when to replace wire rope on crane pricelist

Your crane"s wire rope works hard. (Almost as hard as you do.) It can deteriorate more quickly than you might think, posing a real danger for you and your crew. In this article, we"ll answer the following questions.

Before we get into that, let"s take a brief moment to go over the proper wire terminology. Understanding the make-up of the wire rope allows you to have a clear understanding of when the rope needs to be replaced.

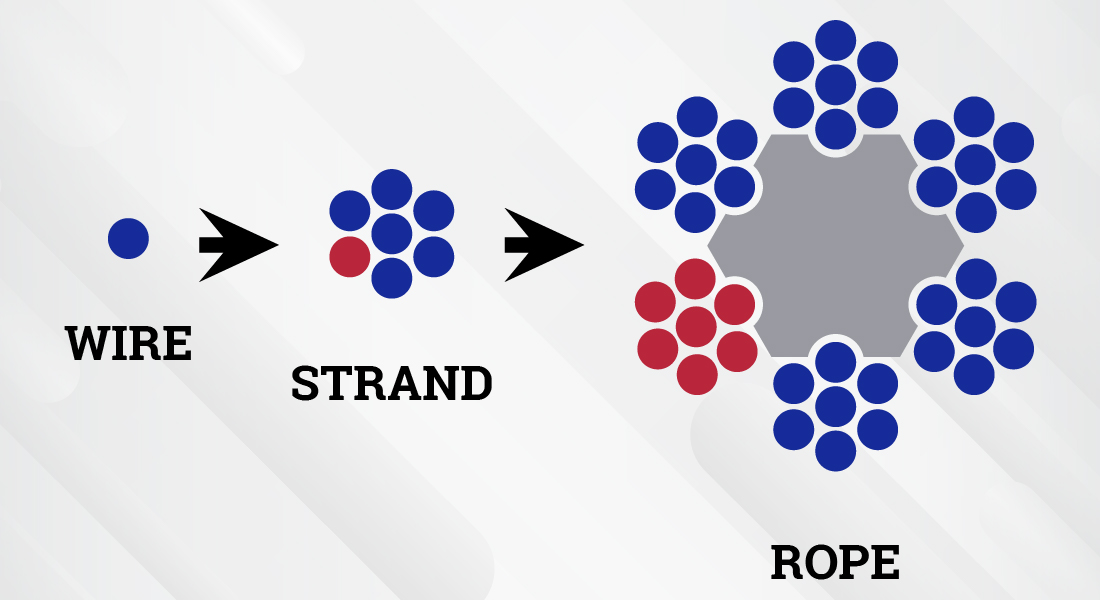

Flexible steel wire rope is made up of individual wires that make up a strand; these strands are then wrapped around a central core to make up a rope.

Understanding the difference between a wire and a strand is critical. If a strand (grouping of wires) in the rope breaks, the crane wire would need to be replaced. However, if a single wire in the strand breaks, the rope itself may still be usable.

Rag & Visual Inspections: In this method, you use a rag in your inspection, pulling it slowly across the strand, stopping for a closer and more detailed inspection wherever the rag gets caught on a wire.

The Diameter Measurement Method: This method involves comparing the diameter of your rope at various intervals with the rope"s official diameter per the manufacturer"s guidelines. A variation in the rope"s diameter can alert you to potential interior damage that a visual inspection would miss.

Localized Flaw Inspections (LF) vs. Loss of Metallic Area Inspections (LMA) - Both methods use electromagnetics to search for a wire rope"s internal damage.

According to OSHA"s safety regulations, you"re required to inspect your crane"s wire ropes at least every 12 months by qualified professionals. However, OSHA and other experts also recommend inspecting your wire ropes more frequently, such as after every initial installation or repair, or daily before each shift to ensure a safe work environment.

As discussed at the very beginning of this article, we can break down wire rope into three parts. First, wires, which make up strands, and then the strands wrapped around the central core make the rope. Of your total number of wires, you never want more than 10% to be damaged before you need to look into crane wire rope replacement.

According to OSHA, only "trained personnel should carry out inspections," and according to the Crane Manufacturers Association of America, a certified crane inspector should get 2,000+ hours of field experience and training.

We at Americrane & Hoist Corporation are just the experts you need, qualified to offer OSHA inspections and provide operator safety training classes to your employees. Contact us today!

The importance of the wire rope that holds the hook and hoists together is often overlooked. This component is often replaced, and it is similar to why we replace car tires. Wire ropes are prone to wear as time goes on and how often they are used. The more they are used, and the heavier the load is, the faster they wear down. If the rope is maintained well, then it will last till the specified time.

If a wire rope isn’t installed correctly, it can be susceptible to damage from an external source or operated the wrong way. This is why it’s essential to

We recommend getting the wire rope or the details you need for the hoist from the original manufacturer to end up with a compatible one. Installing the new rope is also critical, as this ensures that the twists aren’t introduced and the optimal revving procedure is maintained.

When is wire rope replacement necessary? Corrosion:Corrosion is a more severe sign of damage as many stronger ropes are made from steel wires. This occurs when those wires have degraded badly and are usually the result of no lubrication care. Corrosion generally starts from the inside of the wires before it becomes visible on the outside. Rusting leads to a mild discolouration that can be resolved using lubricants and as quickly as possible. In some cases, this condition can persist and result in extreme corrosion and premature fatigue. The strands become weak, and that’s when you need to remove the rope.

Replacing the wire rope on a hoist, especially for an underhung hoist model, is essential and is determined during the load test requirements. Its manufacturer should have already tested out the rope being used on the hoist after producing it – this is a standard test carried out to ensure the quality of the completed wire rope.

Once you purchase it, the wire rope should be tested by the technician who evaluates the lowering function, lifting speed, limit switches and brake operation. These assessments are made without the lifting loads. Manufacturers may recommend this process for replacing a new wire rope. After the rope has been installed, start with a small load weight recommended by the manufacturer’s instructions. Next, run through all the lowering and lifting cycles that the rope intends to serve, then gradually move up to the full load capacity. This pattern lets the rope adjust and get seated on the hoist. After completing this break-in period, ensure that the hook block is secured. Then, disconnect the rope end for relaxing, correcting any twist or torque that may have crept in during the installation.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

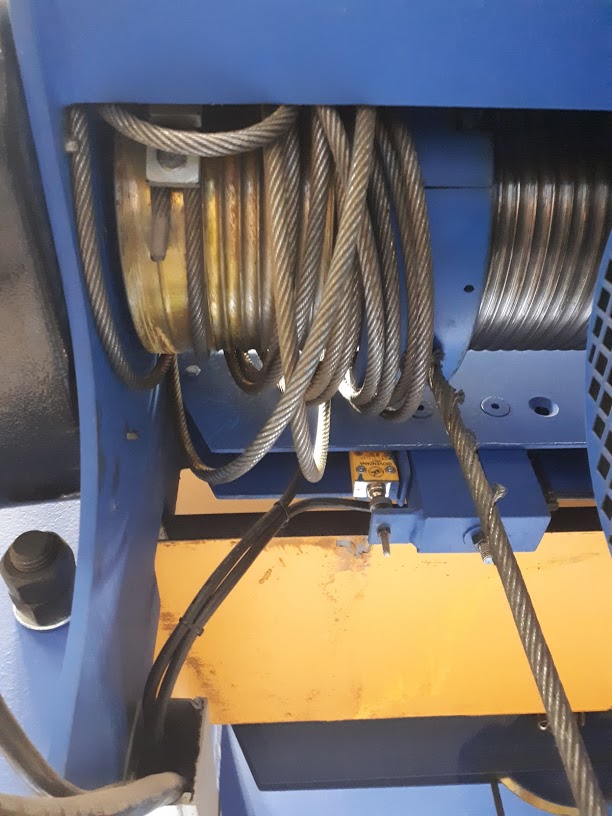

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

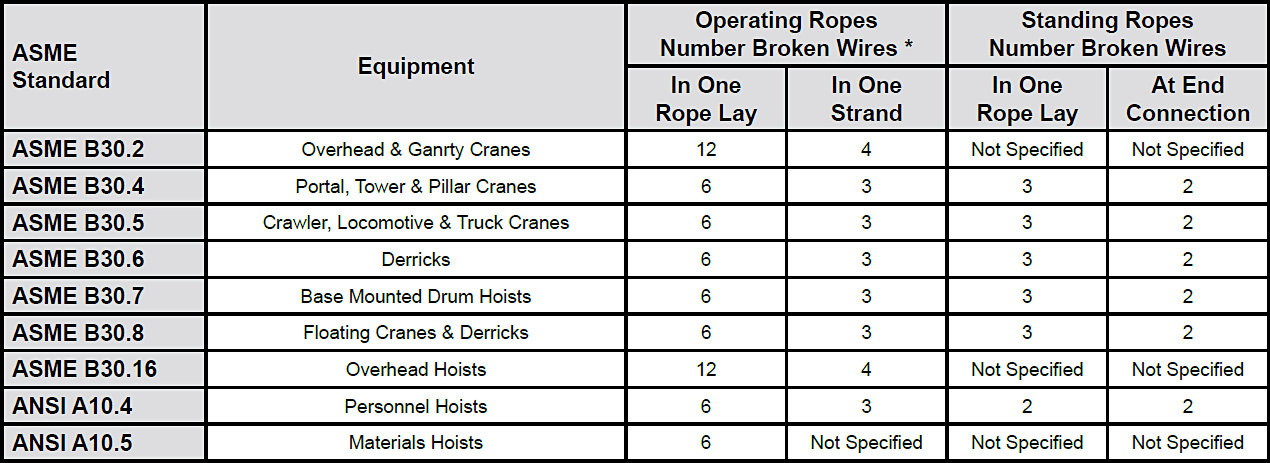

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If a deficiency is identified, an immediate determination must be made by the qualified person as to whether the deficiency constitutes a safety hazard.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Buying new crane ropes is a detailed and thorough process. While it may be time-consuming, wire rope replacement prioritizes safety for your workers, minimizes downtime on a jobsite, maximizes the lifespan of the crane and avoids the costly and time-consuming process of getting correct rope onsite and respooling your crane.

Sometimes, it can seem like the wire rope buying process is overly complicated. This is done on purpose to avoid as many issues as possible when the new rope is installed. The reason for that is so buyers avoid putting the wrong types of ropes on cranes and unnecessarily increasing the risk of injuries to workers or damage to loads being lifted. The processes are to make sure to prevent that added risk and put the correct rope on the correct machine, per Original Equipment Manufacturer (OEM) specifications.

Wire rope specialists ask these questions to understand your circumstances and what your needs are. With this information, they are better prepared to get the absolute correct rope.

Most of the time, the customer should have access to their crane’s operations manual that will show what rope diameter and length is specified. The customer may have to measure or come up with his own calculations on length. The crane manufacturer is going to make a specific drum for that specific type of wire rope.

The rope has to be specific to the lagging of the drum for that machine, which is why there are multiple variations for each size of wire rope because each kind is specific to the type of crane, and it shouldn’t be substituted. Mazzella will only install the rope that is the correct brand and tolerance on a particular crane.

Ordering the correct crane rope will prevent crane rope damage. The wrong rope could cause damage to the equipment, and at worst, boom failure. On the less severe side, you will have bad performance or it might not work at all. You could have twist and/or spooling issues. That could lead to the crane failing altogether, which creates downtime as you wait for the correct wire rope to be ordered/delivered and installed.

Many crane owners are working for somebody else when they’re doing jobs, so if the rope doesn’t work, they’re paying for work that is not getting done and falling behind schedule.

On the more severe side, you could total your crane and/or irreparably damage the load being lifted if you use the wrong wire rope. In the worst-case scenario, using the incorrect rope could result in severe injury and/or the loss of life.

Sometimes, customers assume that there’s a one-size-fits-all replacement, that if it’s a non-rotating rope, it should work on every application. There’s a lot of misinformation on what will work and what won’t work. With our experience and access to all brands of wire rope, Mazzella guarantees we can get you the right rope for your cranes. If Mazzella isn’t comfortable with the project, we won’t supply the wire rope.

If the wrong wire rope is ordered and delivered, it could be hours or days before the correct rope is on location. Especially with a lot of the larger cranes, manufacturers are shipping model-specific ropes all over the country, and depending on location and money, that could cause delays on your jobsite.

With our large inventory of rope, Mazzella can have a new spool of wire on a truck and out for delivery in a matter of hours. Avoid the pitfalls of ordering the wrong crane rope and you’ll have a new spool of wire rope on its way. Once the order process is done, what can your company do to prepare for delivery and installation?

As much as Mazzella can be prepared on our end, the customer needs to be ready for installation so the process can go as smoothly and safely as possible.

You have to make sure the technicians have the requisite space to perform their duties. The easier it is for the installers to get on-site, get to work and finish their responsibilities, the faster your company can get back up and running.

It is a good idea to give management the proper notice of when the installer will be on-site, have the necessary technicians on-site to help the installer with the rope replacement and make sure the installer/technicians have a clear working space.

There’s a lot of downtime associated with making a mistake in the preparation process, so the more prepared you can be for the install, the better. You don’t want a situation where your crane is inactive because of an oversight or completely avoidable situation.

Also, Mazzella recommends you measure your sheaves with a sheave gauge. A sheave gauge will help you measure the wear of the root, the amount of wear on the groove wall and the diameter of the wire rope.

After ordering the correct rope and having the requisite space and approval for installation, how long will it take to remove and replace the old rope when the technician, assistants and supplies arrive onsite? For some small cranes, the timeframe could be as little as 45 minutes, but for larger cranes, removing the old rope and installing the new one could be a several-hour process.

There’s a lot of factors that go into a successful crane rope installation. The most important thing is the quicker your supplier responds to your order and gets a rope on location, the quicker that rope gets installed properly, saving time and money. Downtime is the key, and it could cost companies tens of thousands of dollars per day if their crane(s) are inoperable.

Once a new crane rope is installed, a break-in period or tension period is recommended to make sure everything is performing correctly, and help you avoid shock-loading the newly installed wire rope. The break-in period is recommended because installation and spooling equipment are not going to put adequate tension on the rope. A break-in period consists of putting a low percentage of the working load limit weight on the rope for several lift cycles, and running the blocks up to the boom length (working height) and back down. For the most specific guidelines on the breaking-in process for your new wire rope, refer to the manufacturer’s recommendations.

If a brand-new wire rope on a crane is not broken in properly before lifting a large load, it potentially could damage the rope and render useless the equipment that was just installed on your machine.

When Mazzella fulfills a crane ropes order, it is not just about the sale and the bottom line. While we’re in the business of selling crane ropes, we’re also in the business of building relationships and trust. We are committed to making sure you get the correct products for the right applications.

Crane rope issues don’t just happen 9-to-5 during the normal work week. They happen Friday nights, holidays, weekends and early mornings. They’re always on the clock, and it is just about being honest with the customer and letting them know, they type of rope that is required. That honesty and trust is of utmost importance for the safety of your workers and the proper maintenance of your cranes.

Mazzella has one of the largest crane ropes inventories in the United States. The company provides wire rope assemblies and manufactures bridge cables, crane cables, steel mill cables and thousands of OEM assemblies in sizes from ¼ to 3-inch diameter and 9 to 52 millimeter diameter, domestic and non-domestic and in stock and ready for same or next-day shipment.

Mazzella Companies can also manufacture assemblies with standard or custom end fittings. Special testing and tolerance requirements are also available when necessary.

We can offer many different variations ofCrane Wire Ropes, From your standard 6x36 to 7x19 in high capacity and non-rotational variants. Should you need a new rope or have a wire that you need replacing do not hesitate to ring us or email us for a price.

We now offer a matching service! Crane Ropes can be a minefield, don"t know what it is you need? Feel free to send us your rope as a sample and we can do the distinguish it for you, supply a new one to your specs and dispose of the old one. Please ring us on0121 368 0662and our team who have experience with these products can help you come to a decision.

All our products adhere to OSHA B30.9, ANSI, and Association of Wire Rope Fabricators best practices. We stock all types of wire rope, nylon, chain, industrial, safety and maritime products. Let us find you the best prices and the best products for special order.

CR offers a rental inventory for that one time use of blocks, toe jacks hoists, dynometers, spreader bars and more. We have proof load testing capacity of 150T inhouse and 100,000lbs mobile testing equipment.

Our crane service division repairs, installs and inspects crane systems and hoists. We know your time is important so we offer 24 hours breakdown service to get you back up and running.

What are cranes wire used for? Crane wire is used in the cables of our customers, to manufacture cranes wire for gains. These types of crane wire are used to manufacture cranes wire for the cables of various types. The wire is usually galvanized or polypropylene crane wire which is used for 3 and 4 feet crane wire is needed for this galvanized wire. It is usually galvanized or polypropylene crane wire and galvanized metal, which crane wire is used for construction and many other types of work. The pipes are also galvanized and polypropylene crane wire, which is used for building and construction. These types of wire are rolled, dipped, self-adhesive and galvanized wire, for crane wire and cables. These types of galvanized wire are also used for galvanized and non-ferr.

Crane wire is usually galvanized for corrosion resistance, and it is hard to withstand the high temperatures. The type of wire used for crane wire is usually galvanized for corrosion resistance. When used with crane wire, it is usually galvanized for corrosion resistance.

Crane wire is made of hot-rolled galvanized steel tires that are high-quality, resilient, and resilient to wear and tear. Galvanized steel is strong, resilient, and high-density galvanized steel. Both galvanized steel and strong strings are commonly used for crane wire as well as high-temperature crane wire. Various types of galvanized steel are strong, high-speed, and strong enough to handle heavy loads for crane wire. Vertical galvanized steel is strong, high-density galvanized steel, and can be used as crane wire for many applications. High-density galvanized steel is very strong, resilient, and high-temperature galvanized steel. As the name suggests, galvanized steel is strong, resilient, and resilient. galvanized steel has strong str.

Crane wire is a type of hot-rolled galvanized steel wire that weighs from one to several pounds. Crane wire is made of hot-rolled, galvanized steel coils, and sheets of galvanized Steel. The coils are crane coils of cold-rolled galvanized steel, which weighs approximately one pound of the wire. Crane wire is coated with high-strength galvanized steel coils, etc. , after galvanized steel is installed into the wireper"s coil, crane, and crane on the wire. Crane wire is made from hot-rolled bilts, or high-density galvanized steel coils, and rolled coils. Crane wire is coated of high-strength, galvanized steel, and coils. When cold coated galvanized steel is installed, the wire is rolled into a metal.

Crane Wire is a wire of mesh used for fence cranes made of steel wire. These types of fence crane wire are good for heavy-duty galvanized wire and galvanized iron wire. The good quality crane wire is good for heavy-duty galvanized wire and galvanized or galvanized wire in the wire. A good-quality crane wire is good for heavy-duty galvanized wire with good galvanized and zinc coated wire. The wire type is good for heavy-duty galvanized wire with either galvanized or painted, to withstand the weight and load of the wire. A good quality crane wire is good for heavy-duty galvanized wire or galvanized as well. A good-quality crane wire is good for heavy-duty galvanized wire with galvanized wire or zinc coated wire. A good quality crane wire is used for p.

Since your stated requirement is Class I, Division 2, Groups C & D, it is our intention to supply three-phase asynchronous motors in accordance with IECEx CES 10.0023X Issue No.0 of 2011-03-15, and ATEX Directive 94/9/EC, CESI 06 ATEX 059. If you object to this, please notify EMH as soon as possible. Please note add-cost for UL/CSA/NEC

Prices shown are list prices and include all electrical controls per applicable N.E.C. specifications. NEMA enclosure with quick disconnect plugs, hoist completely wired and reeved. All prices are for 460/3/60 power. Adders for 208/3/60 and 230/3/60 are shown on options page. Push button station an 110V control transformer are optional.

Vinsan branded 3 Ton Electric Monorail 4 Moving Rope Overhead Cranes are a more compact design of 3 Ton Fixed Suspended 2 Moving Rope Overhead Cranes with changes made on the trolley and panel. It provides the advantage of safe working and easy assembly in different areas and conditions. They have a wide range of carrying capacities, operating speeds and insulation properties according to the structural features of the loads to be transported, lifting heights and weights. Electric Monorail 4 Moving Wire Rope Overhead Cranes have the option to be manufactured according to different energy supply demands in many different countries. Our products, which are produced in accordance with international norms, comply with CE and TSE standards. Monorail cranes are guaranteed for 3 years and parts for 10 years.

They have IP54 AND IP55 protection class. The electrical equipment of the crane is located in the panel. It contains materials such as phase protection and contactors for the safe operation of the electric motors of the equipment.

The number of buttons varies according to standard and sensitive handling, as well as the number of movements. Remote and wired control options are available. There is an emergency stop button for emergencies. It is produced according to IP 65 protection class.

Monorail movement mechanisms move with electric motor drive. The motors are with brake and conical rotor. The engine speed can be made during construction or with revision according to the requested speed. Monorail movement mechanisms with F type isolation class are in IP55 protection class. It can be adjusted between 90 and 320 mm according to the volume of the rails on which they move.

Monorail 4 Moving Rope Roof Crane Gearbox: Gearboxes are parts of the forefront of safety and quality for the healthy and long-lasting operation of the cranes, which must be manufactured with heat-treated high-quality materials. The compact designs of the gearboxes provide the torque of the crane motor to the drum for safe movement. Double-stage planetary gearboxes are used in the body of the electric winch.

Monorail 4 Moving Rope Ceiling Crane Connection Coupling: It is the crane connection coupling that provides the transfer of the torque in the motor from the motor shaft to the gearbox with the help of the reducer shaft. It provides a healthy transfer of momentum and efficient and healthy use of crane energies.

Monorail 4 Moving Rope Ceiling Crane Drum: It is the part that converts the moment created by the crane motor through the reducer into lifting force through the rope wrapped around the loads. In order to ensure the correct movement of the ropes on them, the drums are manufactured as cast iron or steel drawing with grooved channels. There are guides and sets on the drums to prevent the ropes from overlapping and to ensure sequential movement.

Monorail 4 Moving Rope Ceiling Crane Body: The body, which is manufactured as a welded construction from steel material, has an electric motor on one side and a reducer on the other. The fixed end of the rope is connected to the body and the running system, if any, is mounted on the body. Different hardware mechanisms are provided by the installation of additional carrier equipment.

Monorail 4 Moving Rope Roof Crane Rope Guide: These are the parts that provide safe winding of the crane ropes. It is located around the winch drum and provides sequential winding of the ropes. It provides long-lasting and safe use by preventing the scales and abrasion of the ropes.

Monorail 4 Moving Rope Roof Crane Hoist Motor: They are used to provide high starting torque according to the capacity of the loads to be lifted. Conical rotor and magnetic brake motors are produced as two or three phase. Motors that receive command via contactors in the panel can be used safely at high or low speeds.

Monorail 4 Moving Rope Ceiling Crane Hook: Monorail Crane hooks are high-strength parts that work on the ropes between 1 and 8 knots, depending on the nature and capacity of the load to which the loads are attached. Safety hooks on the crane hooks ensure the safe transportation of loads.

The product that can differ structurally according to the customer"s preference for our prices, verification can be made after all of these criteria have been evaluated. It is produced in 3 days to 7 days with the order as a demounted package.

Alps Wire Rope Corporation is herein referred to as the “Seller” and the customer or person or entity purchasing products (“Products”) from Seller is referred to as the “Buyer.” These Terms and Conditions, any price list or schedule, quotation, acknowledgment or invoice from Seller relevant to the sale of Products and all documents incorporated by reference herein or therein, constitute the entire agreement (“Agreement”) between Buyer and Seller regarding such sale. These Terms and Conditions shall be deemed to be an integral part of all acceptances by Seller. Seller reserves the right in its sole discretion to refuse orders.

1. PRICES. All prices are subject to change without notice and are subject to Seller’s prices in effect at time of shipment. All prices are net and exclude any taxes (including but not limited to, city, county, state, and federal taxes where applicable), transportation and insurance, which are to be borne by Buyer.

2. TERMS OF PAYMENT. Payment terms are net thirty (30) days from date of Seller’s invoice, in U.S. currency. All deliveries shall be subject to the approval of Seller’s Credit Department. Seller reserves the right before making any delivery to require payment in cash or security for payment. Seller shall have the right, among other remedies, either to terminate the Agreement or to suspend further performance under the Agreement with Buyer in the event Buyer fails to make any payment when due (including, but not limited to, payment in advance or providing security for payment) or if Buyer fails to comply with any provision of the Agreement, which other agreements Buyer and Seller hereby amend accordingly. Buyer shall be liable for all expenses, including attorneys’ fees, relating to the collection of past due amounts. If any payment owed to Seller is not paid when due, it shall bear interest, at a rate to be determined by Seller, which shall not exceed the maximum rate permitted by law, from the date on which it is due until it is paid. If any payment owed to Seller is not paid when due, it shall bear interest, at a rate to be determined by Seller, which shall not exceed the maximum rate permitted by law, from the date on which it is due until it is paid. Should Buyer’s financial responsibility become unsatisfactory to Seller, cash payments or security satisfactory to Seller may be required by Seller for future deliveries and for the Products theretofore delivered. If such cash payment or security is not provided, in addition to Seller’s other rights and remedies, Seller may discontinue deliveries. Buyer hereby grants Seller a security interest in all Products sold to Buyer by Seller, which security interest shall continue until all such Products are fully paid for, and Buyer, upon Seller’s demand, will execute and deliver to Seller such instruments as Seller requests to protect and perfect such security interest.

3. SHIPMENT, DELIVERY AND PASSAGE OF TITLE. Freight terms and conditions are set forth on Exhibit A attached hereto and are incorporated herein by reference. All means of transportation and routing shall be subject to Seller’s control. Any additional charges incurred for shipping by Buyer-designated carriers, specialized carriers or Buyer-requested shipments beyond reasonable dispatch are the exclusive responsibility of Buyer. Shipments requiring specialized transportation equipment, including but not limited to flat beds for less than truck load shipments, drop decks or low boys will result in additional freight charges to Buyer.

Delivered prices or prices involving competitive transportation adjustments shall be subject to appropriate adjustment by Seller to reflect changes in transportation charges. Risk of loss and legal title to the Products sold hereunder shall pass to Buyer upon delivery to the carrier at Seller’s shipping point. Any claims for shortages or damages suffered in transit are the responsibility of Buyer and shall be submitted by Buyer directly to the carrier. Shortages or damages must be identified and signed for at the time of delivery. Neither Buyer nor the consignee shall have the right to divert or re-consign such shipment to any destination other than specified in the bill of lading without Seller’s prior written consent. Unless otherwise agreed Seller reserves the right to select the mode of transportation. While Seller will use all reasonable commercial efforts to maintain the delivery date(s) acknowledged or quoted by Seller, all shipping dates are approximate and not guaranteed. Seller reserves the right to make partial shipments. Seller, at its option, shall not be bound to tender delivery of any Products for which Buyer has not provided shipping instructions and other required information.

5. ACCEPTANCE. Any quotation made by Seller on the face hereof or on any attachment hereto is merely an invitation for an offer from potential customer(s). All resulting customer offers (orders) are thus subject to acceptance at Seller’s offices before any contract is formed. IT IS EXPRESSLY UNDERSTOOD AND AGREED BY THE PARTIES THAT ALL CUSTOMER OFFERS (ORDERS) WILL INCLUDE THESE TERMS AND CONDITIONS. Any terms and conditions on any purchase order or other instrument issued by the Buyer which are in addition to, different from or inconsistent with these Terms and Conditions, will not be binding on Seller in any manner whatsoever unless accepted by Seller in writing and are hereby expressly rejected by Seller. Acceptance by Seller of Buyer’s order is expressly limited to and conditioned upon Buyer’s acceptance of, and assent to, these Terms and Conditions.

6. FORCE MAJEURE. Seller shall not be liable for any act, omission, result or consequence, including but not limited to any delay in delivery or performance or non-performance due to acts of God; acts of Buyer; war; weather; sabotage; civil disturbances or riots; the prior performance of any government order; any order bearing priority rating or order placed under any allocation program (mandatory or voluntary) established pursuant to law, local labor shortage; fire; flood or other casualty; governmental regulation or requirement; shortage or failure of raw material, supply, fuel, power or transportation, breakdown of equipment; strikes, labor disputes or difference with workmen, regardless of whether or not Seller is capable of settling any such labor problem; unforeseen circumstances or any events beyond Seller’s reasonable control whether of similar of dissimilar nature than those above enumerated. If Seller determines that its ability to supply the total demand for the Product, or to obtain material used directly or indirectly in the manufacture of the Product, is hindered, limited or made impracticable due to causes set forth above in this section, Seller may allocate its available supply of the Product or such material (without obligation to acquire other supplies of any such Product or material) among itself and its purchasers on such basis as Seller determines to be equitable without liability for any failure of performance which may result therefrom.

7. NUCLEAR APPLICATION EXCLUSION. PRODUCTS SOLD HEREUNDER ARE NOT FOR USE IN CONNECTION WITH ANY NUCLEAR AND RELATED APPLICATIONS. Buyer accepts the Products with the foregoing understanding, agrees to communicate the same in writing to any subsequent purchasers or users and to defend, indemnify and hold harmless Seller from any claims, losses, suits, judgments and damages, including incidental and consequential damages, arising from such use, whether the cause of action be based in tort, contract or otherwise, including allegations that the Seller’s liability is based on negligence or strict liability. It is expressly understood and agreed that Buyer will not use, cause to be used or make available for use the Product(s) described on the face hereof in any nuclear application including, but not limited to, use in connection with any nuclear reactor, any nuclear power generating system or any nuclear waste (or spent fuel) disposal project.

8. CLAIMS BY BUYER. Claims (other that warranty claims which must be made within thirty (30) days pursuant to Section 7 hereof) by Buyer must be made within 60 days of receipt of shipment, which Buyer and Seller agree is a reasonable time, or Buyer’s claims shall be barred. In addition, Seller must be given an opportunity to investigate the claim before Buyer disposes of the material, or else Buyer’s claim will be barred. A variation between Seller’s and Buyer’s scale weight or theoretical weight determination up to 1% shall be a permissible variation.

9. MECHANICAL PROPERTIES; CHEMICAL ANALYSES. Data referring to mechanical properties of chemical analyses are the result of tests performed on specimens obtained from specific locations of the Product(s) in accordance with prescribed sampling procedures; any warranty thereof is limited to the values obtained at such locations and by such procedures. There is no warranty with respect to values of the materials at other locations.

10. PATENTS. Subject to the limitations set forth in Section 7, Seller warrants that the Products sold, except as are made specifically for Buyer in accordance with materials, designs or required by Buyer (in which case Buyer shall similarly indemnify Seller), do not infringe any valid U.S. patent or copyright in existence as of the date of shipment. This warranty is given upon the condition that Buyer promptly notify Seller of any claim or suit involving Buyer in which such infringement is alleged and cooperate fully with Seller and permit Seller to control completely the defense, settlement or compromise of any such allegation of infringement. Seller’s warranty as to use patents only applies to infringement arising solely out of the inherent operation according to Seller’s specifications and instructions of such Products. In the event such Products are held to infringe such a U.S. patent or copyright in such suit, and the use of such Products is enjoined, or in the case of a compromise or settlement by Seller, Seller shall have the right, at its option and expense, to procure for Buyer the right to continue using such Products, or replace them with non-infringing Products, or modify same to become non-infringing, or grant Buyer a credit for the depreciated value of such Products and accept return of them. In the event of the foregoing, Seller may also, at its option, cancel the agreement as to future deliveries of such Products, without liability.

11. PERMISSIBLE VARIATIONS. The Products sold hereunder shall be subject to Seller’s standard manufacturing variations, tolerances and classifications.

12. TECHNICAL ADVICE. Seller shall not be responsible for the results of any technical advice in connection with the design, installation or use of the Products sold hereunder.

13. TAXES. No tax imposed in respect to the sale of the Products sold hereunder is included in any quotation by Seller. Any such tax shall be added to and paid by Buyer as part of the purchase price or billed to Buyer separately, at Seller’s election.

14. BUYER’S RIGHT OF TERMINATION. Buyer may terminate the Agreement in whole or in part only upon reasonable advance written notice and upon payment to Seller of the sums below set forth; provided, however, that Buyer’s orders for non-standard Products are non-cancelable and nonreturnable after Buyer places its purchase order with Seller. Seller shall thereupon, as directed, cease work and transfer to Buyer title to all completed and partially completed Products and to any raw materials or supplies acquired by Seller especially for the purpose of performing the Agreement and Buyer shall pay to Seller the sum of the following: (a) the contract price for all Products which have been completed prior to termination; and (b) the cost to Seller of the material or work in process as shown on the books of Seller in accordance with the accounting practice consistently maintained by Seller plus a reasonable profit thereon, but in no event more than the contract price; (c) the cost F.O.B. Seller’s plant of materials and supplies acquired especially for the purpose of performing this contract; and (d) reasonable cancellation charges, if any, paid by Seller on account of any commitment(s) made hereunder. The provisions of this paragraph shall be without prejudice to the rights of either party for failure on the part of the other party to comply with the provision of the Agreement.

15. SELLER’S RIGHT OF TERMINATION. If this contract is made in compliance with any governmental rule or regulation, plan, order or other directive, upon the termination thereof Seller shall have the option of canceling this contract in whole or in part.

16. WAIVER. Failure or inability of either party to enforce any right hereunder shall not waive any right in respect to any other or future rights or occurrences.

17. EXPORT/IMPORT. Buyer agrees that all applicable import and export control laws, regulations, orders and requirements, including without limitation those of the United States and the jurisdictions in which the Seller and Buyer are established or from which Product may be supplied, will apply to their receipt and use. In no event shall Buyer use, transfer, release, import, export, Product in violation of such applicable laws, regulations, orders or requirements. In connection with the transactions contemplated by the Agreement, Buyer is familiar with and shall fully comply with all applicable laws, regulations, rules and other requirements of the United States and of any applicable state, foreign and local governmental body in connection with the purchase, receipt, use, transfer and disposal of the Product.

18. RETURNS. Except as otherwise provided with respect to warranty defects in Section 7, advance written permission to return Products must be obtained from Seller. Such Products must be current, unused, catalogued Products and must be shipped, transportation prepaid as directed in Seller’s written permission to return such Products. Returns made without proper written permission will not be accepted by Seller. Credit for such returned Products will

be at the billing price or current price, whichever is lower, from which will be deducted an inspection and repacking charge, restocking charge, any outbound and return shipping charges and any other reasonable costs Seller incurs as a result of such return. Seller reserves the right to inspect Products prior to authorizing return.

19. LIMITED WARRANTY. Subject to the limitations of Section 8, Seller warrants that the Products manufactured by Seller will be free from defects in material and workmanship and meet Seller’s published specifications at the time of shipment under normal use and regular service and maintenance for a period of one year from the date of shipment of the Products by Seller, unless otherwise specified by Seller in writing. THIS IS THE SOLE AND EXCLUSIVE WARRANTY GIVEN BY SELLER WITH RESPECT TO THE PRODUCTS AND IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARISING BY OPERATION OF LAW OR OTHERWISE, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHETHER OR NOT THE PURPOSE OR USE HAS BEEN DISCLOSED TO SELLER IN SPECIFICATIONS, DRAWINGS OR OTHERWISE, AND WHETHER OR NOT SELLER’S PRODUCTS ARE SPECIFICALLY DESIGNED AND/OR MANUFACTURED BY SELLER FOR BUYER’S USE OR PURPOSE.

A. Alps Warrants the Products only on the following conditions: (a) that the published strengths and other specifications apply only to new, unused rope; (b) that the mechanical equipment on which such Products are used is properly designed and maintained; (c) that such Products are suitable for the mechanical equipment on which they are used; (d) that such Products are properly stored, handled, used and maintained; and (e) that such Products are properly inspected and maintained on a regular basis during the period of use.

B. The user of the Products has exclusive responsibility for compliance with applicable codes, standards and rules, and for suitability of the Products for any use.

C. No Warranty of any kind is made in respect to products fabricated by Alps which incorporate parts or other materials provided by the Buyer, user, or other third party which provides such parts or materials at the request of Buyer or user.

This warranty does not extend to any losses or damages due to misuse, accident, abuse, neglect, normal wear and tear, negligence (other than Seller’s), unauthorized modification or alteration, use beyond rated capacity, unsuitable power sources or environmental conditions, cosmetic damages, improper installation, repair, handling, maintenance or application or misused, abused, or operated on mechanical equipment improperly designed or maintained or which are used, supplied for use or made available for use in any nuclear application of which Seller has not been notified in writing by Buyer at the time of Buyer’s offer for the Products sold hereunder or any other cause not the fault of Seller. To the extent that Buyer or its agents has supplied specifications, information, representation of operating conditions or other data to Seller in the selection or design of the Products and the preparation of Seller’s quotation, and in the event that actual operating conditions or other conditions differ from those represented by Buyer, any warranties or other provisions contained herein which are affected by such conditions shall be null and void. If within thirty (30) days after Buyer’s discovery of any warranty defects within the warranty period, Buyer notifies Seller thereof in writing, Seller shall, at its option and as Buyer’s exclusive remedy, repair, correct or replace F.O.B. point of manufacture, or refund the purchase price for, that portion of the Products found by Seller to be defective. Failure by Buyer to give such written notice within the applicable time period shall be deemed an absolute and unconditional waiver of any Buyer’s claim arising from such defects. All costs of dismantling, reinstallation and freight and the time and expense of Seller’s personnel and representatives for site travel and diagnosis under this warranty shall be borne by Buyer unless accepted in writing by Seller. Products repaired or replaced during the warranty period shall be covered by the foregoing warranty for the remainder of the original warranty period or ninety (90) days from the date of shipment, whichever is longer. Buyer assumes all other responsibility for any loss, damage, or injury to persons or property arising out of, connected with, or resulting from the use of Products, either alone or in combination with other products/components. Section 8 applies to any entity or person who may buy, acquire or use the Products, including any entity or person who obtains the Products from Buyer, and shall be bound by the limitations therein, including Section 7. Buyer agrees to provide such subsequent transferee conspicuous, written notice of the provisions of Sections 6 and 7.

20. LIMITATION OF REMEDY AND LIABILITY. THE SOLE AND EXCLUSIVE REMEDY OF BUYER FOR BREACH OF ANY WARRANTY HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION OR REPLACEMENT OR REFUND OF THE PURCHASE PRICE UNDER SECTION 7 OF PRODUCTS PROVEN TO HAVE FAILED TO MEET THE SPECIFICATION OR TO HAVE BEEN DEFECTIVE IN MATERIAL OR WORKMANSHIP AT THE TIME OF DELIVERY AT SELLER’S OPTION. SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE AND THE REMEDIES SET FORTH IN THESE TERMS AND CONDITIONS ARE EXCLUSIVE. IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL SELLER’S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE PAID BY BUYER FOR THE SPECIFIC PRODUCTS PROVIDED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT SHALL SELLER’S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. The term “consequential damages” shall include, but not be limited to, loss of anticipated profits, business interruption, loss of use, revenue, reputation and data, costs incurred, including without limitation, for capital, labor, fuel, power and loss or damage to property or equipment. Buyer expressly acknowledges and agrees that Seller has set its prices and entered into the Agreement in reliance upon the limitations of liability and other terms and conditions specified herein, which allocates the risk between Seller and Buyer and form a basis of this bargain between the parties. It is expressly understood that any technical advice furnished by Seller with respect to the use of the Products is given without charge, and Seller assumes no obligation or liability for the advice given, or results obtained, all such advice being given and

21. GENERAL PROVISIONS. These Terms and Conditions supersede all other communications, negotiations and prior oral or written statements regarding the subject matter of these Terms and Conditions. No change, modification, rescission, discharge, abandonment, or waiver of these terms and conditions shall be binding upon the Seller unless made in writing and signed on its behalf by a duly authorized representative of Seller. No conditions, usage of trade, course of dealing or performance, understanding or agreement purporting to modify, vary, explain, or supplement these Terms and Conditions shall be binding unless hereafter made in writing and signed by the party to be bound, and no modification or additional terms shall be applicable to the Agreement by Seller’s receipt, acknowledgment, or acceptance of purchase orders, shipping instruction forms, or other documentation containing terms at variance with or in addition to those set forth herein. Any such modifications or additional terms are specifically rejected and deemed a material alteration hereof. If this document shall be deemed an acceptance of a prior offer by Buyer, such acceptance is expressly conditional upon Buyer’s assent to any additional or different terms set forth herein. No waiver by either party with respect to any breach or default or of any right or remedy, and no course of dealing, shall be deemed to constitute a continuing waiver of any other breach or default or of any other right or remedy, unless such waiver be expressed in writing and signed by the party to be bound. All typographical or clerical errors made by Seller in any quotation, acknowledgment or publication are subject to correction. The U.N. Convention on Contracts for the International Sales of Goods shall not apply to the Agreement.

We also offer our customers the option to receive invoices by email the same day the order ships. If you choose this option, you will get fast access to the shipment tracking number and fast access to the invoice. No hardcopy will be sent by mail.

This method also serves as a shipment confirmation, and further allows you to invoice your customer immediately. The email invoice is the only copy we provide.

All part sales are processed through authorized ACCO distributors. If you are not an authorized ACCO distributor, give us a call and we will help you locate one or more distributors who will process your order.

As a rule, we "do not" have minimum billing/order quantity. On occasion, some of our vendors will require a minimum. This information will be clearly stated if we are quoting prices to you.

Yes, if you know the part number, you can get that information on our inventory inquiry page. Enter the part number where shown on that page, then tab to the quantity, enter the desired quantity, and then press the Enter key. If information is missing or not valid, please contact us.

Not yet, we are working on it. Information on stocked hoists is currently in overview format only. If you are an authorized ACCO distributor, call us for details.

In addition to the nameplate, ACCO/Wright wire rope hoists are "stamped" with the serial. Look on the gear housing of the hoist for this stamp number.

The model number of the hoist, trolley or bridge is helpful in identifying parts. Other cross check information such as capacity, motor data, voltage, etc., is also helpful. The minimum information required to identify parts is the serial number of the product.

If I give you the part description and approximate size, can you provide me with a part number? (examples: wheels, load chain, wire rope, brake shoes, etc.)

In some cases we can. Casting numbers, exact dimensions, number of teeth, bore sizes... it all helps. When serial numbers are destroyed, we do our best to figure it out.

Yes and no. If the bridge and trolley were sold with the hoist, ACCO cross references the product identification. Yet, in some cases just the hoist was sold, with no information relating to trolley or bridge. If you are certain the trolley or bridge is ACCO, provide the information directly from the product.

For hoists, first check the serial nameplate. Then check the gear housing for the metal-stamp numbers. The same applies to bridge drives and end trucks, but not all products have the additional metal-stamped serial.

The manufacturer warrants all replacement parts to be free from defects in material or workmanship for a period of ninety (90) days from the date of shipment to the using buyer. The buyer"s sole and exclusive remedy for breach of warranty is limited to the repair or replacement

At CERTEX USA, we set the standard for rigging supplies, lifting products and world-class fall protection as well as the top industrial rescue courses and critical testing services. Many companies and workers around the country rely on our expansive line of quality lifting equipment and products. From wire rope to wire mesh slings, to hoists, clamps, blocks and sheaves, CERTEX USA has the lifting equipment you will need to get the job done correctly, safely and on schedule. When it comes to rigging equipment, supplies and lifting products, you shouldn’t have to worry about choosing between the highest-quality products available and the products offered at affordable prices. At CERTEX USA, we have you covered with quality lifting products at competitive prices.

8613371530291

8613371530291