wire rope catalogue brands

Alps Wire Rope® is your favorite provider of General Purpose, Elevator, Specialty Crane, Oilfield, Marine and Industrial Cables. Please select one of our Product Brochures below for more information regarding each individual product. Just click the download buttons below.

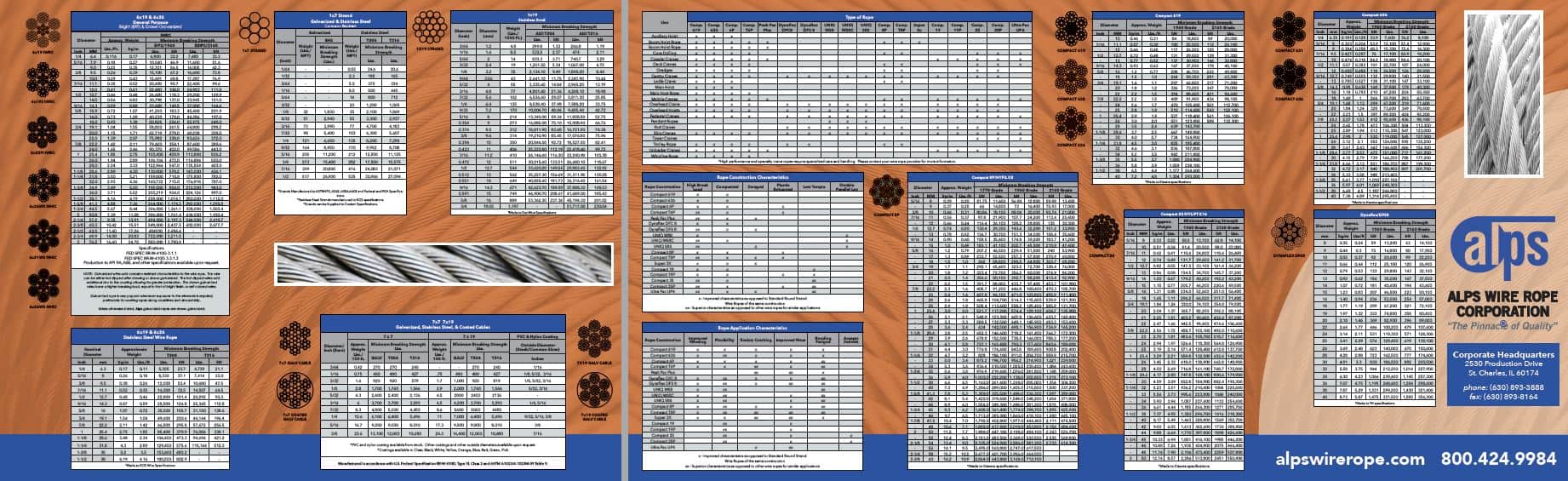

Wire rope strength in the United States is typically shown in tons of 2,000 lbs. The wire rope strength is shown as minimum breaking force (MBF). This is a calculated strength that has been accepted by the wire rope industry. When tested on a tensile machine, a new rope will break at a value equal to- or higher than – the minimum breaking force shown for that rope. The published values apply to new, unused rope. A rope should never operate at – or near- the minimum breaking force. The minimum breaking force of the rope must be divided by the design factor required for the application to determine the maximum load allowed on the rope. During its useful life, a rope loses strength gradually due to natural causes such as surface wear and metal fatigue.

Fatigue resistance involves fatigue of the wire used to make up a rope. To have high fatigue resistance, wires must be capable of bending repeatedly under stress – for example, as a loaded rope passes over a sheave during operation. Increased fatigues resistance is achieved in a rope design by using a large number of wires. It involves both the wire properties and rope construction. In general, a rope made of many wires will have greater fatigue resistance than a same – size rope made of fewer, larger wires because smaller wires have a greater ability to bend as a rope passes over a sheave or around drums. To overcome the effects of fatigue, ropes must never bend over sheaves or drums with a diameter so small as to bend wires excessively. Standard for specific applications contain requirements for minimum sheave and drum sizes. Every rope is subject to metal fatigue from bending stress while in operation, and therefore the rope’s strength gradually diminishes as the rope is used.

Crushing is the effect of external pressure on a rope, which damages it by distorting the cross-section shape of the rope, its strands or core -or all three. Crushing resistance therefore is a rope’s ability to withstand or resist external forces, and is a term generally used to express comparison between ropes. When a rope is damaged by crushing, the wires, strands and core are prevented from moving and adjusting normally during operation. In general, IWRC ropes are more crush

resistant than fiber core ropes. Regular lay ropes are more crush resistant than lang lay ropes. 6-strand ropes have greater crush resistance than 8-strand ropes or 19-strand ropes. Compacted strand ropes are more resistant than standard round-strand ropes.

When a load is placed on a rope, torque is created within the rope as wires and strands try to straighten out. This is normal and the rope is designed to operate with this load-induced torque. However, this torque can cause both single part and multiple part hoisting systems to rotate. Load induced torque can be reduced by specially designed ropes. In standard 6 and 8- strand ropes, the torques produced by the outer strands and the IWRC are in the same direction and add together. In rotation-resistant ropes, the lay of the outer strands is in the opposite direction to the lay of the inner strands, thus the torques produced are in opposite directions and the torques subtract from each other.

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

Introducing our brand new Performance Wire Ropes Catalog. Included in this catalog is our crane usage table, our high performance compacted strand ropes, category 1 and 2 ropes, and end fittings and connections. Call 215-721-9333 to get a physical copy, or click below to download a PDF version.

OFFSHORE DIVISION PROVEN STRENGTH More than 200 years of experience in development and manufacturing of synthetic and steel wire ropes have proven the strength of Lankhorst

OFFSHORE DIVISION COMPANY INFORMATION ROPE SELECTION BY APPLICATION STEEL WIRE ROPES 6X36WS+IWRC 6X36WS+IWRC COMPACTED LANKO®TOP LANKO®TOP COMPACTED LANKO®PACK LANKO®LIFT COMPACTED SPIRAL STRAND 6X19S+IWRC 6X26WS+IWRC TUF-KOTE DRILL LINE COATINGS QUALITY SYSTEM & CERTIFICATIO

OFFSHORE DIVISION COMPANY INFORMATION Lankhorst Ropes is a member of the Royal Lankhorst Euronete Group. With more than 200 years of experience and 1,250 employees we are a worldwide innovative group with fully equipped production sites and R&D departments, located in The Netherlands, Portugal, Greece and Brasil, equipped for the production of a wide range of products in maritime and offshore ropes, technical yarns, fishing gear, Pure® composites, recycling and moulding material. In July 2012, the Royal Lankhorst Euronete Group was acquired by WireCo WorldGroup, of Kansas City, Mo, USA....

OFFSHORE DIVISION Lankhorst Ropes combines more than two centuries of experience with a strong innovative ability and modern production techniques. In close cooperation with clients world-wide, the company develops innovative solutions for specific applications in the maritime and offshore industry. These solutions can be either new products or optimised existing techniques. Casar is a global brand, consisting of specialty wire rope and hoisting cables, characterized by advanced engineering, innovation, and high technology. Casar delivers superior performance for mission critical...

ROPE SELECTION BY APPLICATION MOORING AND ANCHOR LINES 6X36WS+IWRC SPIRAL STRAND OFFSHORE CRANE ROPES 6X36WS+IWRC 6X36WS+IWRC COMPACTED LANKO®PACK LANKO®LIFT COMPACTED LANKO®TOP LANKO®TOP COMPACTED

OFFSHORE DIVISION Standard wire rope with higher breaking strength. Used for all kinds of purposes, i.e. luffing, mooring, towing, anchoring and coupling push barges. The independent wire rope core provides more strength and stability to the wire rope compared to fibre core. Construction according to ISO standard. More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. Diameter Metallic (mm) area (mm) These data are for guidance purposes only and are subject to change without prior notice. More...

OFFSHORE DIVISION Can be used for all applications when a very high MBL is not required and can be used for flexible slings. The special feature of Lanko®top is that in the production process the core is covered by an especially designed HDPE extruded cover. This gives the wire rope stability, avoids point to point contact between wires of the outer and inner strands and stops corrosion and wear of the core. When the high breaking strength is added, this luffing wire rope is surpassed. Diameter Metallic Weight MBF MBF More details and specifications are available on request. These...

Lanko®pack Diameter Metallic Weight (mm) area (mm) (kg/m) MBF (kN) MBF (MT) cc O X in LL LL O Can be used for all cranes and high performance lifting applications where non-rotating and high MBL ropes are required. Recommended for offshore, deck cranes and marine environment. Diameter Metallic Weight (mm) area (mm) (kg/m) 22 24 26 28 30 32 34 35 36 38 40 41 42 44 46 48 50 52 54 56 58 60 More details and specifications are available on request. More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice.

Spiral Strand I"..* .I V. ■: *■" v OFFSHORE DIVISION A586 Galvanized Structural Spiral Strand Grade 2 Class A Coating Throughout Diameter Metallic Weight MBF MBF This rope is used where high strength and high modulus is required in a stationary structure/application. More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice.

Metric Weight (kg/m) More details and specifications are available on request. These data are for guidance purposes only and are subjectto change without prior notice. These data are for guidance purposes only and are subject to change without prior notice. TUF-KOTE Drill Line 6-strand TUF-KOTE ropes are plastic impregnated with plastic polymer applied at high pressure which cushions the strands, distributes internal stresses, keeps in wire rope lubricant and keeps out dirt and debris. This polymer doesn"t melt or soften from the heat of normal operating temperatures. It"s also virtually...

OFFSHORE DIVISION Open spelter sockets with pin for wire 0 dm inch Strand 0 im inch Dimensions (mm) D 0H 0P T OSS 196 P OSS 197 P OSS 198 P OSS 199 P OSS 100 P OSS 104 P OSS 108 P OSS 111 P OSS 115P OSS 118P OSS 120 P OSS 125 P OSS 128 P OSS 130 P OSS 132 P OSS 135 P OSS 138 P OSS 140 P OSS 142 P OSS 144 P OSS 146 P OSS 150 P OSS 155 P Open spelter sockets with bolt and nut for wire 0 dm inch Strand 0 im inch Dimensions (mm) D 0H 0P T OSS 196 B OSS 197 B OSS 198 B OSS 199 B OSS 100 B OSS 104 B OSS 108 B OSS 111 B OSS 115B OSS 118B OSS 120 B OSS 125 B OSS 128 B OSS 130 B OSS 132 B OSS 135...

• Tensile Strengths are determined in accordance with Cordage Institute 1500.2. Test Methods for Fiber Rope. Minimum Tensile Strength (MTS) published assumes spliced eye tenninations at each end of the rope. Weights actually calculated at linear density under state preloaded (200d’J plus 4%. Diameter and circumference size published is nominal and reflects rope size after loading (10 cycles) to 50% ofMTS. See reverse side for application and safety information .

Plasma® 12 strand is the highest strength synthetic rope available. Plasma® 12 strand is manufactured from High Modulus Polyethylene (HMPE) that has been enhanced by Cortland’s patented recrystallization process. This process is especially effective in medium to large diameter ropes where strengths are over 50% higher and creep is significantly less than that of standard Spectra® 12 strand.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

We are a full service rigging supply company located in Ridgway, Pennsylvania. Our location is fully equipped to handle your wire rope fabricating, chain and synthetic sling and hardware needs.

8613371530291

8613371530291