wire rope 4 leg bridle slings supplier

When looking for strength and durability on that next big rigging job, look no further than our array of HSI Wire Rope Slings. A wide-variety of sizes and styles are available whether working on a small-load lift or preparing to maneuver a massively heavy element. Our slings are there to solve your hoisting, lifting and towing problems.

HSI slings are assembled in an ISO 9001:2015 certified facility where quality, safety and efficiency are priority. Audits are conducted every year by an independent third-party to ensure manufacturer compliance with the set standards.

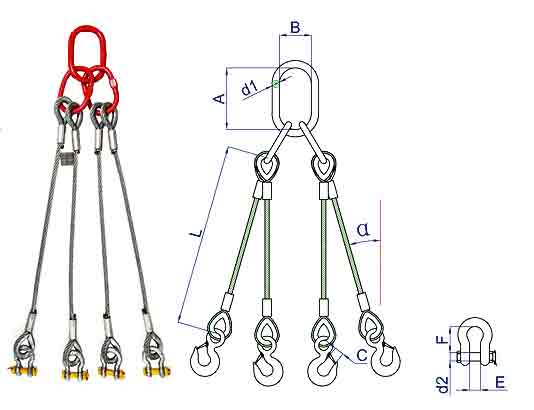

Four leg slings are used for both balanced and unbalanced loads. This connection style is recommended for heavier loads where the design calls for more weight distribution as the four connection points offer additional levels of load security. Each eye on these slings is formed using the mechanical Flemish Eye Splice. This process allows for the most efficient use of the rope capacity with top-quality steel as the pull is directly along the centerline of the rope and eye.

All Slings are manufactured with galvanized carbon Steel Sleeves for greater resistance to corrosion and they all come with a stainless steel identification plate for information to last longer. Turn back Slings are manufactured with Aluminum Sleeves.

Choose wire rope slings by diameter based on capacity ratings. Then shop by length. Our domestic quad leg wire rope slings are comprised of four lengths of wire rope that are connected at the top with a single oblong master link, for a design that offers both excellent load balance and control. Also known as a 4 leg bridle wire rope slings, our domestic 4 leg cable slings, feature Crosby® alloy latched eye hooks on each end length, but customization with different hardware is an option. Thimbles on the loop eyes connecting the lengths to the oblong link protect the wire rope at the point of contact to extend the working life of the sling. All of our domestic 4 leg wire rope slings feature a flemish eye splice and carbon steel sleeve, for superior use of rope capacity.

Rated capacities of all of our domestic 4 leg wire slings will vary based on the angle/direction of the pull in the lift, as will the configuration of the wire rope. We use both a 6x19 EIPS rope and a 6x36 EIPS rope, depending on the diameter. All of our domestic 4 leg bridle wire rope slings feature an Independent Wire Rope Core (IWRC) for crush resistance.

Wire rope slings are measured by the length of the sling leg only. The length of the oblong master and eye hooks should not be included in the overall measurement.

Our slings are available in a variety of lengths, but can also be customized to any length you need. Give our sales team a call for more information or to place a custom order.

Proof testing certificates can be supplied with your order for a nominal fee and must be requested at the time of order. Proof tests are performed in the factory where the sling is pull tested to 2x the vertical rating and officially recorded as proof for governing bodies. During the standard manufacturing process, only random slings during a production run are tested for compliance; in order to provide proof testing certificates with your order, every sling must be pull tested at the time of manufacture.

Choose wire rope slings by diameter based on capacity ratings. Then shop by length. Quad leg wire rope slings are comprised of four lengths of wire rope that are connected at the top with a single oblong master link, resulting in a design that provides excellent load balance and control. Also known in the industry as 4 leg bridle wire rope slings or simply 4 leg cable slings, they are traditionally made with latched eye hooks at the end of each rope length, but each leg can be customized with different hardware as needed. We"ve added thimbles to the "eyes" or loops that connect the lengths to the oblong, to offer protection at the point of contact, thereby extending the life of the sling. All of our four leg wire rope slings feature a flemish eye splice and carbon steel sleeve, for superior use of rope capacity.

Rated capacities of 4 leg wire rope slings will vary widely based on the angle/direction of the pull in the lift. The type of wire rope will also vary its uses and capacities. We offer 4 leg wire slings in both a 6x19 EIPS configuration and a 6x36 EIPS configuration; all feature an Independent Wire Rope Core (IWRC) for resistance, even in harsh environments.

Wire rope bridles are measured by the length of the sling leg plus the end hook. The length of the oblong master should not be included in the overall measurement.

Our slings are available in a variety of lengths, but can also be customized to any length you need. Give our sales team a call for more information or to place a custom order.

Proof testing certificates can be supplied with your order for a nominal fee and must be requested at the time of order. Proof tests are performed in the factory where the sling is pull tested to 2x the vertical rating and officially recorded as proof for governing bodies. During the standard manufacturing process, only random slings during a production run are tested for compliance; in order to provide proof testing certificates with your order, every sling must be pull tested at the time of manufacture.

Lift-All Permaloc slings are made using the Flemish Eye splice technique to form the eyes. Unlike the simple return loop method that places 100% of its strength on the swaged sleeve, Permaloc slings have reserve strength should the sleeve become damaged in use.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

Safe and Secure (SSTE) leading supplier of custom-build fabricated Steel Wire Rope Sling as per customer specification and need. “4-Four-Quadruple Leg Steel Wire Rope Bridle Sling, Master Link Assembly on Top and Legs ending in heavy duty thimble hard eyes ”

Please Note : Select Steel Wire Rope , by default Steel Wire Rope Selection is 1 meter for each (four) leg, 2 meter of Steel Wire Rope means 2 meters for each (four) leg and so on.

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Rated loads for a sling in a choker hitch are the values shown in Table 7, 9, 11, 13, 14, or 15, provided that the angle of the choke is 120 degrees or more (Fig. 2). Use the values in Fig. 2 or those from the sling manufacturer or a qualified person for angles of choke less than 120 degrees.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

Ensure that multiple-leg slings are selected according to Tables 7 through 15 when used at the specific angles given in the tables. Ensure that operations at other angles are limited to the rated load of the next lower angle given in the tables or calculated by a qualified person,

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

When using a basket hitch, ensure that the legs of the sling contain or support the load from the sides, above the center of gravity, so that the load remains under control,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

Looking for a professional supplier of wire rope bridle slings? The SichWireRope is a recognized manufacturer and supplier of wire rope slings in China, offering low-price but high-quality personal fall limiters. This single leg wire rope sling is with fiber core material.

Do you want to find a truthful China wire rope bridle slings manufacturer? This steel core single leg wire rope sling is a type of suspension device that can be used to lift and move objects. It consists of only one leg, with an oval master link on the other end.

The JF Brand fiber core 2-Leg bridle wire rope sling consists of two single-leg wire rope slings with a thimbled eye on each end. This type of sling is very strong and can be used to lift heavy loads. They can attach with a hook or shackle.

You cannot go wrong with our steel core 2 leg bridle wire rope slings, the steel core provides additional strength and durability, making it ideal for applications where high levels of tension are required

Do you want to find 4 leg bridle wire rope slings? The SichWirerope wire rope sling manufacturer provides fiber core 4 leg bridle wire rope slings, which consist of four single-leg wire rope slings with a thimbled eye on each end.

The JF Brand 4-Leg bridle wire rope sling is made up of four individual wire ropes that are attached to one another at each end, forming a bridle. They can attach with hooks or shackles.

A wire rope bridle sling is a type of rigging used to support loads. In our SichWirerope wire rope sling manufacturer, we have 2 types of bridle slings: fiber core and steel core. The option for wire rope coating includes galvanization (with/without lubricant) and smooth surface (with lubricant).

For fiber core wire rope bridle sling, it consists of two wire ropes, each attached to one end of the load, and the fiber core in the middle that connects the two.

For steel core wire rope bridle sling, it consists of two wire ropes, each attached to one end of the load, and a third wire rope in the middle that connects the two.

The advantage of using a bridle sling is that it evenly distributes the weight of the load, making it easier to lift and transport. Bridle slings are often used in construction and industrial settings.

In our SichWirerope wire rope sling manufacturer, we mainly have 3 types of bridle slings: single leg, 2 leg, and 4 leg wire rope bridle sling with EN13414-1: 2003, EN13411-3: 2004, GB/T16762-2009, GB/T14737-2009, GB/T30589-2014 standards. And all of their safety coefficient of different components is 5:1 for wire ropes, 5:1 for hooks, and 6:1 for shackles.

Wire rope single leg bridle sling:we have fiber core and steel core of single leg wire rope sling, they all can attach with hooks or shackles. Fiber core: wire rope pattern series 6×37+FC is used in the sling sets listed, its nominal tensile strength is 1670MPa. Steel core: wire rope pattern series 6×37(a)-steel core is used in the sling sets listed, its nominal tensile strength is 1770MPa.

Wire rope 2 leg bridle sling: they consist of two single-leg wire rope slings with a thimbled eye on each end. Fiber core and steel core 2 leg bridle slings can all attach with hooks or shackles. Fiber core: wire rope pattern series 6×37+FC is used in the sling sets listed, its nominal tensile strength is 1670MPa. Steel core: wire rope pattern series 6×37(a) steel wire rope is used in the sling sets listed, its nominal tensile strength is 1770MPa.

SichWirerope is one of the largest companies that specialized in providing large numbers of reliable wire rope slings and excellent service. We can produce the largest and heaviest slings in the industry.

We are in control of the manufacturing process and the core technology of wire rope slings, and we use highly efficient management and control systems to ensure the stability, safety and high quality of our products.

As a professional lifting and hoisting solution service company, you can get expert advice and assistance from our wire rope slings manufacturer. Also, we can customize your wire rope slings with your drawings.

We have a witty and innovative R&D team that ensures we continue to stay on top of the market. And we have designed and developed 696mm diameter and 8000 ton slings.

> SichWirerope manufacturer the wire rope slings have been exported to more than 60 countries and districts such as Europe, Australia, South America, Japan, Southeast Asia, and the Middle East in the past 40 years.

Wire rope slings are a great way to quickly and easily attach equipment for simple tasks. I found many different models from SichWirerope manufacturer, but my favorite was the regular style because it"s easy-to use! When selecting what type of sling you want in order make sure that its right fit with your project needs - they have specialists who can help do this too if needed--and they"re all very nice people at these factories.

After doing a lot of research on Alibaba, I found that the quality wire rope sling factories were not up to par. But then one day while browsing through SichWirerope factory"s products all their products are inspected and certified. And the verification test certificate of wire rope slings provided along with my order it put me very much at ease!

SichWirerope factory has been a lifesaver! They offer related products and accessories in addition to their custom steel cable slings, so I no longer need search for other suppliers. This saves me hours every day on paperwork or making phone calls with manufacturers looking haven’t found what we want either way--saving our time as well!

Eye and Eye slings can be used in choker, vertical and basket hitches. Slings with Half Twist (Type 4) eyes are furnished unless Flat (Type 3) eyes are specified. Sling eyes will be wrapped at the bearing point unless otherwise specified.

Eye & Eye nylon & polyester lifting slings featuring flat eyes can be used in all three hitches: choker, vertical and basket. Heavy duty nylon rigging slings featuring the Flat Eye and Eye design are made in widths ranging from as narrow as 1 inch and as wide as 12 inches. All Lift-It® Flat Eye & Eye slings feature protection at the sling eye bearing points. The extra protection wrapped around the sling eye provides additional service life as this is a critical wear area for all polyester and nylon rigging slings.

Sling eyes are automatically tapered to a narrower width on Eye and Eye lifting slings that are over 3 inches in width. At Lift-It we do not charge extra to taper the eyes for your 2 inch wide rigging straps.

Flat Eye, Eye and Eye nylon lifting slings used by crane and rigging customers around the world provide for the lowest profile eye available. Low profile eyes make sling removal easier when tight clearances are unavoidable.

If a more supple body composition is desired consider using Lift-It® polyester roundslings in the eye and eye style. Eye & Eye polyester round slings are formed by passing an exterior sleeve over the strands of the polyester roundsling.

Wire rope lifting slings, bridles and assemblies provide great durability and high tensile strength for lifting heavy loads. In addition, wire rope lifting slings are lighter in weight and more cost efficient than chain slings. Wire rope slings, sometimes referred to as wire slings, or cable lifting slings, are constructed using a variety of different styles and sizes of steel wire rope. Every style and size of wire rope offers different properties and benefits such as:

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel IWRC (independent wire rope core) core.

Wire rope lifting slings, bridles and assemblies are highly customizable, so if you are unable to find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

The durability of steel cable lifting slings is also put to the test in the harsh environments seen in steel mills and forging facilities. Every steel wire rope configuration will offer different properties and will be better equipped to handle certain applications. Generally, a smaller number of large outer wires will provide more wear, corrosion and abrasion resistance. Conversely, a larger number of smaller outer wires will provide better flexibility and fatigue resistance.

After you decide what construction and size of wire rope fits your application, you must configure the entire sling. Wire rope bridles and assemblies are available in single-leg, double-leg, triple-leg, and quadruple-leg configurations. They most commonly have 2 eyes and are constructed using a mechanical flemish splice. Wire rope lifting slings can be used in vertical, choker and basket hitches. They can also be equipped with a variety of attachments and fittings to accommodate almost any overhead lifting application.

Although wire rope sling fittings and attachment can be reused, the wire rope itself is not repairable. If a wire rope sling fails an inspection, it is to be properly destroyed and disposed of

It is important to inspect wire rope slings regularly and to keep a record of all sling inspections. At Tri-State Rigging Equipment we offer a full range of rigging inspection and repair services. The standards that govern wire rope sling inspection are OSHA 1910.184 and ASME B30.9. It is recommended that wire rope rigging slings first undergo an initial inspection when you receive the lifting sling from the manufacturer. The purpose of this initial inspection is to:

Wire rope slings, bridles and assemblies should also be inspected by a designated and qualified individual every day before use to make sure that the sling is in working condition and will lift its rated capacity. The person performing the inspection should examine all the wire rope, fastenings and attachments on the wire rope sling. The inspector is looking for visual indications of any defects, deformities and general damage that might affect the integrity of the sling.

Depending on your application, it may be recommended that you perform these visual inspections more than once a day. If the wire rope sling is used many times throughout the day, by multiple individuals, across multiple shifts, it is imperative that the sling be inspected before every shift change and before any change in lifting application.

ASME standards further require a thorough periodic inspection to be performed at least once a year by either a professional service provider, or by a Qualified Person. In addition, written records must be kept until the next periodic inspection. The rejection criteria for periodic wire rope sling inspections are as follows:

10 or more randomly distributed broken wires in one rope lay, or 5 or more broken wires in one strand in one rope lay, for strand-laid grommets and single part slings.

If your wire rope sling shows any of the rejection criteria above, you must remove the sling from service, and it must be destroyed. Properly destroying rigging equipment is imperative because you can be held accountable for damage done by people who find and use your discarded slings. Therefore, lifting slings deemed not suitable for service must be destroyed beyond use and beyond repair. The process for destroying a wire rope sling is as follows:

The purpose of daily and periodic wire rope sling inspections is not to get anyone in trouble but rather to gain knowledge of the frequency of use, severity of conditions, and nature of lifts, and consider how all these factors affect your wire rope sling. The most important reason to perform daily and periodic wire rope sling inspections, however, is to keep you and your coworkers safe.

Tri-State Rigging Equipment is a custom manufacturer, service provider and distributor for all wire rope lifting slings serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Safe and Secure (SSTE) leading supplier of custom-build fabricated Steel Wire Rope Sling as per customer specification and need. “4-Four-Quadruple Leg Steel Wire Rope Bridle Sling, Master Link Assembly on Top and Legs ending in heavy duty thimble hard eyes ”

8613371530291

8613371530291