wire rope clip sizes quotation

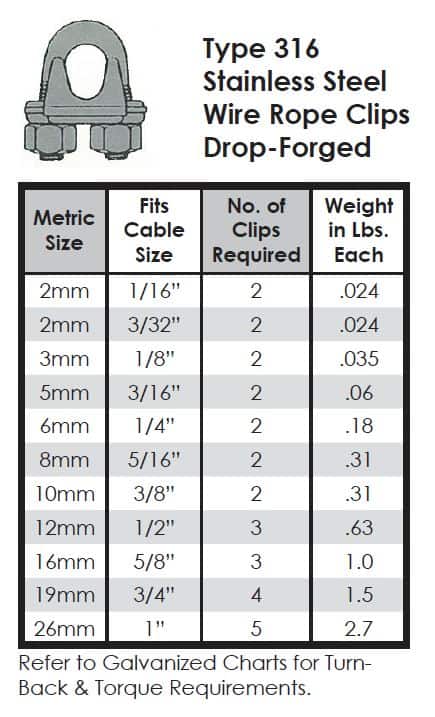

The Wire Rope Clip is available in sizes ranging from 1/16″ to 1-1/4″ to ensure a perfect fit for every project. This wire clip is precision cast and made from grade 304 stainless steel for maximum corrosion resistance and durability. It is ideal for marine and industrial rigging applications.

Caution: Wire rope clips are not to be used on PVC coated cable without first stripping off the PVC. Wire rope clips should be installed over bare cable only and nuts must be re-tightened or re-torqued regularly.

Stainless Wire Rope Clips & Clamps are available in sizes ranging from 1/8″ to 1/2″ for all projects, large or small. They are made from Grade 304 Stainless Steel for corrosion resistance and durability and are ideal for marine, industrial and architectural wire projects.

CAUTION: Wire Rope Clips are not to be used on PVC coated cable without first stripping off the PVC. Wire rope clips should be installed over bare cable only. Nuts must be re-tightened or re-torqued regularly.

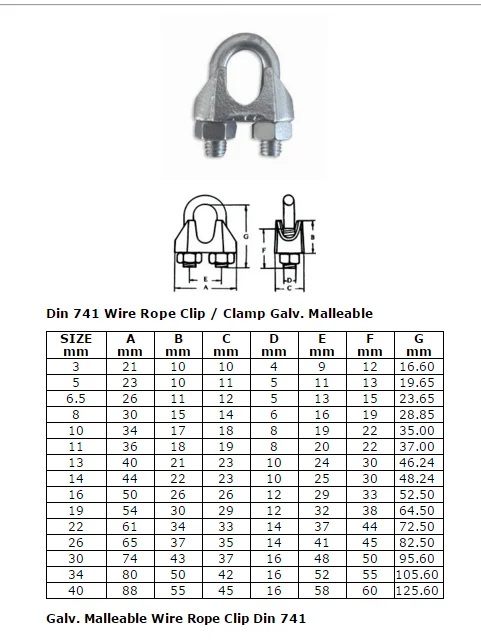

Malleable wire rope clips are designed for lighter loads but offer considerable cost advantages. Applications that malleable wire rope clamps can be used for include fencing, guard rails, hand rails, etc. As a rule of thumb, if it is an overhead or critical system, drop forged or precision cast steel wire rope clips should be used.

Fortune Rope is an industry-recognized supplier of aircraft cable, wire rope, chain, coated cable, and hardware fittings to a wide range of industrial and commercial customers who has the in-house capability to fabricate the custom cable assemblies you need — from one assembly to medium or high volume production runs.

Type 304 stainless steel U-bolt wire rope clips are most often used in rigging applications to secure the wire rope on the turn back and are ideal for use with moderate load applications. Please refer to the instructions below for more information on wire rope clips.

Turn back specified amount of rope from thimble or loop. Apply first clip one base width from dead end of rope. Tighten nuts evenly, alternating from one nut to the other until reaching the recommended torque.

When two clips are required, apply the second clip as near the loop or thimble as possible. Tighten nuts evenly, alternating until reaching the recommended torque. When more than two clips are required, apply the second clip as near the loop or thimble as possible, turn nuts on second clip firmly, but do not tighten.

When three or more clips are required, space additional clips between first two—take up rope slack—tighten nuts on all clips, alternating from one nut to the other until reaching the recommended torque.

The number of clips shown is based upon using RRL or RLL wire rope, 6 x 19 or 6 x 37 Class, FC or IWRC, IPS or XIP. If Seale construction or similar outer wire type construction in the 6 x 19 Class is to be used for sizes 1″ and larger, add one additional clip The number of clips shown also applies to rotational-resistant RRL wire rope, 8 x 19 Class, IP, IIP, sizes 1-1/2″ and smaller, and to rotation-resistant RRL wire rope, 19 x 7 Class, IPS, IIP, sizes 1-1/2″ and smaller. For other classes of wire rope, additional clips may be necessary. Length of rope turn-back should be increased when more clips are used. Efficiency ratings for wire rope end terminations are based upon the breaking strength of wire rope. The efficiency rating of a properly prepared loop or thimble eye termination for clip sizes 1/8″ through 7/8″ is 80% and for sizes 1″ through 1-1/2″ is 90%. In accordance with good rigging and maintenance practices, the wire rope end termnation should be inspected periodically for wear, abuse and genera adequacy.

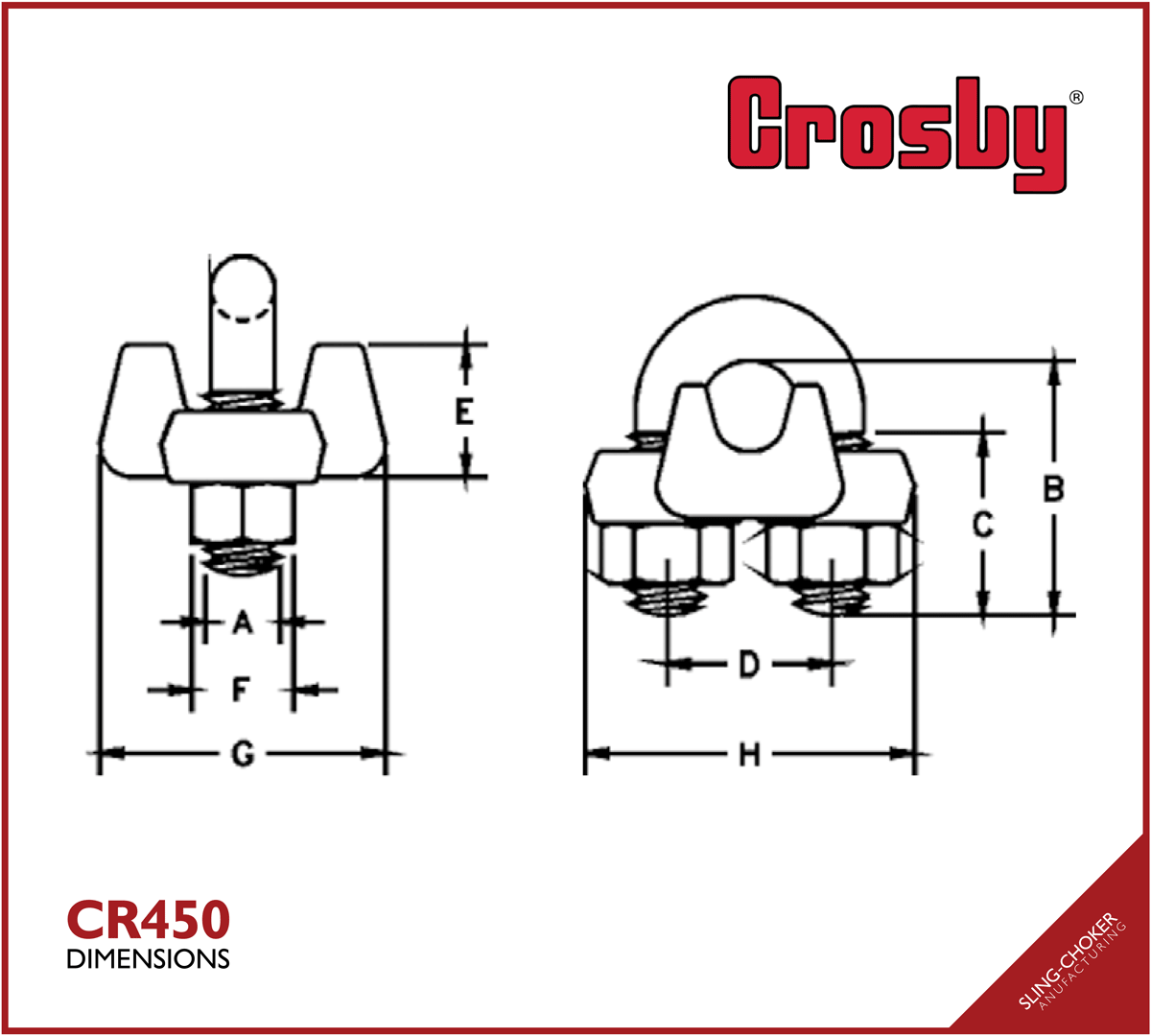

Crosby® G-450 heavy duty wire rope clips are drop forged and have a Red U-Bolt® for easy identification. These wire rope clips are ideal for heavy duty applications and most often used with heavy duty rigging applications to secure the wire rope on the turn back. Each base has a Product Identification Code (PIC) for material traceability, the name CROSBY or CG, and a size forged into it.

The correct way to attach wire rope clips is illustrated above. Apply the first clip one base width from the dead end of the wire rope. The base or saddle should bear on the line end of the rope – U-bolt on the short end. Tighten nuts firmly.

Attach balance of clips spaced equally between first two clips. Tighten all nuts completely. Apply initial load – inspect nuts and retighten. Inspect all clips periodically.

The number of clips shown is based on using right regular or Lang lay wire rope, 6×19 class or 6×37 clasee, fibre core IWRC, IPS or XIPS. The number of clips shown also applies to right regular lay wire rope, 8×19 class and 18×7 class, fibre core, IPS or XIPS, sizes 1-1/2-inch and smaller.

If Seale construction or similar large outer wire type construction in the 6×19 class is to be used for sizes 1-inch and larger, add one additional clip. For other classes or wire rope not mentioned, it may be necessary to add additional clips to the number shown. If more clips are used than shown, amount of rope turn back should be increased proportionately.

Delta Rigging and Tools stocks 3 styles of Forged Wire Rope Clips for use as Wire Rope end Fittings. G-450 Red-U-Bolt® Clips, G-429 Fist Grip Clips and G-460 Soft Eye Bundle Clip, and the G-461 Thimble Eye Bundle Clip.

Wire Rope Clips are used for forming eyes in the ends of wire rope by following an installation procedure provided by Crosby® and OSHA 1926.251. Efficiency ratings of a properly prepared loop or thimble eye terminations for clip sizes 1/8" through 7/8" is 80%, and sized 1" through 3-1/2" is 90%. U-Bolt style clips are not recommended for elevator, personnel hoist and scaffold applications, refer to ANSI A17.1 and ANSI A10.4.

G-460 Soft Eye Bundle Clip and G-461 Thimble Eye Bundle Clips are used to hold pre-slinged choker eyes in position. These Bundle Clips reduce the rigging and handling time of drill pipe, casing and other down hole tubulars at shore bases, supply vessels and offshore installations.

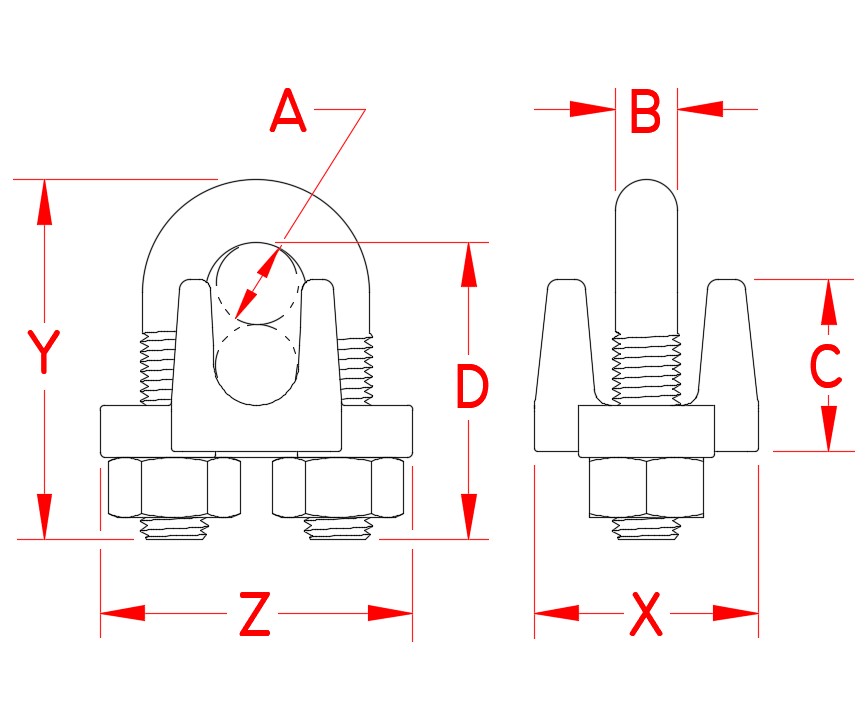

Wire rope clip is otherwise known as a wire rope clamp, wire cable clamp, wire clamp, wire clip, U-bolt, etc. It is widely used for making eye-loop connections or join two wire rope cable ends together. The traditional styles of wire rope clips usually have three components: a U-shaped bolt, a forged or cast iron saddle, and two nuts.

The wire rope clips are available in a range of sizes and finishes, while you can easily find the difference from the appearance, traditional wire clips with u bolt, saddle and nuts, fist grip, stamped cable clamp.

Cast and malleable wire rope clips can only be used under light duty loads applications with relatively light loads, such as handrails, fencing, guard rails, etc.

While the drop forged wire rope clip variety is recommended for important, critical or sustaining overhead loads, such as guy lines, support lines, scaffolding, etc. The drop forged wire rope clips can be used in critical suspending, guying, and tie-down applications for the die forging process make them strong and more durable and the heating and hammering steps make their structure to be consistent and conform to the shape of the forged item.

Simplex and duplex cable clamps are also known as single stamped wire clip and double stamped cable clip are composed of stamping plate, saddle, and bolts, feature an aesthetic design, used for outdoor light duty applications.

Wire rope clips are available in a variety of materials and finishes but basically three types of materials, carbon steel, cast, malleable iron, and stainless steel.

Carbon steel wire rope cable clamps are galvanized, or hot dipped galvanized, the galvanised metal wire clamp has an added zinc layer to prevent rusting and protect against scratching and the addition of carbon corresponds with an increase in the hardness and strength of wire rope cable clamps. G, but stainless steel wire rope clamps are the best choice for corrosion-resistant applications that can be used for saltwater environments.

Commonly wire rope clamp installation is very simple, there’s a well-known saying can help you remember how to attach wire rope clips, that reads “never saddle a dead horse.” Just follow the recommendation ways:

Keep three or more wire rope clips attached at the end of the wire rope dead end, space between each wire rope clip should be at least 6 times the wire rope diameter.

You can see the correct and incorrect ways of installation from the following pictures and find how many wire rope clips to use at one wire rope loop.

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

US type stainless steel wire rope clips are made by AISI 316 marine grade stainless steel or 304 stainless steel with tough, durable, and corrosion-resistant, we also have malleable wire rope clamps stainless steel for your option. Meet the performance requirements of U.S. standard.

Bishop Lifting stocks 3 styles of Forged Wire Rope Clips for use as Wire Rope end Fittings. G-450 Red-U-Bolt® Clips, G-429 Fist Grip Clips and G-460 Soft Eye Bundle Clip, and the G-461 Thimble Eye Bundle Clip. Bishop Lifting is a proud distributor for the Crosby group including their line of wire rope clips.

Wire Rope Clips are used for forming eyes in the ends of wire rope by following an installation procedure provided by Crosby® and OSHA 1926.251. ASME states that when used for lifting wire rope clips shall be drop-forged steel of single saddle (u-bolt) or double saddle clip. Malleable cast iron wire rope clips shall not be used. The use of wire rope clips to fabricate slings is generally prohibited as per ASME B30.9. Efficiency ratings of a properly prepared loop or thimble eye terminations for clip sizes 1/8" through 7/8" is 80%, and sized 1" through 3-1/2" is 90%. U-Bolt style clips are not recommended for elevator, personnel hoist and scaffold applications, refer to ANSI A17.1 and ANSI A10.4. Consult the manufacturer before installing wire rope clips on plastic coated or plastic impregnated wire rope.

Before installing the wire rope clips make sure that you have the proper size clips and that the turnback is the proper length based on manufacturer"s recommendations. Place the wire rope clips on in the proper sequence, and make sure that you torque all of the wire rope clips evenly. The saddle of the wire rope clip should be placed on the live end of the wire rope, and the u-bolt should be placed on the dead end. Make sure that you use at least the minimum number of wire rope clips, proper spacing, and turnback length recommended by the manufacturer. Also make sure you torque the wire rope clips to the torque values recommended by the manufacturer. After assembly make sure that you test the connection to at least the anticipated working load, and the check and retighten the wire rope clips to the recommended torque values.

Crosby wire rope clips can be reused if they were installed properly and can pass inspection in between uses. Wire rope clips will wear out over time when they are reused. Check the threads for stretch and corrosion and check the saddle area for wear, deformation, and corrosion. The u-bolt must fit into the base without requiring a forceful change in u-bolt spread. The wire rope clip assembly must be properly installed and capable of being torqued to the proper values. The roddles (ridges) in the clip base must be undamaged, and the clip assembly must be retorqued after the initial load application to the specified torque values.

G-460 Soft Eye Bundle Clip and G-461 Thimble Eye Bundle Clips are used to hold pre-slinged choker eyes in position. These Bundle Clips reduce the rigging and handling time of drill pipe, casing and other down hole tubulars at shore bases, supply vessels and offshore installations.

If you are interested in a Wire Rope Clip, you have come to the right place. We offer U-Clips made with stainless steel or galvanized steel. These clamps are used to apply terminations on a cable assembly.

If you are looking for swage sleeves, which fulfill similar functions, we also have those available in their own category. However, if you are interested in picking up some Wire Rope Clips, we have prepared some information that you should find useful.

As we mentioned before, Wire Rope Clamps are used for a similar function to their not-so-distant cousin, the swage sleeve/ferrule. They are used to establish dead-ends and eyes at the end of a wire cable.

While using a clip may decrease the breaking strength of a rope slightly more than a swage would, there are a few advantages over swages. A Wire Rope Clip can be removed and even reused without much wear. This makes clips ideal for less permanent fixes.

When a clip is installed properly, the decrease in the breaking strength of the wire. Eyes installed with Cable Clips will maintain 80-90% of their strength. However, when a clip is not installed properly, the decrease in breaking strength will be much more significant.

Since we just discussed the importance of installing a wire clip properly, let’s talk about what you will need to get this kind of job done. If you already work with wire cables, chances are you already have everything you need.

For the most part, Galvanized Steel is a little easier on your wallet than Stainless Steel and it will take a lot of abuse without much damage to show. However Galvanized Steel is not quite as strong as Stainless Steel and it can’t be used in jobs where the rope may be exposed to saltwater or excessive moisture.

When you are choosing your wire cable, there is a general rule of thumb. Large wires generally stand up very well to abrasion but are not as resistant to fatigue as smaller wires. The size of the rope will help to determine both its strength and flexibility.

Steel Cable Clamps are used in a wide variety of applications. They can be used in towing, loading, rigging, agriculture, and household uses just to name a few areas. The key advantage to using Wire Cable Clamps is that they can be used in any application where an eye termination may need to be removed at some point.

US Rigging are a manufacturer and master distributor of climbing ropes, fall protection equipment, and industrial rigging equipment located in Santa Ana, California. This Orange County based company is proud to provide American Made products with both safety and service in mind. US Rigging has a legacy lasting over 40 years and are known for operational excellence.

We offer a variety of Wire Rope Clips to fulfill your needs in rigging, lifting, towing, and heavy construction applications. These Cable Clips are designed to reliably splice wires with dead-end eye terminations. They are perfect for applications where you need to apply terminations that can be removed.

Although Carl Stahl Sava Industries is known for producing the world’s tungsten, stainless steel and galvanized steel mechanical cable, exotic wire rope materials remain a less common, yet critical member of our family of cable offerings. Nitinol, titanium, Vitallium®, Inconel® and Molybdenum round out Sava’s compliment of specialty mechanical cable materials...

8613371530291

8613371530291