wire rope abrasion in stock

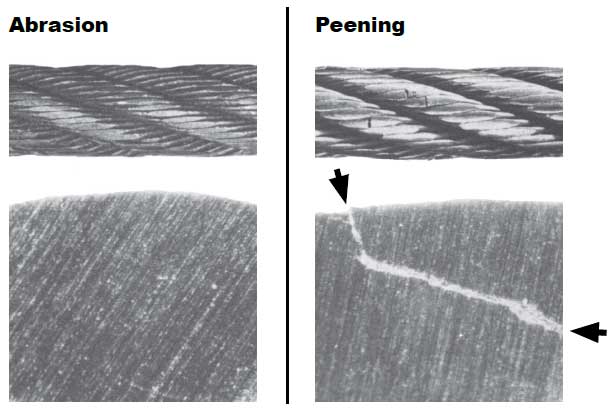

The two pictures in this post illustrate what wear, abrasion and peening look like through the service life of a wire rope. In both cases these wire ropes were replaced.

What do both these wire ropes tell us? Note the rust.Corrosion was in process due to insufficient lubrication on the wire rope by the end users. Corrosive damage is very difficult to assess, but should always be noted. Advancement of damage is usually greater than the external symptoms indicate.

What is the cause of abrasion? Abrasion can simply be caused by the constant passing of the wire rope over the drum, or the sheaves in the application of work. However, improper lubrication during service of the wire rope will accelerate the affects of abrasion as wires begin to stick together. In addition, a badly corrugated, or worn sheave can also damage a new wire rope. Check your sheaves to avoid premature wire rope replacement.

Why are some of the wires on the strands shiny? If you look carefully at the left side of the top picture you will note a sheen and also a flattening affect on the crown wires. The bottom picture shows a more advanced case of the same wear. When you see examples of wear, abrasion and peening as illustrated in these pictures, replace the wire rope. Remember to lubricate your wire ropes to achieve maximum service life!

The fact that the wires of regular lay rope are subject to higher pressure, increases the rate of wire rope abrasion and peening of both wire and mating surface of the drum or sheave. Moreover, this higher pressure is transmitted to the interior rope structure and this, in turn, decreases fatigue resistance.

Finally, the worn crown of the regular lay wire combined with its shorter exposed length, permits the wire to spring away from the rope axis. Subsequent passage on and off a sheave or drum, results in fatigue breakage.

A note of caution: lang lay rope has two important limitations. First, if either end is not fixed, it will rotate severely when under load, and secondly, it is less able to withstand crushing action on a drum or sheave, than is regular lay rope. Hence, lang lay rope should not be operated without being secured against rotation at both ends; nor should it be operated over minimum-sized sheaves or drums under extreme loads. Additionally, poor drum winding conditions are not well tolerated by lang lay ropes.

Pre-forming is a wire rope manufacturing process wherein the strands and their wires are formed-during fabrication-to the helical shape that they will ultimately assume in the finished rope or strand.

The wire arrangement in the strands is an important determining factor in the rope’s functional characteristics, i.e., its ability to meet the operating conditions to which it will be subjected. There are many basic strand patterns around which standard wire ropes are built; a number of these are illustrated in Figure 5.

Like all industrial equipment, aircraft cables and wire ropes wear while in service, and will require replacement. Though the cycle life of each cable varies based on construction and application, factors such as load and pulley condition can actually reduce this lifespan by triggering wire breaks. Not all wire breaks look the same, and understanding these differences can help detect issues in your system before they damage additional cables, or put human lives in danger. Here is a quick guide to help you understand where wire breaks occur (crowns vs. valleys), and three common examples of wire breaks (tension, fatigue, and abrasion).

Wire breaks typically occur in two different locations on the outside of wire rope or aircraft cable. The first location is on the crowns of the strands, which are the highest points with the most surface area exposure. The second location is the valleys, or the spaces between the strands. Though crown breaks typically result from normal wear and tear, valley breaks are more suspicious and may indicate issues with the pulley system or wire rope itself.

Wires that have been worn to a knife-edge thinness are characteristic of abrasion breaks. Abrasion can occur from a number of different sources, but sheaves are the most common. Remember to check sheaves for signs of wear, damage, or deformity and replace as necessary.

If you notice one end of a broken wire is cupped, and the other end resembles a cone, your wire rope likely experienced a tension break. Tension breaks result from excessive loading, causing the wires to stretch beyond their limits until they snap. Once one wire break appears, others will continue to occur if the cable is not addressed.

Fatigue damage is usually represented by zig-zag breaks with square ends. Like abrasion breaks, fatigue breaks can be triggered by a broad range of factors, including incorrect pulley size and excessive vibration. Check for worn pulleys and slack in the system to prevent issues from exacerbating.

Once you have replaced your damaged pulleys, or removed sharp obstructions in your system, begin your quote for brand new wire rope at https://strandcore.com/contact/. Our wire rope craftsmen can help you select the ideal wire rope for your application, and oftentimes provide a better solution for your existing setup. Browse our selection ofwire rope and aircraft cableonline, and do not hesitate to contact our sales team at sales@sanlo.com if you have any questions.

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

I’d like to pass along some insight into what makes these slings, from their construction to the maintenance and inspections that keeps them safe but, at the same time, don’t want to make your eyes bleed. That said, today, we’ll cover wire rope and we’ll cover the other sling types in future installments.

So we all know wire rope derives its strength from the strands of wire that are twisted around a core cable, right? You may ask what else is there to know about their construction beyond that. Well, frankly, a lot.

Our rental fleet has sizes of wire rope ranging from 3/4” up to 4” in diameter for single part slings and 2-1/2″ to 11″ diameter in our 9-part braided slings, but there are larger varieties available for purchase. Each wire rope sling is made up of several strands, which is then twisted in a helix around a central strand that is often the same composition as the outer strands. A wire rope strand is typically made up of anywhere between 19 and 36 wires but can reach as high as 109 wires, which are then twisted around a core wire or strand, depending on the configuration of wire rope.

Knowing the composition of the sling you’re using gives an understanding of what the rope will be able to do or, in some cases, how it will act. Various configurations exist to combat crushing, allow for greater flexibility or reduce the chances of rotation among other things. Ensuring you’ve got the correct wire for the project can be the difference between a successful job or causing damage or complete failure. As a general rule of thumb, improving one aspect will tend to reduce another. For example, a wire rope made up of smaller diameter wires provides increased flexibility, but doesn’t offer great abrasion resistance, whereas a wire rope of larger wires increases abrasion resistance while remaining more rigid.

The most common configuration of wire rope, the 6×19 class, consists of six outer strands comprised of 15-26 wires each that are twisted around a center core of smaller diameter wires in a 6×19 configuration consisting of the same number of wires as the outer strands. This configuration offers greater abrasion and crushing resistance while sacrificing a bit of flexibility and is available in sizes ranging from 3/4″ to 1-1/8” outer diameter. The next variation, for thicker outside diameters, is the 6×36 class comprised of six outer strands made up of 27-49 wires. This configuration offers increased flexibility due to the thinner wire diameters while maintaining crushing resistance but does sacrifice some of the abrasion resistance seen on the 6×19 class. LGH has 6×19 and 6×36 wire ropes from 1-1/4” to 4” outside diameter ranging from 5.6 to 130 tons safe working load (SWL) as well as 9-part braided slings that range from 59 tons to 485 tons SWL.

The next aspect of wire rope to consider is the lay of the wires that make up the strands as well as the way the strands are laid around the core. There are two main classifications of wire rope lay seen with alternating directions within each. These classifications are Regular Lay and Lang Lay.

Regular Lay wire ropes are formed with the wires that make up the strands being twisted in one direction, either left or right, and the completed strands are then laid the opposite direction, which causes the finished product to appear like the wires are running parallel to the axis of the rope. Regular lay rope is more flexible and carries better resistance to crushing forces and is easier to splice than Lang lay rope but has a shorter lifespan. Regular lay rope also tends to spool on a drum more easily and is naturally more rotation resistant.

Lang Lay wire ropes have both the wires forming the strands and the finished strands twisted the same direction, either right or left, and causes the finished product to appear with the wires running diagonally to the axis of the rope. The advantage of Lang lay rope is the increased abrasion resistance leading to a longer lifespan, but that comes at the price of flexibility.

During production, wire rope is heavily lubricated, allowing the lubricant to penetrate throughout the entire rope and into the core, which allows for slight movement of the individual wires within the rope to increase the lifespan of the rope as well as to reduce friction of the ropes as they rub against one another. From this point, maintaining proper lubrication is critical in preserving the life and structure of the wire rope and should be addressed with a combination of penetrating and coating lubricants. Penetrating lubricants reach the core and coat each strand of wire by utilizing petroleum solvent that evaporates once it reaches into the core and leaves the lubricants behind. Coating lubricants would then be used to seal the outside of the cable from moisture and reduce wear and corrosion during use.

The Discover television series “How It’s Made?” came out with an episode in 2011 showing the production of wire rope as well as crane cable and would make for an interesting view if you have five minutes available, providing further insight into the intricacies of wire rope and its composition. You can find that video here.

For more information or to rent wire rope slings and accompanying equipment, reach out to Lifting Gear Hire at www.rentlgh.com or call us at 800-878-7305.

A finished wire rope is comprised of individual wires, make up individual strands, which are then laid in a helical pattern around a synthetic or steel core.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope. Selecting the proper wire rope for your application is essential to long-lasting performance in a wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other,

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

Did you know wire ropes were used as far back as the 1830s for mining hoist applications? Nowadays, we can use steel ropes for many different applications such as lifting and hoisting in elevators and cranes, and for mechanical power transmission. US Cargo Control’s wire rope slings are an excellent choice for heavy-duty jobs as their fabrication offers excellent abrasion resistance and heat resistance for extreme conditions.

Although these slings are beneficial for the lifting and rigging industry, there are a few specifications to know before purchasing them. Continue reading what is wire rope, what are important specifications to look for, and how it’s different from cable rope.

These slings carry different properties that can determine their performance. Wire rope is constructed where a strand consists of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Once the wires are formed, they all come together to create greater strength and flexibility.

These slings work well for lifting, hoisting, towing, or anchoring loads. They’re manufactured in a variety of configurations, with 6×19 and 6×36 being the most common. When you see 6×19 or 6×36 from our website, these numbers represent the number of wires making up the strand and the number of strands wrapped around the core.

For example, a 6×19 indicates that there are 19 wires making up a strand, and 6 strands wrapping around the core. To learn more about our 6×19 wire ropes, look into our bestselling 1/2″ Galvanized Wire Rope EIPS IWRC, 1/2″ Stainless Steel Wire Rope IWRC T304, and 1/2″ Bright Wire Rope EIPS FC.

The configurations will offer different benefits for certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance. Continue reading to learn which wire rope fits your job.

There are different versions of wire rope slings, ranging from single leg to 4 legs, as well as braided wire rope and domestic wire rope slings (manufactured in the U.S. with Crosby® hardware). When looking at the types of slings we offer at US Cargo Control, be sure to consider how much versatility and capability you need.

For example, a braided wire rope has increased flexibility and friction to grip loads over a regular wire rope. Adding an additional leg to the sling can add additional versatility and strength.

This is the measurement of the rope’s diameter and can be displayed in inches or millimeters. These sizes commonly display different strand patterns where the number of layers, wires per layer, and size of the wires per layer all affect the strand pattern. Wire rope can be constructed using one of the following patterns below or using two or more patterns.

Warrington – this construction has two layers of wires around a center with one diamter of wire in the inner layer, and two diameteres of wire alternating large and small in the outer layer.

The type of lay refers to the way the wires are laid to form a strand. They’re how the strands are laid around the core which can be regular lay, long lay, or alternate lay.

The wires line up with the axis of the rope. This is where the wires are twisting in one direction, and the strands in the opposite direction create the rope. Regular lay is less likely to untwist and less likely to crush.

This is the opposite of regular lay where the wires form an angle with the axis of the rope. The wires and strands spiral in the same direction and run at a diagonal to the centerline of the rope. Lang lay is more flexible and resistant to abrasion than regular lay wire ropes. The only con is this type of lay will be more likely to twist and crush than the regular lay.

Sometimes known as reverse lay, this type of lay consists of alternating regular lay and long lay strands. This unites the best features of both types, and it’s using relatively large outer wires to provide an increase of abrasion resistance.

This refers to the protective coating that’s applied to the wire rope. There are three types of finishes which are galvanized (zinc-coated), stainless steel, and bright (unfinished steel).

The grade of the rope means the grade of steel being used. The plow steel strength calculates the strengths of most steel wire ropes. Some classifications include Improved Plow Steel (IPS), Extra Improved Plow Steel (EIPS), Extra Extra Improved Plow Steel (EEIPS), Galvanized Improved Plowed Steel (GIPS), and Drawn Galvanized Imrpoved Plow Steel (DGEIP).

EIPS is 15% stronger than IPS, and EEIPS is 10% stronger than EIPS. Along with that, GIPS and DGEIP wires can add corrosion resistance to your application, but DGEIP wires have a higher break load than GIPS.

The type of core is what makes up the center of the wire rope. There are three types of core: Fiber Core (FC), Independent Wire Rope Core (IWRC), and Wire Strand Core (WSC).

A steel core can either be an independent wire rope or individual strand. The steel cores can provide adequate support, or in an operating environment where temperatures can exceed very high heat.

Wire and cable ropes are terms that are often interchangeable but do have one varying difference. Wire rope refers to the diameters that are larger than 3/8 inch. Sizes smaller than this are classified as cable rope or even cords. Regardless of the size difference, cable and wire rope are still classified as a “machine.” Even a group of strands laid around a core would still be called a cable or wire rope.

We have a large inventory of wire rope in our various locations in sizes from 1/4” to 3” diameter and 9 mm to 52 mm diameter in all types and constructions. All wire rope stock is maintained for immediate delivery.

8613371530291

8613371530291