wire rope clips how to use supplier

Wire rope clip is otherwise known as a wire rope clamp, wire cable clamp, wire clamp, wire clip, U-bolt, etc. It is widely used for making eye-loop connections or join two wire rope cable ends together. The traditional styles of wire rope clips usually have three components: a U-shaped bolt, a forged or cast iron saddle, and two nuts.

The wire rope clips are available in a range of sizes and finishes, while you can easily find the difference from the appearance, traditional wire clips with u bolt, saddle and nuts, fist grip, stamped cable clamp.

Cast and malleable wire rope clips can only be used under light duty loads applications with relatively light loads, such as handrails, fencing, guard rails, etc.

While the drop forged wire rope clip variety is recommended for important, critical or sustaining overhead loads, such as guy lines, support lines, scaffolding, etc. The drop forged wire rope clips can be used in critical suspending, guying, and tie-down applications for the die forging process make them strong and more durable and the heating and hammering steps make their structure to be consistent and conform to the shape of the forged item.

Simplex and duplex cable clamps are also known as single stamped wire clip and double stamped cable clip are composed of stamping plate, saddle, and bolts, feature an aesthetic design, used for outdoor light duty applications.

Wire rope clips are available in a variety of materials and finishes but basically three types of materials, carbon steel, cast, malleable iron, and stainless steel.

Carbon steel wire rope cable clamps are galvanized, or hot dipped galvanized, the galvanised metal wire clamp has an added zinc layer to prevent rusting and protect against scratching and the addition of carbon corresponds with an increase in the hardness and strength of wire rope cable clamps. G, but stainless steel wire rope clamps are the best choice for corrosion-resistant applications that can be used for saltwater environments.

Commonly wire rope clamp installation is very simple, there’s a well-known saying can help you remember how to attach wire rope clips, that reads “never saddle a dead horse.” Just follow the recommendation ways:

Keep three or more wire rope clips attached at the end of the wire rope dead end, space between each wire rope clip should be at least 6 times the wire rope diameter.

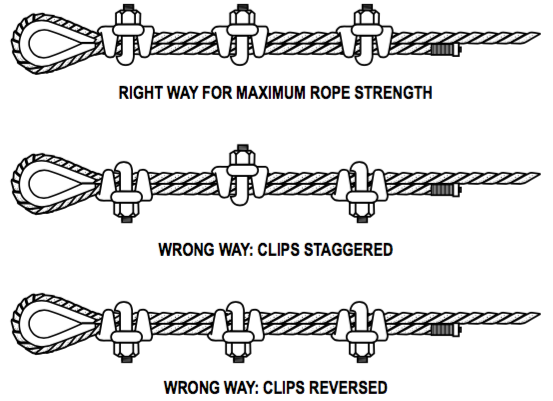

You can see the correct and incorrect ways of installation from the following pictures and find how many wire rope clips to use at one wire rope loop.

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

My name is William Yang, I’m the business manager of Hilifting. I have been in Rigging industry for more than 10 year. Feel free to contact us. I’m happy to provide you the best service and products.

1.Turn back specified amount of rope from thimble or loop. Apply first clip one base width from dead end of rope. Apply U-Bolt over dead end of wire rope with live end resting in saddle. Tighten nuts evenly, alternating from one nut to the other until reaching the recommended torque.

2. When two clips are required, apply the second clip as near the loop or thimble as possible. Tighten nuts evenly, alternating until reaching the recommended torque. When more than two clips are required, apply the second clip as near the loop or thimble as possible, turn nuts on second clip firmly, but do not tighten.

3. When three or more clips are required, space additional clips equally between first two – take up rope recommended slack – tighten nuts on each U-Bolt evenly, alternating from one nut to the other until reaching recommended torque.

4. Apply first load to test the assembly. This load should be of equal or greater – weight than loads expected in use. Next, check and retighten nuts to recommended torque.

In accordance with good rigging and maintenance practices, the wire rope and termination should be inspected periodically for wear, abuse and general adequacy.

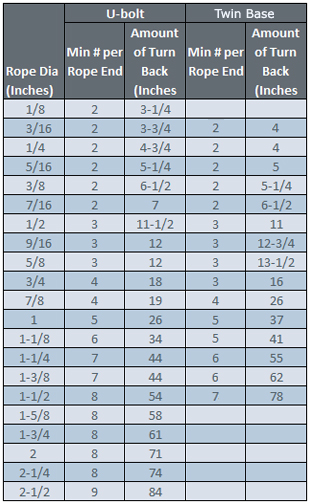

A termination made in accordance with the above instructions and using the number of dips shown, has an approximate 80% efficiency rating. This rating is based upon the nominal strength of wire rope. If a pulley is used in place of a thimble for turning back the rope, add one additional clip.

The number of clips shown is based upon using right regular or lang lay wire rope, 6×19 classification or 6×37 classification, fiber core or IWRC, IPS or EIP. If Seale construction or similar large outer wire type construction in the 6×19 classification, fiber core, IPS, sizes 11/2? and smaller; and right regular lay wire rope, 19×7 classification, IPS or EIP, sizes 1 3/4? and smaller.

If a greater number of clips are used than shown in the table, the amount of rope turnback should be increased proportionately. ABOVE BASED ON USE OF PROPER SIZE U-BOLT CLIPS ON NEW ROPE.

IMPORTANT: Failure to make a termination in accordance with mentioned instructions, or failure to periodically check and retighten to the recommended torque, may cause a reduction in efficiency rating.

Disculpa, pero esta entrada está disponible sólo en Inglés Estadounidense. For the sake of viewer convenience, the content is shown below in the alternative language. You may click the link to switch the active language.

Wire rope clips are quite small in relation to an entire wire rope setup, but this small hardware piece plays a key role in security and durability. The role of the wire rope clip is to join the end of the wire rope securely to create a loop. This may be used for overhead lifting, along with other numerous purposes, like:

There are different design styles for wire rope clips, but all clips work similarly. There is a rounded opening that fits around the wire rope. The clip is closed by two screws with bolts, causing the rounded opening to tighten around the wire rope, holding it firmly in place.

Since this hardware is used in applications that involve heavy equipment, which can be dangerous, wire rope clips need to be used correctly. Here are the things to keep in mind for a safe wire rope installation:

There are two types of wire rope clip designs: U-bolt or double saddle. It should be noted that only drop forged U-bold wire rope clips are permitted for overhead lifting, double saddle clips are not.

A U-bolt clip is made with a U-shaped bolt, along with a metal base or saddle piece that fits around the wire rope. This is held in place with two nuts that screw on the bottom of the clip.

A double saddle wire rope clip is made from two separate bolts that are held in place by bolts on either side. This different design is somewhat easier to use, as there is no top or bottom. However, they have a lower load capability, which is why they aren’t recommended for rigging.

There are also several types of metals used to make wire rope clips. As mentioned, drop forged clips are the only type that is permitted for overhead lifting. This is made from molten steel that is shaped into place with a ram hammer, making it quite durable. This type of clip is also hot galvanized for additional protection and corrosion resistance.

Wire rope clips may also be purchased in stainless steel and malleable electro-galvanized options. While stainless steel is a very strong metal, it is considered soft and may bend under heavy-duty applications – which is why it shouldn’t be used for overhead lifting. Malleable wire rope clips may even fracture under heavy loads and are best used for light-duty applications like fencing.

The way that a wire rope clip is installed is extremely important, as the placement and angle can interfere with its strength and hold. Before installing, the wire ropes should be inspected and the clips should be checked for several things, including:

Remember to inspect the wire rope before adding the clips on as well. Without proper care or handling, wires in the rope may snap or corrode. Even though the wire rope clips may be in good shape, they won’t hold well if the wire rope is damaged.

Be sure to double-check all safety factor calculations as well. When clips are used to create a sling for overhead lifting, it diminishes up to 75% of the wire rope’s original working load limit. Keep this in mind!

The next step in wire rope clip installation is placement and securement. First, you will measure out the end length of the wire rope that will need to be secured with the clips. A heavy-duty thimble may be added inside of the loop for added support.

Next, undo the clips so they are separated into two parts and fit the U-bolt around the two wire ropes. Then, tighten both of the bolts evenly until they are securely fastened, holding the ropes firmly in place.

Multiple clips should be used for added security with space measuring between 1.5 to 3 times the length of the clip apart. All wire rope clips must be facing the same direction and should be evenly spaced apart.

The majority of issues come with not following the proper requirements for wire clip installation. Failing to follow the rules for spacing, placement, or using the wrong type of clip can be quite dangerous, causing the rope to slip.

Another common issue is not torquing the bolts correctly. This includes both under-torquing and over-torquing. If the bolts are too tight, they will actually wear down the threads of the wire rope beneath. Be sure to follow the manufacturer’s directions on the clips for proper torquing techniques.

Finally, wire rope clips will need to be retightened or cycled out. No bolts will stay perfectly in place for a prolonged period of time, especially if there is a high level of friction. Clips should also be relocated and cycled out after multiple uses.

Ultimately, the quality of your wire rope clips should be a top priority, as this will impact how well the clips work and how long they last. You can purchase top-quality wire rope clips and additional hardware like thimbles, hooks, and wire ropes from Elite Sales. Contact us online to learn more or place an order today!

Wire rope is commonly used to lift heavy loads. It consists of braided strands of metal, such as steel. When compared to traditional rope, wire rope is stronger and able to support heavier loads.

When using wire rope, however, you’ll need to secure it to an appropriate anchor point. Fortunately, there are wire rope clips available for this purpose

Wire rope clips are load-bearing components that are designed for use with wire rope. To lift an object with wire rope, you’ll typically need to use a load-bearing component. Wire rope clips offer an effective solution. You can mount them to the top of an object, after which you can secure the wire rope to it. The wire rope clip will hold the wire rope while allowing you to lift the object to which it’s mounted.

How do wire rope clips work exactly? There are different types of wire rope clips, each of which works in a different way. One of the most common types, though, is U-bolt.

U-bolt wire rope clips consist of a U-bolt, a saddle and a pair of nuts. You can see an example of a U-bolt wire rope clip in the photo above. The U-bolt itself is the semi-circular orange piece. The saddle, conversely, is the set of pronged metal pieces on the sides of the U-bolt. Finally, the nuts are the threaded fasteners attached to the bottom of the U-bolt.

To use a U-bolt wire rope clip, you’ll need to remove the nuts from the U-bolt. You can then insert the U-bolt wire rope clip onto the top of the object that you intend to lift. Once positioned, you’ll need to reattach the nuts. The nuts will hold the U-bolt wire rope clip to the object. You can then lift the object by placing wire rope through the center of the U-bolt.

There are also dual-saddle wire rope clips. As the name suggests, dual-saddle wire rope clips have two saddles rather than a single saddle. Each of the two saddles has a built-in bolt, which is attached to a nut. You can remove the nuts to place a dual-saddle wire rope clip on an object.

Wire rope clips are anchor points for wire rope There are U-bolt wire rope clips and dual-saddle wire rope clips. They work by creating a secure load-bearing point on objects so that equipment can lift the object with wire rope.

Northern Strands, safety is one of our top priorities. Therefore, knowing how to properly clip wire rope using Crosby clips is very important in order to practice safe rigging. Keep in mind that the wire rope clip must be the correct size for the diameter of the rope that is being used and that there is a specific number of clips that are required according to rope size.

A quick rule of thumb for proper clip installation is, "Never Saddle a Dead Horse". This refers to the live end of the wire rope that rests in the saddle of the forged wire clip and the U-bolt that is placed on the dead end of the wire rope.

US based company with manufacturing in US and China. ISO 9001:9002, ISO 9001:2000 & ISO/TS 16949 certified manufacturer & distributor of clips including automotive clips, stainless steel clips & wire rope clips. Products are available in different sizes. Capabilities include aluminum die casting, investment casting, iron sand casting, steel forging, sheet metal stamping and forming, plastic injection molding and aluminum extrusion. Services include CAD model development, stress analysis, mechanical & chemical lab tests & prototyping service. Local US customer service handles project from beginning to end.

Distributor of industrial rigging hardware & supplies including drop forged wire rope clips. Types include galvanized drop forged wire rope clips, stainless steel drop forged wire rope clips, imported galvanized drop forged wire rope clips & fist grip/galvanized drop forged wire rope clips. Galvanized drop forged wire rope clips are available for use with rope sizes ranging from 1/8 in. to 3-1/2 in. Stainless steel drop forged wire rope clips are available for use with rope sizes ranging from 1/8 in. to 5/8 in. drop forged wire rope clips are available for use with rope sizes ranging from 1/8 in. to 3-1/2 in. Fist grip drop forged wire rope clips are available for use with rope sizes ranging from 3/16 in. to 1-1/2 in.

Made in Japan with chromed plating! Easy to understand directions included! Mounted on our security wire rope clip hook so they will never fall off or come loose when using your anchor strips no matter what swimming conditions it may be. Just bend them into shape over a hook and let the lock hold them tight.

This product comes as a pair of 30cm long wire rope clips paired with strong security style short cable hooks for a quick turn on/off and an easy way to secure your anchor, anchor or boat lines that take all kinds of line.

In the petroleum industry, wire rope clips are utilized in hundreds of places to tie bundles together. These often require an extremely strong clip but can be given multiple uses depending on how it is configured. The way these industrial clamp works is that the larger D-shaped portion (where pressure needs to hold down) will usually have a secondary inner "B" bar added for rigidity by now placing another piece between them known as a spreading bar, which will perform the same function but on sliding typesetting with two clamps placed between it. This is commonly used while swinging and bouncing oil drums off of rollers that have large posts where they connect together to lower them onto ones" cars.

They are also called u-bolt or u-bolt clips, they can be used to join two wire rope ends together, make an eye for a pulling application, or to secure the loose end of a wire rope after a wedge socket has been placed in the center of the rope.

We have created this premium quality product using only the best quality raw materials. They are made to withstand tons of load without breaking up or cracking up. The bolt has multiple uses it is a means by which the frame lifting device can be removed from its crudely welded position into the shop. The typical application of this product is on a shop floor where either one or both sides have been removed, thus it serves as an eye bolt to hold the lifting device into place. Attach them at strategic points by using special high strength bolts and attach rigging components at maximum angles while still retaining their holding abilities. It can also be used in other lifting applications such as vertical loading.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Looking for a wood clamp or a bar clamp to level up your woodworking workshop and skills? Look no further! At Alibaba.com, you can browse an endless variety of wholesale wire rope clamps and find the perfect fit for you regardless of experience.

If you are looking to further your woodworking skills, woodworking clamps such as the spring clamps can be your next best investment! Head over to Alibaba.com to get your brand new wire rope clamps for your next pet project! Who knows, this purchase may be the catalyst to your future greatness!

You can even get a beam clamp to suspend or secure fixtures, wires, threaded rods, and other hardware to beam flanges. They offer secure fixing without the need for welding and drilling, making it the perfect purchase for your next DIY project! Find affordable cable clamps made with quality materials on Alibaba.com!

On the other hand, if you would prefer to work with drilling and welding for your pet projects, you may browse our massive selection of metal clamps and welding clamps. The metal clamps will provide a more durable option to the other wire rope clamps you can find on the market! Find the most suitable product for your needs and level of expertise today on Alibaba.com and get free shipping and further discounts on your purchase!

We have invested millions of dollars in our own test labs and factories, so our tools will go toe-to-toe with the top professional brands. And we can sell them for a fraction of the price because we cut out the middleman and pass the savings on to you. It"s just that simple!

8613371530291

8613371530291