wire rope bridge design supplier

Structural wire rope cables have played a major role in the engineering and architecture of many large structures and are widely used on projects involving bridges, vessels, stadiums and glass facade/membrane buildings to name a few. Using steel cables in the design of such projects has proved more cost effective than solely using raw materials such as Iron or concrete and is now very much the preferred choice within the construction and engineering sector.

The starting point for FATZER products is high-tensile steel wire. Fabricated into steel wire ropes, it enables architects, engineers and contractors to create technically sophisticated rope architecture.

FATZER manufacture a wide range of rope diameters, suitable for use on the most complex of projects. The performance parameters of all products are monitored and confirmed by independent test bodies.

It goes without saying that steel wire ropes must meet the highest safety requirements. What sets them apart though, is the way they provide freedom for aesthetically creative design. It is the elegant HYEND series of end connections, in particular, which turns these technical products into true “design objects”.

Spiral strand and fully locked coil ropes are manufactured in Switzerland in FATZER"s own factory. This covers the whole process including stranding, pre-stretching, marking and in some cases socketing. Handling customised product solutions is a challenge we tackle on a daily basis. In all cases rope assemblies arrive on site ready for installation.

All materials are fully certified and has full traceability in line with our ISO9001 procedures. The most common constructions of wire rope used for structural purposes are: Spiral strand ropes and fully locked coil rope (EN 1993-1-11:2006). All ropes are available with HYEND fittings to guarantee the best quality and safety standard (EN 13411-4).

SWR have the capacity to design and manufacture these assemblies, and can provide structural advice on load ratings and fixing terminals should this be required. Both galvanised and stainless steel can be used depending on the location and specification of the project.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

Bethlehem Structural Strand is an arrangement of wires laid helically around a center wire to produce a symmetrical cross section. Structural strand is used as a load-carrying tension member where great flexibility and bending are not major requirements. For any given diameter, wire strand is the least flexible of steel cables. Structural strand provides a high strength-to-weight ratio, a high modulus of elasticity and a small diameter-per-unit strength. These are the features that permit strand to adapt so successfully to structural applications. WW manufactures Bethlehem Structural Strand to meet ASTM Specification A586, and we have the capability to manufacture strand as large as 5-1/2"diameter. Refer to Table 1 for structural strand data.

Bethlehem Structural Wire Rope consists of six strands made from zinc-coated wire with strands laid helically around a core, such as another strand or smaller wire rope. Structural wire rope provides greater flexibility when compared with coarse strand constructions and is generally the structural cable of choice where bending ability is an important requirement, such as forming flemish eye ends (drop terminals). WW manufactures Bethlehem Structural Wire Rope to meet ASTM Specification A603, and has the capability to manufacture wire rope as large as 7"diameter. Refer to Table 2 for Bethlehem Structural Wire Rope data.

Wirerope Works, Inc. offers SS-265™, a high strength structural strand designed specifically for use in tower applications. Compared with standard structural strand, SS-265 offers an increase in minimum breaking force of 15% above the values for strand manufactured to specification ASTM-A586. Using SS-265 also offers these advantages:

Reduced Structural Strand Diameter—Now that designers can utilize a smaller diameter strand for the guying system, SS-265 offers a lower cost per foot, allowing the user to cut valuable dollars from the cost of a project.

For users who opt to use SS-265 without downsizing the diameter of the strand, other benefits apply. For example, using a 2-inch diameter as an example, the minimum breaking force increases from 245 tons to SS-265’s 282 tons. The higher strength results in an increased design factor of the guying system. SS-265 also may be used in other applications where structural strand manufactured to ASTM-A586 is utilized. Please contact your WW regional sales manager or customer service representative for further information.

To ensure quality of all Bethlehem Wire Rope and Strand products, WW utilizes Statistical Process Controls (SPC). In doing so, we are able to test and certify the following:

Manufacturer of structural steel fabrications. Specializes in structural steel fabrications and weldments for buildings, bridges, and other infrastructure projects. Also provides steel framing members for athletic, museum and educational facilities, crane girders for industrial facilities, plate girders for train stations and power plants, and box beams for an airport expansion. In-house blasting and paint finishing operations can be provided. Also provides value-added engineering, structural steel erection, and shipping services. Serves the construction industry.

PFEIFER Structures designs, engineers, and installs cables, wire ropes, and other tension members as components of some of the most iconic suspension bridge structures in the world. Suspension bridges are long-span bridges capable of connecting roadways or walkways over large bodies of water such as rivers and bays. Suspension bridges are differentiated from other bridge structures by how the cables connect to the towers or pillars. A cable(s) will connect to the towers or pillars, and then to the ground, bearing the load of the structure. Cables and tension rod systems will then connect from the load-bearing cable(s) to the bridge. A suspension bridge can function as a pedestrian bridge or footbridge, a very efficient lightweight structure that allows pedestrians to cross potentially dangerous areas such as highways, rivers, and ravines.

Built in a fraction of the time and at around half the cost of conventional construction, our precision-engineered lightweight structures give architects, city planners, and developers a great alternative to traditional, heavy, and time-consuming methods of bridge construction. There are shapes, forms, and solutions we can create with lightweight architecture that cannot be replicated with any other method of construction, for example – a curved bridge deck.

In addition, the advanced membrane and cable materials can be used for covered walkway canopies to provide protection from the elements for pedestrians or to bring an architectural flair to any bridge.

Cable bridge structures are low maintenance, very economical, quick to install, provide long service life, and are sustainable. Our tension members are also used as part of a structural system of large suspension bridges offering superior material properties and exceptional performance over a long life span.

Contact us to get more information about our suspension bridge structures or to get a free consultation with the most experienced designers and engineers in the lightweight structure industry. Fill out the contact form on this page or call us toll-free at 1-877-887-4233.

Find metal structure from experienced Chinese manufacturers at an affordable price. Select suspension bridges from available designs or present your design and the suppliers make it for you. Metal structures are suitable for factory buildings, warehouses, garages, workshops, stores, and industrial buildings. A steel structure consists of columns and beams for supporting the roof and the walls. These columns are made of angle steel, steel pipe, or hot rolled H beam. They provide support to purlins used to support the roof. Walls and roofs are made of either single-layer corrugated steel sheets or sandwich panels. Sandwich panels consist of many layers, making them ideal for heat and sound insulation. Doors are either sliding or rolling made of sandwich panels or metal. The windows are made of plastic steel, PVC, or aluminum alloy.

Roofing style can be flat, single slope, arch, and so on, depending on the size and design of the structure. Metal structures are equipped with gutters and downpipe for rainwater collection. They also come with natural ventilation as well as air supply systems. The steel is galvanized or painted to protect it from rust. Most manufacturers use fire-resistant material to construct the whole structure. Unlike other kinds of structures, suspension bridges can withstand most natural hazards. You can find suspension bridges with earthquake-proof of grade 9, and capable of resisting winds of up to 180km/h.

suspension bridges are made in the factory, then transported to the customer’s site where they’re then assembled. You can choose from many designs and colors. You can even get customized suspension bridges to fit your required size and the environmental conditions of your location. Shop from Alibaba.com and select suspension bridges from many available options. Enjoy lower prices when you buy from Chinese wholesalers.

Longer span Rope Bridges can be anchored across rivers, lakes and even canyons. Perfect for going tree-to-tree in woodlands, for Tree-Top Walkways and for adding that extra air of excitement in gardens, woodlands, resorts and adventure parks.

Short span Rope Bridges are perfect for treehouses and the ideal go-between when adding platforms or play ‘islands’. Adds real adventure and fantasy plus a playful connection to our whole world of play.

Our Log Rope Bridges are a perfect solution where a treehouse adventure starts from the lawn or woodland floor, leading upwards to a treehouse or platform. Our Log Rope Bridges make an awesome treehouse or platform entrance.

Suspended Rope Bridges can offer a perfect solution when looking to cross over large areas, such as rivers, lakes, ponds and even canyons. They also provide an exciting and flexible design option in Adventure Parks.

We work from anchor points established at each end, using either a zero-impact certified and proprietary ground buried anchor system or suitable ground buried concrete ‘pads’ with integrated structural anchor plates, that are designed and fabricated at our workshop. Typically, if suitable trees are available, we can ‘anchor’ to trees at each end of the Rope Bridge using tree-friendly webbing slings or rope soft-shackles.

In every project, the anchor points can always run longer than the actual Rope Bridge span, allowing us to also integrate ground-based deck platforms (with balustrades if necessary) at each end. This not only creates a truly impressive looking ‘start’ and ‘finish’ to the Rope Bridge, it also helps us to negotiate the height of the Rope Bridge above water, should there be any relevant issues with flood forecasts.

The most common lengths of Rope Bridges we have installed has been anywhere from 5m up to 45m. But if you’re thinking of something on a grander scale, that’s not a problem at all.

We have designed and installed 45m long Rope Bridges that span across rivers and canyons, and on one project, even installed a Rope Bridge directly into granite boulders when the availability of ground anchors or nearby trees was not an option. Whatever your wish our teams at Treehouse Life will always look for a way to make it work.

As ever, with Rope Bridge design and build, the key to structural integrity and design success is very much down to the lay of the land at the proposed location. While we can initially work from location photos to advise and consult regarding your Rope Bridge options, we do offer an on-site visit consultancy so that we can to discuss all opportunities.

Structurally, suspended Rope Bridges work from anchor-to-anchor using structural steel cables or ropes with all elements suspended inbound on the structural lines, including the round timber uprights at each end that are required for the rope-work balustrades.

This is what we call a ‘floating Rope Bridge’ solution, which allows us to work with our own Rope Bridge system in many unique and incredible locations both throughout the UK and around the world.

Our fixed-beam Rope Bridges are a perfect design solution to reach a treehouse or link up multiple platforms or decks. The purpose of the integrated fixed-beam is simply to hold the two ends apart; it typically sits at half-height within the rope balustrades, but can also sit lower or even closer to the upper ‘hand-rail‘.

On this particular Rope Bridge design and installation solution, because the ‘stress-and-strain‘ between the two fixed points is taken up by the fixed-beam, we support the timber walkway treads underneath with ropes that are fixed at each end to a round timber beam.

Structurally perfect and beautiful in design, Fixed-Beam Rope Bridges for treehouses, platforms and decks can add a whole other dimension of fantasy and imaginative play.

With the bridge always sitting level end-to-end, it is possible for us to increase (or decrease) the overall height by installing an additional step up and/or down at either end (usually 300mm).

Although this is a fully integrated Rope Bridge design and installation, there is however a limit to the distance the bridge can actually cover. This is determined by the length of the actual fixed- beams we use; a 3m span or less works perfectly, although there are some other excellent options if a span of up to 6m long is required.

Overall, the structural integrity is always going to be heavily dependent upon what is available at each end of the bridge – so our advice (based on years of experience) would always be for a Rope Bridge to be integral to an overall design rather than being an add-on after everything else has been built.

Include some Climbing Walls, Zip Wires and Fireman’s Poles as part of your child’s treehouse world and you will create the ultimate adventure and fantasy land and a playful connection to a whole world of possibilities – the perfect setup for every family back garden or school playground.

Our Log Rope Bridges are a perfect solution for every magical journey, starting each new treehouse adventure right from the middle of the lawn or woodland floor, and leading it all the way upwards to a treehouse or platform.

What better entrance could there be, than feeling those butterflies of excitement and the rush of make-believe from the moment you place your foot on that very first log and then cross the Rope Bridge into a faraway kingdom or land.

When incorporating a change in height into our designs, using flat Rope Bridge ‘slats’ simply wouldn’t do the job; too much of a gradient and the bridge would literally turn into a slide! The answer is in the use of round timber logs set inbound on ropes or steel cables, providing the intrepid climber with suitable ‘steps’ whilst they hold onto the rope balustrades.

Typically, with Rope Bridges up to approximately 4.8m in length (which is ideal for a Rope Bridge entrance), we integrate a fixed-beam into the Rope Bridge to hold the two ends apart.

The route up and into a treehouse needs to be exciting and imaginative and very much a part of the play journey itself and this is where the magic begins. Log Rope Bridges offer that perfect – not to mention most adventurous – entrance to any garden or backyard treehouse play-set or platform decks.

A selection of Treetop Walkway Bridges by Treehouse Life. These stunning bridges act as large hammocks, perfect for woodland relaxation and fun. Immense enjoyment and excitement for adventurers of all ages. Wonderful adventure play equipment by Treehouse Life.

A professional Rope Bridge built to a high standard. With beautiful materials and quality construction, this bridge is both functional and fun. Spanning across an impressive river this is something to behold.

Incredible suspended tree canopy platform. The perfect way to view the surrounding woodland from a high vantage point. Use the treetop walkway bridges to reach the wooden deck and look out to see birds and wildlife. Built within an RSPB nature reserve you can spot, bats, rare birds and other woodland creatures.

Treetop Walkways by Treehouse Life are able to find new pathways up high in the tree canopy. View nature from the branches within touching distance of leaves and wildlife alike. Safe, functional and exciting these bridges are a magical way to enjoy time in the woods.

An amazing project, a Rope Bridge over a woodland river. An exciting way to introduce new and creative pathways through your own garden. Reach new ground with ease in an adventurous way. A brilliant addition to a family home.

Log Rope Bridge treehouse entrance from the garden lawn, creating magic, adventure and fantasy. A stunning treehouse and Log Rope Bridge for a garden project in Lancashire, The Old Vicarage. From a treehouse platform, with rope balustrades both sides and round pressure treated timber logs as ‘steps’.

Rope Bridges with a ‘fixed-beam’ structure from treehouses leading to decks and platforms. Perfect for bridging level platforms, decks or treehouses – Fixed-Beam Rope Bridges have an end-to-end ‘beam’ through the rope balustrades.

Amazing aerial adventure park, built in surrounding woodlands and nature. With Treetop Walkway bridges, Rope Ladders, Zip Wires and Tree Swings this play area hosts a wealth of exciting play equipment.

Natural, ‘secret’ and magical – discover a Log Rope Bridge entrance to a beautiful woodland treehouse. Hidden within a private client’s woodland with a ‘secret‘ Log Rope Bridge entrance weaved within the trees with lots of Adventure, Make-Believe, Fun and Fantasy.

Great photos of Treehouses fitted with Treetop Walkway Rope Bridges. The best way to experience nature up high in the canopy. Get a sense of adventure and exploration using these safe and exciting rope bridges.

A stunning collection of professional Rope Bridges accompanied with 4-sided rope ladders. An incredible way to walk around the tree canopy in a safe and exciting way. Brilliant for adding new pathways high in the tree canopy close to nature and wildlife. The hanging V-shaped Hammock Bridges are wonderful for relaxing and laying down in as well as a ton of fun.

Awesome Rope Bridge addition for a woodland treehouse project. A beautiful construction that spans across a river, for extra excitement. Beautiful wooden Rope Bridge made of pinewood and natural hemp rope

A superb gallery showcasing some stunning rope bridges and treetop walkways for an Oxford treehouse project. Nestled in a wonderful woodland this adventure play treehouse hosts many different play options and encourages hours of fun in the great outdoors.

A beautiful woodland walkway bridge built within some palm trees in Marbella. A fantastic project creating some adventure play equipment for an exciting treehouse project. Exhibiting Treetop Walkway bridges, Rope Ladders and a Treehouse with Rope Bridges, Slide and Climbing Walls this project offers many different play options.

“Treehouse Life Ltd created a stunning Treehouse and Rope Bridge for our garden project in Lancashire, The Old Vicarage. The structure is a timeless addition to the garden and is loved by the family. As a garden feature, a destination and a source of play it is just perfect. We have had many enquiries and admiring comments regarding the Treehouse, in fact it features in some of our most popular photos on Houzz. The project was a finalist at the Northern Design Awards in 2015. We would highly recommend Paul and his team to any client and hope very much to join forces in the near future.”

"We hired Paul and his team to build a Rope Bridge in the Seychelles on the site of a Spa we are constructing for a 5 star resort. We are very pleased with the efficient quality service and we were provided with and the end result looks fantastic."

“I would highly recommend Treehouse Life. Their design for a play area for my children was well thought out and fitted perfectly into the space we had. They were quick to install and the quality of the materials and the overall build is exceptional. My children love playing there, so in short it was well worth it.”

OVM is now a leading product supplier and specialist contractor in China in the field of prestressing and other special construction techniques. With a strong reputation for reliability, professionalism and innovation, OVM Systems have successfully worked on numerous projects, including bridges, buildings, tunnels, harbours, dams and nuclear power plants, and in doing so have achieved worldwide acknowledgement

Rope Bridge Kits are intended to create a suspended passageway between two or more tree platforms, but can also be used to span rivers and other obstacles. Each kit includes everything you need to build the bridge except the walking surface. Step by step instructions are included. Sometimes engineers specify extra cable kits, so we offer those as well. Scroll down for more information.

Bekaert has a long track record in providing wire, strand and cable solutions for a wide range engineering structures. Our super high tensile wire has a particular strong track record in deep water mooringapplications as well as for cable stayed bridges such as:

Manufacturer of a wide range of products which include Wire Rope Suspension Bridge, Wire Rope Suspension Bridges Design Service and Suspension Bridge.

Our company producesWire Rope Suspension Bridge made from high quality raw material. These bridges have a roadway that is suspended from cables anchored at either end and generally supported by towers at fixed intervals. Our bridges are appreciated by clients for their durability, sturdy construction, long applicability and cost effectiveness.

Design and consultancy for structures and bridges , we are ISO certified company for providing design and consultancy for various structures like dams , dam gates , steel structures , steel arch and suspension bridges , towers , tanks and vessels , RCC bridges , bridges bearings and hinges ,We have a team of design engineers comprising of very Sr. level retired government officers who were involved in design of huge government structures to very young and efficient engineers ,Our designed structures are vetted by most recognised central government agency like CWC , New Delhi to IIT , Delhi and various reputed state engineering colleges ,Any new assignment for design and consultancy , we consider as challenge and take up with great enthusiasm ,Also we provided very efficient agencies to take up work on contract basis and to complete under our technical supervision

We are one of the reliable manufacturers of Suspension Bridge, which is defined as a bridge where cables are strung across the river or stream and the deck is suspended from these cables. These precision engineered bridges are high in performance and durable. These bridges are easy to install and are customized as per the clients’ needs.

Established in the year1992, we, Apicon Real Infra Pvt. Ltd. (M/s Aquatic Pumps Industries) an ISO 9001 : 2015 certified company engaged in fabrication & installation of suspension bridge, wireless tower, industrial pressure vessels, storage tanks, industrial storage tanks, mobile storage tanks & tankers, dam/canal gates and a host of other metal fabricated products. Since our establishment, we are excelling towards becoming global suppliers of our range of products & services. From designing & engineering to installation and post sales services, we endeavor to exceed our client"s expectations by offering them customized services. We constantly upgrade our infrastructure so as to fabricate superior quality product at most competitive prices. We export our products in all over the world.

Earlier, our company was engaged in offering submersible pumps but since 1992 we are exclusively involved in fabrication work. As a committed manufacturer, we ensure that all our fabrications are manufactured with accuracy and complete attention is laid to every minute detail/ specifications that is required to be incorporated. Competent technical teams with wide industry expertise back all our operations. They support us to design, develop & deliver according to client"s specifications. Our rich exposure to various types of clients (from diverse segments/ industries) has always been a guiding factor and this steers us towards measures success.

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Manufacturer of a wide range of products which include wire rope suspension bridge, wire rope suspension bridges design service and suspension bridge.

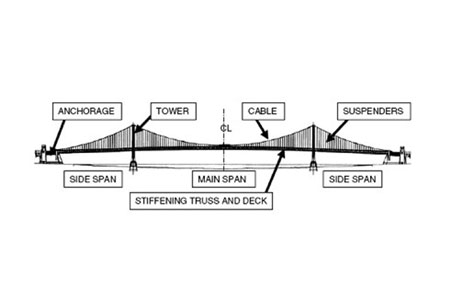

Suspension bridges are a type of structure where the deck is hung below a series of suspension cables that are on vertical suspenders. The first modern examples of this design began to appear in the early 19th century. Simple bridges without the suspenders have been in place in the mountainous regions of the world for many centuries.

Suspension bridges have cables that suspend between its towers to help carry the weight of the deck with its vertical suspenders. This design allows for the deck to arc upward for additional clearance or to sit level. Many of them built without falsework.

For the suspension design to work, there must be cables anchored to each end of the structure. Any load applied to the bridge transforms into tension that the main cables must support. That’s why they continue beyond the pillars to the supports at the deck, and then continue into the ground anchors to provide enough support.

Suspension bridges are relatively economical to build in the sense that only a minimum amount of supplies is needed to create the structure. You only need the anchors to support the construction, cables that support the deck, and then the pathway for pedestrians or vehicles.

This structure can prove to be a comprehensive solution for communities looking to build a functional bridge without plenty of funds, primarily because wood and rope are just as useful as steel or iron for its construction. Despite the lack of funds, a suspension bridge can still look visually appealing and thoroughly operative from a practical viewpoint.

China has built half of the 10 longest suspension bridges currently operational in the world today. The current record holder is the Akashi-Kaikyo Bridge in Japan for a suspension standpoint, with a central span that measures almost 2,000 meters. The six lanes of combined traffic that it supports offer a combined length of almost 4,000 meters. It took ten years to complete the construction, supporting Honshu and Shikoku by highway and rail. It can withstand an 8.5-magnitude earthquake or wind speeds of up to 286 kilometers per hour.

The Xihoumen Bridge connects Cezi Island with Jintang Island in China, providing a main span of 1,650 meters. The four expressway lanes measure a total of 5,300 meters, built from 2004 to 2009 as part of a long-term infrastructure improvement plan. This design is effective for long spans because the support mechanisms remain the same.

Once the construction of the suspension bridge is complete, there are relatively few materials required to maintain its upkeep. Most communities can get by with routine checks of the hardware and structural components, a layer of paint every so often, and some deck repair. There are fewer needs for major overhauls because there aren’t as many moving components with this design. That means the ongoing expenses for the span are less, so you can save money establishing the bridge and while taking care of it.

The undulating shapes of the standard suspension bridge make it an aesthetically pleasing experience. The linear features and curved shapes help communities to design a landmark that can draw tourism dollars to the region. Iconic bridges like the Golden Gate, Tower, or Brooklyn all bring people to the structure because they want to see it. Suspension bridges already provide a familiar shape and user confidence with their design, encouraging all of them to become famous in their own way.

Except for the installation of the first temporary cables during the construction of the bridge, there is very little access required from below to finalize this structure. That makes it possible to leave a waterway open while the bridge is under construction since almost all of the work occurs on top of the bridge. This advantage also makes the cost of labor less than it is for other designs, allowing for a lower overall installation cost.

Even when ongoing maintenance becomes necessary with a suspension bridge, this advantage still applies. Unless there are pipes, cables, or additional items outfitted to the span for some reason, there is no need to service it from below.

When installing a new suspension bridge over a span of any size, the deck can be built so that it can have sections of it replaced. This advantage allows a community to expand the section to widen the lanes of traffic or add pedestrian-specific areas for travel. You can also make adjustments to the amount of weight that the bridge can support over time. That means the structure can evolve with the area so that it can continue to offer a useful deck for whatever traffic needs to cross.

You don’t need as many anchorages with a suspension bridge when comparing it to non-suspension options. There are fewer anchors necessary as part of the overall design, which means you don’t need as many cables to support the deck. If a community decides to go with a cable-stayed design, then a single tower may be enough to complete the entire foundational process. This advantage makes it possible to reduce the amount of time it takes to take the bridge from concept to reality.

When building a suspension bridge, there are different deck structure types that engineers can use to complete the structure. Most of them use an open truss structure after discovering the issues with plate girders after the collapse of the Tacoma Narrows Bridge in 1940. That deck option twisted and vibrated violently at wind speeds of only 40 miles per hour. There are sharp entry edges and sloping under-girders that are also useful in some designs.

Engineers can opt for suspender cable terminations. These are created by inserting a suspender wire rope into the narrow end of a cone-shaped cavity orientated into a line where strain on the bridge exists. There are different cable types too, such as chain, linked bars, or multiple strands of wire. The latter adds strength and improves the reliability of the span since a flawed strand won’t have the same impact as a broken link.

When engineers decide that an underspanned suspension bridge is useful for an installation point, then the primary cables hang entirely below the deck of the structure. They are still anchored into the ground in a manner similar to the conventional design. Only a few bridges of this style have ever been built since the deck is much less stable when suspended below the cables. The Micklewood Bridge is one of the best-known examples of this design, and it may have been the first of its type. It was 103 feet in length, had heavy cross braces, and the main cables were chains.

The only remaining underspanned bridge in the United States currently in use is the Kellams Bridge. It spans the Delaware River between Hankins, NY and Stalker, Pennsylvania. It recently underwent a $4.5 million renovation project.

The goal of a suspension bridge is to continually transfer the tension and weight of traffic as it moves along the span. All of the cables work together to make this happen, but there is an upper weight tolerance that one must consider. If the focused weight of a heavy object crossing the span were to be greater than the weight limit of a single cable, then the entire structure would be at risk of collapse. That’s why you do not usually see this design in place when significant rail traffic needs support.

All bridges have a risk of failure when extreme stresses impact the structure. Suspension bridges tend to struggle with this issue more readily because the deck “floats” with the use of the anchors and cables. Since each point has limitations that must be taken under consideration, a combination of vertical pressures and side wind speeds can lead to a failure of the span. This disadvantage causes them to not remain sturdy under high wind conditions unless reinforcements are built into the structure.

When there is a stiff breeze that comes across the face of a rigid suspension bridge, then the forces acting on the structure can cause the deck to begin vibrating. Most of the spans in use today require aerodynamic profiling or added stiffness to its design so that this outcome does not occur. This disadvantage can be cumbersome in some situations since the added weight or extra components may not be fully supported by the installation point.

Suspension bridges try to limit the amount of time that workers spend underneath the deck because access points can be challenging. This issue cannot be entirely removed from the construction plan, even with cable-stayed bridges, because of the need to support the overall structure. That means a backup plan is necessary for waterways so that traffic can get through accordingly. Most of the work involves lifting the deck units and the initial cables, but there can be other requirements to manage as well.

The typical suspension bridge design offers a relatively low deck stiffness compared to other spans that don’t use this engineering concept. That makes it virtually impossible for the span to carry heavy rail traffic when highly concentrated live loads occur frequently. Reinforced designs can minimize this disadvantage to a certain extent, but the design will rarely have a chance to compete with non-suspension options. That’s the reason why you usually see the suspension designed used for vehicular traffic, cycling, or pedestrian needs and not on railroad crossings.

If the suspension bridge needs to be built in an area that has a lot of soft ground, then engineers must spend a considerable amount of time working on the foundation of the structure. Extensive reinforcement of the tower anchors is necessary because the weight of the bridge would force it to begin sinking into the ground over time. Every heavy load that the span would support would force it deeper into the earth. Even when this work takes place, there is no guarantee that the result will be successful.

The Kutai Kartanegara Bridge in Indonesia suffered a catastrophic collapse in 2011. There were 20 people killed and 40 injured, along with 19 people listed as being missing. The deck of the structure was completely destroyed. Two bridge pillars were standing at the time of the collapse. The reason for the incident was human error. The structure collapsed when workers were repairing a cable.

Only one support cable snapped to cause the suspension bridge to suffer a catastrophic failure. That’s why continuous maintenance and inspection must occur, along with the support of experienced engineers and laborers who can support the health of the span. Almost every recorded collapse of a suspension bridge has been due to overloading in some way.

Suspension bridges are one of the more affordable span options that communities can build to support transportation networks. It is also more expensive to install them when compared to some of the other options. When a suspension bridge fails for some reason, it is usually replaced with an arch bridge because of the effectiveness of the design and its overall tensile strength when combined with the final cost in comparison.

Humans have constructed suspension bridges since the beginnings of our history. The earliest versions of this technology were a simple rope span that was slung from one end of a canyon to the other. Then the deck was either at the same level or slightly below the ropes to facilitate pedestrian movement.

Thangtong Gyalop began using iron chains to build simple suspension bridges in eastern Bhutan during the 15th century. This effort was so strong that the final one, located in Duksum on the route to Trashiyangtse, didn’t wash away until 2004.

When looking at the advantages and disadvantages of suspension bridges, it is clear to see that there are some weak points in the design to consider. When engineers can create an effective design that counters these problems, then the potential of this span is pretty amazing. If that outcome is not possible, then there is a significant risk of collapse that must be taken under consideration.

RMD9629B–Brooklyn Suspension Bridge, New York: Putting wire wrapping around the suspension cables, each of which was made up of more than 5,000 separate strands. Wood engraving published 1883, the year the bridge opened. Designed and built by JA Roebling and his son WA Roebling.

RMPYB63E–Sappers suspension bridge over the River Conwy built in 1930 and a prominent landmark in the village of Betws-y-Coed in North Wales. In Black and Whit

RMG15CXC–John Augustus Roebling (June 12, 1806 - July 22, 1869) was a German-born American civil engineer. He designed and built wire rope suspension bridges, in particular the Brooklyn Bridge, which has been designated as a National Historic Landmark and a Nation

RMHTMKAK–Brooklyn Suspension Bridge, New York, designed and built by John Augustus Roebling (1806-1869) and his son Washington Augustus Roebling (1837-1926). Opened 1883. Top: Laying cable. Bottom: Bridge during construction. From Park Benjamin Appleton"s Cyclopae

RM2HTY4KD–East River Bridge, Brooklyn, bridge, connection, traffic, sight, houses, sun, harbour, wire ropes, river, sailboats, steamer, smoke, New York

RM2HHTG59–Army Engineers: Some of the first pictures taken of R.F"s in night battle course training when picked men were used to cross a wire cable "bridge" to capture the bank of the river in actual battle conditions when flash bombs, gun cotton, was used by "enemy," during Western Command exercises at training School. November 1942 P014911

RM2AN0J9A–Scientific American Volume 47 Number 18 (October 1882) . RESIDENT. MANUFACTUREltS OF WIRE ROPE, BRIDGE CABLES, SHIP RIGGING, Tramway Ropes, Champion Barbed Wire, etc. Office and Works; Send for Office and Warehouse:

RFR1H0DA–Old suspension footbridge covered with wooden planks in the village of Debnevo, Stara Planina mountain, Bulgaria. Black and white picture, nice perspe

RMD96283–Brooklyn Suspension Bridge, New York, opened 1883: EF Farrington, master mechanic, testing the first span of wire cables. Bridge Designed and built by JA Roebling and his son WA Roebling. Wood engraving c1900.

RFTBNTXX–Bridge, suspension, rope icon vector image.Can also be used for building and landmarks . Suitable for mobile apps, web apps and print media. eps10

RM2ABWT7X–Letters on Geology and other Subjects. FAMILY MAGAZINE DEMOREST"S MONTHLY ROUND WOOD BOXES mcrtket - SMiTHviltE.suS.CO.N.J v BEATTY"S Machine Company DRIVE DIRECT with HOUSE ENGINE RUBBER BACK SQUARE PACKING. MANUFACTURERS OF WIRE ROPE BRIDGE CABLES SHIP RIGGING GEORGE WESTINGHOUSE JR. RALPH The Westinghouse Will make Special Contracts Speed Machinery t THE WESTING VAN DUZEN"S PATENT LOOSE PULLEY OILER., scientific american, 1882-11-25

RFTT0XY1–New York - April 4, 2008: The Brooklyn Bridge showing span and cables with Arches in distance as well as pedestrians in distance Black and white.

RM2AN0GB6–Scientific American Volume 47 Number 18 (October 1882) . RESIDENT. MANUFACTUREltS OF WIRE ROPE, BRIDGE CABLES, SHIP RIGGING, Tramway Ropes, Champion Barbed Wire, etc. Office and Works; Send for Office and Warehouse:. IRON REVOLVERS, PERFECTLY BALANCEb, Has Fewer Farts than any other Blower.P. H. &, F. M. ROOTS, Manufacturers, CONNERSVILLE, IND.B. B. TOWNSEND, Gen. Aet.,60ortlandSt.,8 Dey St.,COOKE & CO., Selllnis. Agts., 6 Cortland Street,J&S. BEQQS & CO., Selllner Aerts. 8 Dey Street, PB-B-vv -iroxt.3£.. SEND FOR PRICED CATALOGUE. VERTICAL ENGINES ? THE BEST IN THE M4RKET ?; AT REASONABLE P

RMMXYC1H–U.S. Marines with the Combat Camera section, Marine Corps Combat Service Support Schools, crawl under a barbed wire obstacle while conducting an obstacle course on Camp Johnson, N.C., December 12, 2016. The Combat Camera Marines ran through multiple obstacle courses as part of section physical training in order to maintain a state of constant readiness and strengthen unit cohesion. (U.S. Marine Corps photo by Cpl. Andrew Kuppers)

RMD96297–Brooklyn Suspension Bridge, New York: EF Farrington, master mechanic on the bridge, testing the first span of wire cables. Wood engraving published 1883, the year the bridge opened. Designed and built by JA Roebling and his son WA Roebling.

RMRB77J5–U.S. Marines with the Combat Camera section, Marine Corps Combat Service Support Schools, crawl under a barbed wire obstacle while conducting an obstacle course on Camp Johnson, N.C., December 12, 2016. The Combat Camera Marines ran through multiple obstacle courses as part of section physical training in order to maintain a state of constant readiness and strengthen unit cohesion.

RM2ABWRKC–COPELAND & BACON Agents New York. NEW YORK BELTING AND PACKING COMP"Y. The Oldest and Largest Manufacturers of the Original EMERY WHEELS. „JOHN CHEEVER Treas. 19 PARK ROW NE YORK. Stemwinding Permutation Locks art MANUFACTURERS OF WIRE ROPE BRIDGE CABLES SHIP RIGGING Tramway Ropes Champion Barbed Wire etc. $72 $5 to $20 W. C3 Sal ITINTM IRON REVOLVERS PERFECTLY BALANCED CONNERSVILLE IND. INFEANT "nal RIK SEND FOR PRICED CATALOGUE. SPEAKING TELEPHONES. AMERICAN BELL TELEPHONE COMPANY( DEAN BROS" STEAM PUMP WORKS Boller Feeders Fire Pumps Pumping Machinery, scientific american, 1882-06-17

RM2CHWBRH–. Scientific American Volume 47 Number 17 (October 1882) . Bds, and a knife that will pleasett. Blades are oil temper andwill replace free any soft or1 3 as shown in cut sent postpaidvith the two large blades, 75c.;li one large and small blade, 50c.;jxtra heavy two-blade knife, 75c.; Gents three-blade, $1. Discount to clubs. 40-pape list free. Also -How to Use a Kazor. MAHER & GROSH, 40 Monroe Street, TOLfUDO, OHIO. IRESIDENT. MANPFACTtlRERS OF WIRE ROPE, BRIDGE CABLES, SHIP RIGGING, Tramway Ropes, Champion Barbed Wire, etc. Office and Works:WILKESBABRE, PA. Office and Warehouse; 87 LIlSERIf

RMMXYC1A–U.S. Marine Corps Lance Cpl. Samuel Roque, a production specialist with the Combat Camera section, Marine Corps Combat Service Support Schools, struggles through a barbed wire obstacle while conducting an obstacle course on Camp Johnson, N.C., December 12, 2016. The Combat Camera Marines ran through multiple obstacle courses as part of section physical training in order to maintain a state of constant readiness and strengthen unit cohesion. (U.S. Marine Corps photo by Cpl. Andrew Kuppers)

RMD962A2–Brooklyn Suspension Bridge, New York: Designed and built by JA Roebling and his son WA Roebling, opened 1883. Wood engraving from "Scientific American", New York, 14 July 1883.

RMRB77J4–U.S. Marine Corps Lance Cpl. Samuel Roque, a production specialist with the Combat Camera section, Marine Corps Combat Service Support Schools, struggles through a barbed wire obstacle while conducting an obstacle course on Camp Johnson, N.C., December 12, 2016. The Combat Camera Marines ran through multiple obstacle courses as part of section physical training in order to maintain a state of constant readiness and strengthen unit cohesion.

RM2ABWT8J–MANUFACTURERS OF WIRE ROPE BRIDGE CABLES SHIP RIGGING COLUMBIA Bicycles. THE POPE F"G CO 597Washington Street Boston Mass. THETHE BEST WATCH CASE DUE BER The" MONITOR." Steel Castings JOHN HOLLAND 1 9 W. 4th St. Cincinnati 0. STEAM PUMPS BOILER FEEDERS. - Address HAMILTON. OHIO. EVAPORATING: FRUIT UPRIGHT DRILLSsp"Eicciput4 H.BICKFORD. THE SEIBERT CYLINDER OIL CUP CO. tives Marine and Sta Sight Feed. THE SEIBERT CYLINDER OIL CUP CO. NATDir FL Si OF .eirrmrirwes of Light to place manufacture THE COMMON SENSE DRY KILN. MAGIC LANTERNS leffel Water Wheels Prices Greatly Reduced. KORTING UNIVERSAL

RMREN1PK–. Dominion Wire Rope Works [microform] : manufacturers of iron and steel machine made wire rope, bridge cables, ships" rigging, hoisting ropes, wheels and ropes for transmitting power, .. Wire rope; Wire-rope industry; Cables métalliques; Fils et câbles. iind Eye Uo which draw it. the fact mt these stfength ^"hese are o make a "ire Rope 5 ofsWire. ircuififer COOPER, FAIRMAX ^ CO. «7 This cut shows the metallic Socket in cross sec- tioiis. It iUustrate^ clearly the solidity of the metallic combination. No<interstices, but the union of socket and wire rope is complete. BARREL SOCKET.. Pleas

RMD96JWC–Brooklyn Suspension Bridge, New York, designed and built by John Augustus Roebling (1806-1869) and his son Washington Augustus Roebling (1837-1926). Opened 1883. Top: Laying cable. Bottom: Bridge during construction. From Park Benjamin Appleton"s Cyclopaedia of Applied Mechanics, New York, 1880. Engraving

RM2ABWRP3–7forIMIIM 1 ! Founded by Mathew Carey 1785. BAIRD"S NUT TAPPING DURRELL"S PATENT. SPEAKING TELEPHONES. BENTEL MARCEDANT & CO. SKILLED ENGINEERS ARE EN WATCHMAKERS. BARREL KEG $66 SIBLEY COLLEGE OF MECHANIC ARTS OPIUM RUPTURE mc. . CAVEATS COPYRIGHTS LABEL REGISTRATION EPIC. " RELIABLE" APURIFIER v).e ROOT"S NW RON BLOWER IRON REVOLVERS PERFECTLY BALANCED $12 PORTABLE AND STATIONARY ENGINES AND BOILERS Sea Screw Cutting Foot Lathe. WESTINGHOUSE ENGINE 6i DAMASCUS BRONZE. ELETRIC LIGHTS WIRE ROPE BRIDGE CABLES SHIP RIGGING Tramway Ropes Champion Barbed Wire etc BLAKE"S CHALLENCE " ROCK BREAKER

RMREN1RD–. Dominion Wire Rope Works [microform] : manufacturers of iron and steel machine made wire rope, bridge cables, ships" rigging, hoisting ropes, wheels and ropes for transmitting power, .. Wire rope; Wire-rope industry; Cables métalliques; Fils et câbles. ., ..»-. This cut illustrates a crucible cast steel wire Switch Rope, with Healey"s Patent Metallic Splice at each end. This splice utilizes the full strength of the rope, firmly secures all the strands in a neat smooth socket; entirely obviating all danger to the hands of employees, and is in every respect sujierior to the tucked splice.

RM2ABW8W4–Machine for Testing the Strength of Metals Wire Rope Chain Cast Iron Columns Bridge Bolts and Boiler Plates. RIEHLE BROTHERS" TESTING MACHINE. Junction of the Black and Caspian Seas. Delprino"s Mode of Treating Silk Worms., scientific american, 1872-03-30

RMREN1FC–. Dominion Wire Rope Works [microform] : manufacturers of iron and steel machine made wire rope, bridge cables, ships" rigging, hoisting ropes, wheels and ropes for transmitting power, .. Wire rope; Wire-rope industry; Cables métalliques; Fils et câbles. COOPEA", FAJRMAN &• c9. HAILEABLE IROR 31 KS FOR WIRE ROPE. * ^?" f. Single mn Bope Block, WITH BECKET. Block. Size of Sheave. Size of Rope, j 14 inch. 10 X i>4 % to 5^ «5 18 13 X 2 H to 34. J^ to I Sonble"^Xnn Bope Block, NO BECKET, " ... ^ " < Price. Single $ 7.50 double 18.S0 1 Triple 10.50 Single. 10.50 Double .....

RM2ABW8W3–WIRE ROPE. Machinists" Tools Brass & Copper SEAMLESS TUBING Merchant &. C Swain Turbine. THE SW AIN TURBINE CO. worth Chelmsford. Mass. Bridge and Roof Bolts. STEEL &IRON SET SCREWS THE BAND SAW I Its ORIGIN and 206 STEAM DRILLS: SCHLENKER"S PATENT BOLT CUTTER LUBRICATORS. Working Models Safes and Mechanical Supplies A. S. & J. GEAR & CO. PENN WORKS" SIBLEY"S Leveling Instrument 13ABCOCK DESCRIPTIVE PRICE LIST OF Waltham Watches. PORTLAND CEMENT Canadian Inventors ENGINEERS EMERY WHEELS BOSTON. MASS. CLUB PREMIUMS. MUNN &. CO. 37 PARK ROW NEW YORK. TERMS FOR 1872. L.W.Pond—New Tools. EXTRA

RMREN1R4–. Dominion Wire Rope Works [microform] : manufacturers of iron and steel machine made wire rope, bridge cables, ships" rigging, hoisting ropes, wheels and ropes for transmitting power, .. Wire rope; Wire-rope industry; Cables métalliques; Fils et câbles. ^v I". ""I*""*" DOMIXIOX WIRE ROPE WORKS tJlll.E OP Transmission of Power by Wita Ropes Diunieter { Number Diameicr of whtd of Kevo- of infee^. Iiitlons. Rope. 4 4 4. 4 5 5 -5 5 6 6 6 6 7 7 7 7 8 8 8 8 9 9 9 9 H "A % "A A Vs. H >^ 8o lOO. 120 140 80 too 120 140 80 "100 120 140 80 100 " 120 140 80 106 120 140 Hor.e "â¢|an"«

RM2ABWTBC–Bicycles. T. M. 1V.A.ari.aE ERIE PA. Manufacturer of Portable Stationary AND Agricultural Steel Castings BESTI c -cs CD PANN KORTING UNIVERSAL OFFICES AND WAREROOMS: "- Y IN THELVCiST -9 THE 14IARKP:i GATE GLOBE ANGLE CHECK AND SAFETY. MANUFACTURERS OF WIRE ROPE BRIDGE CABLES SHIP RIGGING Office and Works:Sendfor ç Office and Warehouse: Only $3.20 a year including postage to United States and Canada. $4 a year including postage to all countries in the Postal Union. FOR. 1E383. CLARK"S RUBBER. WHEELS., scientific american, 1882-12-30

RMREN1PC–. Dominion Wire Rope Works [microform] : manufacturers of iron and steel machine made wire rope, bridge cables, ships" rigging, hoisting ropes, wheels and ropes for transmitting power, .. Wire rope; Wire-rope industry; Cables métalliques; Fils et câbles. ircuififer COOPER, FAIRMAX ^ CO.

8613371530291

8613371530291