wire rope clamp position supplier

Manufacturer of wire rope clips made from stainless steel and die-cast zinc materials. Grip and U-bolt clips are offered. Available in various wire rope diameters with drop forged, hot galvanized, self-colored and zinc plated finishes. Suitable for tillers and cables. Clips are also distributed. Serves the transportation, mining, railroad, construction, architectural, fitness, automotive, marine, OEM, military, display, signage, lighting, security and recreation industries. Some clips meet military specifications and are made in the USA.

Wire rope clips, sometimes referred to as u bolt clamps, u bolt clips, u clips, u clamps or cable clamps, are used to secure the loose end of a wire rope when forming an eye. Wire rope u clips have a u-bolt that is secured into a saddle by two nuts. Wire rope assemblies almost always require two, or more wire rope clamps to secure the wire rope properly. When using wire rope cable clamps to form an eye in a wire rope, the working load limit of the wire rope is reduced by about 20%.

Here at Tri-State Rigging Equipment we pride ourselves on providing only the highest quality wire rope clamps from only the most reputable manufacturers. We can provide you with any wire rope clip on the market so, if you are unable to find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

Wire rope cable clamps come in a variety of materials ranging from galvanized and zinc plated steel, to stainless steel. The two most important different types, however, are drop forged and malleable wire rope u bolt clips.

Drop forged wire rope clips are more heavy duty than malleable rope clips and can therefore be used for more heavy-duty rigging applications. In addition, they are galvanized with a heavy coating of zinc that resists the corrosion and abuse found in rugged work environments. Wire rope cable clamps of every type are not designed to be used in an overhead lift but drop forged wire rope u bolt clamps can be used to suspend an overhead load. This makes wire rope cable clamps ideal for use with:

Regarding the first question, if the load is being moved, wire rope clips are not to be used. If the load is being held in place, heavy-duty drop forged wire rope clips can be used. For the second question, if the load is near the ground, malleable wire rope clips may be used, as their lighter duty design is more than enough for the job. On the other hand, if the load is being suspended above the ground, heavier duty drop forged wire rope clamps must be used.

In the rigging and lifting industry there is a common saying that is used to remember the correct way to use wire rope u clips: “Never saddle a dead horse.” This means that the saddle of the u clamp should always be in contact with the live side of the wire rope rather than the dead side. The dead side of the wire rope is the side of the eye that has the cut end. The dead end is attached to the live end of the wire rope to form an eye and it is imperative that the saddle be on the live side of the wire rope.

Tri-State Rigging Equipment is a service provider and distributor for all wire rope cable clamps, and u bolt clips for rigging serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

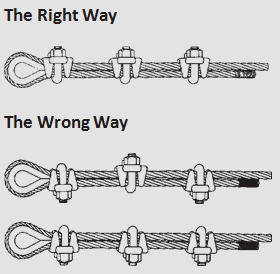

U-bolt Clips.There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in TheRightWayimage below. The base of the clip bears on the live end of the rope; the “U” of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached—only the center clip in the top view is correct. When the “U” of the clip bears on the live end of the rope, there is a possibility of the rope being cut or kinked, with subsequent failure.

Looking for a wood clamp or a bar clamp to level up your woodworking workshop and skills? Look no further! At Alibaba.com, you can browse an endless variety of wholesale wire rope clamps and find the perfect fit for you regardless of experience.

If you are looking to further your woodworking skills, woodworking clamps such as the spring clamps can be your next best investment! Head over to Alibaba.com to get your brand new wire rope clamps for your next pet project! Who knows, this purchase may be the catalyst to your future greatness!

You can even get a beam clamp to suspend or secure fixtures, wires, threaded rods, and other hardware to beam flanges. They offer secure fixing without the need for welding and drilling, making it the perfect purchase for your next DIY project! Find affordable cable clamps made with quality materials on Alibaba.com!

On the other hand, if you would prefer to work with drilling and welding for your pet projects, you may browse our massive selection of metal clamps and welding clamps. The metal clamps will provide a more durable option to the other wire rope clamps you can find on the market! Find the most suitable product for your needs and level of expertise today on Alibaba.com and get free shipping and further discounts on your purchase!

We are a full service rigging supply company located in Ridgway, Pennsylvania. Our location is fully equipped to handle your wire rope fabricating, chain and synthetic sling and hardware needs.

US type stainless steel wire rope clips are made by AISI 316 marine grade stainless steel or 304 stainless steel with tough, durable, and corrosion-resistant, we also have malleable wire rope clamps stainless steel for your option. Meet the performance requirements of U.S. standard.

Bishop Lifting stocks 3 styles of Forged Wire Rope Clips for use as Wire Rope end Fittings. G-450 Red-U-Bolt® Clips, G-429 Fist Grip Clips and G-460 Soft Eye Bundle Clip, and the G-461 Thimble Eye Bundle Clip. Bishop Lifting is a proud distributor for the Crosby group including their line of wire rope clips.

Wire Rope Clips are used for forming eyes in the ends of wire rope by following an installation procedure provided by Crosby® and OSHA 1926.251. ASME states that when used for lifting wire rope clips shall be drop-forged steel of single saddle (u-bolt) or double saddle clip. Malleable cast iron wire rope clips shall not be used. The use of wire rope clips to fabricate slings is generally prohibited as per ASME B30.9. Efficiency ratings of a properly prepared loop or thimble eye terminations for clip sizes 1/8" through 7/8" is 80%, and sized 1" through 3-1/2" is 90%. U-Bolt style clips are not recommended for elevator, personnel hoist and scaffold applications, refer to ANSI A17.1 and ANSI A10.4. Consult the manufacturer before installing wire rope clips on plastic coated or plastic impregnated wire rope.

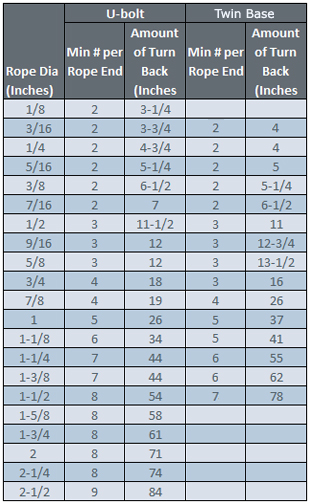

Before installing the wire rope clips make sure that you have the proper size clips and that the turnback is the proper length based on manufacturer"s recommendations. Place the wire rope clips on in the proper sequence, and make sure that you torque all of the wire rope clips evenly. The saddle of the wire rope clip should be placed on the live end of the wire rope, and the u-bolt should be placed on the dead end. Make sure that you use at least the minimum number of wire rope clips, proper spacing, and turnback length recommended by the manufacturer. Also make sure you torque the wire rope clips to the torque values recommended by the manufacturer. After assembly make sure that you test the connection to at least the anticipated working load, and the check and retighten the wire rope clips to the recommended torque values.

Crosby wire rope clips can be reused if they were installed properly and can pass inspection in between uses. Wire rope clips will wear out over time when they are reused. Check the threads for stretch and corrosion and check the saddle area for wear, deformation, and corrosion. The u-bolt must fit into the base without requiring a forceful change in u-bolt spread. The wire rope clip assembly must be properly installed and capable of being torqued to the proper values. The roddles (ridges) in the clip base must be undamaged, and the clip assembly must be retorqued after the initial load application to the specified torque values.

G-460 Soft Eye Bundle Clip and G-461 Thimble Eye Bundle Clips are used to hold pre-slinged choker eyes in position. These Bundle Clips reduce the rigging and handling time of drill pipe, casing and other down hole tubulars at shore bases, supply vessels and offshore installations.

Murphy offers many sizes of wire rope clips in 4 different fabrications: zinc plated, stainless steel malleable, galvanized drop forged, and stainless steel drop forged.

You can use wire cable clips to secure the loose ends of your wire ropes. They often have nuts, u-shaped bolts, and cast saddles. You can put the wire rope in the bolt and then place the saddle over the bolt’s rope. By using the nuts, you can then secure the rope in its place.

There are a couple of ways to make the process stronger. For example, if you have a cable coated with vinyl, then you can take off the vinyl in the place where you put it in the wire rope clip.

We offer our clips in a range of materials, which gives you more options. You can use the clips for semi-permanent or permanent applications, or just temporary ones. You can use your hand tools to secure them to your stainless steel wire rope. They are also cost-effective.

You can count on our company to offer sturdy and long-lasting clips, so you can secure your loose ends well. We have good knowledge of the requirements of various industries, allowing us to offer you the best products. You can expect our wire rope clips to last for a long time.

With so many different kinds of rope clips and ropes to choose from, we know making a choice can be difficult. Luckily, Murphy Industrial Products, Inc. is here to help. Feel free to contact us today if you want to know more about our stainless steel wire rope clips and related products.

The Crosby Group provides product users with “Red” U-Bolt Clips and forged Fist Grip Clips. Our wire rope clips meet the Federal Specification Number FF-C-450, considered the industry standard.

Compared to cast iron clips, forged clips provide a greater rope bearing surface and have been proven to be more consistent in strength and durability. Whether wire rope forged clips perform efficiently or not depends on whether the manufacturing practices were done properly.

First Grip Clips, for example, provide a saddle for both the live and the dead-end of the wire. This results in needing fewer forged clips for each termination. However, this is not the case with malleable cast iron clips. Forged wire clips reduce the possibility of hidden defects that are sometimes present in the cast iron clips. Cast iron clips should only be used in non-critical applications.

The wire rope clips are forged and galvanized, which ensures resistance to corrosion and rusting. The double saddle design eliminates the possibility of incorrect installation. The bolts are opposite one another, designed as an integral part of the clip. As a result, the nuts can be installed in such a way as to enable the operator to swing the wrench a full arc for easy installation.

The Crosby traceability system is actively used throughout all manufactured forged wire rope clips. All material analysis for each heat of steel is verified within our own laboratory.

We provide detailed warning information for all wire rope clips. Every clip is bagged or tagged with the warning information. This ensures that the information is available at the point of use for every wire rope clip during installation. The warning system is designed to attract the attention of the product user, with the goal to inform the user of the factors involved in the task and provide the user with proper application procedures.

Wire rope clips are used to fix the loose end of the loop back to a wire rope. These clips generally consist of a U-shaped bolt, forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is fitted over the ropes on to the bolt. The nuts secure the arrangement in place. When installing the clips, the saddle portion is placed on the load-bearing or live side. It is not to be placed on the non-load-bearing or dead side of the cable. This is to protect the stress-bearing end of the rope against crushing and abuse.

The size of the wire rope must be measured to allow selecting the proper size wire rope clip. The wire rope end must be seized prior to forming the eye to prevent the wire rope strains and core from shifting while forming the eye. The use of a soft wire to wrap the end of the wire rope is one method. Once properly wrapped, be sure to tighten the soft wire wrapping with plyers.

The number of clips required must be determined by referring to the information on the Crosby bag or on our catalog. Always use a thimble to protect the wire rope against wear and abrasion as it is used. Make sure the turn back is the proper length by using the tape measure to measure it.

As the clips are installed, it’s important to remember that the first clip is applied one base width from the dead-end, that should have been secured earlier. Always apply the U-bolt over the dead-end of the wire rope. Once the nuts are placed on the U-bolt by hand, they must then be tightened evenly. Using a torque wrench, alternate tightening from one nut to another nut until reaching the recommended torque.

The second wire rope clip is then applied as close to the loop or thimble as possible. When three or more clips are needed, space the clips equally between the first two. Take out any rope slack and place the nuts on these additional wire rope clips by hand. Tighten all of them with the torque wrench.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. Whether for use on cranes or for other lifting applications, it’s important to have a solid understanding of the rigging components that are being used to attach to and lift a load.

As a rigger or end-user of wire rope, it’s necessary to understand the types of wire rope end termination, or treatments that can be used at the ends of a length of wire rope—one of the most common being wire rope clips.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

As a general guideline, they are NOT to be used for making slings, as ASME B30.9 Slingsstandard states: “Mechanical wire rope terminations requiring periodic adjustment to maintain efficiency shall not be used to fabricate slings.”

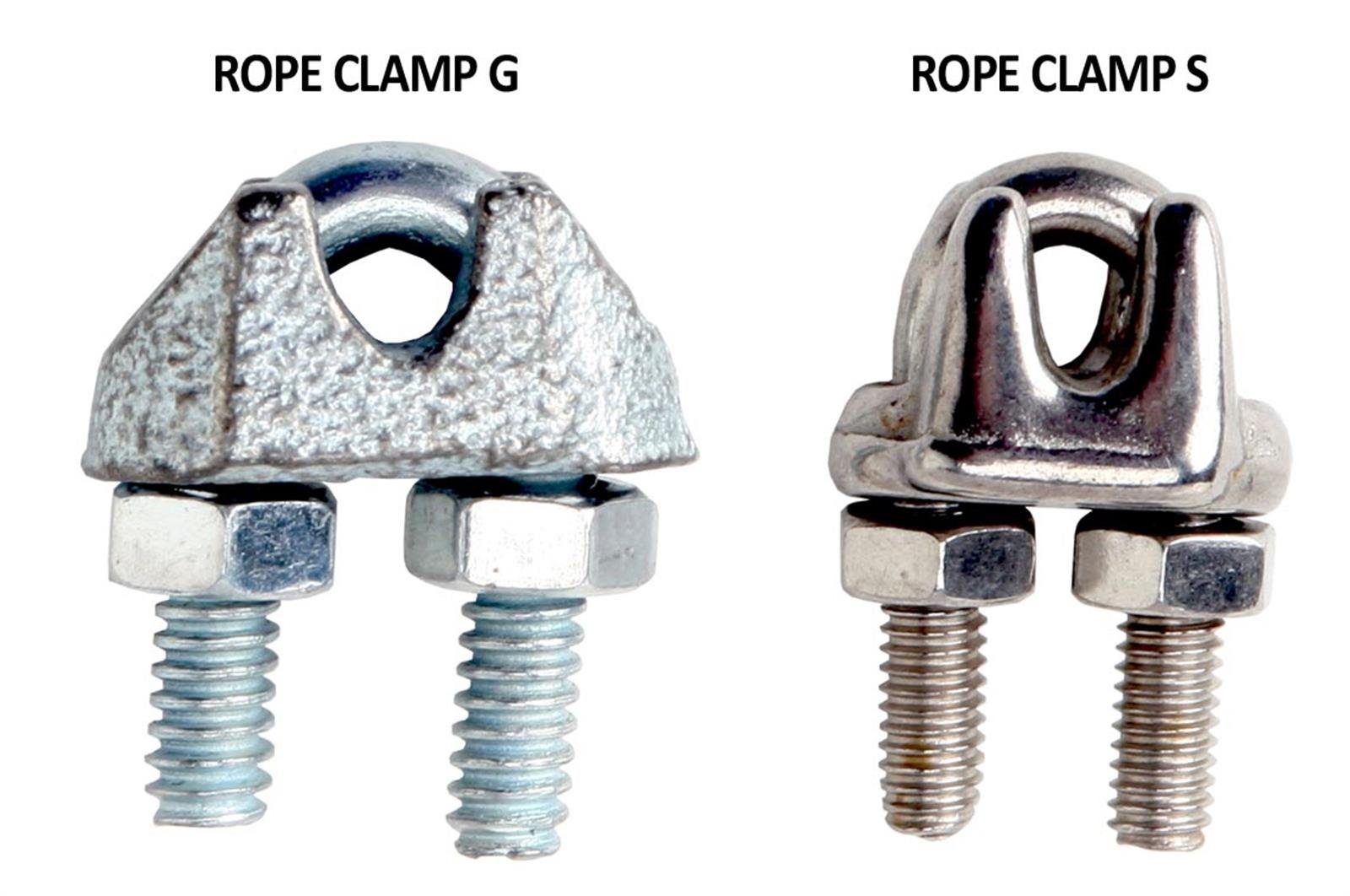

There are two main types of wire rope clips—U-Bolt and double saddle clips. U-Bolt wire rope clips are the most common and may be made of forged or malleable metal.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Unfortunately, it is not uncommon to see a wire rope clip applied incorrectly. Some of the most common mistakes include:Not torquing to the manufacturer’s expectations

Wire rope clips require the use of a torque wrench in order to function properly. Torquing the nuts on the clips too much or too little can cause the clip to fail. If the clip is over-torqued, it could damage the threads of the wire rope. If the clip is under-torqued, the holding power of the clip is diminished and the wire rope could slip through.

There are a minimum number of clips required for use related to the wire rope diameter. Using less than the number of specified clips could result in decreased efficiency and possible failure.

Depending on the number and size of the wire rope clips, there is a proportional amount of space required between the placement on each clip on the rope.

There are two sides of a U-Bolt style wire rope clip: the saddle and the U-Bolt. When securing a wire rope eye, it is important to place the clip on the correct end of the rope.

A saying commonly used in rigging to help remember this is: “Never saddle a dead horse!” In other words, never put the saddle on the dead end of the rope.

The turnback is the portion of the wire rope eye that runs from the end of the bearing eye to the live end. Having less than the suggested amount of turnback will decrease the efficiency of the wire rope eye and could lead to failure.

It is important to be sure you are using the correct wire rope clip—forged or malleable wire rope clips—for the application. Malleable clips can only be used for non-critical uses, such as tension rope to form a perimeter around a parking lot.

If the use is critical—an application where, if there is a failure, you have potential injury or loss of life or damage to property—a forged clip must be used.

The clip size used—whether it be 1/8”, 3”, or otherwise—must match the diameter size of the wire rope. If it doesn’t, the wire rope could slip out of the clip.

After installing clips, it is necessary to regularly cycle the rope and retighten the clips. Monitoring the torque on the nuts is important, as they will loosen over repeated use.

Basic steps for installing a wire rope clip include:First, wrap the wire rope around the thimble or to form the eye, and turn back the correct amount of rope—as specified by the manufacturer.

Apply the first wire rope clip at the end of the dead end, with one base width of space. Use a torque wrench to tighten the nuts on the wire rope clip.

When applying the second clip (if required), place it as close to the eye loop or thimble as possible. Again, be sure to properly tighten the nuts of the clip with a torque wrench.

Wire rope clips are a common and necessary piece of rigging hardware when it comes to using wire rope and forming end terminations. They are used to form a wire rope eye or to connect two cables together. It’s important to understand how to correctly install a wire rope clip, as incorrect installation leads to decreased efficiency in the wire rope assembly.

The minimum number of clips, clip location, amount of rope turn back, and amount to torque the bolts will vary depending on the wire rope size. Always refer to the manufacturers specifications for proper installation.

8613371530291

8613371530291