wire rope construction details for sale

Structural wire rope cables have played a major role in the engineering and architecture of many large structures and are widely used on projects involving bridges, vessels, stadiums and glass facade/membrane buildings to name a few. Using steel cables in the design of such projects has proved more cost effective than solely using raw materials such as Iron or concrete and is now very much the preferred choice within the construction and engineering sector.

The starting point for FATZER products is high-tensile steel wire. Fabricated into steel wire ropes, it enables architects, engineers and contractors to create technically sophisticated rope architecture.

FATZER manufacture a wide range of rope diameters, suitable for use on the most complex of projects. The performance parameters of all products are monitored and confirmed by independent test bodies.

It goes without saying that steel wire ropes must meet the highest safety requirements. What sets them apart though, is the way they provide freedom for aesthetically creative design. It is the elegant HYEND series of end connections, in particular, which turns these technical products into true “design objects”.

Spiral strand and fully locked coil ropes are manufactured in Switzerland in FATZER"s own factory. This covers the whole process including stranding, pre-stretching, marking and in some cases socketing. Handling customised product solutions is a challenge we tackle on a daily basis. In all cases rope assemblies arrive on site ready for installation.

All materials are fully certified and has full traceability in line with our ISO9001 procedures. The most common constructions of wire rope used for structural purposes are: Spiral strand ropes and fully locked coil rope (EN 1993-1-11:2006). All ropes are available with HYEND fittings to guarantee the best quality and safety standard (EN 13411-4).

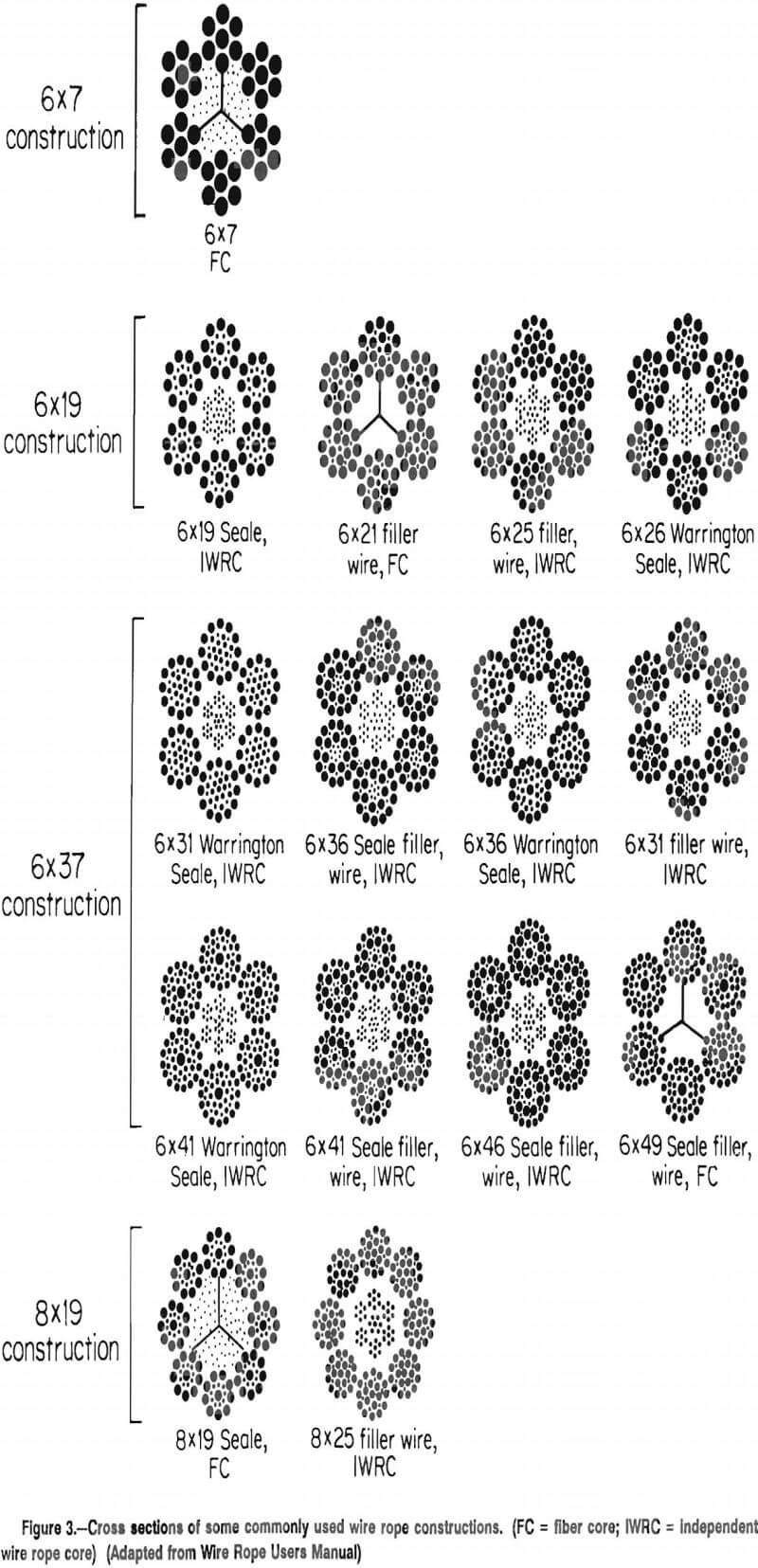

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

To accommodate for heavier weights and more heavy-duty applications, industrial wire ropes are available in different designs. Some of the most important elements to consider when purchasing wire rope for sale are:

Elite Sales offers a wide range of options for wire rope. Wire rope capacity can be adjusted based on your individual applications. Here are a few options to consider:

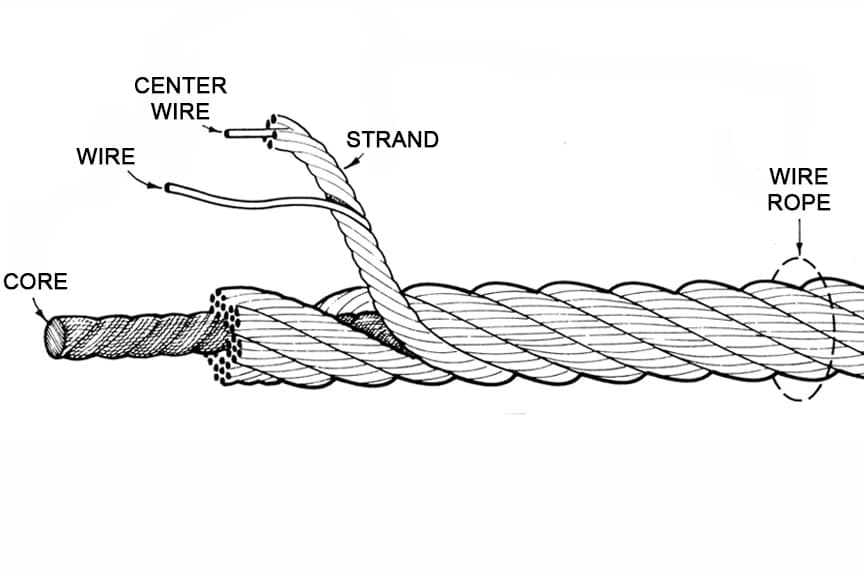

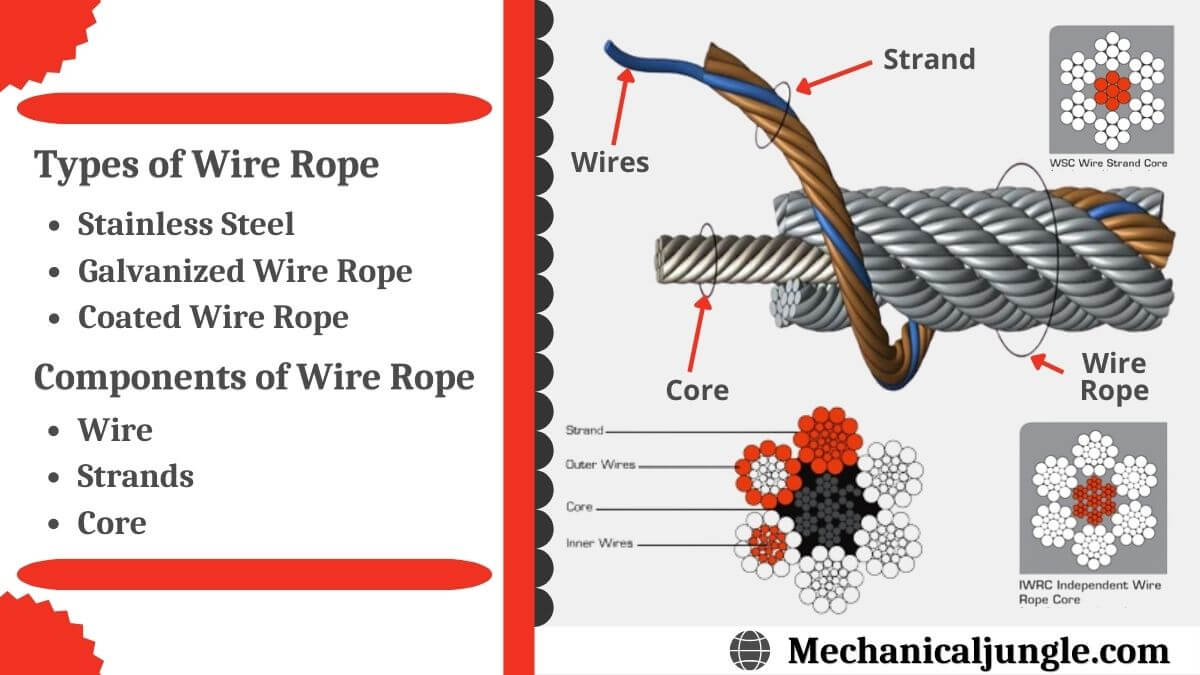

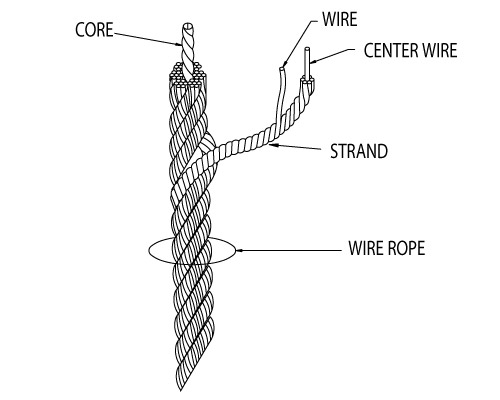

Industrial wire rope or cables are comprised of three key elements which all serve to support the rope’s strength and durability. It is important to understand the purpose of each of these components and the options available.

Wires: The most basic element of the wire rope are the individual wires used to form the cable. The thicker the diameter of the wire, the stronger it is, while thinner wires are more flexible.

Strands: A combination of multiple wires that are woven together form a strand. These strands are wrapped tightly together to maximize their strength and prevent uneven wear or breakage.

Fiber Core(FC) which can be made of natural or synthetic fibers that gives the wire rope some elasticity. However, it is not extremely strong nor is it optimal for high heat.

Wire Strand Core (WSC) consists of a singular wire strand which the other wires are wrapped around. This provides added stability while providing flexibility in the wire rope.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

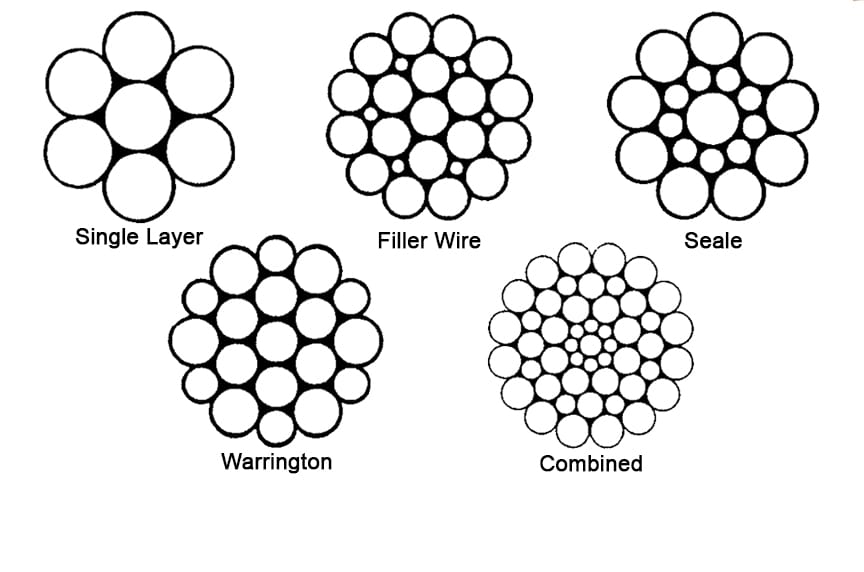

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Galvanized steel wire ropes are constructed of galvanized wires which are dipped in the tank containing molten zinc to form a thick layer of zinc coating before the wire is drawing through dies. Then these galvanized wires are drawn to reduce diameter and increase tensile strength. At the same time, zinc coating bonding to steel wires is compressed to form a more excellent layer to protect the steel form corroding.

Bright steel wire rope refers to general wire rope without surface treatment, free from zinc, tin, copper and other types of metallic coatings. So they are normally lubricated with grease to protect the wire rope from corroding.

Rasmussen Equipment has been helping customers fulfill their wire rope needs since 1947. Our wide range of wire rope options are made of the highest quality materials and components, making them perfect for anything from large construction projects to small DIY home improvements.

We only work with the best wire rope manufacturer on the market, so you feel comfortable knowing our wire rope can withstand any project. Choosing the right general wire rope for your next project can be challenging. Here’s some helpful information about our products to guide your choice. If you need additional help deciding what wire rope you should buy, our specialists are always happy to answer your questions.

6×7 Wire rope is your go-to solution for heavy duty, coarse laid, construction wire. This rope is meant to withstand more resistance to wear and tear, impact, and abrasion than other wire rope options. With fewer, but sturdier chords, this wire rope option is stiff and will require large drums and sheaves. It is not ideal for bend stressors like rope with finer wire. With 6 chords, each wire will bear a more significant portion of load. Safety must always be top of mind when using load-bearing 6×7 wire.

The 6×19 classification of wire rope is the most widely used rope configuration. This rope boasts a mix of flexibility and durability, meeting a wide variety of construction needs and making it the preferred wire rope for most projects. The seale class refers to a strand construction where one size of outer wires covers the same number of smaller sized wires within the inner layer This rope is ideal as your go-to, versatile wire rope solution.

The 6×19 Warrington’s fiber core construction has alternating large and small outer wires, providing excellent flexibility and strength. With the increased flexibility, this construction has lower abrasion and crush resistance. This wire rope may not be suited for all job sites. If you have more questions, or are wondering if the 6×19 Warrington wire rope is right for your project, give Rasmussen a call.

The 6×25 possesses the best combination of flexibility and wear resistance in the 6×19 Class due to the filler wires providing support and stability to the strand. This rope has an independent wire rope core (IWRC) that improves durability.. If you have more questions, or are wondering if the 6×25 filler wire with IWRC is right for your project, give Rasmussen a call.

The 6×26 Warrington Seale construction has a high resistance to crushing. This wire rope is a good choice for projects that need the wear resistance of a 6×19 Class Rope and the flexibility midway between a 6×19 class and 6×37 class rope.

For whatever your project requires, Rasmussen Equipment Company has an expansive selection of rope and rigging supplies in Salt Lake City. If you’re unsure what exact tools you’ll need for your specific job, our sales team will be happy to help. You can reach our specialists by calling (801) 972-5588. We’ll be pleased to answer any questions you have.

The construction of your strand, aircraft cable, or wire rope defines a large percentage of the final performance characteristics. The strength, flexibility, fatigue life, and torque resistance all rely heavily on the manner in which wires and strands are laid together in the finished rope. When choosing the construction to use in your next product or project, take the time to review the difference between common constructions listed below and to understand the potential impact each can have in your application.

Strand Core produces strand, cable, and wire ropes up to 5/8" in diameter and can provide custom products and configurations meeting the most demanding specifications. All Wire Ropes are manufactured in stainless steel, galvanized, bright carbon steel, as well as other alloys. As a manufacturer, Customized constructions are available on request. If you have any questions about these constructions, or any aspect of selecting a strand, aircraft cable, or wire rope, please contact us today.

Main difference between both types are the number of outer strands: 19x7 has 12 while 18x7 has just 11. In pactice this difference is neglectable; European ropes tend to be of the 18x7 type having 11 outer strands.

Using the rope to it’s maximum fatigue life will cause the rope to deteriorate from the inside out. Sudden rope failures may be the result. There have been fatal and catastrophic accidents involving this rope construction because of undetected inner rope fatigue.

It is much critical to inspect these rope on a regular basis. Immediately remove such ropes if you detect a difference in diameter between the working section and the the part in front of the wedge socket or safety drum wraps.

Wire rope classification is done by the number of strands as well as by the number of wires in each strand, e.g., 6 x 7, 6 x 19, 6 x 37, 8 x 19, 19 x 7, etc. However, these are nominal classifications that may or may not reflect the actual construction. For example, the 6 x 19 class includes constructions such as 6 x 21 filler wire, 6 x 25 filler wire, and 6 x 26 Warrington Seale. Despite the fact that none of the three constructions named have 19 wires, they are designated as being in the 6 x 19 classification.

Hence, a supplier receiving an order for 6 x 19 rope may assume this to be a class reference, and could possibly furnish any construction within this category. But, should the job require the special characteristics of a 6 x 25 filler wire, and a 6 x 19 Seale is supplied in its stead, a shorter service life may result.

To avoid such misunderstandings, the safest procedure is to order a specific construction. In the event that the specific construction is not known or is in doubt, the rope should be ordered by class along with a description of its end use.

Identification of wire rope in class groups facilitates selection on the basis of strength and weigh/foot since it is customary domestic industry practice that all ropes (from a given manufacturer) within a class have the same nominal strength and weigh/foot. As for other-functional-characteristics, these can be obtained by referencing the specific construction within the class.

Only three wire ropes under the 6 x 19 classification actually have 19 wires: 6 x 19 two-operation (2-op), 6 x 19 Seale (S), and 6 x 19 Warrington (W). All the rest have different wire counts. In the 6 x 37 class there is a greater variety of wire constructions. The commonly available constructions in the 6 x 37 class include: 6 x 31 Warrington Seale (WS), 6 x 36 WS, 6 x 41 Seale Filler Wire (SFW), 6 x 41 WS, 6 x 43 Filler Wire Seale (FWS), 6 x 46 WS, etc. – none of which contain exactly 37 wires.

In this full length handbook, learn the basics of wire rope including how to choose and measure wire rope. Additionally, you will understand the fundamental mechanics behind our most popular rope constructions and classifications. Finally, you will learn the proper way to care for and use your wire rope, including end treatments, inspection, and removal criteria.

Twisted hoist lines can bring a construction project to a sudden halt, resulting in downtime. But the good news is that you can minimize block rotation through proper installation, handling and corrective measures. In this reference document, you will better understand torque and gain tips on how to reduce block rotation.

Our galvanized strand products meet or exceed ASTM specifications A475 and ASTM A363. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn what the strands are tested for. Additionally, a chart detailing the physical properties of zinc-coated steel wire strand is included.

Our industry has its fair share of terminology and phrases. In this reference document (an excerpt from the Wire Rope Users Handbook), you will be provided a comprehensive glossary of all Wire Rope words. From “Abrasion” to “Warrington”, your questions are answered here.

How long will your rope last? While there is not a simple answer, there are several factors involved. In this reference document (an excerpt from the Wire Rope Users Handbook), you will the factors affecting the longevity of your ropes life. Additionally, information regarding the cleaning and lubrication of your ropes is included.

There is a correct methodology behind measuring of wire rope diameter. Learn this methodology in this reference document (an excerpt from the Wire Rope Users Handbook). Also, the definition of design factor is available. And finally, detailed information regarding metric conversion and equivalents is included.

Yes, there is a RIGHT way to unreel, uncoil and store a wire rope. Learn the proper steps in this reference document (an excerpt from the Wire Rope Users Handbook). Additionally, the three stages of kinking are vividly displayed.

Wires are the basic building blocks of a wire rope. And, a rope core will greatly impact the performance of your rope. Learn how the number of wire strands and construction determine a wire rope classification. In this reference document (an excerpt from the Wire Rope Users Handbook), you will become familiar with the standard rope classifications and special rope constructions.

The types of wire, lay and performing greatly affect wire rope performance and operation. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the basic types of wire used in ropes, the common grades of wire rope and the meaning of “lay”.

In this Product Bulletin, you will learn about the new rope description format that WireCo WorldGroup will follow in all of our product descriptions. This format will adopt symbols and designations that are part of ISO, ASTM, and other industry standards and specifications.

Rotation-resistant ropes can frequently provide the best and most economical service in specific applications, when you choose, handle and use them properly. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the difference between Category 1, Category 2 and Category 3 Rotation-Resistant Rope.

Previously known as “aircraft” cable, and now known as “utility cable, these small diameter specialty ropes are used in a variety of applications, including control cables, window and door closures, different kind of remote control systems and boat riggings. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn how Union specialty small ropes are engineered and fabricated, and the special lubrication and testing they require. Additionally, a minimum breaking force and weights for 7x7, and 7x19 utility cable is included.

Our industry has its fair share of abbreviations. In this reference document (an excerpt from the Wire Rope Users Handbook), you will be provided a comprehensive glossary of all Wire Rope words. From “PRF” (preformed) to “XIP®” (Extra improved plow steel), your questions are answered here.

Swaged ropes and “Double-Swaged” ropes provide excellent strength for some specific applications. In this reference document (an excerpt from the Wire Rope Users Handbook), you will find the definition of swaged and PowerFlex (aka double-swaged) ropes. Minimum breaking force and weights charts for 6x19, 6x36, PowerFlex, 3x19 and 3x36 ropes are included.

Our most popular Tech Report, this Wire Rope Inspection Tech Report explains why periodic inspection of wire ropes are necessary. Learn how to properly inspect wire rope, what tools are necessary for inspection, and how to use inspection forms. Additionally, you will learn how often you should inspect your wire rope, what your ‘critical’ points are, how to inspect your end attachments, how to make an internal rope examination, how to inspect sheaves, and how to evaluate drums. Finally, you will understand how to properly measure rope diameter and rope lay.

In applications where a specific length is critical, the constructional stretch can be minimized by prestretching the rope prior to installation, HOWEVER, learn why WireCo WorldGroup advises against prestretching Tuf-Kote/PFV rope. After reading this product bulletin, you will understand the rationale behind WireCo WorldGroup’s recommendation against prestretching Tuf-Kote/PFV Rope.

Engineering and producing wire rope slings for your application is a highly specialized field - with exacting standards that we gladly live by. In this marketing flier, learn the different Union Wire Rope Sling constructions. Additionally learn more about Union Spelter Sockets (both open and closed). There are capacity and diameter charts associated with each product.

In this Product Bulletin, learn the various definition of "US made wire rope" including references to the Buy American Act and the Buy America Requirement. Additionally, learn how Union wire rope meets these definitions.

Most ropes are shipped with the ends seized as they are prepared for cutting, however, in some cases, the rope requires special end preparations. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the two chosen methods for seizing cut ends of your wire ropes. Illustrations and step-by-step instructions are included.

All wire ropes will wear out eventually and gradually lose work capability throughout their service life. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn why periodic inspections are critical. The purposes for inspection, guidelines around timing and choosing the right person to inspect are included. Additionally, illustrations regarding “what to look for” in a wire rope is available.

There is obvious evidence of wire rope wear and abuse, and specific criteria regarding removal of your wire rope. In this reference document (an excerpt from the Wire Rope Users Handbook), you will learn the various types of wear and abuse (illustrations included) and the exact removal criteria. A chart on when to replace your wire rope – based on number of broken wires is included.

In this product bulletin, learn why WireCo WorldGroup refers to XLT4 as a low-torque rope and not a rotation-resistant rope. Also included are the definitions of ASTM A1023 and ASME B30.5.

Understanding the basics of wire rope will help guide you on how to choose the right wire rope for your job. Application, required strength, and environmental conditions all play a factor in determining the type of wire rope that is best for you.

But when it comes to buying wire rope, the various numbers and abbreviations that describe the different types of wire rope can be confusing. EIPS wire rope, 6X19 IWRC wire rope, and lang lay wire rope are just some of the many variations available. But what does it all mean?

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available from 1/8” wire rope to 2-1/2” wire rope. Thicker sized wire rope has a higher break strength. For example, our Wire Rope has a 15,100 lb. break strength while our Wire Rope has a 228,000 lb. break strength.

The numbers indicate its construction. For example: in wire rope, as shown above the first number is the number of strands (6); the second number is how many wires make up one strand (19).

When it comes to wire rope basics, regular lay also refers to right lay or ordinary lay. This indicates that the strands pass from left to right across the rope and the wires in the rope lay in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

This term indicates that the wires twist in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Independent wire rope cores offer more support to the outer strands and have a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

Many of our customers use our rope and our wire rope clips to create rope assemblies. Check out of video blog on Wire Rope Clips to Wire Rope Assemblies to learn more.

For any questions on our wire rope products, call (877) 923-0349 or email customerservice@uscargocontrol.com to speak with one of our product experts.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. Wire ropes are attached to a crane or hoist and are fitted with swivels, shackles or hooks. These are suitable for lifting or lowering elevators and are also used for supporting suspension bridges or towers.

In this article, we"ll cover details on the top U.S. providers of wire ropes, along with our featured list of top wire rope suppliers on Thomasnet.com.

Below is a list of featured suppliers of wire rope from our platform. Included with these companies is their location, year established and the number of employees.

Below we have assembled information on the top suppliers of wire rope in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

With the help of the provided details on the wire rope suppliers in the United States in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

8613371530291

8613371530291