wire rope clips and thimbles free sample

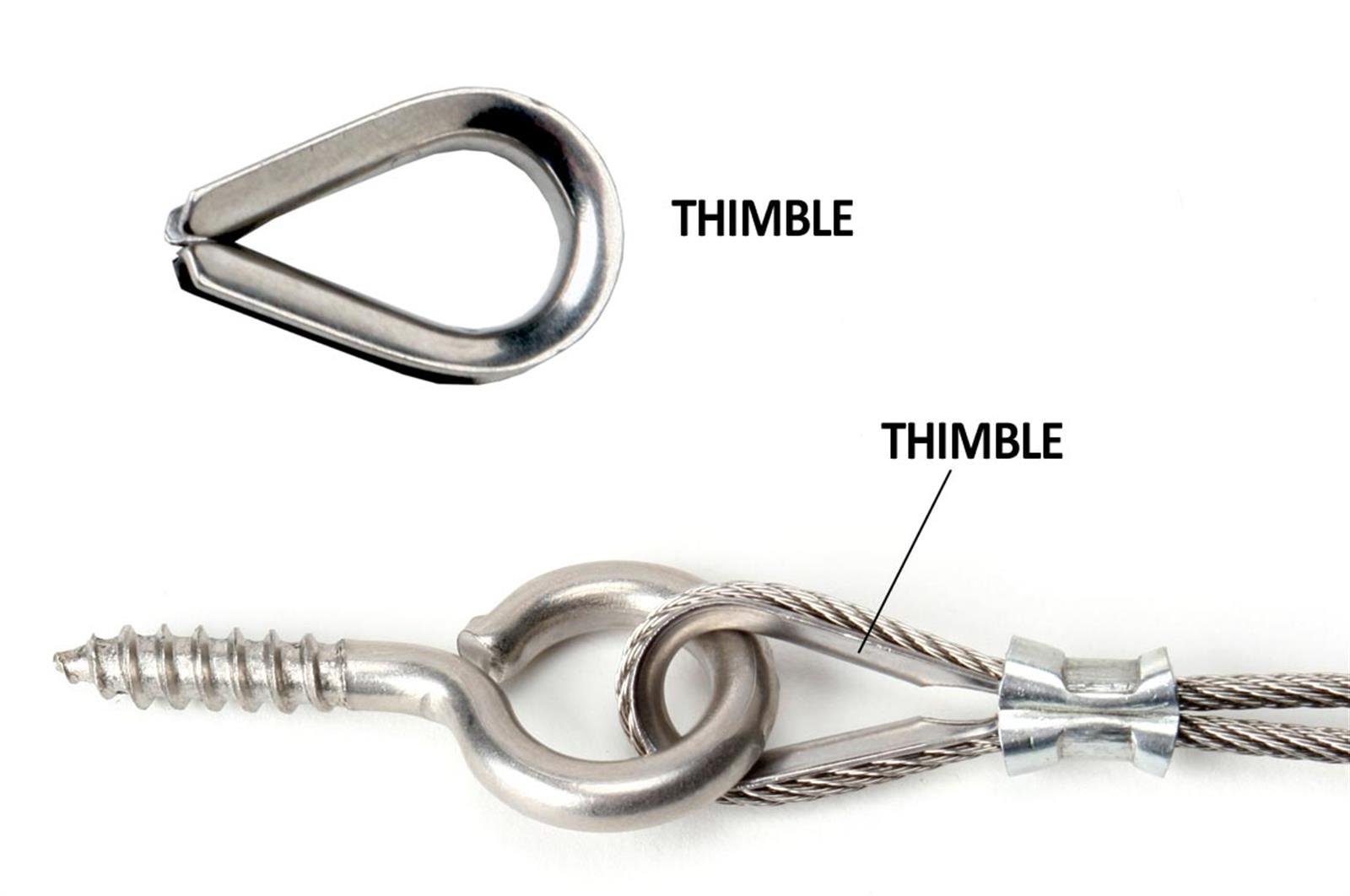

Wire rope thimbles also known as cable thimbles, are used for making reinforce loop(eyelet) with grips, clips or clamps by preventing fraying caused by friction at the bearing anchor point to protect and extend the service life of the wire rope or sling. They are just one of the many types of wire rope fittings (ferrules, wire rope clips, terminals, etc.).

Wire rope thimbles are available in a variety of strengths and materials(carbon steel and stainless steel, see our post on Surface Finish: 4 Common Types You Should Know) but mainly they come in two different duty grades.

If you use it in high moisture or corrosive environments, recommend our stainless steel wire rope thimbles which can offer resistance to corrosion on the surface, particularly in marine applications.

Simply wrap the end of the wire rope around the outer groove of the thimble, lace the dead end of the wire rope past the U-bolt of the wire rope grips or a wire rope ferrule crimp to hold onto the bearing anchor point at the end of the thimble to prevent fraying caused by friction.

Once in place, put another wire rope clip as near the loop you just wrapped over the thimble. Turn nuts firmly but do not yet tighten to the proper torque, we recommend using a crimping/swaging tool to compress the ferrule firmly onto the rope to hold your thimble loop securely.

Alternatively, you can use a wire rope ferrule crimp to secure your thimble in place. this method is quick and easy to install. For further information on installation using a wire rope ferrule please – click here

Wire rope thimbles are used in conjunction with cable and rope to protect the eyes and will allow for smooth rope guiding around natural curves. So that the most important thing is to make sure the thimble eye securely fastened. Here are some tips for correctly using wire rope thimble:

Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized rigging fittings.

While you are using a vinyl coated cable, you should multiply the actual size of the cable, usually use a larger size thimble than normal, for the actual diameter is the thickness of the vinyl coating plus the inside wire rope diameter. For example, if you are using a 5/16″ vinyl coated cable that is coated to 3/8″ diameter, you’d want to use a 3/8″ wire rope thimble.

My name is William Yang, I’m the business manager of Hilifting. I have been in Rigging industry for more than 10 year. Feel free to contact us. I’m happy to provide you the best service and products.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. Whether for use on cranes or for other lifting applications, it’s important to have a solid understanding of the rigging components that are being used to attach to and lift a load.

As a rigger or end-user of wire rope, it’s necessary to understand the types of wire rope end termination, or treatments that can be used at the ends of a length of wire rope—one of the most common being wire rope clips.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

As a general guideline, they are NOT to be used for making slings, as ASME B30.9 Slingsstandard states: “Mechanical wire rope terminations requiring periodic adjustment to maintain efficiency shall not be used to fabricate slings.”

There are two main types of wire rope clips—U-Bolt and double saddle clips. U-Bolt wire rope clips are the most common and may be made of forged or malleable metal.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Unfortunately, it is not uncommon to see a wire rope clip applied incorrectly. Some of the most common mistakes include:Not torquing to the manufacturer’s expectations

Wire rope clips require the use of a torque wrench in order to function properly. Torquing the nuts on the clips too much or too little can cause the clip to fail. If the clip is over-torqued, it could damage the threads of the wire rope. If the clip is under-torqued, the holding power of the clip is diminished and the wire rope could slip through.

There are a minimum number of clips required for use related to the wire rope diameter. Using less than the number of specified clips could result in decreased efficiency and possible failure.

Depending on the number and size of the wire rope clips, there is a proportional amount of space required between the placement on each clip on the rope.

There are two sides of a U-Bolt style wire rope clip: the saddle and the U-Bolt. When securing a wire rope eye, it is important to place the clip on the correct end of the rope.

A saying commonly used in rigging to help remember this is: “Never saddle a dead horse!” In other words, never put the saddle on the dead end of the rope.

The turnback is the portion of the wire rope eye that runs from the end of the bearing eye to the live end. Having less than the suggested amount of turnback will decrease the efficiency of the wire rope eye and could lead to failure.

It is important to be sure you are using the correct wire rope clip—forged or malleable wire rope clips—for the application. Malleable clips can only be used for non-critical uses, such as tension rope to form a perimeter around a parking lot.

If the use is critical—an application where, if there is a failure, you have potential injury or loss of life or damage to property—a forged clip must be used.

The clip size used—whether it be 1/8”, 3”, or otherwise—must match the diameter size of the wire rope. If it doesn’t, the wire rope could slip out of the clip.

After installing clips, it is necessary to regularly cycle the rope and retighten the clips. Monitoring the torque on the nuts is important, as they will loosen over repeated use.

Basic steps for installing a wire rope clip include:First, wrap the wire rope around the thimble or to form the eye, and turn back the correct amount of rope—as specified by the manufacturer.

Apply the first wire rope clip at the end of the dead end, with one base width of space. Use a torque wrench to tighten the nuts on the wire rope clip.

When applying the second clip (if required), place it as close to the eye loop or thimble as possible. Again, be sure to properly tighten the nuts of the clip with a torque wrench.

Wire rope clips are a common and necessary piece of rigging hardware when it comes to using wire rope and forming end terminations. They are used to form a wire rope eye or to connect two cables together. It’s important to understand how to correctly install a wire rope clip, as incorrect installation leads to decreased efficiency in the wire rope assembly.

Thimbles are designed to extend the longevity of wire rope loops by preventing fraying that can occur due to friction at the bearing point. Thimbles must be used in conjunction with either sleeves or wire rope clips in several specifications.

KingChain Wire Rope Clips and Thimbles are used to create a complete and secure eye or loop on wire rope. Wire rope should be the same diameter as rope clip and thimble. Wire Rope Clips consist of a U-shaped bolt, a forged saddle and 2 threaded nuts. The 2 layers of wire rope are placed in the U-bolt and clamped into place for a tight connection. Wire Rope Thimbles form the inside of the loop eye and provide rigidity and abrasion resistance for the inside of the loop. Both clips and thimbles are made from steel with a zinc-plated finish for weather resistance. If used on plastic coated cable, remove the coating from the assembly area before creating the loop. Do not use to hang loads, lift loads, support weight of persons or objects, and do not use on athletic or playground equipment.Use exclusively with 1/8 in. wire rope

For a safe connection, be sure to use the right number of clips, number of clips to use: 1/16 in. to 3/8 in. rope - 3 clips, 1/2 in. to 5/8 in. rope - 4 clips, 3/4 in. rope - 5 clips

KingChain Wire Rope Clips and Thimbles are used to create a complete and secure eye or loop on wire rope. Wire rope should be the same diameter as rope clip and thimble. Wire Rope Clips consist of a U-shaped bolt, a forged saddle and 2 threaded nuts. The 2 layers of wire rope are placed in the U-bolt and clamped into place for a tight connection. Wire Rope Thimbles form the inside of the loop eye and provide rigidity and abrasion resistance for the inside of the loop. Both clips and thimbles are made from steel with a zinc-plated finish for weather resistance. If used on plastic coated cable, remove the coating from the assembly area before creating the loop. Do not use to hang loads, lift loads, support weight of persons or objects, and do not use on athletic or playground equipment.Use exclusively with 3/16 in. wire rope

For a safe connection, be sure to use the right number of clips, number of clips to use: 1/16 in. to 3/8 in. rope - 3 clips, 1/2 in. to 5/8 in. rope - 4 clips, 3/4 in. rope - 5 clips

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

Professional technical support, huge sales network, perfect distribution center and convenient and efficient service make our Wire Rope Clips, machine room dumbwaiter lift, Vinyl Coated Wire Rope the first choice of companies all over the world. We have enough experience and resources to complete each project and make you satisfied, and most of us can provide in-stock products and satisfactory prices. We are recruiting talents in continuous development and change, and sincerely hope to encourage each employee to develop themselves. As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline.

G411 is a standard duty wire rope thimble with electric galvanized surface treatment. This thimble provides a hard eye in a wire rope lifting sling. The galvanized surface increases the corrosion resistance. It is recommended for light duty applications.

We have a large market share in Wire Rope Thimble DIN6899b field. We will improve the quality of our personnel, improve our service capability, improve our training capability, and improve our per capita income generation. Innovation is the number one driving force that leads our development and is present in our work every day.

There’s only one right way to install cable clips to get maximum efficiency (up to 85%) out of a prepared loop or thimble-eye termination – otherwise, the termination can be severely reduced in capacity.

You also need to know the number of clips required, the amount of rope to turn back from the thimble, and the torque needed to tighten the nuts. There are tables that detail all of this information.

All three clips must be installed with the saddle part on the live end of the rope. This allows the live end to rest in the saddle, and to not be crushed by the U-shaped part of the clip.

8613371530291

8613371530291