wire rope california factory

Use our thorough list of wire rope manufacturers and suppliers in California to examine and sort top wire rope manufacturers with previews of ads and detailed descriptions of each product. Any wire rope manufacturers can provide wire rope products to meet your company"s specific qualifications. An easy connection to reach wire rope manufacturers through our fast request for quote form is provided as well. This source is right for you whether it"s for cable railing, marine rigging, or any other wire rope needs.

BC Wire Rope & Rigging is a full service provider of wire rope, slings, chain, hoists, and rigging equipment. BC Wire Rope has served the heavy lifting needs of customers throughout Los Angeles, San Diego, Las Vegas, Tucson and the Western United States since 1974. Specializing in lifting products ranging from fall protection to synthetic slings, BC Wire Rope & Rigging carries products from the industry’s most reputable vendors including Crosby, Slingmax, Campbell, and Bridon American. With ample testing and manufacturing capabilities, BC Wire Rope is also the manufacturer of KWIK synthetic slings.

BC Wire Rope was onsite as the last steel beam was raised by Schuff Steel at the new, future home of the Los Angeles Rams and LA Chargers at SofFi Stadium in Inglewood, California. The raising of the last beam is marked by the raising of a ceremonial Christmas Tree, […]

Established nearly 40 years ago in Southern California, BC Wire Rope now manufacturers and distributes wire rope from 5 locations to strategically serve customers across the West Coast. Headquartered in a 35,000 square foot warehouse and manufacturing facility in Anaheim, BC Wire Rope is the premier provider of rigging throughout the greater Orange County and Los Angeles area and also has branches in Tucson, Las Vegas, San Diego, and Elko. These locations allows BC to stock a full inventory of specialty lifting products and enables BC to efficiently meet a wide range of manufacturing needs.

Full in-house testing and wire rope manufacturing capabilities help ensure that BC Wire Rope can meet or exceed its customers’ needs. BC Wire Rope can press wire rope slings and swaged boom pendants, splice slings and soft rope, and can fabricate special end fittings. BC also manufacturers its own line of synthetic slings through its KWIK Products division. KWIK Products include nylon eye & eye endless flat slings, high performance fiber slings, polyester round slings, and choker and basket hardware slings. BC Wire Rope also provides customers with proof testing through use of its 4 test beds that can test slings, blocks, and hardware with up to 1 million pounds of force.

BC Wire Rope & Rigging’s unrelenting focus on customer service and industry leading products is evidenced by its ‘Quality – No Compromise’ motto. BC Wire Rope has been a proud member of the wire rope industry’s trade association—Associated Wire Rope Fabricators (AWRF)—for over 35 years. The commitment to longstanding industry relationships is also demonstrated by the fact the more than half of BC Wire Rope’s employees have remained with the company for over 18 years.

With years of industry knowledge and a full product inventory, chances are that BC Wire can meet your lifting needs. Contact the specialists at BC Wire Rope today to find out more about what BC Wire Rope can do for you.

Adelanto, Agoura Hills, Alameda, Albany, Alhambra, Aliso Viejo, Alturas, Amador City, American Canyon, Anaheim, Anderson, Angels Camp, Antioch, Arcadia, Arcata, Arroyo Grande, Artesia, Arvin, Atascadero, Atwater, Auburn, Avalon, Avenal, Azusa, Bakersfield, Baldwin Park, Banning, Barstow, Beaumont, Bell, Bell Gardens, Bellflower, Belmont, Belvedere, Benicia, Berkeley, Beverly Hills, Big Bear Lake, Biggs, Bishop, Blue Lake, Blythe, Bradbury, Brawley, Brea, Brentwood, Brisbane, Buellton, Buena Park, Burbank, Burlingame, Calabasas, Calexico, California City, Calimesa, Calipatria, Calistoga, Camarillo, Campbell, Canyon Lake, Capitola, Carlsbad, Carmel-by-the-Sea, Carpinteria, Carson, Cathedral City, Ceres, Cerritos, Chico, Chino, Chino Hills, Chowchilla, Chula Vista, Citrus Heights, Claremont, Clayton, Clearlake, Cloverdale, Clovis, Coachella, Coalinga, Colfax, Colton, Colusa, Commerce, Compton, Concord, Corcoran, Corning, Corona, Coronado, Costa Mesa, Cotati, Covina, Crescent City, Cudahy, Culver City, Cupertino, Cypress, Daly City, Dana Point, Davis, Del Mar, Del Rey Oaks, Delano, Desert Hot Springs, Diamond Bar, Dinuba, Dixon, Dorris, Dos Palos, Downey, Duarte, Dublin, Dunsmuir, East Palo Alto, Eastvale, El Cajon, El Centro, El Cerrito, El Monte, El Segundo, Elk Grove, Emeryville, Encinitas, Escalon, Escondido, Etna, Eureka, Exeter, Fairfield, Farmersville, Ferndale, Fillmore, Firebaugh, Folsom, Fontana, Fort Bragg, Fort Jones, Fortuna, Foster City, Fountain Valley, Fowler, Fremont, Fresno, Fullerton, Galt, Garden Grove, Gardena, Gilroy, Glendale, Glendora, Goleta, Gonzales, Grand Terrace, Grass Valley, Greenfield, Gridley, Grover Beach, Guadalupe, Gustine, Half Moon Bay, Hanford, Hawaiian Gardens, Hawthorne, Hayward, Healdsburg, Hemet, Hercules, Hermosa Beach, Hesperia, Hidden Hills, Highland, Hollister, Holtville, Hughson, Huntington Beach, Huntington Park, Huron, Imperial, Imperial Beach, Indian Wells, Indio, Industry, Inglewood, Ione, Irvine, Irwindale, Isleton, Jackson, Jurupa Valley, Kerman, King City, Kingsburg, La Cañada Flintridge, La Habra, La Habra Heights, La Mesa, La Mirada, La Palma, La Puente, La Quinta, La Verne, Lafayette, Laguna Beach, Laguna Hills, Laguna Niguel, Laguna Woods, Lake Elsinore, Lake Forest, Lakeport, Lakewood, Lancaster, Larkspur, Lathrop, Lawndale, Lemon Grove, Lemoore, Lincoln, Lindsay, Live Oak, Livermore, Livingston, Lodi, Loma Linda, Lomita, Lompoc, Long Beach, Los Alamitos, Los Altos, Los Angeles, Los Banos, Loyalton, Lynwood, Madera, Malibu, Manhattan Beach, Manteca, Maricopa, Marina, Martinez, Marysville, Maywood, McFarland, Mendota, Menifee, Menlo Park, Merced, Mill Valley, Millbrae, Milpitas, Mission Viejo, Modesto, Monrovia, Montague, Montclair, Monte Sereno, Montebello, Monterey, Monterey Park, Moorpark, Moreno Valley, Morgan Hill, Morro Bay, Mount Shasta, Mountain View, Murrieta, Napa, National City, Needles, Nevada City, Newark, Newman, Newport Beach, Norco, Norwalk, Novato, Oakdale, Oakland, Oakley, Oceanside, Ojai, Ontario, Orange, Orange Cove, Orinda, Orland, Oroville, Oxnard, Pacific Grove, Pacifica, Palm Desert, Palm Springs, Palmdale, Palo Alto, Palos Verdes Estates, Paramount, Parlier, Pasadena, Paso Robles, Patterson, Perris, Petaluma, Pico Rivera, Piedmont, Pinole, Pismo Beach, Pittsburg, Placentia, Placerville, Pleasant Hill, Pleasanton, Plymouth, Point Arena, Pomona, Port Hueneme, Porterville, Portola, Poway, Rancho Cordova, Rancho Cucamonga, Rancho Mirage, Rancho Palos Verdes, Rancho Santa Margarita, Red Bluff, Redding, Redlands, Redondo Beach, Redwood City, Reedley, Rialto, Richmond, Ridgecrest, Rio Dell, Rio Vista, Ripon, Riverbank, Riverside, Rocklin, Rohnert Park, Rolling Hills, Rolling Hills Estates, Rosemead, Roseville, Sacramento, St. Helena, Salinas, San Bernardino, San Bruno, San Carlos, San Clemente, San Diego, San Dimas, San Fernando, San Francisco, San Gabriel, San Jacinto, San Joaquin, San Jose, San Juan Bautista, San Juan Capistrano, San Leandro, San Luis Obispo, San Marcos, San Marino, San Mateo, San Pablo, San Rafael, San Ramon, Sand City, Sanger, Santa Ana, Santa Barbara, Santa Clara, Santa Clarita, Santa Cruz, Santa Fe Springs, Santa Maria, Santa Monica, Santa Paula, Santa Rosa, Santee, Saratoga, Sausalito, Scotts Valley, Seal Beach, Seaside, Sebastopol, Selma, Shafter, Shasta Lake, Sierra Madre, Signal Hill, Simi Valley, Solana Beach, Soledad, Solvang, Sonoma, Sonora, South El Monte, South Gate, South Lake Tahoe, South Pasadena, South San Francisco, Stanton, Stockton, Suisun City, Sunnyvale, Susanville, Sutter Creek, Taft, Tehachapi, Tehama, Temecula, Temple City, Thousand Oaks, Torrance, Tracy, Trinidad, Tulare, Tulelake, Turlock, Tustin, Twentynine Palms, Ukiah, Union City, Upland, Vacaville, Vallejo, Ventura, Vernon, Victorville, Villa Park, Visalia, Vista, Walnut, Walnut Creek, Wasco, Waterford, Watsonville, Weed, West Covina, West Hollywood, West Sacramento, Westlake Village, Westminster, Westmorland, Wheatland, Whittier, Wildomar, Williams, Willits, Willows, Winters, Woodlake, Woodland, Yorba Linda, Yreka, Yuba City, Yucaipa

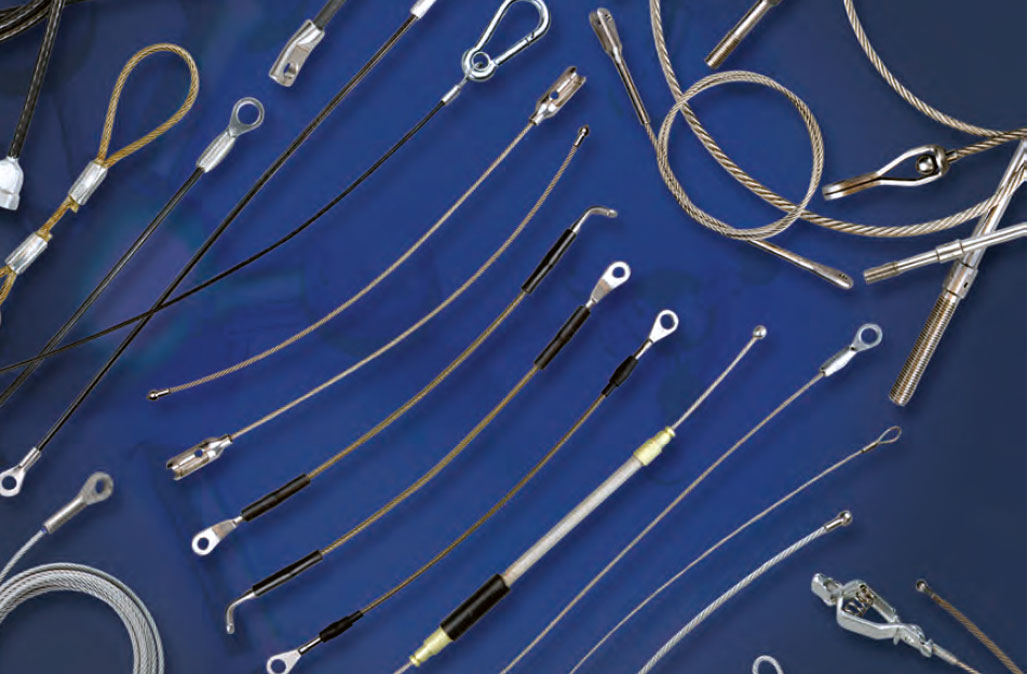

Distributor, Manufacturer, & Custom Fabricator. All Sizes, Constructions, & Finishes Of Aircraft Cable, Wire Rope, Strand, Wire & Banding, Cordage, Chain & Chain Assemblies, Truck Tie Down Equipment, Slings & Lifting Assemblies, Hardware & Connectors, Winches, Hoists, Come-Alongs, Cutting & Crimping Tools, Safety & Fall Protection Products, Mil-Spec & Marine Fittings, Carabiners & Climbing Ropes, Stair & Parking Garage Railing Assemblies, Fixture Hangers & Earthquake Restraint Assemblies. Rotary & Hydraulic Swaging, Socket Pouring, Hand Splicing, & Rod Clevis Assemblies

Use our thorough list of rope manufacturers and suppliers in California to examine and sort top rope manufacturers with previews of ads and detailed descriptions of each product. Any rope manufacturers can provide rope products and services to meet your companies specific qualifications. An easy connection to reach rope manufacturers through our fast request for quote form is provided as well. This source is right for you whether it"s for winch rope, wire rope, elastic rope or any other rope needs.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

Three men lean on a table in the Pacific Wire Rope plant at 1840 East 15th in Los Angeles. The table is covered with a large circle that is marked with numerous measurements. There are flat circular discs with holes in the middle resting on the diagram, and one of the men is holding a disc and pointing to it with a pencil.

Landmann Wire Rope Products, Inc. is a wholesale distributor of imported steel wire rope, rigging hardware, chain, cargo control and fastening materials. We have established ourselves as a market leader on the West Coast of the USA with outlets in Southern California, Northern California, the Pacific Northwest and near Omaha Nebraska. Over the last 10+ years, we have expanded our product line to include many other products. The key employees at Landmann bring a total of over 100 years of accumulated experience in the rigging industry to provide superlative customer service.

Our product line is basically made up of 5 main categories, Wire Rope, Chain Products, Cargo Control, Rigging Hardware and Fastening Materials which we import primarily from South Korea, China, Mexico and Japan. Within the wire rope category, we carry diameters from 3/64” to 2” in galvanized, plain and stainless steel finishes in a wide array of constructions. In the rigging hardware category, we have expanded our product line dramatically in the last few years to include a wide variety of stainless steel hardware and fastening materials to go along with our regular product line. This diverse product line allows us to supply our customers who service a wide range of industries including, logging, fishing, mining, industrial, construction and architectural to name a few. This diversification of rigging hardware as well as the range of wire rope, cable and chain products allows us to better serve you, the customer as a one stop shop for all your wire rope and rigging needs.

Our three warehouse locations along the West Coast, USA are in Santa Fe Springs, California, Vacaville California and Fife, Washington. We also have a distribution center near Omaha, Nebraska. This allows us to serve our customers better by shipping most orders the same day for quick deliveries. We also specialize in direct mill shipments that come from the factory directly to you whether our customers are located on the East Coast USA, or in Europe.

One final note about Landmann Wire Rope Products. We realize the importance of being different than our competitors. We strive to make your experience with Landmann one where you feel that we are a part of your success and that you can count on Landmann to fulfill your needs, whether they are big or small. Customized and professional client service is a mainstay at Landmann.

They say you should never visit the sausage factory, and that may be true, but the wilfully ignorant are not to be trusted, and steel wire rope is certainly a special type of sausage. It was a visit that put me through the emotional spectrum, from disinterested to bemused, to bewildered, and finally awed at the sheer scale of the operation. It’s a little bit like when you find out where babies come from: Horrifying and weird to begin with, but before long you find yourself utterly fascinated…

Flexible steel wire rope has been one of the mainstays of heavy industry for more than a hundred years. Whether you want to lash down scaff planks, carry out lifting and cranage, use draglines for surface mining, or even pull down a massive statue of Saddam Hussein, wire rope has thousands of applications.

The Wirerope Works factory in Williamsport, Pennsylvania has a long history of producing this essential component of progress in the 20th century, and although cheaper imports from China and India continue to flood the market, the caretakers of the Bethlehem Wire Rope brand are still proud to produce a product of the highest quality on local labour and quality materials.

Based in Lycoming County in Pennsylvania, Wirerope Works (WRW) began its life as the Morrison Patent Wire Rope Company in 1886. The original mill was built upstream on the banks of the Susquehanna River to service the softwood logging industry, however regular flooding led to the relocation and inevitable expansion of the factory in the town of Williamsport.

The design and manufacture of steel wire rope was no longer in its infancy at that stage. The first practical use of steel rope in 1834 was credited to a German mining official named Wilhelm August Julius Albert, who worked at the Clausthal silver mines in Saxony.

Up until that point, all mining haulage was done with hemp fibre rope or chains. In the humid, damp conditions of an underground mine, moisture would cause the ropes to perish from rot, the gradual deterioration reducing their load bearing capacity, so they required frequent replacement.

That first incarnation of modern steel wire rope was extremely effective for heavy haulage, and much more reliable than rope or chain. Albert Rope, as it came to be known, was a simple construction of three 3.5mm gauge wrought-iron wires, hand-wound into strands, with three or four of those strands wound into a single rope. However, Albert rope lacked the flexibility of rope or chain, meaning it couldn’t be drawn through a pulley sheave, and its use stopped in the 1850s.

But the idea for wire rope had already caught on in England, where thinner wires were woven around a fibre core, with six of those strands woven around a central fibre core, resulting in a more flexible product. This design, as well as a mechanical system for its construction (called a strander), was patented by Robert Newall, who brought the new technology to America, and the boom-time economy of the California Gold Rush.

However, it was in Pennsylvania where a German-born engineer and surveyor named John Roebling began to develop ropes which were entirely constructed of wire. Roebling used a 6/19 construction (6 strands; 19 wires per strand). A strand built of 19 wires of the same gauge resulted in a hexagonal profile, and desiring a round shape Roebling conceived of using three different gauges of wire to achieve that result. The effect of this was to reduce the space inside the rope, tightly packing the wires together, which gave the rope greater stability under load.

With massive demand for coal haulage in Pennsylvania, as well as cable car applications for public transportation, and most importantly civil engineering projects to service, Roebling set up a wire rope factory in 1849 in Trenton, New Jersey. But he wasn’t the first to invest in a factory like that: Other people had the same idea, and wire rope mills were starting to pop up around the United States. In only 14 years wire rope had gone from a hand-made experiment in a German silver mine, to a globally recognised tool of industry with high demand for scaled-up production.

If Roebling had any hubris about cashing in on this amazing new invention, you could be forgiven for thinking it was a little dampened when his arm and shoulder were horrifically mangled in an accident with one of his stranding machines. But it would seem that Roebling’s interest in wire rope was not strictly for profit, however, as he had for some time harboured a bit of an obsession with sketching suspension bridges. He was a big fan of the expansionist philosophy of Manifest Destiny, and had been very keen on establishing a utopian settlement called Germania (now the town of Saxonburg), where people like him trying to escape the brutal oppression of post-Prussian War Europe could be free to make sauerkraut and smoked pork products, unmolested by the authorities.

But Roebling recovered from his injuries, his factory continued to produce wire rope, and he designed and built a number of suspension bridges using his own product right up until he began design work for the Brooklyn Bridge. Unfortunately, Roebling managed to get his foot crushed by a ferry while standing on a dock trying to work out where the bridge should go. He died of tetanus 24 days later, but his son Washington went on to complete the Brooklyn Bridge project, while his son Charles would invent an 80 tonne wire rope machine.

By 1886, the year the Brooklyn Bridge was opened, a venture like setting up a wire rope factory in Pennsylvania was not at all a bad way to invest $100,000 (probably about $US3 million today), and that is precisely what three businessmen from Williamsport did.

Morrison Patent was changed to the Williamsport Wire Rope Company in 1888, manufacturing steel and galvanised wire rope “from one-eighth of an inch to two and one-half inches in diameter, and any length up to two miles in one continuous piece”, according to an 1892 history of Lycoming County.

The lumber boom in Lycoming peaked in 1891, and the neighbouring Indiana County saw a coal-mining boom start in 1900, so the industrial economy was perfect for the growth of the Williamsport rope mill. A new wire mill was built in 1916, and the current rope mill was built in 1928, which was pretty poor timing considering the Great Depression would start the next year.

By 2004, the Williamsport site had been bought and sold a number of times, changing company names like a serial divorcee, acquiring assets from other defunct companies such as Roebling Wire Rope (the company started by John Roebling in 1849) but always keeping the Bethlehem Wire Rope brand, which became synonymous with top quality steel cable, and is still proudly emblazoned on their rope spools to this day.

In 2002 Williamsport Wirerope Works bought out the bankrupt Paulsen Wire Rope, a rope mill located in nearby Sunbury, and continued to produce under the Paulsen name. But by 2003 the company was also in financial strife, and the management were looking for another buyer who could bail out the company and keep the 600,000 square foot Bethlehem factory running.

The US wire rope manufacturing industry had changed dramatically over the course of 100 years. From an exciting new industry that would allow explosive growth in the productivity of coal mining through the development of dragline surface mining operations in the early 20th century, as well as enabling some of the biggest civil engineering projects ever seen since the Pyramids of Giza, the US stable of 27 wire rope companies had been consolidated down to just three names: Bridon, WireCo, and Bethlehem.

Bridon is another Pennsylvania company, based 100 kilometres away in Wilkes-Barre. Unlike Williamsport which remained a local manufacturer, Bridon expanded rapidly, acquiring other wire rope companies and branching out across the world, developing into a massive, multinational conglomerate, as did WireCo Worldgroup.

With two global entities for domestic competition, Bethlehem also faced increasing pressure from low-cost offshore wire rope producers in countries like China, Korea and India.

Present executive vice-president Lamar J Richards remembers circumstances were looking grim for the Bethlehem brand and for the local employees, with a bid for takeover by Pennsylvania, USA and world market rival WireCo Worldgroup in late 2003.

“Instructions from the ownership at the time were, because we were about to be bought by a competitor we really weren’t going to be making wire, so we had to get rid of all the raw material, the rod, our starting point for the wire,” he said.

But I didn’t know any of those things when I found myself standing, probably in the same spot as Mr Saltsgiver did when starting his tour, right there in the foyer of the single largest wire rope manufacturing facility in North America on a muggy Thursday morning. I had arrived at the factory with a junket of assorted journalists, exhausted from touring a gamut of other factories and fighting off a particularly vicious head cold, quite oblivious to the fact that our tour bus had, having dropped us off, already left with my camera bag still on board. Perhaps one could have forgiven me for being a little out of sorts at first. But not for long…

Walking into the front offices of Wirerope Works on Maynard Street, it’s clear there’s pride in the product here. Foot-long samples of rope in varying configurations and gauges lie on polished timber plinths in the foyer, cleaned of oil with sharp edges ground smooth for safe handling by visitors.

On the walls hang photographs of major construction projects which were supplied with Bethlehem brand wire rope: Madison Square Gardens, the restringing of the Brooklyn Bridge, the Niagara Falls tightrope.

Lamar J. Richards, the executive vice president of Wirerope Works, explains to us some of the history of the plant (see Australian Mining February 2016), but one of the most touching stories he tells us is about how the present owner, Tom Saltsgiver, came to buy the company and keep it alive for the sake of the local economy in Williamsport.

As it turned out, the newly renamed Wirerope Works became profitable after 18 months of capital support. Shortly after that, the housing bubble burst.

One of the first things shown to us is the floor. The factory is tiled with timber bricks, grain pointing upward and creating a very unique effect where the timber had been polished by decades of wear. The timber floors are a result of Williamsport’s logging history, when wooden blocks were cheap and readily available in bulk. To this day when any flooring needs repairs or replacement, Wirerope Works still uses the original material. To walk on it is remarkably different from concrete, and where I can compare the two it is noticeably easier underfoot. Bear in mind the factory is 620,000 square feet, so a lot of what essentially was scrap lumber had been put to good use.

First we are shown the raw material: 4mm steel wire in loose looking coils about 6 foot across, lifted by forklifts and taken through to a hydrochloric acid bath which will strip off any contaminants. Having been battling a common cold for a few days, I didn’t need to be told the fizzing pool before me was acid. Plumes of vapour were pouring off the bath, and before I could think of doing anything about it the congestion in my head loosened and poured down the back of my throat, and I suddenly I could breathe more clearly and easily than I had done for days! I realised it was the corrosive vapour that had cleared my head, and it might soon start to work on the tissues of my sinus. I tried to hold my breath while our host laughed and tried to explain, incoherently over the roar of the factory, the process of treating the raw material.

We all back away from the deadly head-cold cure and are led to the furnace, where 12 of the washed coils are set up to feed wire through an oven blazing at 1000 degrees Celcius, only 360 degrees shy of melting point. I realise wearing my jacket, despite the cool Pennsylvania humidity, was not the smartest thing in the world to do and we walk past the contained inferno, pouring with sweat.

It’s becoming amply clear to me that this is an extremely dangerous workplace, and we continue to the other side of the furnace where the cherry glowing wires are fed down into a simmering oil bath for quenching.

We file past, only a couple of feet from the long vat of hellbroth with no rails or guards and I think to myself, ‘this must be the single most dangerous thing I have ever stood near’. Having been a labourer and rigger for most of my adult life, I have certainly worked in some unsafe conditions, from high rise buildings with no fall arrest equipment to a uranium mine with no proper PPE, but even those experiences didn’t seem to come close to standing next to this long vat of near-boiling oil. What would happen if one of us stumbled, reaching out for grip and finding only oil that could burn off a limb in seconds, or worse, what if one could fall in altogether! I reassured myself a victim of clumsiness would pass out almost instantly from the shock of the burn. Small comfort as we tried to stay as far away from the vat as possible, with a few feet of leeway for space.

Once cool enough, the wire passes through hydrochloric acid to wash off all traces of contaminant, and I hold my breath as we walk the length of the pool, our host taking deep breaths as if it were fresh spring air and not lung melting fumes, laughing as he watches the visitors squirm… Does he know something I don’t? I sure hope so.

A coating of zinc phosphate, another rinse, and another final coating prepares the wire for extrusion, which has two key functions. The most obvious is for achieving the correct gauge of wire required for twisting into the various rope products, but extrusion also means the steel wire is stretched to align the structure of the steel to align in a single direction, which strengthens and increases the breaking strain of each wire.

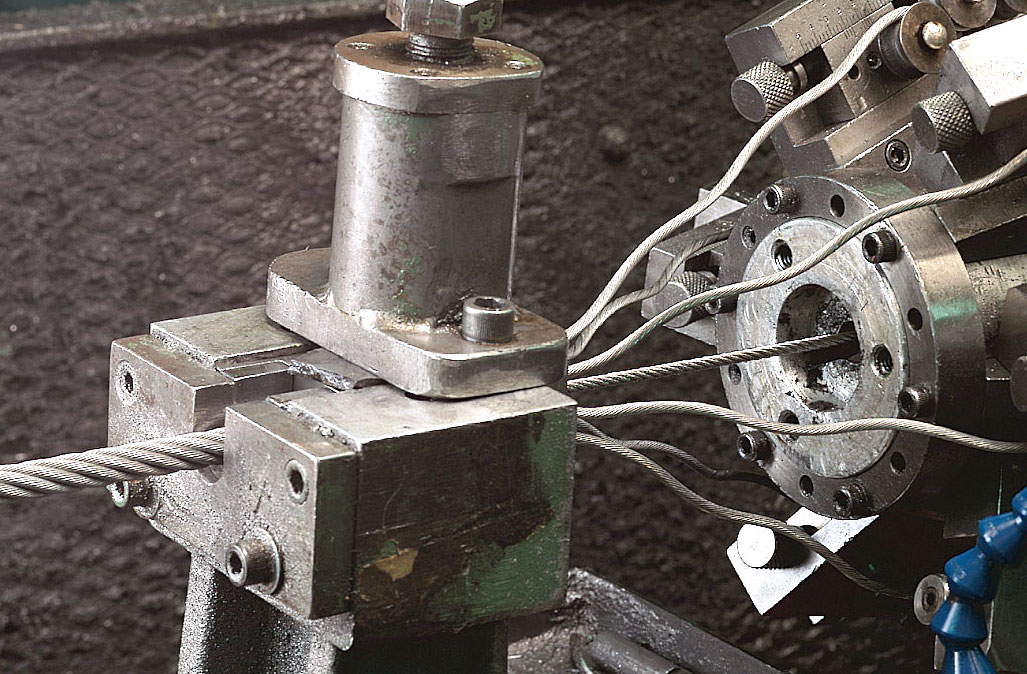

However, the most important part of all of this is the stranding process, and here is where my reactions turn from shock to awe. As a rigger using steel wire rope on a daily basis for slinging, I had often wondered how the rope was produced, and here it was before my eyes: The factory floor – acres of it – was full of lines of planetary stranders, all with sets of wires in large bobbins, as many as 64 wires on a single machine, feeding into a single, oily strand of rope. The factory had machines of all sizes hard at work, furiously spinning to produce the some 1200 different combinations of wire rope that come out of the factory every three months.

Finally, we come to the heart of the factory: We stand, astonished, gazing up at the 12 foot tall, 800 tonne closing machine, designed to produce the 7 inch rope for dragline boom pendants, and construction cable like that used to build the Brooklyn Bridge. The already huge strands are all dragged into a central point, slowly weaving the helical pattern of wires around a hefty centre rope into a single massive cable which will one day end up on a dragline somewhere in the world.

With a history spanning 120 years, the Wirerope Works factory has seen plenty of hard times, but it’s also had a lot of luck. With good leadership at the helm from the likes of Saltsgiver and Richards, and ongoing demand for steel wire rope, the old Williamsport factory could continue to produce its quality bespoke products for another 120 years.

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Andrew Hallidie is considered the father of the cable car, although he was not the only inventor to dabble in the use of cable as a means of transportation. Hallidie and his father both held several patents for the manufacture and use of cable, or wire rope as it was called. Wire rope served a number of purposes in the mines of California, Nevada and other western mining centers in the latter half of the 19th century. Woven much like hemp rope but much stronger, it ranged in gauges from the thickness of a hair to a finger, and was used to transport ore from the mines, equipment and supplies to the mines, and occasionally passengers as well, who both trembled and wondered at the breathtaking views they saw from the aerial trams operating on the wire ropes.

The first commercial success of wire rope was in England when, in 1830, George Binks convinced the Royal Navy to replace hemp rope on its fleet of ships with wire rope. Binks was joined shortly after by Andrew Smith, a Scot, who held patents on several improved varieties of wire rope and was incidentally the father of young Andrew, who took the name Hallidie from his godfather Sir Andrew Hallidie, royal physician to the court of Queen Victoria.

Across the water in the United States, John A. Roebling, who would later build the Brooklyn Bridge, was manufacturing wire rope at his factory in Pennsylvania, in 1840. Roebling"s company expanded, as did the demand for wire rope, until it became one of the largest producers of iron and steel rope used in building bridges during the 19th century. One of Roebling"s friends and competitors, Peter Cooper, began dabbling in aerial tramways to transport materials for factories on the East Coast.

Hallide developed the first successful aerial tramways in the West, after a few years of drifting from camp to camp working claims, narrowly avoiding disasters both natural and manmade, and briefly running a restaurant at Michigan Bluff in the Mother Lode. Then in 1855, young Hallidie built a wire suspension bridge and aqueduct 220 feet long at Horse Shoe Bar on the Middle Fork of the American River. A year later he built a flume near Gray Eagle Bar that transported ore to a quartz mill 1100 feet up a hill. The cars operated along Hallidie"s wire rope, which replaced regular rope, by gravity, the loaded cars pulling empty ones up to the mill as they went down. Hallidie manufactured rope for this project consisting of three spliced pieces one-eighth of an inch thick, 1200 feet long, which lasted for two years as opposed to 75 days for the previous type used.

In 1857 Hallidie left the Mother Lode and returned to San Francisco where he set up a factory on the corner of Mason and Chestnut Streets to manufacture wire rope. In addition to aerial tramways, his rope was used to build suspension bridges across creeks and rivers throughout northern California. He was often away from the City on his bridge projects until in 1865 he returned to San Francisco and focused his energies entirely on manufacturing and perfecting wire rope. The discovery of the Comstock Lode in Nevada increased the need for wire rope. The City became a major industrial center for mining operations in the 1860s and Hallidie prospered, becoming a leading entrepreneur, citizen, and in 1868 President of the prestigious Mechanic"s Institute.

It was also about this time that Hallidie began to implement a scheme for urban transportation he had been pondering for some time, based upon his use of wire rope for aerial tramways transporting material up steep mountainsides and across gorges. He worked on improving the tensile strength and flexibility of his wire to develop an "endless" wire rope that could be would around large pulleys, which could then provide continuous underground propulsion for a car that could be attached or released at will from the cable. Hallide took out a patent for this "Endless Wire Ropeway" and for the next decade or so dominated the construction of tramways at mines across the west. However, it was the implementation of his Endless Wire Ropeway for moving streetcars in San Francisco that brought him lasting fame and a place in the history books.

The cable used in the present system measures 1 1/4 inches in diameter, is made of steel with a hemp center to increase flexibility, and varies in length - the California (21,700 feet), Hyde (16,000 feet), Mason (10,300 feet), and Powell (9,300 feet).

The cable itself is composed of six steel strands of 19 wires each that are wrapped around the sisal rope center. It has an average life of 6 to 8 months, and if it becomes worn, the system is shut down at night and a splice is made in the powerhouse.

Hallidie, who was a trained mechanical engineer, emigrated from Britain to California in 1852 to work in the state’s gold country. He worked variously as a blacksmith, surveyor, bridge builder and inventor (Kahn, 2). While working at a mine along the American River in 1856, he produced the state’s first wire rope pulley system, replacing the traditional fabric rope system, which wore out quickly. Seeing a commercial opportunity, Hallide began manufacturing wire rope from a workshop in San Francisco, and during the 1850s and 1860s became well known for building wire suspension bridges over many of the rivers throughout gold country (Kahn, 3). In the late 1860s, Hallidie began experimenting with a new “elevated traveling wire rope” capable of bending around a turn and straightening out without fracturing (Kahn, 6). He soon considered the possible commercial applications of this so-called “Hallidie Ropeway (Hallidie, 1),” particularly in the field of transportation. By the early 1870s, Hallide, along with several business associates, formed the Clay Street Railway Company and constructed the first underground cable railway along Clay Street. The cable ran from Portsmouth Square in today’s Chinatown up to the top of Nob Hill. In the early morning of August 1, 1873, Hallidie and his associates boarded a test car at the top of Nob Hill and slowly went down Clay Street to the end of the line at Kearny Street. At the bottom of the hill, they turned the car around and went back up marking the first successful test of cable traction technology in California (Kahn, 8).

There was an immediate rush on cable car franchises in the city. New lines soon opened on Sutter, California, Geary, and Union streets. The cable car succeeded in opening up San Francisco’s inaccessible hilltops, once considered “waste areas,” to urban development and real estate opportunities. The city’s wealthy population migrated away from neighborhoods in the South of Market area to the newly accessible hilltops in the Western Addition, Russian Hill, and Nob Hill where they built mansions, luxury apartments, and hotels (Kahn, Cable Car Days, 42). In addition to his technological and commercial achievements, Hallidie was involved in the city’s civic life as a supporter of public libraries and public education. He served as President and Secretary of the Mechanics" Institute, a private library to support the mechanical arts, as one of the original regents of the University of California, serving from 1868-1900, and as a member of the board of the San Francisco Public Library system when it opened in the late 1870s. THE HISTORY OF A BOOK Using the Online Archive of California, I eventually tracked down a collection containing a document signed by Hallidie. The James L. Warren Papers, 1846-1889, held at UC Berkeley, contains documents related to Warren’s activities as editor of the California Farmer, including an 1864 correspondence from the Mechanics’ Institute, penned and signed by “A. S. Hallidie, Secy, Lecture Committee.” I was able to obtain a copy of the original letter from our wonderful colleagues at the Bancroft and you can see that the signature from the letter appears to match the signature in our book.

The book’s backstory is I think one of the most fascinating things about this bibliographic investigation. It’s not a stretch to say the book was very likely part of Hallidie’s personal library. He was no doubt a book lover and the subject matter is certainly within his area of expertise. We can see from the preface page that the book was originally acquired by Berkeley in about 1935 and was probably transferred to UCLA as a duplicate copy. But where the book was between Hallidie’s death in 1900 and its acquisition in 1935 is unknown. The book contains no significant marginalia, only some circled page numbers and pencil markings highlighting certain paragraphs. It’s also fascinating to think about whenhe owned the book. Was Hallidie using it beforehe developed the cable car as a sort of professional reference material? Perhaps we can imagine the “mechanical genius” consulting it in the early 1870s, struggling to figure out how to modify a road surface so he could install and operate a continuously running cable underground. I guess we’ll never know. The book, which has been in UCLA’s collection since 1936, was removed from the circulating stacks and transferred to Library Special Collections where it was fully cataloged including more information on its provenance. The book now includes the copy of the signature which validates the Hallidie signature. By Chris Salvano, Research Support Librarian, CRIS, Charles E. Young Research Library Works cited: “About the Mechanics’ Institute.” Mechanics’ Institute Library & Chess Room. Accessed June 26, 2012. http://www.milibrary.org/about. Hallidie, Andrew S. The invention of the cable railway system. [San Francisco, 1885]. Hilton, George W. The cable car in America: a new treatise upon cable or rope traction as applied to the working of street and other railways. San Diego, Calif. : Howell-North Books, 1982. Kahn, Edgar Myron. Andrew Smith Hallidie: originator of cable railway transportation. San Francisco: [s.n.], 1940. Kahn, Edgar Myron. Cable car days in San Francisco. Stanford University, Calif. : Stanford University Press, [c1940]. “The Regents of the University of California.” University of California Regents. Last modified June 21, 2012. Accessed June 26, 2012. http://www.universityofcalifornia.edu/regents/regentslistb.pdf. San Francisco Board of Supervisors. San Francisco Municipal Reports. San Francisco: Board of Supervisors, 1878/1879.

The inspection shall consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in subsection (a)(2). Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

1. Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

a. In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

b. In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

c. In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

(A) If a deficiency in Category I [see subsection (a)(2)(A)] is identified, an immediate determination shall be made by the qualified person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question shall be prohibited until:

2. If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this section, the employer shall ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

(B) If a deficiency in Category II [see subsection (a)(2)(B)] is identified, operations involving use of the wire rope in question shall be prohibited until:

2. If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this section, the employer shall ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

2. If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this section, the employer shall ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

(D) Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope shall be tagged-out, in accordance with Section 1616.1(g)(1), until the wire rope is repaired or replaced.

(3) Wire ropes on equipment shall not be used until an inspection under this section demonstrates that no corrective action under subsection (a)(4) is required.

(1) At least every 12 months, wire ropes in use on equipment shall be inspected by a qualified person in accordance with subsection (a) (Shift Inspection).

(B) The inspection shall be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under subsection (c)(2) is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections shall be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

2. If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this section, the employer shall ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

8613371530291

8613371530291