what is the minimum bending radius of wire rope for sale

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

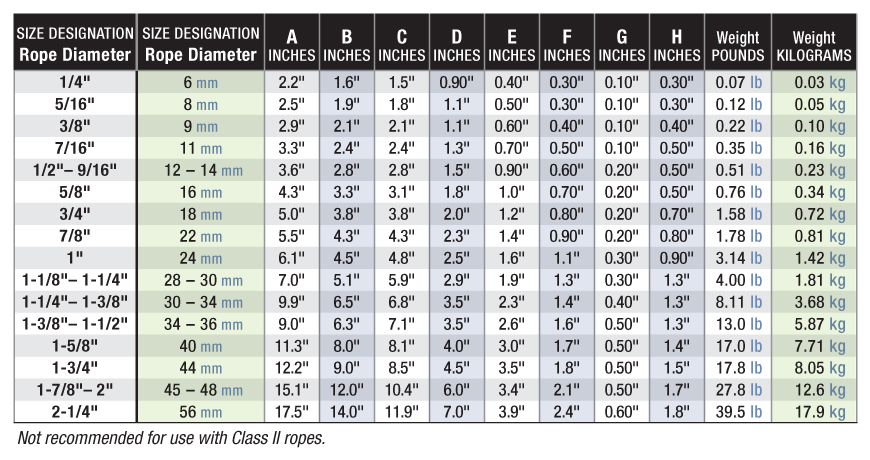

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

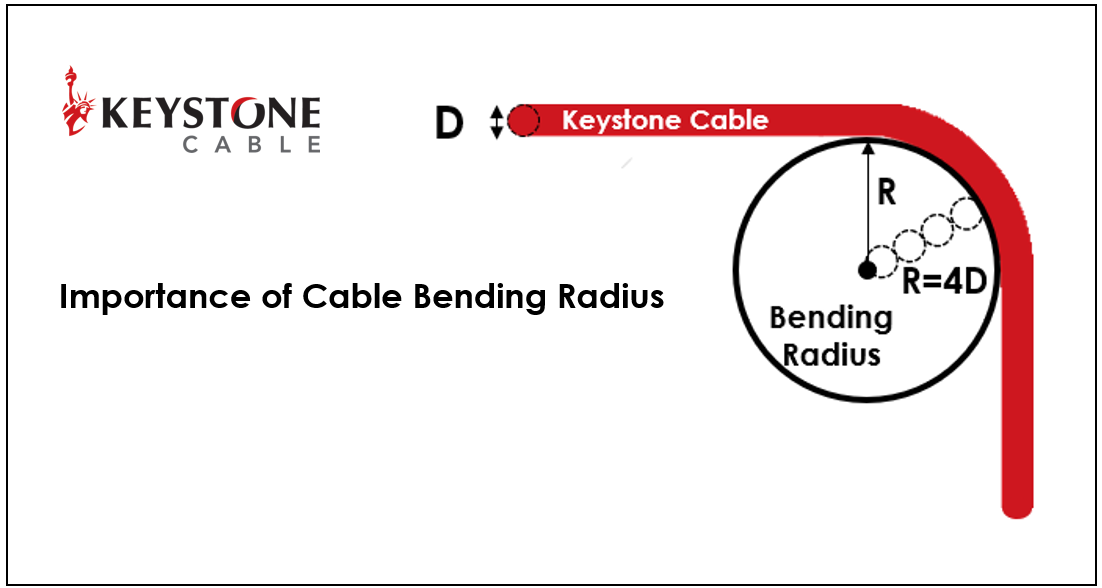

Bend radius is the minimum radius a pipe, cable, wire, sheet, cable, tube or hose can bend without damaging it (including kinking). The smaller the radius, the greater is the flexibility of the material. The minimum bend radius is the radius below which an object should not be bent.

Factors which influence the minimum bending radius include the cable size, the cable construction, the conductor type and the sheathing and insulation types used. The bending radius is normally expressed as a factor of the overall dimension of the cable for example, 6D or 6x the outer diameter of the cable.

According to Table 1, the minimum bend radius is found to be six times the cable’s overall diameter. The overall diameter of the cable is given as 2.08 inches in the product catalog. Multiplying 2.08 inches by six, we get 12.48 inches.

The minimum bend radius will vary depending on the specific fiber cable. However, in general, the minimum bend radius should not be less than ten times the outer diameter (OD) of the fiber cable. Thus a 3 mm cable should not have any bends less than 30mm in radius.

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm.

However, in general, the minimum bend radius should not be less than ten times the outer diameter (OD) of the fiber cable. Thus a 3 mm cable should not have any bends less than 30mm in radius. Telcordia recommends a minimum 38 mm bend radius for 3 mm patch cords.

thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness. And between 0.8 and 2 in.

Flange length must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times the material thickness.

The minimum bend radius A typical value for a cable under no load conditions, or “unloaded,” is 10 times the cable’s outside diameter. When a cable is under tensile load or “loaded,” the minimum bend radius is usually 15 times the cable’s outside diameter. Learn more: Fibre cable and pulling eyes.

The normal recommendation for fiber optic cable bend radius is the minimum bend radius under tension during pulling is 20 times the diameter of the cable. When not under tension (after installation), the minimum recommended long term bend radius is 10 times the cable diameter.

Bend radius is the minimum radius a pipe, cable, wire, sheet, cable, tube or hose can bend without damaging it (including kinking). The smaller the radius, the greater is the flexibility of the material. The minimum bend radius is the radius below which an object should not be bent.

Recommended Bend Radius Rope Diameter Minimum Recommended Pulley Tread Diamete Approximate Bend Radius .009″ 3/8″ 3/16″ .014″ 5/8″ 5/16″ .018″ 13/16″ 13/32″ .024″ 1″ 1/2″

Answer: SHD-GC is a shielded mining cable. According to Table 1, the minimum bend radius is found to be six times the cable’s overall diameter. The overall diameter of the cable is given as 2.08 inches in the product catalog. Multiplying 2.08 inches by six, we get 12.48 inches.

For cable connectors such as ferrules or clamps, holding the cable in place may also flex the cable beyond its recommended bend radius. In addition, pulling the cable at an improper angle in relation to the connector may cause damage. Questions?

Depending upon your application, please consider that Carl Stahl Sava Industries offers customers a rich and detailed guide for your cable selection needs. Please take a moment to get familiar with the cables you require to satisfy your unique application circumstances.

Carl Stahl Sava Industries uses 95% 304 Stainless Steel in making cable, with the balance being 302 Stainless Steel. This is for standard catalog cables and many others for Sava customers. While Sava does use 316 on occasion and upon request, it is far less common. 302/304 is prevalent in the US, while 316 is common in Europe, Japan and other countries. 316 has slightly less tensile strength and on average about 90% of the strength of 302/304 SS. In order of increased corrosion resistance: 302, 304 and most corrosion resistant, 316.

Nylon should be used in applications over pulleys in all cases where possible. It is designed to be integrated into the cable when applied as it is pressurized into the cable stranding. Nylon has excellent adhesion to the cable. Vinyl is used for basic applications outdoors and when coating will not be used over pulleys. It is the least expensive option for coating, available in many colors and has UV inhibitors ideal for outdoor use. Vinyl has limited adhesion to the cable. FEP is a clear color (also available in colors upon request) extrusion that is vacuum formed to the cable, so it has very limited adhesion. It should not be used over pulleys, as it will quickly delaminate and come off the cable. FEP has excellent corrosion resistance to many chemicals and can be used in many environments as a result. FEP has a very low coefficient of friction as well, so it is slippery on the surface.

The smallest stainless steel cable diameter is .006” (Sava P/N 2006, SS .006” 1X7), while the largest is 3/8” (Sava P/N 2375, SS 3/8” 7X19 and Sava P/N 3375, GAC 3/8” 7X19).

Yes. Carl Stahl Sava Industries extrudes the coatings at our manufacturing facility in Riverdale, NJ. Please let us know what your application requires are and we may have the material and/or color available.

No. Carl Stahl Sava Industries is a manufacturer of mechanical cable and cable assemblies. However, some of the cable assemblies are used in electromechanical applications.

Yes. Depending on size and quantity, Sava can accommodate your metric requirements. However, generally all of our sizes are in inches. Contact Sava to discuss your production requirements.

Yes. Carl Stahl Sava Industries has a proven, standard operating procedure to test all of our cable for breaking strength, diameter and material, ensuring that all industry standards are met. Cable assemblies are manufactured and tested, as a first stage, in process inspection as well as final inspection, promising that the breaking strengths and dimensions are consistent throughout the manufacturing run.

Two kinds of stretch occur in cable: constructional stretch and elastic stretch. They are due to two different causes. To learn more about cable stretch, visit the Cable Expertise portion of our website.

When strand and cable are made, the load at the closing head is light. Therefore, there are small clearances between the wires and strands, and between the strand and the core. The application of initial load causes wires and strands to seat properly, and a slight overall elongation of the strand or cable accompanies this section. The amount of constructional stretch is not constant for all cables, as it depends on such variables as type of construction, length of lay and other factors, including the load applied.

Elastic stretch is the actual elongation of the wires of a strand or a cable. This is caused by the application of a load, up to the yield point of the metal, and the stretch is approximately proportional to the load applied. When the load is released, strand or cable subjected to elastic stretch returns to its approximate original length, providing the stretch has not reached the yield point of the metal.

Yes. Cable does have a tendency to stretch, depending upon the load being applied. Proof loading each cable assembly serves two purposes. First, it ensures the efficiency of the assemblies; and second, it prestresses the cable, removing some of the constructional stretch. Proof loading is generally done at 60% of rated breaking strength. The removal of constructional stretch means that frequent adjustments are not necessary to maintain proper tension in a control system. After assemblies are proof loaded, subsequent handling should be held to a minimum, otherwise the prestressing effect will be partially removed. If stretch is critical in your application, Sava suggests contacting our engineering department for further information.

Carl Stahl Sava Industries can electrocut the bare cable, which is a system to fuse the ends of the wires together. When this is not possible, it is recommended to use Sava cable cutter C07, C09 or C12, which encircles the bare cable, keeping the wires together before cutting through it. Other cable cutters are scissor-like and induce fraying before the cable is even cut. The cable can also be stress relieved or preformed. Coated cable can be mechanically cut with the Sava cable cutters mentioned above or using standard cable cutters.

Stress relieving is a process in which the bare cable is passed through a certain temperature to reduce the fraying when mechanically cut. This process also helps to keep the cable straighter when laying flat and assists in minimizing the residual oils from the wire drawing process. Cable assemblies can also be vapor degreased and/or ultrasonically cleaned to further remove any residual oils from the above process. These methods have been used widely in medical applications.

A long time ago when I was first running Ethernet cabling, I was told by an older installer that the best way to determine how much you could bend a cable was with a DVD/CD. He said the cable should not curve tighter than the outer edge of the disk. I thought this was a great rule of thumb! This was wise advice then, but a bit outdated today. Further, this was in the context of RG6 coaxial cable, a different animal than what we are talking about here.

Why should you be concerned with how much to bend an Ethernet cable (or any cable for that matter)? Think of your cable as a garden hose. Water should flow through it freely. Now, put a nice hard kink in that hose and the water stops. When discussing Ethernet cable, this is not a bad way of thinking about it. A kink, or too tight of a bend, can and does interfere with the signaling characteristics of the cable. The hose analogy is an extreme example as the water stops altogether. In the case of Ethernet cable the speeds at which devices connect may be reduced, or there may be consistent packet errors. Or even worse…intermittent and hard to track down packet errors.

Arethere rules for how much you can bend Ethernet cable? Yes. According to ANSI/TIA-568-0.E, a manufacturer’s guidance around maximum bend radius trumps any generic guidelines. In absence of manufacturer stated rules, the generic guidance isfour times (4X)the cable jacket diameter for U/UTP Ethernet cable oreight times (8X)for F/UTP (and SF/FTP)solidcopper structure cable.

These rules change forstrandedcopper Ethernet patch cabling, however. Patch cables are held to the 4X rule, whether shielded or not. If you are confused about the difference between stranded and solid copper conductor cabling, see .

For trueCABLE U/UTP solid copper unshielded cable, we follow the ANSI/TIA guidelines. The inside radius of bends should be no tighter than 4X theouter diameter (OD) of the cable.For trueCABLE F/UTP solid copper shielded cable the inside radius of the cable should not be tighter than 7X the OD of the cable. See the table below for actual measurements, giving a far more useful dimension, the bend diameter.

If you are dealing with cable that is not trueCABLE brand, and that manufacturer provided no guidance around bend radius limitations,there is a nice little formula and it does not matter whether it is calculated in millimeters or inches. If the Ethernet cable has a specified OD published by the manufacturer, this formula is easy to apply.

When putting this into practice, visualizing a bend radius is tough. Rather than rely upon bend radius to be your guide, rely on bend diameter. Bend diameter is simply calculated as:

The result is far easier to visualize. Diameter is the width of the inside of a circle. For an example of how this looks in practice, here are some pictures that may help.

I am sure many out there will provide stories about how much tighter they can bend a cable and get away with it. Sometimes, a sharper turn is simply unavoidable. My only advice is to obey the rules of thumb, but use common sense and don’t bend a cable at a right angle! Performance testing is the best way to confirm your cabling works as expected.

trueCABLE presents the information on our website, including the “Cable Academy” blog and live chat support, as a service to our customers and other visitors to our website subject to our website

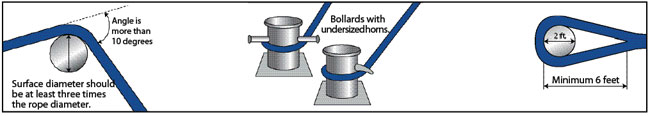

When a wire rope is bent around any sheave or other object there is a loss of strength due to this bending action. As the D/d ratio becomes smaller this loss of strength becomes greater and the rope becomes less efficient. This curve relates the efficiency of a rope diameter to different D/d ratios. This curve is based on static loads and applies to 6-strand class 6×19 and 6×37 wire rope.

The LOOP of an eye & eye sling has nearly DOUBLE the strength of its body. For this reason the D/d ratio in the LOOP is just half as critical as opposed to when the sling is used in BASKET hitch.

In most cases the shackle or hook over which the sling is placed will have a sufficient D/d ratio. On the other hand, do not place too LARGE an object into the sling eye as this will result in splitting forces affecting the sling splice and sling safety. The object (a shackle, a crane hook, a steel bar, etc.) you place into the sling eye must not be larger than 1/2 of the sling eye length.

When a sling is used in a BASKET- or CHOKER HITCH with D/d ratios smaller than listed in the capacity tables, the rated capacities (or WLLs) must be decreased.

For example: The BASKET and CHOKER hitch capacities listed (in all Standards and Regulations) for 6-strand ropes are based on a minimum D/d ratio of 25:1.

An object you place into a 1" diameter 6-strand wire rope sling using a basket- or choker hitch must have a minimum diameter of 25". If the object is smaller than the listed 25:1 D/d ratio the capacity (or WLL) must be decreased. Table A) illustrates the percentage of decrease to be expected.

Note: The minimum D/d ratio for GATOR-FLEX® and for TRI-FLEX® slings is just 5:1. If you need to lift small objects and don’t want your sling to kink or bend permanently use these types.

If the object lifted with a 6-strand wire rope sling in a basket hitch is at least 25 x larger than the sling diameter (D/d 25:1) the basket capacity need not to be adjusted.

It is better to use a larger shackle or a Wide Body shackle type. If the shackle or object has at least 5x the sling diameter (D/d 5:1) the basket sling capacity must still be reduced by about 25%.

Load Hooks must have sufficient thickness to ensure proper sling D/d ratio, particularly when using slings in an inverted basket hitch; that is the sling BODY is placed into the hook and the sling EYES are facing downwards.

Endless (or Grommet) slings DO NOT HAVE A LOOP which has double the strength of the sling body. Prior to EVERY lift, YOU, the user, has to determine if the D/d ratio is equal or higher than the ones listed in the capacity tables.

The bend radius is the radius at which a cable can be bent without damaging it (including kinking). The smaller the radius, the greater the required flexibility of the material. A frequently asked question in this context is: how much can we bend a cable without damaging it or impairing its function? The answer depends mainly on the particular cable being considered. There are several industry standards, such as IEEE 1185, ICEA S-75-381, ICEA S-66-524 or ICEA S-68-516, which provide minimal bend radii for many different cable types.

The minimum bend radius is the radius below which an object cannot be bent. In many installations, cable carriers are used, so the question arises: how do we select the bend radius of a cable or a cable carrier?

When deciding on a cable management system, there are several ways to extend the service life of the cable. One of the most important factors is the selection of the right bend radius for the cable carrier. It is important that the radius (except, perhaps, in space constrained applications) is greater than the recommended minimum bend radius of the cables. One of the key factors in long service life and operational reliability is choosing the right radius for the cable carrier. All cable carriers have several bend radii to choose from and each manufacturer proposes a minimum bend radius . The radius chosen for the cable carrier depends on the cable with the largest diameter.General rules and recommendations for selecting the radius

Do not exceed the manufacturer"s recommended minimum radius - but the maximum radius is optimal. Basically, cables with flexible specifications that move must be supported so that the connection points are not mechanically stressed and a sharp bend is avoided. If this is achieved by a loop, the cable must be provided with a bend radius of at least 10 times the diameter of the cable. The larger the radius, the less stress is exerted on the cables, which ensures a longer service life. It should be noted that the minimum bend radius is partially based on a temperature range for the bending. Particular care should be taken when the ambient temperature reaches or exceeds this temperature for the cable.

This is especially true for cryogenic applications where thermoplastic cables tend to stiffen when exposed to cold. Rigid cables can increase the radius of the cable carrier and lead to mechanical errors. It is recommended to use a cable with a PUR or TPE jacket at low temperature and/or to consult the manufacturer for recommendations on bend radii. For space constrained applications, the cable carrier radius must be less than the recommended minimum bend radius for the filling pack. This is not ideal, but if it cannot be avoided, cables designed specifically for low bend radius installations should be used. The igus chainflex range includes load-bearing control cables, servo and motor cables or robot cables as well as encoder cables, bus cables and data cables, which can be safely used in demanding environments and are characterised by their very long service life.

Thinking about it and looking again at the info. from loosco above, it also depends on what you want the bend for. Their info. is for rope use over pulleys (a "moving" application), but if you look at wire rope slings (let us call them a "static" application), there is no way they are made to those sizes.

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

8613371530291

8613371530291