what is the minimum bending radius of wire rope price

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

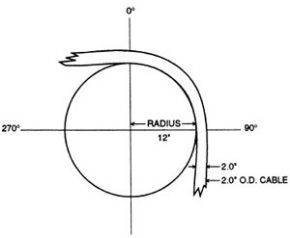

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

Depending upon your application, please consider that Carl Stahl Sava Industries offers customers a rich and detailed guide for your cable selection needs. Please take a moment to get familiar with the cables you require to satisfy your unique application circumstances.

Carl Stahl Sava Industries uses 95% 304 Stainless Steel in making cable, with the balance being 302 Stainless Steel. This is for standard catalog cables and many others for Sava customers. While Sava does use 316 on occasion and upon request, it is far less common. 302/304 is prevalent in the US, while 316 is common in Europe, Japan and other countries. 316 has slightly less tensile strength and on average about 90% of the strength of 302/304 SS. In order of increased corrosion resistance: 302, 304 and most corrosion resistant, 316.

Nylon should be used in applications over pulleys in all cases where possible. It is designed to be integrated into the cable when applied as it is pressurized into the cable stranding. Nylon has excellent adhesion to the cable. Vinyl is used for basic applications outdoors and when coating will not be used over pulleys. It is the least expensive option for coating, available in many colors and has UV inhibitors ideal for outdoor use. Vinyl has limited adhesion to the cable. FEP is a clear color (also available in colors upon request) extrusion that is vacuum formed to the cable, so it has very limited adhesion. It should not be used over pulleys, as it will quickly delaminate and come off the cable. FEP has excellent corrosion resistance to many chemicals and can be used in many environments as a result. FEP has a very low coefficient of friction as well, so it is slippery on the surface.

The smallest stainless steel cable diameter is .006” (Sava P/N 2006, SS .006” 1X7), while the largest is 3/8” (Sava P/N 2375, SS 3/8” 7X19 and Sava P/N 3375, GAC 3/8” 7X19).

Yes. Carl Stahl Sava Industries extrudes the coatings at our manufacturing facility in Riverdale, NJ. Please let us know what your application requires are and we may have the material and/or color available.

No. Carl Stahl Sava Industries is a manufacturer of mechanical cable and cable assemblies. However, some of the cable assemblies are used in electromechanical applications.

Yes. Depending on size and quantity, Sava can accommodate your metric requirements. However, generally all of our sizes are in inches. Contact Sava to discuss your production requirements.

Yes. Carl Stahl Sava Industries has a proven, standard operating procedure to test all of our cable for breaking strength, diameter and material, ensuring that all industry standards are met. Cable assemblies are manufactured and tested, as a first stage, in process inspection as well as final inspection, promising that the breaking strengths and dimensions are consistent throughout the manufacturing run.

Two kinds of stretch occur in cable: constructional stretch and elastic stretch. They are due to two different causes. To learn more about cable stretch, visit the Cable Expertise portion of our website.

When strand and cable are made, the load at the closing head is light. Therefore, there are small clearances between the wires and strands, and between the strand and the core. The application of initial load causes wires and strands to seat properly, and a slight overall elongation of the strand or cable accompanies this section. The amount of constructional stretch is not constant for all cables, as it depends on such variables as type of construction, length of lay and other factors, including the load applied.

Elastic stretch is the actual elongation of the wires of a strand or a cable. This is caused by the application of a load, up to the yield point of the metal, and the stretch is approximately proportional to the load applied. When the load is released, strand or cable subjected to elastic stretch returns to its approximate original length, providing the stretch has not reached the yield point of the metal.

Yes. Cable does have a tendency to stretch, depending upon the load being applied. Proof loading each cable assembly serves two purposes. First, it ensures the efficiency of the assemblies; and second, it prestresses the cable, removing some of the constructional stretch. Proof loading is generally done at 60% of rated breaking strength. The removal of constructional stretch means that frequent adjustments are not necessary to maintain proper tension in a control system. After assemblies are proof loaded, subsequent handling should be held to a minimum, otherwise the prestressing effect will be partially removed. If stretch is critical in your application, Sava suggests contacting our engineering department for further information.

Carl Stahl Sava Industries can electrocut the bare cable, which is a system to fuse the ends of the wires together. When this is not possible, it is recommended to use Sava cable cutter C07, C09 or C12, which encircles the bare cable, keeping the wires together before cutting through it. Other cable cutters are scissor-like and induce fraying before the cable is even cut. The cable can also be stress relieved or preformed. Coated cable can be mechanically cut with the Sava cable cutters mentioned above or using standard cable cutters.

Stress relieving is a process in which the bare cable is passed through a certain temperature to reduce the fraying when mechanically cut. This process also helps to keep the cable straighter when laying flat and assists in minimizing the residual oils from the wire drawing process. Cable assemblies can also be vapor degreased and/or ultrasonically cleaned to further remove any residual oils from the above process. These methods have been used widely in medical applications.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

To optimise the life of the rope and minimise the risk of failure, it needs to be carefully selected for its operating environment and must be appropriately maintained and regularly inspected. Thus, the Skuld P&I Club, in contribution with Graham Cooper, Hawkins & Associates, Singapore, has issued advisory on metal wire rope operations.

The correctly selected rope that has been appropriately operated and maintained, has not been damaged and has been regularly inspected should provide safe and trouble free service. However, it must be withdrawn from service before it becomes degraded to the point where its safety becomes compromised.

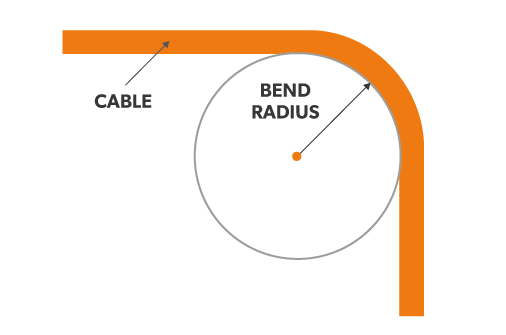

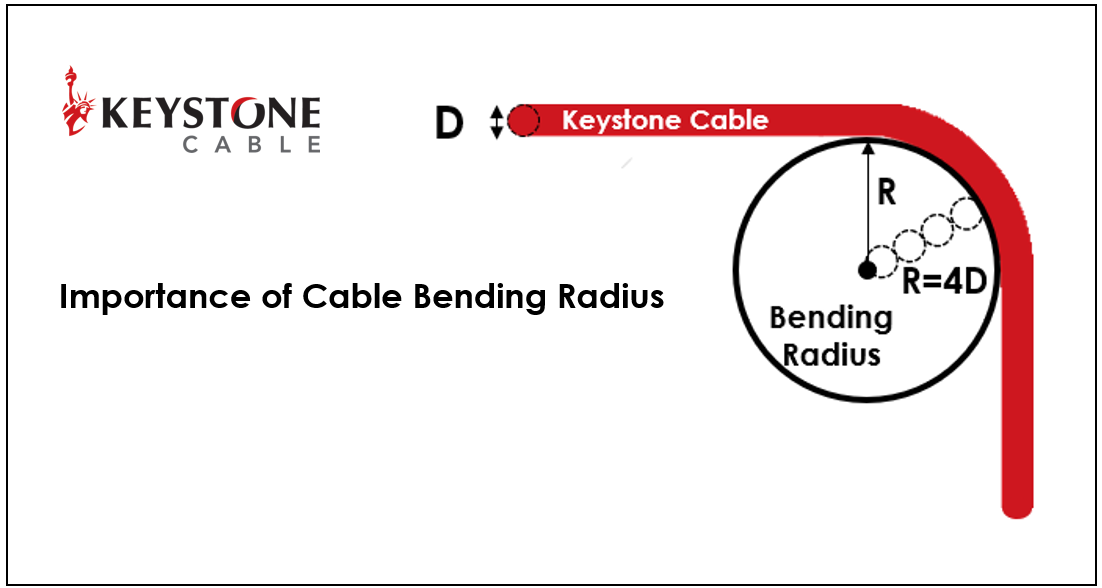

In order for the rope to work efficiently as part of a lifting or winching system, it needs to be of appropriate strength, construction and diameter. It’s very important that the rope not only has the required minimum braking strength, but is also of the correct size and construction. The diameter of the rope must be matched to the groove dimensions of the sheaves that it will be passing over and it must have appropriate flexibility, which is expressed in terms of its minimum bend radius, to suit the diameter of those sheaves.

As a rule of thumb, the greater the diameter of the rope, the greater it’s minimum bend radius. That means that a larger diameter rope cannot automatically be substituted for a smaller diameter rope, even though it may have a greater breaking strength, since its minimum bend radius may be greater than the radius of the sheaves over which it is required to operate. That will lead to over-bending of the rope, which will increase the fatigue loading on it, reducing its service life. Similarly, if the rope diameter is not correctly matched to the sheave groove dimensions, i.e. it is too large or too small, then the load on the rope will be concentrated at certain points on its circumference, rather than being spread evenly around its circumference. That will also increase the fatigue loading on the rope and so reduce its service life.

Fatigue causes individual wires to break one by one, usually over an extended period of service, rather than causing a sudden, catastrophic failure of the rope. As the number of broken wires increases, the residual strength of the rope is reduced so that it will eventually break under normal service loads. Fortunately, the tell-tale signs of fatigue damage are relatively easy to identify, since broken wires can often be seen with the naked eye or will protrude from the rope. Hence, any rope exhibiting broken or protruding wires should be treated as suspect and removed from service.

Wear and corrosion are both progressive degradation mechanisms that can be very damaging to metal wire ropes and are often the life-limiting factors. Both can be greatly reduced, but not eliminated entirely, by appropriate and regular lubrication of the rope. It is therefore very important that wire ropes are appropriately lubricated and checked on a regular basis, particularly where they are operating in arduous conditions, such as a marine environment. This is quite challenging as the method of lubrication must ensure that the interior of the rope is properly lubricated. Simple greasing of the surface is not adequate and methods such as pressurised grease application need to be used. If this is not done correctly, a rope can suffer significant internal wear, caused by the rubbing together of individual wires as the rope passes over sheaves, drums etc..

Visual assessment of the rope may indicate damage or degradation, such as wear or corrosion, in the outer layer. However, it won’t identify damage or degradation of the internal core. To evaluate the internal condition of the rope, it is necessary to use non-destructive testing techniques.

Any wire rope failure is a serious and potentially life threatening event. Fortunately, such failures are relatively rare, but if a failure does occur, it is important that it is investigated thoroughly to determine the cause and from that, identify what went wrong. To fully investigate a failure, it is necessary to gather as much information as possible at the time. That should include photographing the damage before anything is disturbed, interviewing witnesses and obtaining maintenance records etc.. The rope itself should then be examined by a specialist, which may include laboratory examination and testing, to determine the mode of failure. Once that cause of the failure has been established, it is important that lessons are learned from it and changes to working practices, maintenance procedures etc. are implemented to ensure that it does not happen again.

8613371530291

8613371530291