wire rope calculation formula pricelist

Always customer-oriented, and it"s our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Stainless Steel Clad Plate , SS Wire Rope , Cold Rolled Stainless Steel Coil , We"re going to endeavor to maintain our fantastic track record as the very best products supplier in the planet. When you"ve got any questions or reviews, you should get in touch with with us freely.

Our target is always to satisfy our customers by offering golden support, superior value and high quality for PriceList for Stainless Plate - 316 Stainless Steel Wire Rope – Saky Steel, The product will supply to all over the world, such as: Frankfurt, Zimbabwe, Jersey, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

Structural Stretch is the lengthening of the lay in the construction of cable and wire rope as the individual wires adjust under load. Structural Stretch in Loos & Co., Inc. products is less than 1% of the total cable length. This form of stretch can be completely removed by applying a cable or wire rope prestretching operation prior to shipment.

Elastic Stretch is the actual physical elongation of the individual wires under load. The elastic stretch can be calculated by using the following formula*:

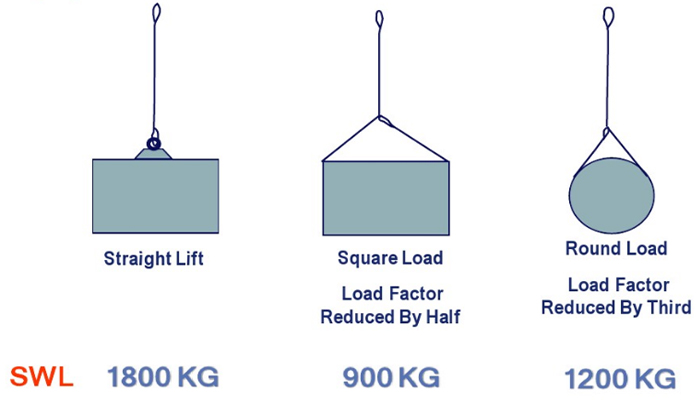

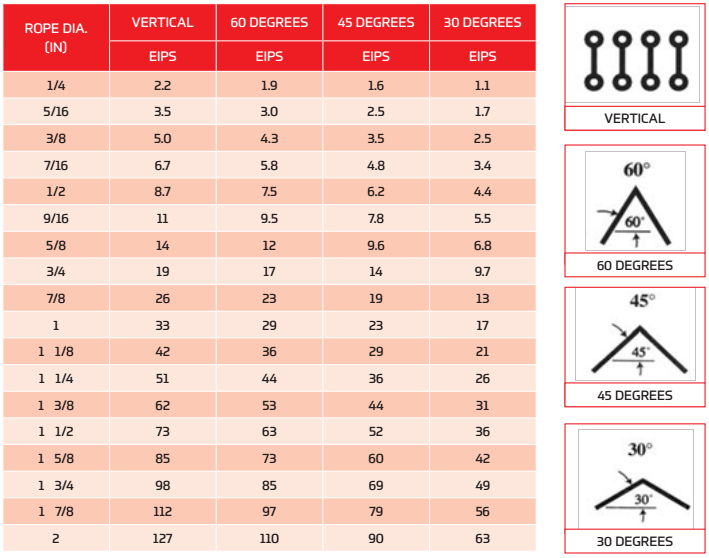

Enter the diameter of the wire rope, in mm, into the calculator to determine the safe working load (SWL). This calculator is for education purposes only, follow manufacturing guidelines for true SWL values.

A safe working load of a wire rope is a measure of the total load or weight that a wire rope can safely support during operation. Values greater than the SWL could result in a failure of the rope.

While it is virtually impossible to calculate the precise length of wire rope that can be spooled on a reel or drum, the following provides a sufficiently close approximation.

* This formula is based on uniform rope winding on the reel. It will not give correct results if the winding is non-uniform. The formula also assumes that there will be the same number of wraps in each layer. While this is not strictly correct, there is no appreciable error in the result unless the traverse of the reel is quite small relative to the flange diameter (“H”).

** The values given for “K” factors take normal rope oversize into account. Clearance (“x”) should be about 2 inches unless rope-end fittings require more.

Our order book follows a 3-4 month cycle and we pass on price changes to the customers based on changes in prices of steel and zinc in three to four months, Bharat Wire Ropes, tells ET Now.

At a time when copper and zinc prices have come down, how does that dynamics of the wire business change? Do you get inventory losses, do you pass price hikes to consumers or do you keep your long-term contracts unchanged?

The wire rope industry is not about commodity items like wire industries. Our order book position is normally a 3-4 month cycle and we pass on price changes to the customers based on changes in prices of steel and zinc in three to four months. Our major raw material is high carbon steel and zinc and recently there was almost 20% decrease in the zinc prices and steel prices also become soften almost by 10%. These benefits we are going to get in the near future and we are going to quote slightly lower price to the customers.

So far as inventory loss is concerned, we carry some inventory but the margin is much higher for absorbing this type of losses so far as raw material and zinc prices are concerned. We are very confident that the volatility in raw material and zinc prices would not affect our business as our value addition is much higher compared to other commodity items like wires or similar products.

Bombay Wire Ropes Ltd.. captures the information on Price and Volume for a user defined time interval. It also contains the Live Stock Price and Volume, 52 Week High Low, Bid and Offer Price and Volume, Intraday and Historical Price Chart.

Mazzella has been in the lifting and rigging business for nearly 70 years, and we’re going to provide some answers to why the price and availability of wire rope, slings, rigging hardware, and other lifting gear has been so abnormal, and what the outlook is for the immediate future.

In this article, you’ll learn the answers to the following questions:What factors are affecting the price and availability of wire rope, slings, and rigging products?

Mazzella is doing everything in our power to keep inventory levels as high as possible for wire rope, slings, and rigging hardware. Fortunately, Mazzella has stayed ahead of the demand increase and supply shortage by procuring product early and often throughout 2021.

By making an investment in wire rope, slings, and rigging hardware, Mazzella has attempted to position ourselves to minimize any supply chain disruption for our customers.

While many competitors rely on one supplier for certain products, our footprint and volume has allowed us to maintain relationships with four domestic wire rope suppliers and eight domestic hardware vendors.

With our national footprint and diverse product offerings, which include, but are not limited to lifting and rigging supplies to crane ropes, general-purpose wire rope, warehouse solutions, and fall protection, Mazzella can be a one-stop shop for service and products to meet your needs.

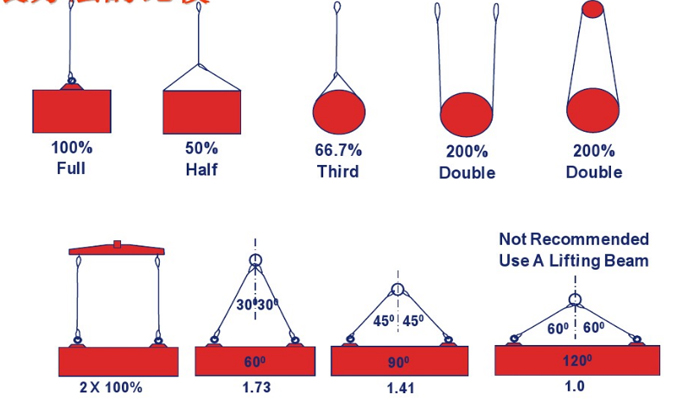

Block Division, Inc., has established through an accredited testing laboratory the capacity at which our products may be safely used. This may be defined as the safe working load limit, a chain or cable rope pulley block load calculation, or a force calculator. The safe working load limit (mechanical advantage) is the maximum load in pounds which should ever be applied, and when the load is applied uniformly and in direct tension to a straight segment of wire rope. By changing the degree of angle between lead and load angle, this also affects the stress on the block. The stress on the eye may be decreased by increasing the angle between the load and the lead angle. See chart 1 and illustration below.

8613371530291

8613371530291