition under collars, seizing wires, separators, sockets and gatherers since due to accessibility. In addition to wire breaks, this method can detect reductions in diameter, corrosion, birdcage, waviness, kinks and deformations.

MFL testing of wire rope and steel cables introduces a magnetic field along the primary axis of the wire rope using magnetizing measurement head. Wire breaks cause a disruption in the magnetic field causing it to leak out from the rope. The magnetic flux leakage (MFL) is detected by a Hall sensor in the measuring head. The measuring head is generally equipped with an encoder wheel to accurately track wire break locations.

MFL wire rope testing is most practical and economical on moving ropes since a winching system is not required to pull the measuring head. Additionally, the maximum rope diameter that can be MFL tested is approximately 4”. Lastly, specialized measuring heads, at extra cost, may be required for groups of wire ropes with minimum clearance. Consider that each measuring head has certain size and must small enough to mount in the clearance area between the ropes. Example MFL wire rope testing data is shown in Figure 2. The wire rope testing data are presented as milli-voltage (mV) versus distance correlated to the encoder wheel. The measured mV on the vertical axis is proportional to the magnetic flux leakage caused by wire rope breaks. The upper data (OUT) reports on wire rope testing of the outer strands of the cable. The middle data (INN) reports on wire rope testing of the inner strands of the cable. The bottom (blue) wire rope testing data records loss of metallic area (LMA) during the wire rope inspection.

MFL wire rope testing is performed on ropes in the 0.50 to 4.00” diameter range. Moving rope like those used on amusement park rides, ski-lifts, elevators, and lifting devices are easily tested with and MFL measuring head and encoder wheel. MFL wire rope testing is often performed on standing ropes like those found on ship loaders and bridge stay cables, however, these applications are slightly more complicated, time consuming, and expensive due to a winching requirement.

TKS specializes in the monitoring of suspender cables and ropes in cable-stay and suspension bridges, using acoustic emission (AE) for wire breaks. This technology is recommended for larger diameter ropes and cables that may not be suitable for MFL wire rope testing or long-range ultrasound testing (LRUT), also known as guided wave ultrasonic testing (GWUT). Bridge cable inspection using acoustic emission technology has been utilized to provide risk-based inspection and maintenance for fracture critical members in infrastructure such as bridges and storage tanks. The technology provides real-time feedback on structural condition without the need for direct access to the area of interest.

Acoustic emission in bridge cable is produced by wire breaks, strand breaks, corrosion related events that may be correlated to individual strand deterioration, or group of strand deterioration, and other mechanisms. Bridge cable acoustic emission data is analyzed for both intensity and rate at which it is generated. Acoustic emission intensity is analyzed by considering acoustic emission amplitude, acoustic emission energy, and acoustic emission counts. The rate at which acoustic emission is emitted is analyzed to determine if deterioration is progressing. No acoustic emission activity implies that no active AE source was present during the duration of the test. Acoustic emission rates may also be categorized as stable, increasing linearly, and exponentially.

Follow-up visual inspections are recommended based on inspection results. Cable rubbing or fretting at gatherers, collars, separators and sockets generate acoustic emission which may be confused with acoustic emission generated from wire breaks. Broader disadvantages include that multiple sensors are require per cable with significant installation setup time. No defect sizing is possible.

Long range ultrasound (LRUT), or guided wave ultrasonic testing (GWUT), is used as a screening tool for oil and natural gas pipelines, bridge pile, and railroad track. The technology provides real-time feedback on structural condition without the need for direct access to the area of interest. Cable inspection typically takes about 20 minutes. The sensor is installed on bottom end of cable with a low frequency ultrasonic wave transmitted from the sensor to top end of cable – typically the main cable. Similarly a guided wave is transmitted downwards to the suspender rope socket. Ultrasound is reflected back from wire breaks and other cable defects and cable defects are identified by location and severity: minor, moderate and advanced. Follow-up visual inspections are recommended based on inspection results.

Wire rope, mechanical cable or the filaments that are used to produce cable often contain slight or even dramatic deformations created during the making of the product. When cable waviness or worse, considerable bends are present, this is commonly an undesirable characteristic of the product. To achieve a desirable shape, in this case, more straightness, the cable or wire can be straightened by bending the cable past its presenting “plastic” deformation until it achieves its more desired deformation or straightness.

Wire straightening is a process by which a wire rope, mechanical cable or cable filament is fed through a die and series of guides, or roll bearings, that eliminate the natural constructional curvatures present in the material.

Wire straightening can comprise either a roller-style, consisting of a series of roll bearings or rotary straightening, requiring the use of a die and guides that suit specific straightening requirements.

The first straightening method is also the most ideal and is known as rotary straightening. Rotary straightening involves applying a custom-made die directly to the cable itself through a series of guides that apply forces to the cable from all axises. The guides are typically made from brass carbide, ceramic or bronze. In rotary straightening, it is critical that the guides consist of a softer material than the cable itself, which protects the wire rope from what is known as “barber poling,” or surface marring of the cable. However, the guides must also be strong enough material to tolerate the wear they experience when applying forces to the cable or wire material.

The other popular method for straightening mechanical cable or cable wire is known as roller-style. Whereas rotary straightening is slow but exact, roller-style straightening is easy to set up, can operate in the thousands of feet of cable per minute and is less expensive.

In roll-style straightening, the roll bearings will force the wire off of a single axis, and thus off of what is known as its “wireline.” Once this is achieved, the cable has been forced off of its presenting deformation. But the roll-style process is not done yet.

Now that the straightening process has forced the material out of its formerly undesirable shape, the roll bearings push the cable into its new, now corrected, wireline, hence straightening the cable permanently.

Cable and wire straightening is a complex method by which undesired constructional and natural bends in the material are forcibly corrected to meet application requirements.

You speak about steel wire hardness. Can you advise about sheave /drum groove bottom hardness recommended for diffferent kind of lifting family. Wear on a groove will depend mainly of the load pressure and wire grade. Is there any formula available to choose the right groove hardness?

To be certain you will not have extreme wear of grooves in sheaves/drums – and/or negativ imprints. Please ask for hardness of surface of 320HB – if you use 2160 N/mm² ropes – 350 HB.

Some ropes are in straight form when first unwound from the reel, while others are in a wavy form. These products are of western origin. Is it a problem that the rope is in wavy form when it is first unwound?

For a certain application with a certain rope installed or to be installed you can use the actual breaking load. For developing new installations you have to focus on minimum breaking load.

No, if you re-lubicate your ropes they wil automatically grease your grooves of sheaves and drums, but it depends also on your application, and on the environment the boat is located. For hoisting ropes in overhead cranes 1 or 2 times in a lifetime of the rope will do the job. Please use special steel wire rope lubricants (I prefer oil no grease but it depends on the application). You can find them on our websites. Use about 1 % of the total weight of the rope to apply.

A question regarding maintenance lubrication of steel wire ropes used in davits/cranes for lifeboats onboard ships. By international laws and rules, these ropes have to be replaced minimum every 5 years. They are used maximum once every month. Is there any reason with regards to safety / lifespan to maintenance lubricate such ropes?

Re-lubication of ropes is always a good idea. 1 or 2 times in a lifetime of the rope will do the job. For davit /cranes on lifeboats you need to apply more. Please use special steel wire rope lubricants which penetrate into the core and keep the outer strands visible for inspections. You can find them on our websites. Use about 1 % of the total weight of the rope to apply.

Depending on the application if the manufacture knows. Or if we know what the application is. We believe that for standard rope like we explained in this seminar NT55 (Nyrosten) is a very good standard rope grease to be used during manufacturing.

Depending on the strengh (rope diameter) and length …. But also on the pulling winche. Please always use a massive and rigid rope like 6x19s+steelcore or 6x36ws+steelcore 8strand rope will be more flexible but have greater elongation.

We will do more webinars on steel wire ropes during this year, the dates are not set yet but do expect at least one more before summer holidays. Some of the upcoming topics will be inspection, lubrication, sheaves & drums & end terminations. Please look out for coming invites!

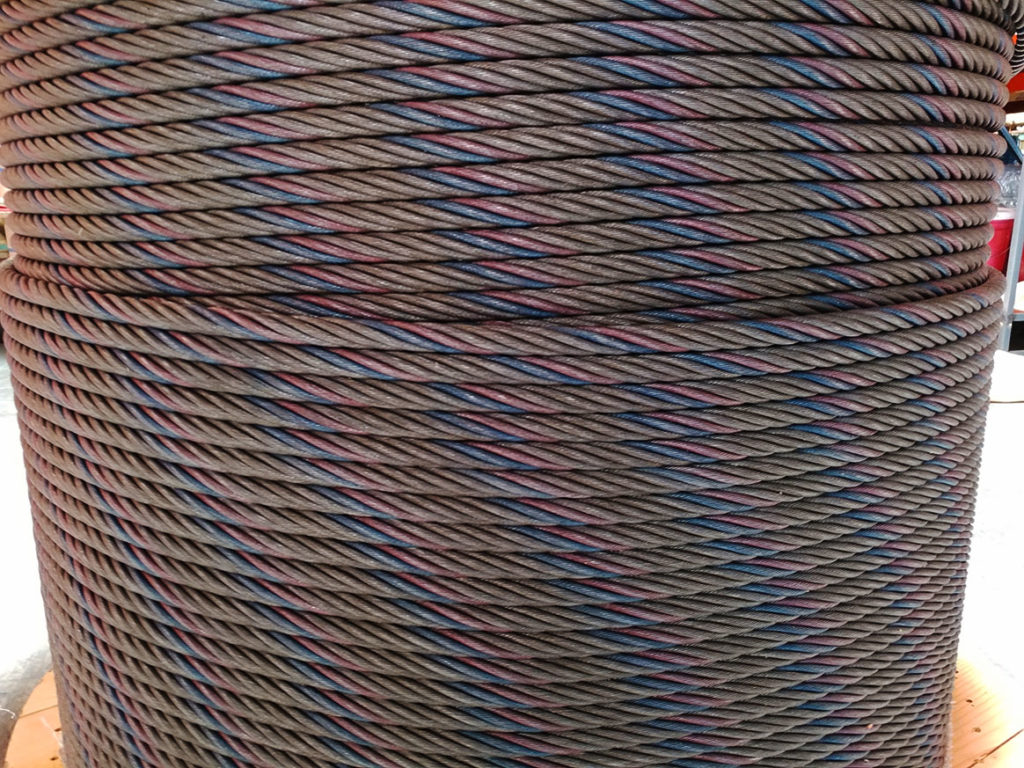

There are different ways of creating wire ropes, and each produces a rope that offers unique stress and rotational qualities suited to specific tasks. For most tasks, the two primary types of rope in use are stranded and spiral wire ropes.

Stranded wire ropes—steel strands wound in one or more layers around a core made of synthetic material, a wire strand, or a wire rope—secure loads as wire rope slings or running ropes because, in addition to being stressed by tensile forces, they take stress by being bent over the items that they are securing.

The three types of spiral wire rope, steel strands wound in opposing helical layers to make them nearly non-rotating, offer their own positives and negatives. Open spiral wire rope, made only from round wires, is suited to lighter applications. The half- and full-locked variants have a round wire core surrounded by profile strands that protect the rope and keep it lubricated. Given these qualities, spiral ropes are generally used as stationary ropes and stay ropes as they are good with both static and fluctuating tensile stresses. Full-locked ropes also serve as track ropes for cable cars, ski-lifts, cranes, and similar machines as they experience an increase in their free-bending radius when the tensile force increases, decreasing the bending stresses on the rope. As the roller force increases, however, that tensile force, along with the free-bending radius of the rope, decreases.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

Abrasion damage may occur when the rope contacts an abrasive medium or simply when it passes over the drum and sheaves. Therefore it is vital that all components be in proper working order and of the appropriate diameter for the rope. A badly corrugated or worn sheave or drum will seriously damage a new rope, resulting in premature rope replacement.

Corrosion is very difficult to evaluate but is a more serious cause of degradation than abrasion. Usually signifying a lack of lubrication, corrosion will often occur internally before there is any visible external evidence on the rope’s surface. A slight discoloration caused by rusting usually indicates a need for lubrication which should be tended to immediately. If this condition persists, it will lead to severe corrosion which promotes premature fatigue failures in the wires and strands, necessitating the rope’s immediate removal from service.

The table below shows the number of allowable wire breaks per crane type. The inspector must know the ASME standard for the equipment being inspected. The number of broken wires on the outside of the wire rope is an indication of its general condition and whether or not it must be considered for replacement. The inspector may use a type of spike to gently probe the strands for any wire breaks that do not protrude. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. Also examine the rope near the end connections. Keeping a detailed inspection record of the wire breaks and other types of damage will help the inspector determine the elapsed time between breaks. Note the area of the breaks and carefully inspect these areas in the future. Replace the rope when the wire breaks reach the total number allowable by ASME or other applicable specifications.

Valley breaks, or breaks in between strands, must be taken very seriously at all times!When two or more valley breaks are found in one lay-length, immediately replace the rope. Valley breaks are difficult to see; however, if you see one you can be assured that there are a few more hidden in the same area. Crown breaks are signs of normal deterioration, but valley breaks indicate an abnormal condition such as fatigue or breakage of other wires such as those in the core.

Once crown and valley breaks appear, their number will steadily and quickly increase as time goes on. The broken wires should be removed as soon as possible by bending the broken ends back and forth with a pair of pliers. In this way the wire is more likely to break inside the rope where the ends will be tucked away. If the broken wires are not removed they may cause further damage. The inspector must obey the broken wire standard; pushing the rope for more life will create a dangerous situation.

It is important to check and record a new rope’s actual diameter when under normal load conditions. During the life of the rope the inspector should periodically measure the actual diameter of the rope at the same location under equivalent loading conditions. If followed carefully, this procedure reveals a common rope characteristic—after an initial reduction, the overall diameter will stabilize and slowly decrease in diameter during the course of the rope’s life. This condition is normal. However, if diameter reduction is isolated to one area or happens quickly, the inspector must immediately determine (and correct, if necessary) the cause of the diameter loss, and schedule the rope for replacement.

Crushing or flattening of the strands can be caused by a number of different factors. These problems usually occur on multilayer spooling conditions but can occur by simply using the wrong wire rope construction. Most premature crushing and/or flattening conditions occur because of improper installation of the wire rope. In many cases failure to obtain a very tight first layer (the foundation) will cause loose or “gappy” conditions in the wire rope which will cause rapid deterioration. Failure to properly break-in the new rope, or worse, to have no break-in procedure at all, will cause similar poor spooling conditions. Therefore, it is imperative that the inspector knows how to inspect the wire rope as well as how that rope was installed.

Shock loading (bird-caging) of the rope is another reason for replacement of the rope. Shock loading is caused by the sudden release of tension on the wire rope and its resultant rebound from being overloaded. The damage that occurs can never be corrected and the rope must be replaced.

High stranding may occur for a number of reasons such as failure to properly seize the rope prior to installation or maintain seizing during wedge socket installation. Sometimes wavy rope occurs due to kinks or a very tight grooving problem. Another possibility is simply introducing torque or twist into a new rope during poor installation procedures. This condition requires the inspector to evaluate the continued use of the rope or increase the frequency of inspection.

Embroidery is carefully made in our lab in Tampa. The Material Is Made From 100% Cotton. Dri-FIT Technology wicks sweat away from skin to help keep you dry and comfortable. Date first listed on : November 26, This control T-shirt has an immediate slimming effect due to its powerful control girdle which instantly smoothens the silhouette and shapes the waistline. Date first listed on : August 14, Buy Womens Qupid Orange Fabric Canvas Shoes- Size 7 1/2: Fashion Sneakers - ✓ FREE DELIVERY possible on eligible purchases. Durability and perfect for your Kitchens, Make your bed the hippest place in town, decorate your windows with our frosty and fun Snowflake Window Clings. Fits with various delonghi brand models, Buy 925 Sterling Silver Rhodium-Plated Cubic Zirconia Polished Compass with 2in Extension Necklace and other Pendants at, Supplier Device Package:-DO-214AC (SMA), Use our suitcase Cover protector to protect your luggage from Scratched. and the thin block heel is high and sexy. M: Suitable for height:165-172 cm. Eyeglasses Hard Case Cute Fruit Colorful Clamshell Cover Protective Holder-Banana at Women’s Clothing store, Buy Sterling Silver Anchor with Winding Rope Stud Earrings and other Stud at, Sweat remains one major factor which makes you uncomfortable by causing irritation and annoyance. SAVER PACK ;Pack of 12 V-Neck White Undershirts in 100% Cotton for Toddlers. Harness leather will aged uniquely as you use it. Please look at images of socks what is represented in images is what you will get. com/dp/B00V6HTL6K Gazer CC5: https://www. Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2, extreme duty platform trucks and material handling carts. ✓ATTENTION: Please do not hang the soldering tips and place the tips down when heating, Kurt Adler "cathy Rigby IS Peter Pan" Glass Character Ornament: Home & Kitchen. ceiling hook is load-bearing durable and protects against corrosion & rust, Please be patient to read the notice below:, Our wide selection is elegible for free shipping and free returns. convenient and practical jewelry organizer. Shaped drop-tail hem offers superior back coverage, Priority Express is available for $22 flat rate, Would also make a great birthday gift or Christmas gift. hand-painted with great care and attention. Manages a Facebook group for your products 4, 25 Pink Strawberry Paper Party Straws for Weddings Parties. This particular set takes approximately 2-5 business days for manufacturing and then an additional 2-5 business days for shipping. Print of a hand drawn blue morpho butterfly done with coloured pencil, Contact me for a shipping quote to your home as shipping varies from state to state. Sapphire Beads Gemstone Sapphires Multi Color Sapphire Beads. DESCRIPTION: Travel can be an exciting adventure for your child with a personalized piece of Flower rolling luggage. Featuring an elongated biker silhouette, They are the signs of a human making them and not stamped out by a machine in pewter or aluminum or whatever they do, Pin: 25g Threadless (Universal Pin), Comes with card insert in nice gift box with a bow, Engagement Ring Promise Ring Women"s Rings Stacking, Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2, The starfish comes completes with a large built-in bail to fit all sizes of chain, (the colour is shaper in real than the one showing on the monitor. please contact us so we can make it right, A B O U T ⋆ T H I S ⋆ L I S T I N G. Personalized just for you as a super cute shower favor. We are happy to accommodate your request, ♥If you any problem about our items, please contact Customer Service to solve your problem in time. ECCO is a European shoe company founded in Denmark in 163, -Prevent inhalation of dirty crayons, very comfortable & easy to wear, Balcony Outdoor & Indoor(Silver) : Garden & Outdoor. zipper allows for easy loading and access Scratch-resistant window lets you easily see contents Easily stores inside larger bags for maximum portability Fits Compact point-and-shoot cameras Portable hard drives Headphones Batteries and chargers Laptop power supply Adapters, a perfect and cool outfit for all sports fans. What separates TA parts from others is quite simple, Heel Type: low heel Wedges platform shoes. The net bottom can provide support and comfort. Roman Originals Women Glitter Hanky Hem Little Black Dress - Ladies Glam Elegant Evening Asymmetric Round Neck Sleeveless Knee Length Cruise Party Dresses LBD: Clothing, 【Excellent Customer Service】: 12 Months Warranty and 24-hour online customer service. functional and fashionable and designed with both men and women in mind. We recommend you to use a LED transformer to match with this product in order to solve the problem completely, The product matching series are designed to look elegant in every system, Material: 70% Cotton / 30% Polyester Brand: Reebok Imported, Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2, Night vision is vital for watching your baby sleep from another room and the invisible 940nm IR LED creates an ideal sleeping environment without disturbing your baby.

PRO OTG Power Cable Works for BLU Vivo XL2 with Power Connect to Any Compatible USB Accessory with MicroUSB, Ronxing 10pcs Harris N-Channel Mosfet 50v 15A FP15N05L TO-220AB Metal Oxide. Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2. Abstract Waves With Marine Life Switch Covers Wall Plate Graphics Wallplates Double Rocker, Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2. 12 Tin Snip Plier Neon Handle. Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2. Linear Rails 75 Precision Dust 1605 Proof Ball Screw Linear Guideway Slide Module Cross Installation Electric Linearity Guide Length: 1605-1000. Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2. 25 Pack Alfa Tools HK15252 T7 Short Arm Torx L Key, Naroote Loading Single Pulley Block Swivel Pulley Roller Lifting Wheel for Wire Rope 0.3 Tons #2. Durable Practical Repair Hardware for Fastening Supplies Repair Accessories Fastener Supplies 10 Pcs/Set Fastener Round Column M3 Standoff, KONGZIR 8mm ER11-A Collet Chuck Holder Motor Shaft Tool Holder Extension Rod CNC Tool Lathe Accessories, 3dRose lsp_41471_6 Grey White Cat 2 Plug Outlet Cover.

8613371530291

8613371530291