wire rope choker capacity manufacturer

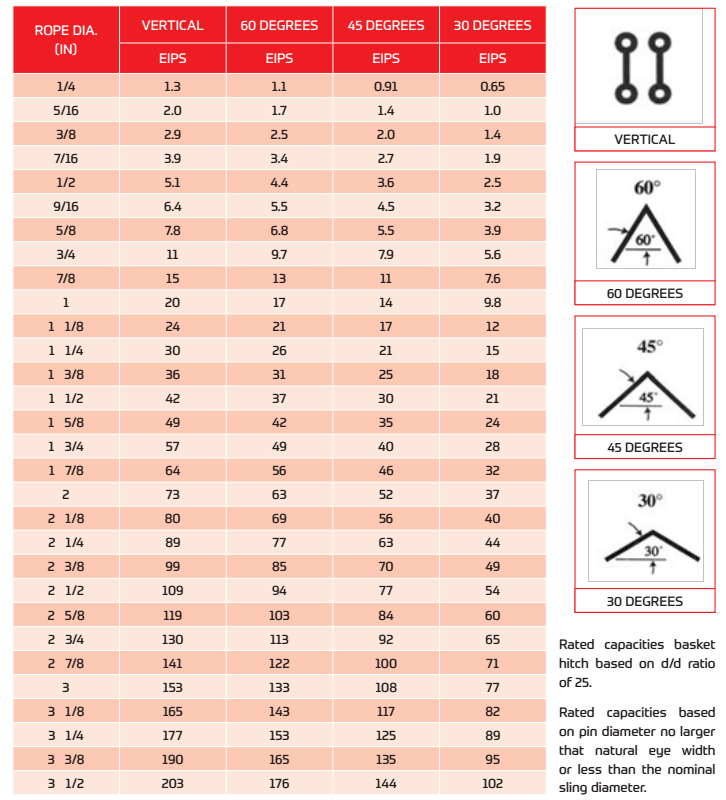

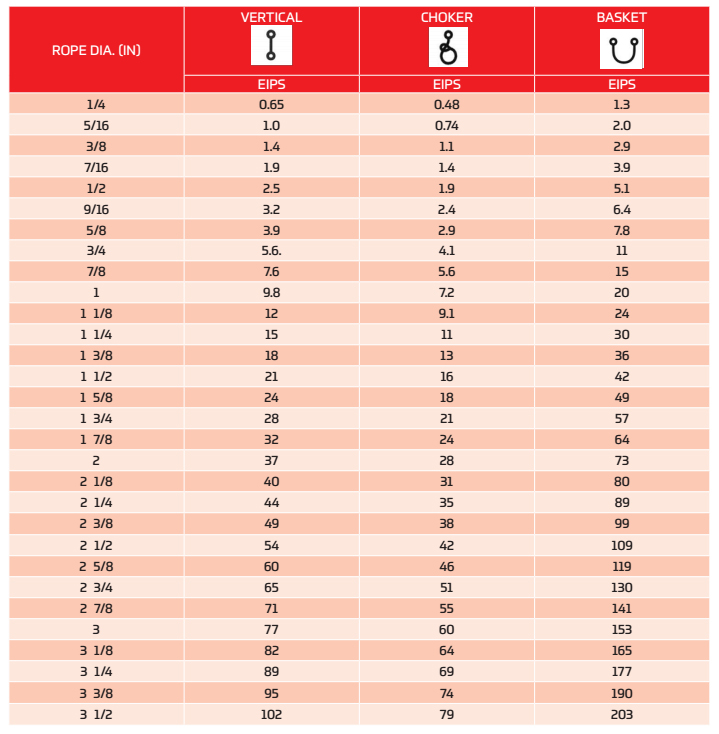

VERTICAL, or straight, attachment is simply using a sling to connect a lifting hook to a load. Full rated lifting capacity of the sling may be utilized, but must not be exceeded. A tagline should be used to prevent load rotation, which may damage a sling.

CHOKERhitches reduce lifting capability of a sling since this method of rigging affects ability of the wire rope components to adjust during the lift. A choker is used when the load will not be seriously damaged by the sling body — or the sling damaged by the load, and when the lift requires the sling to snug up against the load.

The diameter of the bend where the sling contacts the load should keep the point of choke against the sling BODY — never against a splice or the base of the eye. When a choke is used at an angle of less than 120 degrees (see next page), the sling-rated capacity must be adjusted downward.

A choker hitch should be pulled tight before a lift is made — NOT PULLED DOWN DURING THE LIFT. It is also dangerous to use only one choker hitch to lift a load which might shift or slide out of the choke.

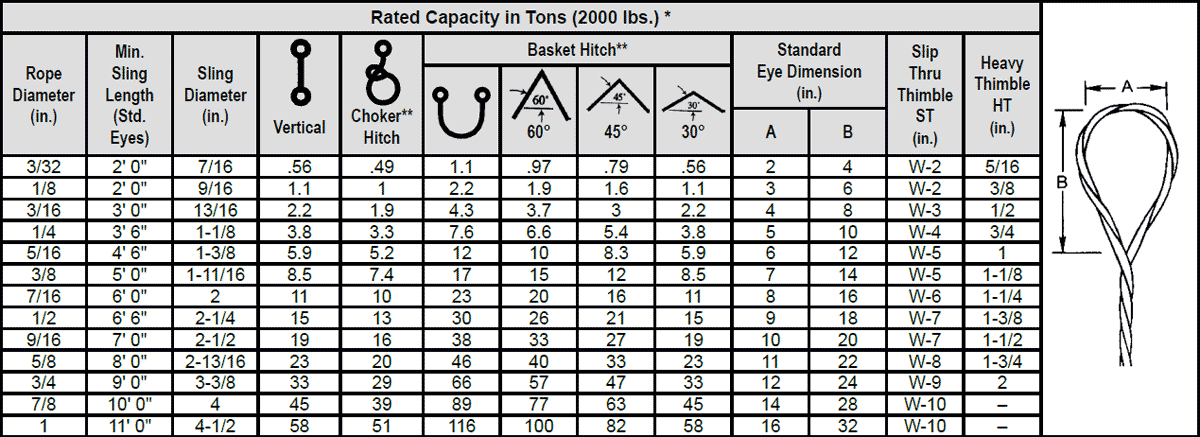

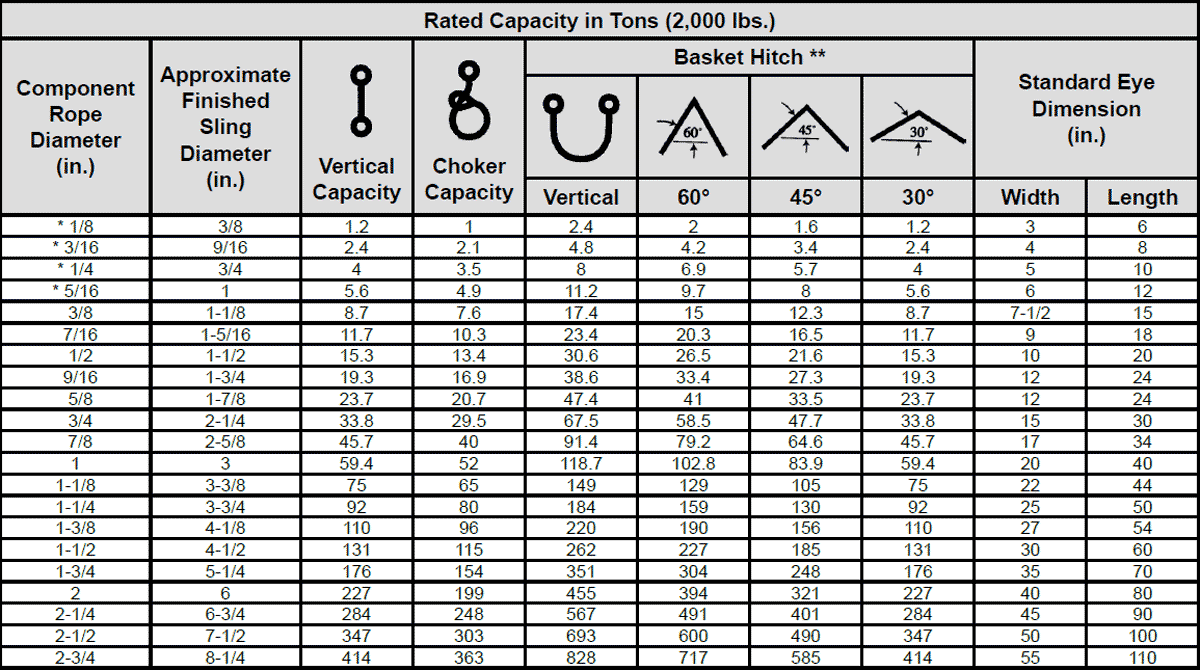

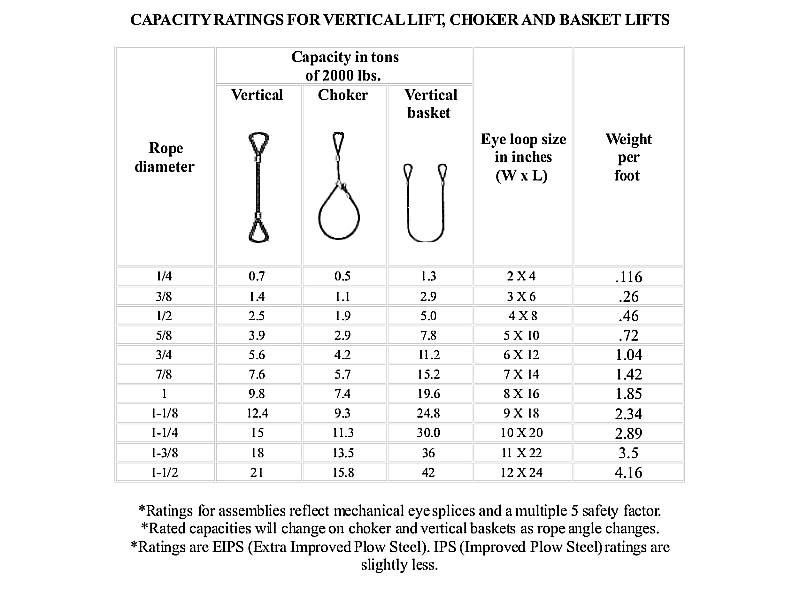

Anytime pull is exerted at an angle on a leg—or legs—of a sling, the load per leg can be determined by using the data in the table above. Proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift.First, divide the total load to be lifted by the number of legs to be used. This provides the load per leg if the lift were being made with all legs being vertically.

Then MULTIPLY the load per leg (as computed above) by the Load Factor for the leg angle being used (from the table at the bottom) – to compute the ACTUAL LOAD on each leg for this lift and angle. THE ACTUAL LOAD MUST NOT EXCEED THE RATED SLING CAPACITY.

The horizontal angle of bridles with 3 or more legs is measured the same as the horizontal sling angle of 2-legged hitches. In this case, where a bridle designed with different leg lengths results in horizontal angles, the leg with the smallest horizontal angle will carry the greatest load. Therefore, the smallest horizontal angle is used in calculating actual leg load and evaluating the rated capacity of the sling proposed.

On the other hand, the eye should always be used on a hook or pin with at least the nominal diameter of the rope—since applying the D/d Ratio shows an efficiency loss of approximately 50% when the relationship is less than 1/1.

When rigged as a basket, DIAMETER of the bend where a sling contacts the load can be a limiting factor on sling capacity. Standard D/d ratios— where “D” is the diameter of bend, and “d” the diameter of the rope—are applied to determine efficiency of various sling constructions, as indicated below:Mechanically Spliced, Single-Part Slings: 25 times rope diameter

Whether to use a single-part sling (one made of a single wire rope in the sling body) or a multi-part sling (several ropes in the body) is usually the first decision to make after determining the sling length and capacity for a lift.

The starting point for this decision involves the handling characteristics of the sling more than any other factor. Based on capacity alone, multi-part slings will be more flexible…more easily handled…than single-part slings. The larger the capacity of a sling, the more important this becomes…to the point, it becomes unrealistic to build big capacity slings from single, very large wire ropes.

In the design of the sling, rope engineers must seek a balance between strength-handling characteristics and number of parts…since there is a tendency to lose strength as core parts are added to increase flexibility.

If a load is hanging free, the normal choke angle is approximately 135 degrees. When the angle is less than 135 degrees, an adjustment in the sling-rated capacity must be made. Choker hitches at angles greater than 135 degrees are not recommended since they are unstable.

Extreme care should be taken to determine the angle of choke as accurately as possible. In controlled tests, where the angle was less than 120 degrees, the sling body always failed at the point of choke when pulled to destruction. Allowance for this phenomenon must be made anytime a choker hitch is used to shift, turn or control a load, or when the pull is against the choke in a multi-leg lift.

This is the length of wire rope between splices, sleeves or fittings. Generally, the minimum body length is equal to ten (10) times the sling body diameter. This allows approximately one and one half (1-1/2) rope lays between splices. For Multi-part slings, the minimum body length between splices is equal to forty (40) times the component rope diameter.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping, and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively, the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is comprised of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper, and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion, and environmental conditions as well as the intended use for the sling.

Adjusting the rated capacity of choker hitch 120 degrees due to the body of the sling being used in the choke, there is reduction in rated capacity. This is reflected in the choker rated capacity tables. Another reduction that must be considered is due to the angle of the choke (not the angle of the leg of the sling).

WARNING: Choker hitches at angles greater than 135 degrees are not recommended since they are unstable. Extreme care should be taken to determine the angle of choke as accurately as possible.

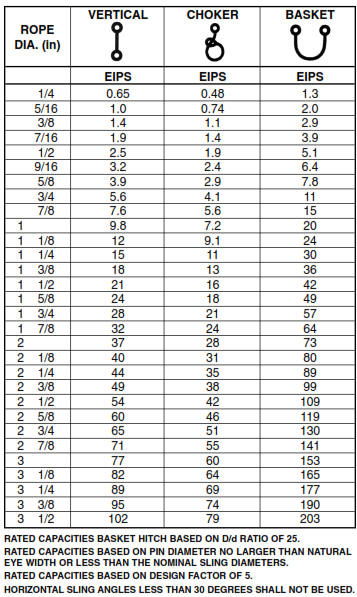

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

The single leg wire rope sling with soft eyes at each end is a best selling style. It can be used in a range of hitches and angles including vertical, choker and basket. Manufactured with mechanical Flemish eye splicing for excellent efficiency and strength. These are the best option for rigging and lifting applications that require heavy-duty slings that are abrasion-resistant but still flexible. Wire rope slings are popular where a variety of heavy loads and rugged conditions exist like construction, automotive, oil & gas, steel mills, forging facilities and general manufacturing industries.

The Design Factor for wire rope slings is a 5:1 ratio, meaning the breaking strength of the sling is five times higher than the rated Working Load Limit (W.L.L). Per the Wire Rope Users Manual, a design factor is necessary to allow for conditions such as wear, abrasion, damage, and variations in loads which are not readily apparent. Although wire rope slings have a design factor, the user should never exceed the rated Working Load Limit.

The single leg wire rope sling with soft eyes at each end is a best selling style. It can be used in a range of hitches and angles including vertical, choker and basket. Manufactured with mechanical Flemish eye splicing for excellent efficiency and strength. These are the best option for rigging and lifting applications that require heavy-duty slings that are abrasion-resistant but still flexible. Wire rope slings are popular where a variety of heavy loads and rugged conditions exist like construction, automotive, oil & gas, steel mills, forging facilities and general manufacturing industries.

The Design Factor for wire rope slings is a 5:1 ratio, meaning the breaking strength of the sling is five times higher than the rated Working Load Limit (W.L.L). Per the Wire Rope Users Manual, a design factor is necessary to allow for conditions such as wear, abrasion, damage, and variations in loads which are not readily apparent. Although wire rope slings have a design factor, the user should never exceed the rated Working Load Limit.

Choose wire rope slings by diameter based on capacity ratings. Then shop by length. Sliding choker wire rope slings are manufactured with a hook that slides between the two eyes. This allows the operator to place one eye on the hook, which creates an adjustable hitch around a load.

Our wire rope sling with sliding choker features a thimbled eye on the sling end that attaches to the hook; this helps prevent abrasions and general wear on the sling eye, which lengthens the working lift of the sling. Our choker wire rope slings are also available with a latched choker hook by special order.

Wire rope bridles are measured by the length of the sling leg plus the end hook. The length of the oblong master should not be included in the overall measurement.

The inclusion of 3 individual parts of wire rope transforms a traditional single part wire rope sling into a multipart wire rope product that is significantly more user friendly and versatile. Large diameter wire rope can be cumbersome and expensive. Utilizing 3 smaller diameter ropes does not only achieve greater flexibility, but it also reduces the overall cost of the sling when compared to large single part wire rope slings. An added benefit of using 3 smaller diameter ropes over a single large diameter wire rope is a greatly reduced D/d ratio. Requiring only a 1.5:1 D/d in the eye and 5:1 D/d in the body. Reduction considerations for working load limits with your wire rope sling becomes less of an issue when utilizing 3 part wire rope slings.

BC Wire Rope & Rigging is a full service provider of wire rope, slings, chain, hoists, and rigging equipment. BC Wire Rope has served the heavy lifting needs of customers throughout Los Angeles, San Diego, Las Vegas, Tucson and the Western United States since 1974. Specializing in lifting products ranging from fall protection to synthetic slings, BC Wire Rope & Rigging carries products from the industry’s most reputable vendors including Crosby, Slingmax, Campbell, and Bridon American. With ample testing and manufacturing capabilities, BC Wire Rope is also the manufacturer of KWIK synthetic slings.

Crosby has determined that 7/8″ shackles with the Product Numbers below that also contain the Production Identification Code (PIC) 5YH may have a reduced capacity and should be removed from service and replaced. 1019542 7/8” 6.50t S-2130 Shackle1019533 7/8” 6.50t G-2130 Shackle1018151 7/8” 6.50t G-213 Shackle1018160 7/8” 6.50t S-213 Shackle1018516 […]

Crosby has determined that some 1″ G-209/S-209 Shackles with product codes 1018534 and 1018543 may have a condition that reduces the load capacity. The impacted shackles were shipped from Crosby between November 23, 2021, and January 28, 2022. These shackles should be removed from service and returned for replacement. Please […]

BC Wire Rope was onsite as the last steel beam was raised by Schuff Steel at the new, future home of the Los Angeles Rams and LA Chargers at SofFi Stadium in Inglewood, California. The raising of the last beam is marked by the raising of a ceremonial Christmas Tree, […]

Established nearly 40 years ago in Southern California, BC Wire Rope now manufacturers and distributes wire rope from 5 locations to strategically serve customers across the West Coast. Headquartered in a 35,000 square foot warehouse and manufacturing facility in Anaheim, BC Wire Rope is the premier provider of rigging throughout the greater Orange County and Los Angeles area and also has branches in Tucson, Las Vegas, San Diego, and Elko. These locations allows BC to stock a full inventory of specialty lifting products and enables BC to efficiently meet a wide range of manufacturing needs.

Full in-house testing and wire rope manufacturing capabilities help ensure that BC Wire Rope can meet or exceed its customers’ needs. BC Wire Rope can press wire rope slings and swaged boom pendants, splice slings and soft rope, and can fabricate special end fittings. BC also manufacturers its own line of synthetic slings through its KWIK Products division. KWIK Products include nylon eye & eye endless flat slings, high performance fiber slings, polyester round slings, and choker and basket hardware slings. BC Wire Rope also provides customers with proof testing through use of its 4 test beds that can test slings, blocks, and hardware with up to 1 million pounds of force.

BC Wire Rope & Rigging’s unrelenting focus on customer service and industry leading products is evidenced by its ‘Quality – No Compromise’ motto. BC Wire Rope has been a proud member of the wire rope industry’s trade association—Associated Wire Rope Fabricators (AWRF)—for over 35 years. The commitment to longstanding industry relationships is also demonstrated by the fact the more than half of BC Wire Rope’s employees have remained with the company for over 18 years.

With years of industry knowledge and a full product inventory, chances are that BC Wire can meet your lifting needs. Contact the specialists at BC Wire Rope today to find out more about what BC Wire Rope can do for you.

8613371530291

8613371530291