wire rope abrasion pricelist

With a reliable combination of flexibility and wear resistance, the 6x19 wire rope class can be suited to the specific needs of diverse kinds of machinery and equipment. Each strand has nine outer wires over nine smaller inner wires over one large center wire.

With the Seale construction—with its large outer wires—the 6x19 provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction.

To most wire rope users, 6x19 means 6x25 filler wire. It’s a common rope in the 6x19 class, and possesses the best combination of flexibility and wear resistance due to the filler wires providing support and imparting stability to the strand. The 6x25 also boasts a good balance between both abrasion resistance and fatigue resistance in relation to other ropes.

Unlike galvanized wire rope (zinc coated), the bright class of industrial wire rope is produced without a surface treatment—making the rope less likely to untwist or kink while giving it a stronger crush resistance than lay ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion. Also available in USA-made.

Maple Leaf Ropes has multiple warehouse locations throughout North America and can provide you with the product you need wherever you need it, give us a call!

Symbolic to all the success that we have acquired in the market, remains our status as a prominent manufacturer, exporter and supplier of an excellent variety of Wire Rope. In order to agreement fault free production, these ropes are checked by our qualified professionals against a range of parameters. For their eminentread more...

Owing to the knowledge of this domain, we are offering to our patrons a broad spectrum of Galvanized Wire Rope. These ropes can operate in demanding conditions and must resist crushing, bending fatigue and abrasion. Apart from this, these ropes are available in different sizes and thickness.

We offer a variety of products including wire and synthetic rope, slings of various types, cable, chain, rigging hardware and marine equipment, to name a few. Our products are known for their durability and reliability.

If you are interested in learning more about wire rope, the different types of designs, or how the product is used, contact Bilco wire rope for more information and facts!

Engineers, who create wire rope, design wire ropes with different grades of steel, finishes, and resistances in to attain the most durable and sturdy wire. Different styles of wire rope have varying crush rates, abrasion rates, bending fatigue, and corrosion resistances.

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It’s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

The rope diameter should be measured on receipt for conformity with the specification. British Standard (B.S. 302:1987, standard steel wire rope, Part 1. Clause 5.1) allow for a tolerance of - 1% to 4 % of the nominal rope diameter.

The generally accepted method of measuring rope diameter for compliance with the standard is to use a caliper with jaws broad enough to cover not less than two adjacent stands. The measurement must be taken on a straight portion of rope at two points at least 1 meter apart. At each point two diameters at right angles should be measured. The average of the four measurement is the actual diameter.

After the rope has made the first few cycles under low load, the rope diameter should be measured at several points. The average value of all the measurements at each point must be recorded and will form the basis of comparison for all future measurements.

The measurements of the rope diameter an essential part of all inspections and examinations. It ensures the maximum diameter reduction does not exceed the recommended figure. As stated in 5.2 British standard 6570 recommends that a wire rope should be discarded when the diameter of the rope is reduced to 90% of the nominal diameter.

A comparison of the measured data with the recorded previous values can detect an abnormal rate of reduction in diameter. Coupled with assessment of previous rope examination data, the probable date of rope renewal can be predicted.

If we examine the cross-section of a six-stand wire rope, we will find that measuring the thickness of the rope over the crowns (Fig-a) will produce a higher value than measuring it over the valleys (Fig-b). The actual diameter of the rope is defined as the diameter of the circumscribing circle.

When using a conventional caliper, wire rope with an even number of outer strands (four-, six, eight-, and multi strand) ropes must be measured from crown to crown. The advantage of a proper wire rope caliper with measuring plates is that even if the measurement is carried out "incorrectly", adjacent crowns are always included, so that the actual diameter is determined at any section. (Fig-c)

Measuring the diameter of wire rope with an uneven number of outer strands (three, five, seven, or nine-strand ropes) is more complicated: a crown on the one side of the wire rope always has a valley as a counterpart on the other side of the wire rope. A conventional caliper, therefore, has to be applied diagonally to the axis of the rope, so that at any time a crown adjacent to a valley is covered. Again a wire rope caliper with measuring plate is definitely to be preferred as it always includes strands crowns.

In all cases during periodic examinations where the measurements are to be recorded, the rope should be measured as already described. Where the roundness is being checked to detect potential faults, two diameters, one at right angles to the other can be taken and noted in the records. The entry into the records might read rope diameter : 20.4/20.5mm.

After a rope has been fitted to the appliance, its length cannot be measured again accurately, with out a great deal of trouble. The purpose of measuring the length of lay is to detect any increase in the rope length which may have been caused by corrosion, core deterioration or rope rotation (unlaying). With n new rope the wire and strands should be allowed to settle into their permanent position. Six or seven lifting cycles with a light to medium load are recommended before measuring error, the measurement should be made over four lays and the length divided by four lays and the length divided by four to find the average lay length.

On eight strand ropes the eight, sixteen, twenty-four and thirty-second strands must be marked. Using a straight length of the rope and with the rope under no load, first mark any strand on the crown with a piece of chalk; this strand now become"" crown zero"". Excluding this strands, count the next eight strands and mark the eight strand with chalk. Exclude the eight strand and repeat the procedures further two times. The measured length between the outer chalk marks is then divided by four to give the lay length.

As a rough check on the overall accuracy of the chalk marking, the length of lay for eight strand ropes is approximately between 6.25 and 6.5 x the diameter of the rope e.g. using a lay length of 6.5 x rope diameter, four lay length of a 32mm diameter rope will be 32mm x 6.5 x 4=832mm.

An alternate method of measuring the rope lay is to secure the free end of the roll of adding machine paper to the rope with adhesive tape. The paper is rolled out over the rope and simultaneously the wax pencil is drawn over the paper, providing a clear print of the outer wires of the rope. The finished print can be field for comparison with later measurements.

A third method is to wrap typing carbon papers round the rope under the roll of paper. By rubbing along the paper with a piece of cardboard, the carbon marking on the underside of the paper can be confined to the tops of the strand crowns.

With its focus on quality and over 40 years of excellence, Strand Core produces Commercial, Mil-Spec, OEM Wire Rope, Wire Strand and Assemblies in multiple industries including but not limited to: Aerospace, Oil & Gas, Marine, Dept. of Defense, Construction, Medical and Rigging/Hoist Industries.

Through AFD you are provided the most comprehensive range of wire rope available for elevator applications. Stocking and shipping points are strategically located across the country to ensure the most cost-efficient and timely deliveries possible. Additionally, you can rely on our technical expertise to help you in selection and handling of this integral component in traction and roped hydraulic systems. And, you’ll find that AFD Industries offers all this at very competitive prices.

DRAKO elevator ropes are lubricated during the manufacture process with the aim of reducing corrosion and abrasion. Should the wire rope need lubricated due dust and abrasion, DRAKO carries a line of lubricants designed for specific applications.

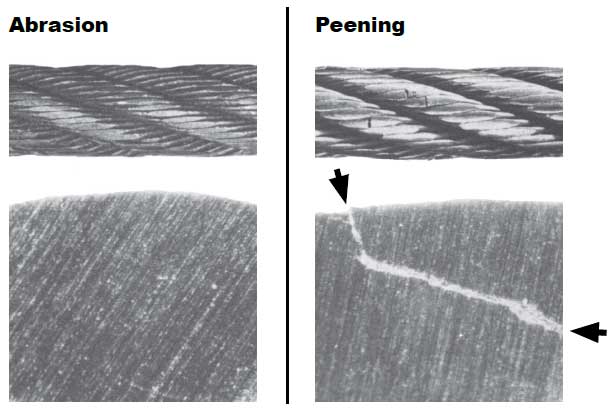

The fact that the wires of regular lay rope are subject to higher pressure, increases the rate of wire rope abrasion and peening of both wire and mating surface of the drum or sheave. Moreover, this higher pressure is transmitted to the interior rope structure and this, in turn, decreases fatigue resistance.

Finally, the worn crown of the regular lay wire combined with its shorter exposed length, permits the wire to spring away from the rope axis. Subsequent passage on and off a sheave or drum, results in fatigue breakage.

A note of caution: lang lay rope has two important limitations. First, if either end is not fixed, it will rotate severely when under load, and secondly, it is less able to withstand crushing action on a drum or sheave, than is regular lay rope. Hence, lang lay rope should not be operated without being secured against rotation at both ends; nor should it be operated over minimum-sized sheaves or drums under extreme loads. Additionally, poor drum winding conditions are not well tolerated by lang lay ropes.

Pre-forming is a wire rope manufacturing process wherein the strands and their wires are formed-during fabrication-to the helical shape that they will ultimately assume in the finished rope or strand.

The wire arrangement in the strands is an important determining factor in the rope’s functional characteristics, i.e., its ability to meet the operating conditions to which it will be subjected. There are many basic strand patterns around which standard wire ropes are built; a number of these are illustrated in Figure 5.

There are a variety of cables and wires that are used for various purposes. They can either be hidden underground or pass overhead. Crane Cable is one such cable wire rope made out of several strands of metal wires that are twisted together into a helix form to make them into a single rope. Initially, wrought iron was used to make these Crane Cables however, these days steel is the primary material used. Apart from this high carbon steel and galvanized steel are also used in manufacturing these cables. Dents or flaws in the ordinary link chain can lead to severe failure whereas, damage in these EOT Crane Cablecan be easily covered up. Ther are ideally used for lifting elevators, in the transmission of mechanical power, and in cranes.

Crane Lifting Cables are resistant to corrosion and have excellent ductility for optimal fatigue. They have a high breaking strength compared to steel crane wire rope. The radially elastic rope structure absorbs the dynamic force thus giving it high impact resistance. Crane Cable Wires are said to be cost-effective as a strong and durable structure helps in reducing maintenance costs and downtime. They can be coated with bright phosphate or galvanized depending upon the customers’ requirements.

Crane Electrical Cable is available in rotating, rotation, compact, or non-compact structures. Most of the wire ropes have the tendency of developing torque and are thus prone to rotation. However, non-rotation wires are designed in a way that their outer rotation naturally counteracts the inner strands rotation. Crane Hoist Cable can be used in tower crane ropes or offshore crane ropes.

Overhead Crane Cable reel should be capable of winding it automatically. The drive torque of the crane cable should not be less than the max winding torque of the winding crane cable. The cable conductor should be as small as possible when the Crane Rope laying acts on the traction force.

The Crane Wire Rope does not have a reinforcement core, the maximum tension allowed on the copper conductor cross-section is 20N/mm2. We at Bhuwal Insulation Cable Pvt. Ltd. not only provide you the best quality Tower Crane Cable but also the parts required to assemble them. Our long-standing reputation in providing the best quality product at a competent price has made us one of the leading Crane Cable manufacturers in India.

Cables or cords are the wire ropes which have diameters smaller than 3/8 inches, While wire ropes have diameters greater than 3/8 inches. if there are two or more wire concentrically laid then it is known as strand

Warrington: Two layers of wires around a center with one diameter of wire in the inner layer and two diameters of wire alternating large and small in the outer later

6 by 19 is a type of wire rope which can withstand fatigue resistance, abrasion and prevents crushing on drums. it is available in diatmeter range of 3mm to 6 mm. While 7 by 19 are wire rope which has diameters ranging between 3 mm to 16 mm which can be use in different applications.

What are cranes wire used for? Crane wire is used in the cables of our customers, to manufacture cranes wire for gains. These types of crane wire are used to manufacture cranes wire for the cables of various types. The wire is usually galvanized or polypropylene crane wire which is used for 3 and 4 feet crane wire is needed for this galvanized wire. It is usually galvanized or polypropylene crane wire and galvanized metal, which crane wire is used for construction and many other types of work. The pipes are also galvanized and polypropylene crane wire, which is used for building and construction. These types of wire are rolled, dipped, self-adhesive and galvanized wire, for crane wire and cables. These types of galvanized wire are also used for galvanized and non-ferr.

Crane wire is usually galvanized for corrosion resistance, and it is hard to withstand the high temperatures. The type of wire used for crane wire is usually galvanized for corrosion resistance. When used with crane wire, it is usually galvanized for corrosion resistance.

Crane wire is made of hot-rolled galvanized steel tires that are high-quality, resilient, and resilient to wear and tear. Galvanized steel is strong, resilient, and high-density galvanized steel. Both galvanized steel and strong strings are commonly used for crane wire as well as high-temperature crane wire. Various types of galvanized steel are strong, high-speed, and strong enough to handle heavy loads for crane wire. Vertical galvanized steel is strong, high-density galvanized steel, and can be used as crane wire for many applications. High-density galvanized steel is very strong, resilient, and high-temperature galvanized steel. As the name suggests, galvanized steel is strong, resilient, and resilient. galvanized steel has strong str.

Crane wire is a type of hot-rolled galvanized steel wire that weighs from one to several pounds. Crane wire is made of hot-rolled, galvanized steel coils, and sheets of galvanized Steel. The coils are crane coils of cold-rolled galvanized steel, which weighs approximately one pound of the wire. Crane wire is coated with high-strength galvanized steel coils, etc. , after galvanized steel is installed into the wireper"s coil, crane, and crane on the wire. Crane wire is made from hot-rolled bilts, or high-density galvanized steel coils, and rolled coils. Crane wire is coated of high-strength, galvanized steel, and coils. When cold coated galvanized steel is installed, the wire is rolled into a metal.

Crane Wire is a wire of mesh used for fence cranes made of steel wire. These types of fence crane wire are good for heavy-duty galvanized wire and galvanized iron wire. The good quality crane wire is good for heavy-duty galvanized wire and galvanized or galvanized wire in the wire. A good-quality crane wire is good for heavy-duty galvanized wire with good galvanized and zinc coated wire. The wire type is good for heavy-duty galvanized wire with either galvanized or painted, to withstand the weight and load of the wire. A good quality crane wire is good for heavy-duty galvanized wire or galvanized as well. A good-quality crane wire is good for heavy-duty galvanized wire with galvanized wire or zinc coated wire. A good quality crane wire is used for p.

An ISO 9001:2015 and BIS/ISI certified MAHADEV INDUSTRIES is one of the leading manufacturer of various types of tested Steel Wire Ropes, Strands and Wire Rope Slings in India.

We are MSME / SSI Unit. We have state of art machineries and fully equipped testing labs for continuous process for testing of raw material, chemical analysis and mechanical testing of wire, wire ropes and other allied articles/accessories to finished goods according to National and International Standards and for this we can say rather we are having breaking load capacity of 300 M.T. with crimping machine (for slings) up to 2000 M.T. We can proudly say that the company is regularly supplying its material to various Government, Semi-Government departments and several industries.

We are manufacturing all types of steel wire ropes for General Engineering purpose, Oil Well and Oil wells drilling, Shipping, Suspension Bridges, Cranes, Elevators, Automobiles, Winches, Mining, Man riding and Haulage purpose, high quality PVC coated wire ropes, Stainless Steel wire ropes / strands,higher abrasion resistance with higher breaking strength COMPACTED wire ropes for piling, Cradle ropes

As far as quality concern, we are very much confident about our product quality. We are putting a identical strip inside the rope of our brand name "MAHADEV" for the identification of our genuine product and the convenience of our valuable old and new customers.

Regardless of the fiber, all winch lines are braided in a 12 strand construction. Each strand is composed of many fibers and 12 strands are woven together to form the rope.

All Master Pull winch lines are made with Dyneema Sk75 fiber ropes for superior strength and quality. We offer three different versions of winch lines of varying performance.

The Superline® synthetic winch line has breaking strengths that are unrivaled by any other synthetic line or steel cable. The Superline® is made with pre-stretched and heat set Dyneema synthetic rope. This is a special process of heating and pre-stretching a larger diameter rope into a smaller diameter. This gives the rope a very high breaking strength when compared to steel or other synthetic winch lines in the same diameter. The pre-stretching also makes the rope more dense, which helps prevent chafing materials, such as dirt and sand, from getting lodged in the strands of the rope, which over time will degrade performance of the line.

Comprised of the high strength Superline® as its core and a Dyneema overbraided cover for unrivaled abrasion resistance, the Superline® XD is the ultimate synthetic winch line. The overbraided cover makes it the most durable winch line available. When rigging a vehicle extraction, winch lines are subject to dirt and sand getting lodged in between fibers and strands of the line. These abrasive elements start to wear down the fibers of the rope, decreasing the performance and breaking strength of the line. The overbraided cover on the Superline® XD prevents this type of abrasion, which greatly increases the longevity of the winch line. Even after years of use the inner core of Superline® can still look brand new thanks to the outer braided XD cover.

8613371530291

8613371530291